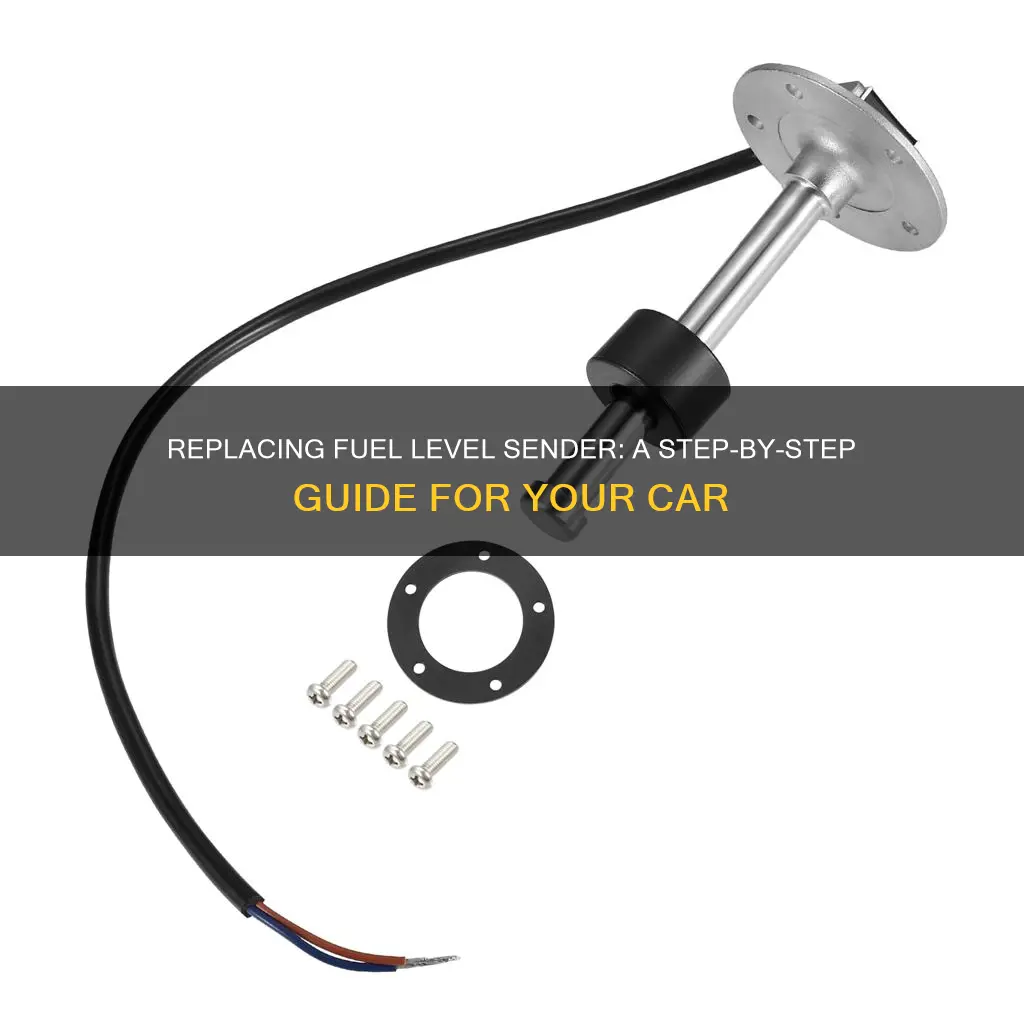

Replacing a fuel level sender is a straightforward process in most cars. The fuel level sender is a device that transmits data from the fuel tank to the fuel gauge, which tells the driver how much fuel is left. Before replacing the fuel level sender, it's important to check for signs of failure, such as a fuel gauge that reads full or empty when the tank is not, or a needle that moves erratically. To replace the fuel level sender, one must first disconnect the negative battery cable to prevent electrical sparks and ensure safety. The sender is located at the top of the fuel tank and is accessible under the back seat or in the trunk. One must then remove the access cover, unplug the wiring harness, and remove the screws or bolts holding the sender in place. Finally, one can install the new sender and plug in the wiring harness.

| Characteristics | Values |

|---|---|

| Tools required | Flathead screwdriver, Phillips head screwdriver, fuel-resistant gloves, ratchet with metric and standard sockets, nine-volt battery saver, fire extinguisher, safety glasses, gloves |

| Preparation | Park vehicle on a flat, hard surface, engage parking brake, disconnect negative battery cable, roll down windows, work in a well-ventilated area, use a professional respirator |

| Location | Top of the fuel tank, accessible under the back seat or carpet in the trunk |

| Removal process | Remove screws holding access cover, unplug wiring harness, remove screws or bolts, use screwdriver to gently tap the sending unit counter-clockwise, remove fuel tank sending unit |

| Installation process | Reverse of removal, plug in new sender, replace fuel filter (optional) |

What You'll Learn

Disconnect the negative battery cable

Disconnecting the negative battery cable is one of the first steps to take when replacing a fuel level sender. Here is a detailed, step-by-step guide on how to do this safely and effectively:

Step 1: Locate the Battery

First, you need to find the battery. In most vehicles, the battery is bolted in place under the hood. If you are unsure where to find it, refer to your owner's manual, which will tell you how to access the hood and where the safety catch is located. In some cases, the battery may be tucked away in the trunk, usually at the rear of the vehicle.

