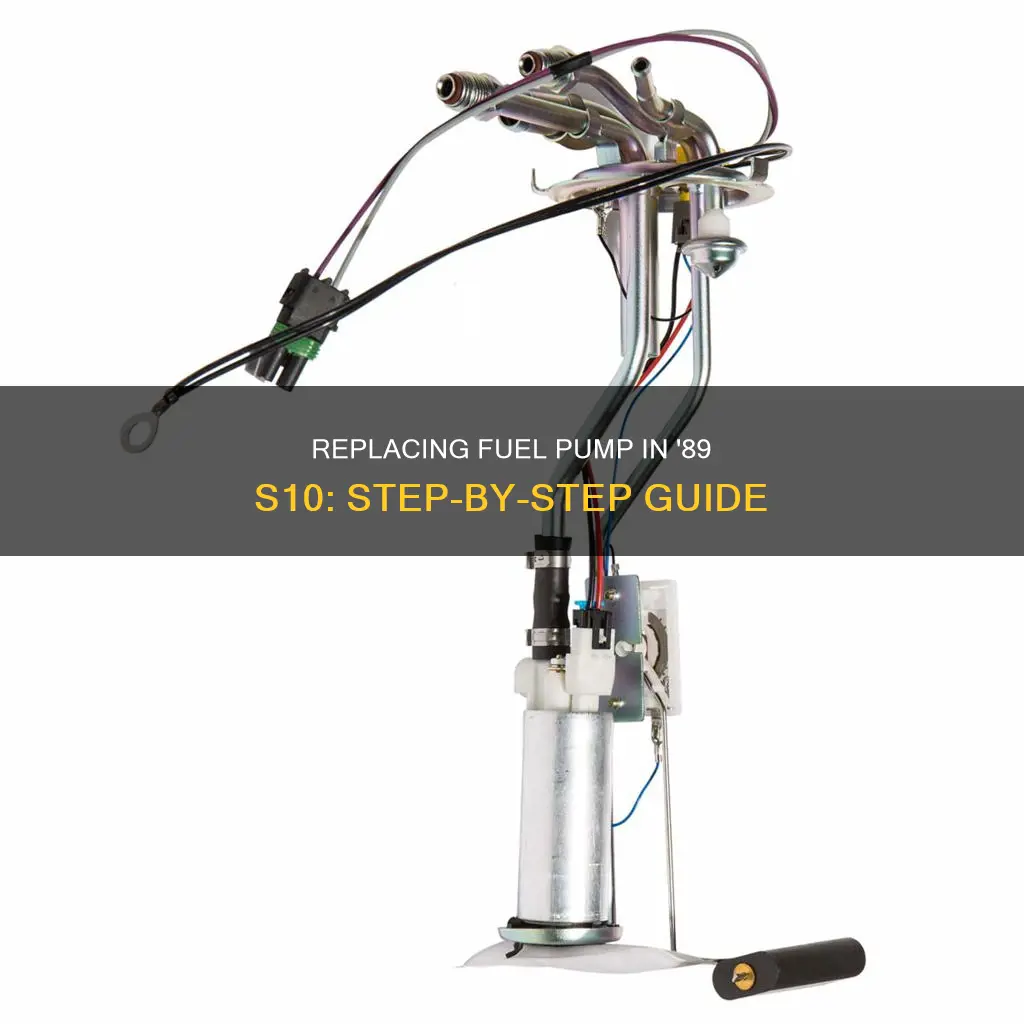

If you're looking to replace the fuel pump on your 89 S10, there are a few things you should know. The fuel pump is an essential part of your vehicle's fuel system, supplying fuel from the tank to the engine. Over time, the fuel pump may wear out or fail, leading to poor engine performance or even a non-functional vehicle. In this guide, we will walk you through the steps to safely replace the fuel pump in your 89 S10.

| Characteristics | Values |

|---|---|

| Year of S10 | 1989 |

| Model of S10 | Chevrolet S10 |

| Method of Fuel Pump Access | Drop the gas tank or remove the bed |

| Tools Needed | Flat-blade screwdriver, jacks |

What You'll Learn

Removing the bed vs dropping the tank

Removing the bed of your 1989 S10 is generally considered to be easier than dropping the tank. Removing the bed gives you better access to the fuel pump, and you can do some rust proofing at the same time. However, if you have equipment mounted under the bed, dropping the tank may be a better option.

