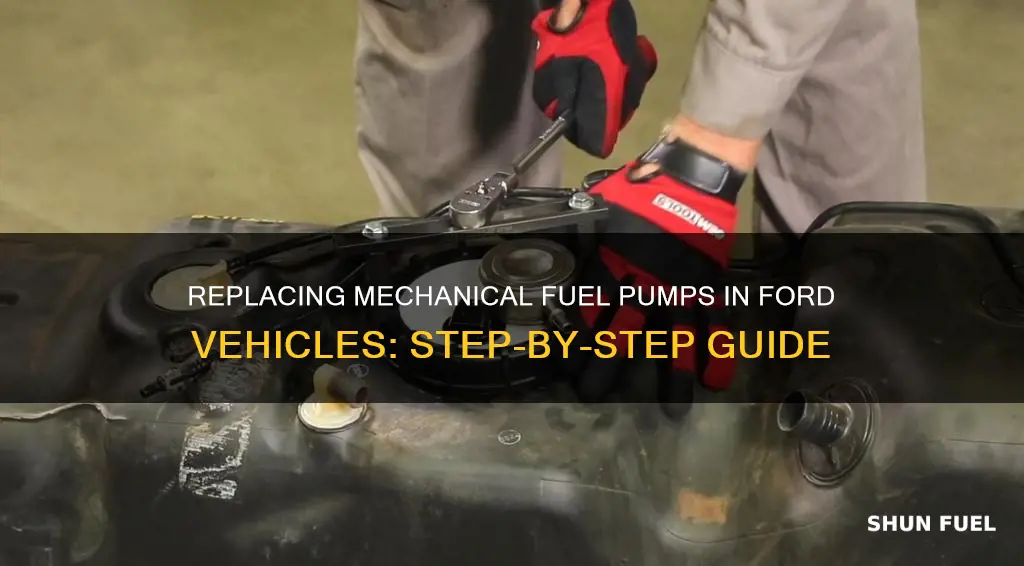

Replacing the mechanical fuel pump in a Ford is a simple task that can be done at home in about an hour or two. It is a messy job, so it is important to be dressed appropriately and work in a well-ventilated area. The process involves first removing the old fuel pump by disconnecting the negative battery cable, fuel tank hose, and outlet line to the carburetor, before extracting the old pump and cleaning the mounting surface. The new pump can then be installed by applying a gasket sealer, attaching the fuel outlet line, and reconnecting the battery ground cable. It is important to check for leaks once the new pump is installed.

What You'll Learn

Disconnecting the negative battery cable

To begin, locate the negative battery terminal, which is usually marked with a "-" symbol or a black cover. It is typically connected to the battery using a clamp or a bolt. Before proceeding, make sure the vehicle is turned off.

Once located, you will need to disconnect the cable. If your Ford uses a clamp, use a wrench to loosen it, then carefully lift the clamp from the terminal. Place the clamp in a safe location away from the battery to avoid any accidental contact.

If your Ford uses a bolt, use the appropriate size wrench or socket to loosen and remove the bolt. Again, set the bolt aside in a secure place. With the cable disconnected, ensure that it is properly secured or insulated to prevent it from accidentally falling back into place and making contact with the battery terminal.

After disconnecting the negative battery cable, it is good practice to cover the exposed terminal with a piece of electrical tape or a terminal cover to prevent any potential short circuits during the fuel pump replacement process.

Remember, working on a vehicle's electrical system can be dangerous, so it is essential to take the necessary precautions. Always wear protective gear, including gloves and eye protection, and ensure that you have a basic understanding of automotive electrical systems before proceeding.

Replacing the Fuel Pump in a Saturn Ion: Step-by-Step Guide

You may want to see also

Removing the old fuel pump

First, disconnect the negative battery cable. Then, clamp the fuel pipe to stop drips or residual fuel leaks. Place a drip tray underneath to catch any fuel. Depending on your setup, you may need to remove the connection to the fuel pump. There may be crushed (lemon) style clips or a simple jubilee clip. If you have a fuel filter, you can either cut or disconnect it.

The output side of the fuel pump should be connected to a metal pipe leading to the carburettor. Unscrew this pipe, being prepared for any remaining fuel to run out. Next, remove the pipe from the output of the fuel pump. The fuel pump body is held in place by two bolts. Undo these bolts and remove the pump from the engine block. Be careful not to let anything fall into the engine block.

Once the pump is removed, clean the engine block surface to ensure the gasket will make a good seal. Use a razor blade scraper to remove any remaining gasket material, working away from the opening and from the centre outwards. Then, use a degreaser on a lint-free cloth to wipe the surface down.

Replacing the Fuel Pump Relay in Your 2001 Acura CL

You may want to see also

Prepping and installing the new fuel pump

Before you begin prepping and installing the new fuel pump, ensure you have the right tools and safety gear. You will need a ratchet wrench set with a universal joint, tubing or open-end wrenches, hose clamp pliers or a screwdriver, a bolt or wooden dowel, and a fire extinguisher rated for gasoline fires. It is also important to dress appropriately for this messy job and to ensure your workspace is well-ventilated.

