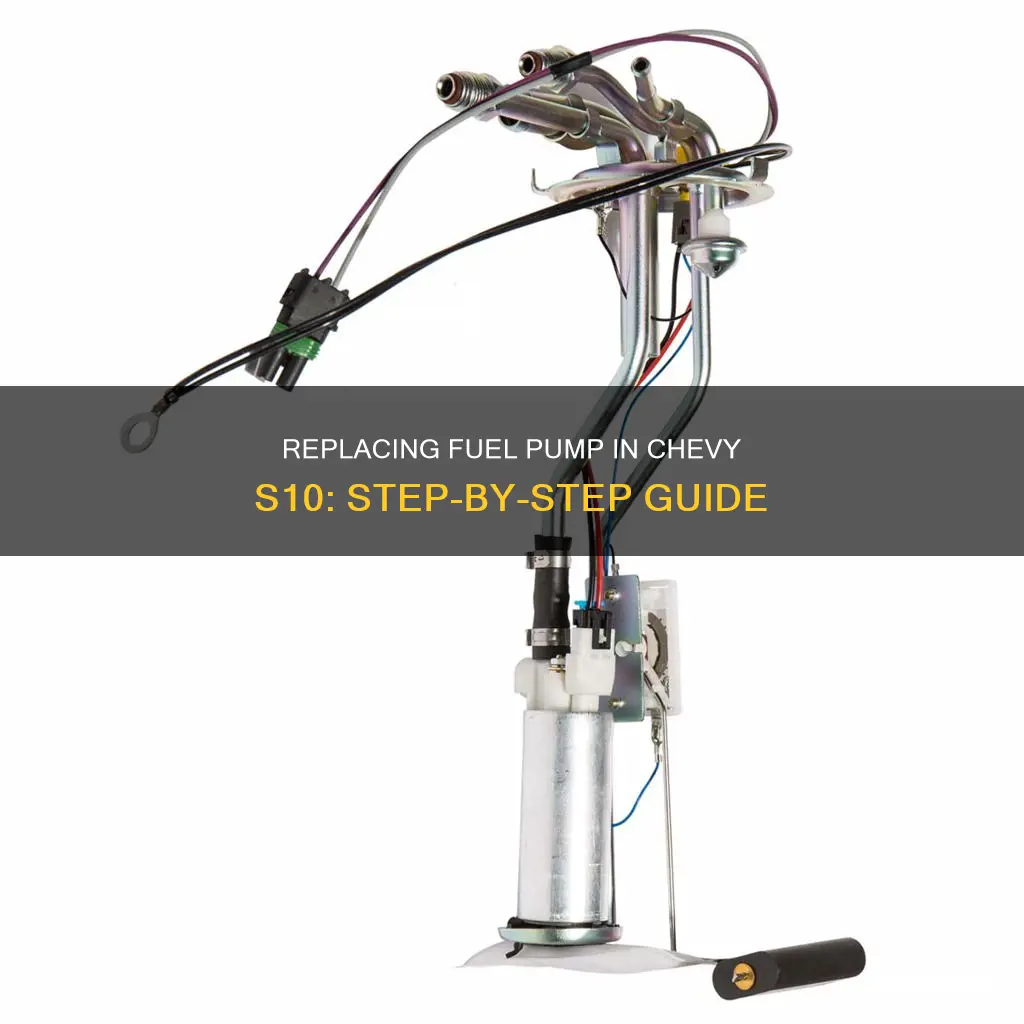

If your 2000 Chevy S10 truck is experiencing issues such as an overheating engine, low fuel pressure, or a sputtering engine, it may be time to replace the fuel pump. The fuel pump is responsible for supplying fuel from the fuel tank to the engine, and when it degrades or fails, it can cause the engine to stall or prevent the vehicle from starting altogether. In this guide, we will walk you through the steps to safely replace the fuel pump in your 2000 Chevy S10 truck.

| Characteristics | Values |

|---|---|

| Vehicle | 2000 Chevrolet S10 |

| Engine | 2.2L |

| Symptoms of a Failing Fuel Pump | Overheating engine, low fuel pressure, sputtering engine, loud whining noises |

| Fuel Pump Replacement Cost | $900 to $1,200 |

| Fuel Pump Replacement Time | 4 to 5 hours |

| Fuel Pump Lifespan | 100,000 to 150,000 miles |

| Fuel Pump Relay Location | Fuse/relay box in the engine compartment |

What You'll Learn

Disconnect the negative battery cable

Disconnecting the negative battery cable is one of the first steps to replacing the fuel pump on a 2000 Chevy S10 truck. This is a crucial step as it ensures that no power can short fuses or relays.

To begin, park your Chevy S10 in a safe place with a level surface and make sure you have enough room to work around the truck. Once you've done that, locate the negative battery cable. It's the black cable connected to the battery. Using a wrench or a pair of pliers, loosen the nut or bolt that secures the cable to the battery terminal. Be careful not to let the wrench or pliers touch any other parts of the car, as this could result in an accidental short circuit. Once the cable is loose, carefully remove it from the battery terminal.

It's important to note that you should never disconnect the positive cable first, as this could result in an electrical short, which can be dangerous and damage your car's electrical system. Always disconnect the negative cable first and, if necessary, cover the terminal with a piece of electrical tape to prevent accidental contact.

Additionally, if your Chevy S10 has a fuse box located near the battery, you may need to remove it to access the battery cable. Make sure to do this carefully and re-install it properly when you're finished.

Now that the negative battery cable is disconnected, you can proceed with the next steps of raising the rear of the truck, draining the fuel tank, and removing the fuel pump for replacement. Remember to work in a well-ventilated area and to take all necessary safety precautions when working with automotive fuel systems.