To remove the bed, you'll need to remove the bolts and disconnect the wiring. You can do this with a couple of people to help, or by using an engine hoist and some straps. If the bolts are rusty, you may need to soak them with penetrating oil and heat them with a torch before attempting to remove them.

If you decide to drop the tank, you'll need to disconnect the wires and hoses. This can be tricky, as the hoses may not be long enough to allow you to fully remove the tank. You'll also need to be careful not to tip the tank, as a full tank of fuel weighs over 125 lbs. A transmission jack can help with this.

Some people have suggested cutting an access hole in the bed as an alternative to removing the entire bed or dropping the tank. However, this may not be an option if you're concerned about rust.

Fuel Filter Maintenance for Suzuki Forenza: 2004 Edition

You may want to see also

Disconnecting the filler neck and taillights

First, locate the filler neck and taillights. The filler neck is the tube that connects the gas cap to the fuel tank, and the taillights are the lights located at the rear of the vehicle, usually mounted on the bed. Once you have located these components, gather the necessary tools for the job, which may include a socket wrench, screwdrivers, and any other standard automotive tools.

Next, begin by disconnecting the filler neck. This is usually secured to the bed with a mounting bracket and a series of bolts or screws. Use the appropriate tool to remove these fasteners, being careful not to drop them into the fuel tank. Once the fasteners are removed, carefully detach the filler neck from the bed, taking care not to damage any surrounding components.

Now, move on to the taillights. These are typically held in place with screws or bolts. Use your screwdriver or socket wrench to remove these fasteners, and then carefully detach the taillight assembly from the bed. Be gentle with the taillights, as they may contain fragile bulbs or wiring. It is recommended to disconnect the taillight wiring harness beforehand, which can usually be accessed from underneath the vehicle.

Once both the filler neck and taillights are disconnected, set them aside in a safe place. You have now successfully completed the disconnection process, and the bed should be ready for removal. Remember to have a helper assist you with the bed removal, as it can be heavy and awkward to handle alone. Always prioritize your safety when working on your vehicle.

By following these steps, you will have effectively disconnected the filler neck and taillights, allowing you to access the fuel pump for replacement or maintenance. Remember to consult a qualified mechanic or a repair manual for further guidance if needed.

Replacing Fuel Injectors in Jeep Liberty: Step-by-Step Guide

You may want to see also

Disconnecting the fuel lines

First, you need to gain access to the fuel pump. This can be done by either dropping the gas tank or removing the bed of the truck. If you choose to drop the gas tank, you will need to safely drain the fuel and remove the tank from the vehicle. Alternatively, removing the bed will give you access to the fuel pump from above. This can be done by locating and removing the bolts that secure the bed to the frame of the vehicle.

Once you have access to the fuel pump, the next step is to disconnect the fuel lines. This should be done carefully to avoid any leaks. Locate the fuel lines connected to the fuel pump and, using the appropriate tools, carefully disconnect them. You may need to use a wrench or pliers to loosen any clamps or fittings holding the lines in place. Be sure to have a container or rag handy to catch any fuel that may spill during this process.

With the fuel lines disconnected, you can now remove the fuel pump assembly. This is typically secured in place with a lock ring, which can be removed with a suitable tool. Again, be careful not to spill any fuel from the pump assembly during this process.

At this point, you should be able to lift the fuel pump assembly out of the vehicle. Be sure to handle it with care, as it contains sensitive components. You can now either replace the entire assembly or just the fuel pump itself. If you choose to replace the pump, you will need to remove it from the assembly and install the new one, ensuring that all connections are secure.

Finally, you can begin the reassembly process by reconnecting the fuel lines to the new or repaired pump assembly. Ensure that all connections are tight and secure before lowering the gas tank or reinstalling the bed of the truck. Always refer to the vehicle's service manual for specific instructions and torque specifications.