Now, onto the new fuel pump!

First, apply a coat of gasket sealer to both sides of the new gasket. Then, put the attaching bolts through the new pump and slip the gasket over the bolts.

Next, install the new pump on the engine, ensuring the push rod is correctly installed in both the engine and the fuel pump. If the push rod slides out, you can pack it with heavy grease to keep it in place while you install the pump.

After this, attach the fuel outlet line that runs to the carburetor. If it is difficult to connect, remove the other end of the line from the carburetor first. Connect the line to the fuel pump, and then reattach the other end to the carburetor. Use a wrench to hold the fuel pump fitting and tighten the line nut with another wrench.

Now, attach the fuel inlet hose from the gas tank and the vapor-return hose. Tighten all clamps.

Finally, reconnect the battery ground cable, start the vehicle, and check for leaks. Once you have inspected your work and ensured it is free of leaks, your Ford is good to go!

Replacing Fuel Pump in Toyota Yaris: Step-by-Step Guide

You may want to see also

Reattaching the fuel inlet hose and vapour-return hose

Before beginning, ensure that you are working in a well-ventilated area. It is important to avoid smoking or any open flames during this process to prevent any safety hazards. Also, make sure to have a fire extinguisher rated for gasoline fires nearby as a precaution.

Now, let's get started:

- Disconnecting the hoses: First, disconnect the fuel tank hose at the fuel pump. It is prudent to plug the hose with a bolt or a wooden dowel to prevent fuel from flowing out. If your vehicle is equipped with a vapour-return hose, be sure to disconnect it as well. Wipe up any spilled fuel with a cloth or rag.

- Inspecting the hoses: Carefully inspect the fuel inlet hose and vapour-return hose for any signs of wear or damage. If you notice any fraying or cracking, it is essential to replace them with new hoses to ensure safety and prevent leaks.

- Reconnecting the hoses: Once you have confirmed that the hoses are in good condition or have replaced them, you can now reattach them to the new fuel pump. Ensure that the hoses are securely connected to the appropriate ports on the fuel pump.

- Tightening the clamps: After reattaching the hoses, ensure that all clamps are tightened securely. This step is crucial to prevent any fuel leaks. Double-check that all connections are secure and tight.

- Reconnecting the battery: With the hoses reconnected and clamps tightened, you can now reconnect the negative battery cable.

- Starting the vehicle and checking for leaks: Turn on the vehicle and carefully inspect the fuel pump and hose connections for any signs of leaks. It is important to allow the vehicle to run for a few minutes to ensure that there are no fuel leaks.

- Final checks: Once you have confirmed that there are no leaks and the fuel pump is functioning properly, your vehicle is ready to go. Congratulations! You have successfully replaced the mechanical fuel pump and reattached the fuel inlet and vapour-return hoses.

Remember, working with fuel can be dangerous, so take your time, follow safety precautions, and ensure that your workspace is well-ventilated. By following these detailed steps, you can confidently replace the mechanical fuel pump in your Ford vehicle and ensure a safe and proper reattachment of the fuel inlet and vapour-return hoses.

Replacing the Fuel Pump in a 2006 Ford F150: Step-by-Step Guide

You may want to see also

Checking for leaks

Once you have finished installing the new fuel pump, you will need to check for leaks.

First, reconnect the battery ground cable and start the vehicle. Inspect the work you have done and check for any leaks. If you have followed the steps correctly, your vehicle is good to go.

However, if you notice any leaks, you will need to act accordingly. Make sure all fittings, hoses, and clamps are tight and check again for any leaks. If you still notice leaks, you may need to apply a gasket sealer to the gasket and pump face. Clean the face with a degreaser and lint-free cloth before applying the sealer.

You should also consider using a fuel pressure regulator to help prevent leaks. A fuel pressure regulator will help maintain the correct fuel pressure and ensure that the carburetor is receiving the correct amount of fuel.

It is important to take your time and be thorough when checking for leaks. Fuel leaks can be dangerous and can cause fires or explosions. So, make sure to take the necessary precautions and seek professional help if you are unsure about anything.

Replacing Fuel Pump Wiring Harness: Step-by-Step Guide

You may want to see also

Frequently asked questions

Your car may need a new fuel pump if it has trouble starting or runs unevenly. You can also check if fuel is reaching the front of the car and inspect the fuel filter.

You should wear appropriate clothing and ensure your workspace is well-ventilated. Do not smoke or use an open flame, and avoid any potential sources of sparks. Have a fire extinguisher rated for gasoline fires nearby.

You will need a replacement fuel pump, fuel filter, gasket sealer, sharp scraper/degreaser, sockets, fuel cut-off clamp, fuel line, clips, rags, and a drip tray.