Replacing the Fuel Sending Unit in Your SL R230

You may want to see also

Drain the fuel tank

To drain the fuel tank of your 2000 Chevy S10 truck, first park your truck in a safe place with a level surface, ensuring you have enough room to work around the vehicle. Disconnect the black, negative battery cable and use a floor jack to raise the rear of the truck. Safely support the truck on two jack stands.

Next, drain the fuel tank into an approved container through the filler pipe. You may need to use a hand siphon pump to do this. Once the tank is drained, disconnect the clamp from the filler hose at the tank with a screwdriver and remove the hose. Remove the tank shield and use a floor jack with a piece of wood on the jack pad to support the fuel tank and avoid damaging it.

Now you can begin to remove the tank itself. First, remove the tank-holding straps with a ratchet and socket. Then, lower the fuel tank so you can access the fuel lines and electrical connections to the fuel pump/sending unit assembly on top of the tank. Disconnect these lines and the electrical connector, and then lower the tank to the floor.

At this point, you can begin to work on the fuel pump/sending unit assembly. Turn the lock-ring tabs holding the assembly to the tank counterclockwise with a drift punch and a soft hammer until the ring is released. Lift the assembly off the tank and remove the pump.

Malibu Maintenance: Replacing Fuel Filter After 10 Years

You may want to see also

Remove the filler hose

To remove the filler hose from your 2000 Chevy S10 truck, you will need to first park your truck in a safe place with a level surface and ensure you have enough room to work around it. Next, disconnect the negative battery cable and raise the rear of the truck with a floor jack. Support the truck safely on two jack stands.

Now, you can begin to drain the fuel from the tank into an approved container through the filler pipe. Use a hand siphon pump if necessary. Once the fuel tank is drained, disconnect the clamp from the filler hose at the tank with a screwdriver and remove the hose. Be sure to also remove the tank shield.

At this point, you will need to support the fuel tank with a floor jack and a piece of wood on the jack pad to avoid damaging the tank. You can then proceed to remove the tank-holding straps with a ratchet and socket.

By lowering the fuel tank, you will gain access to disconnect the fuel lines from the fuel pump/sending unit assembly on top of the tank. Remember to unplug the pump electrical connector before lowering the tank to the floor.

These steps will allow you to safely and effectively remove the filler hose as part of the process of replacing the fuel pump in your 2000 Chevy S10 truck.

Replacing Fuel Level Sender: A Step-by-Step Guide for Your Car

You may want to see also

Disconnect the fuel lines

Disconnecting the fuel lines is a crucial step in replacing the fuel pump on a 2000 Chevy S10 truck. Here is a detailed, step-by-step guide on how to safely and effectively complete this task:

Step 1: Park your vehicle and set the parking brake.

Find a safe, level surface to park your Chevy S10 and engage the parking brake. This will ensure the vehicle remains stationary throughout the repair process.

Step 2: Disconnect the negative battery cable.

Locate the negative battery cable, which is usually black in colour, and disconnect it from the battery terminal. This is an important safety precaution to prevent any accidental electrical shorts during the fuel pump replacement.

Step 3: Drain the fuel tank.

Before disconnecting the fuel lines, you must first drain the fuel from the tank. Use an approved container to safely collect the fuel through the filler pipe. You may need to use a hand siphon pump to complete this step.

Step 4: Locate the fuel lines and disconnect them from the fuel pump/sending unit assembly.

The fuel lines are connected to the fuel pump/sending unit assembly, which is located on top of the fuel tank. Use a screwdriver to carefully loosen and remove the clamp that secures the filler hose to the tank. Once the hose is disconnected, you can access the fuel lines.

Step 5: Lower the fuel tank.

Carefully lower the fuel tank using a floor jack and a piece of wood to avoid damaging the tank. This will give you better access to the fuel lines and the fuel pump/sending unit assembly.

Step 6: Disconnect the fuel lines.

With the fuel tank lowered, you can now disconnect the fuel lines from the fuel pump/sending unit assembly. Gently pull on the fuel lines to detach them from the assembly. Place the disconnected lines aside, ensuring they are away from any potential sources of ignition.

Step 7: Clean the area.

Before proceeding, it is important to clean the area around the fuel pump/sending unit assembly. Use a suitable solvent or cleaner to remove any dirt, grease, or debris that may have accumulated. This will help prevent contaminants from entering the fuel system during the installation of the new fuel pump.

By following these steps, you will have successfully disconnected the fuel lines, allowing you to proceed with the next steps in replacing the fuel pump on your 2000 Chevy S10 truck. Remember to work in a well-ventilated area and take all necessary safety precautions when working with fuel and electrical systems.

Replacing the Fuel Pump in Your 2009 Corvette CPE

You may want to see also

Remove the pump/sending unit assembly

To remove the pump/sending unit assembly, you will need to first lower the fuel tank. Ensure that you have safely drained the fuel tank into an approved container via the filler pipe. Once the tank is lowered, disconnect the fuel lines from the sending unit.

Now, you can turn your attention to the lock-ring tabs that are holding the pump/sending unit assembly to the tank. Using a drift punch and a soft hammer, turn these tabs counterclockwise until the ring is released. Be careful not to apply too much force and damage the tabs or the tank. Once the ring is released, carefully lift the pump/sending unit assembly off the tank.

At this point, you can remove the old pump from the assembly and install a new one. It is recommended to replace the O-ring seal at this time as well. Reinstall the new pump into the sending unit assembly, ensuring that it is securely seated.

Finally, you can set the assembly back into the tank and lock the assembly lock ring by turning it clockwise until it locks into place. Reconnect the fuel lines and the electrical connector to the sending unit assembly.

Asphalt's Role in Diesel: Sulphur's Replacement Explored

You may want to see also