By following these steps, you can safely and effectively disconnect the fuel lines and replace the fuel pump on your 1989 S10.

Replacing the Fuel Pump in a 2004 Tahoe: Step-by-Step Guide

You may want to see also

Replacing the whole unit vs individual parts

When it comes to replacing the fuel pump on your 1989 Chevrolet S10, you may be considering whether to replace the entire fuel pump unit or just the individual parts that make up the assembly. There are advantages and disadvantages to both approaches, and the best option for you will depend on factors such as cost, convenience, and the specific issues you're experiencing with your fuel pump.

Replacing the Entire Fuel Pump Unit

Replacing the entire fuel pump unit means you'll be installing a new, integrated assembly that includes the pump, sending unit connections, and other components. This option can be more expensive upfront, but it offers the advantage of having all new parts, reducing the risk of future repairs. It also eliminates the need to diagnose and disassemble the existing fuel pump, which can be a complex and time-consuming task.

Replacing Individual Parts

Alternatively, you may choose to replace only the faulty components within the fuel pump assembly. This approach can be more cost-effective, especially if you are able to identify and access the specific parts that require replacement. However, it requires a higher level of technical expertise and a good understanding of the fuel pump's inner workings. Additionally, there is a risk that other components within the assembly may fail in the near future, potentially leading to further repairs and costs.

Considerations for Your 1989 Chevrolet S10

For your 1989 Chevrolet S10, replacing the entire fuel pump unit can be a more straightforward option, as integrated fuel pump assemblies are available for your specific year, make, and model. This option ensures that all parts are new and compatible, reducing the likelihood of future issues. However, it is still important to purchase a high-quality unit from a reputable brand, such as Delphi or AC Delco, to ensure longevity.

On the other hand, choosing to replace individual parts can be more challenging, as it requires disassembling the existing fuel pump and accurately identifying the faulty components. While repair kits are available, they may not always include all the necessary parts, and the process can be more complex than simply replacing the entire unit.

In conclusion, the decision to replace the whole fuel pump unit or individual parts depends on your specific circumstances and preferences. Replacing the entire unit offers convenience and peace of mind, while replacing individual parts can be more cost-effective but requires greater technical expertise and carries a higher risk of future repairs. Ultimately, it is important to carefully consider your options, weigh the pros and cons, and select high-quality parts to ensure a reliable and long-lasting repair for your 1989 Chevrolet S10.

Replacing the Fuel Pump in Your 2002 Porsche 996: A Step-by-Step Guide

You may want to see also

Removing the steering wheel

To remove the steering wheel of an 89 S10, you'll need to refer to the Haynes manual, which states that you should remove the bolts from the back of the steering wheel with a 7mm socket. However, one user has noted that they were “not finding a 7mm bolt head".

- Locate the bolts holding the steering wheel in place. These are typically found on the back of the steering wheel, but may vary depending on the vehicle model.

- Using the appropriate socket size, loosen and remove the bolts. Keep them in a safe place so they don't get lost.

- Once the bolts are removed, you should be able to carefully pull the steering wheel off of the steering column. It may require some force, but be careful not to damage any components.

- With the steering wheel removed, you will now have access to the components behind it, such as the turn signal switch or the airbag (if equipped).

It is important to note that removing the steering wheel can be a complex task and should be done with caution. Always refer to the vehicle's repair manual for specific instructions, and if you are unsure, it is best to consult a professional mechanic.

Replacing Fuel Pump in Nissan Versa: Step-by-Step Guide

You may want to see also

Frequently asked questions

It is generally considered easier to remove the bed when replacing the fuel pump on an 89 S10. However, some people prefer to drop the gas tank, especially if they have friends to help.

You will need a flat-blade screwdriver and either a jack or a few friends to help lift the bed.

First, make sure to unscrew the filler neck and taillights from the bed. Then, pop the lock ring off from around the fuel pump assembly, being careful not to spill any fuel. Disconnect the lines and remove the fuel pump assembly.