Step 2: Identify the Positive and Negative Terminals

This is a crucial step. The positive terminal is marked with a "+" sign, while the negative terminal is marked with a "-" sign. Pay attention to this distinction, as disconnecting the wrong cable can lead to safety hazards. Some batteries have plastic caps covering these terminals, which will need to be removed to access the battery cables and cable clamps.

Step 3: Gather the Right Tools

For this task, you will typically need a couple of wrenches, depending on the amount of space available and the type of bolt on the battery cable clamp. Most battery cable clamps use a 10-millimeter bolt, so a 10-millimeter open-end wrench or a socket wrench of the same size will be useful. In some cases, an adjustable open-end wrench may suffice.

Step 4: Unbolt the Negative Cable

Turn off the car's ignition and wear eye protection for this step. Carefully unbolt the negative battery cable. You may need to wiggle and twist the cable to remove it. Ensure that the wrench does not touch both the negative and positive terminals simultaneously. Even with a dead battery, there may be residual electricity, which could create a spark or short out the battery. This could potentially damage the vehicle's electrical system or engine-control computer. Once the negative cable is removed, set it aside, pushing it away from the battery.

Step 5: Disconnect the Positive Cable

Now that the negative cable is safely disconnected, you can proceed to remove the positive cable. Again, exercise caution to avoid any contact between the wrench and the negative terminal. With both cables disconnected, you have successfully disconnected the negative battery cable.

It is important to note that these steps are general guidelines, and specific vehicles may have unique requirements. Always refer to your vehicle's repair manual or seek advice from a certified mechanic if you are unsure about any part of the process.

Fuel Filter Replacement: Signs You Need to Know

You may want to see also

Prepare safety equipment

When preparing safety equipment for replacing a fuel level sender, it is important to take several precautions to ensure your safety and prevent accidents. Here are some essential steps to follow:

Wear Appropriate Safety Gear:

Before starting any work on the vehicle, make sure to put on safety glasses and fuel-resistant gloves. These will protect your eyes from any debris or fuel splashes and shield your hands from fuel and chemicals.

Use a Fire Extinguisher:

Keep a fire extinguisher nearby at all times. Working with fuel and electrical systems can be hazardous, and a fire extinguisher will help you quickly address any potential fires or fuel spillage.

Disconnect the Battery:

Before beginning any repairs or replacements, disconnect the negative cable from the battery to prevent accidental sparks. This is a crucial step to reduce the risk of electrical shorts and fires.

Use a Non-Ferrous Tool:

When removing the retaining ring of the fuel sending unit, use a non-ferrous tool or punch to avoid creating sparks that could ignite fuel vapors.

Handle Fuel with Care:

Fuel is highly flammable, and even a small spark can cause an explosion. Always exercise extreme caution when working with fuel. Avoid smoking or any open flames near the vehicle. If you need to drain the fuel tank, use a siphon pump or a clear plastic tube to carefully transfer the fuel to a safe container. Be extremely cautious to avoid getting fuel in your mouth, and if it does happen, rinse your mouth with plenty of water immediately.

Ensure Proper Ventilation:

Work in a well-ventilated area to avoid inhaling fuel vapors, which can be harmful to your health. Keep the area open and allow fresh air to circulate.

Avoid Creating Sparks:

Do not work near any potential sources of sparks, such as electrical equipment or power tools. Even a small spark can ignite fuel vapors, leading to a dangerous explosion.

Check for Leaks:

After refilling the fuel tank and reconnecting all components, carefully inspect the area for any signs of fuel leaks. Look for fuel drips or listen for the sound of leaking fuel. Use a combustible gas detector if necessary to check for vapor leaks.

Clean Up Properly:

During and after the replacement process, properly manage any spilled fuel or debris. Use lint-free cloths to wipe up spills, and have a suitable container to collect and dispose of waste fuel.

Follow Manufacturer's Instructions:

Always refer to the vehicle's service manual for specific safety precautions and instructions related to your particular make and model. Different vehicles may have unique requirements or considerations for fuel level sender replacement.

Replacing Fuel Filter in Echo Chainsaw: Step-by-Step Guide

You may want to see also

Locate the fuel tank

Locating the fuel tank is the first step in replacing a fuel level sender. This component is typically located at the top of the fuel tank, but it can be accessed by lifting the backseat or the carpet in the trunk. In some vehicles, the fuel tank is situated in the boot under the trim, while others have it mounted through the tank wall.

Before attempting any repairs or replacements, it is crucial to take safety precautions. Ensure that you disconnect the negative battery cable to prevent any electrical sparks. Given that you are dealing with flammable gasoline, it is important to work in a well-ventilated area and avoid any sources of sparks or flames. It is recommended to perform this task outdoors with the vehicle's windows rolled down.

Once you have located the fuel tank, you may proceed with the next steps in the replacement process, which include removing the fuel tank sending unit, addressing any necessary repairs, and installing the new fuel level sender. Remember to refer to your vehicle's repair manual for specific instructions pertaining to your car's make and model.

Replacing the Fuel Pump on Your Ford 3000 Tractor

You may want to see also

Remove the fuel tank sender

Removing the Fuel Tank Sender

Before starting, ensure you have the necessary tools and safety equipment. You will need a flathead screwdriver, fuel-resistant gloves, and a ratchet with metric and standard sockets. It is also important to take safety precautions when working with fuel. Work outside or in a well-ventilated area, and disconnect the negative battery cable to prevent any electrical sparks. Remember that gasoline is highly flammable, so ensure there are no sources of sparks or open flames nearby.

The fuel tank sender is located inside the fuel tank and attached to the fuel pump. It has a base with a rod and a float attached. The float is hollow and lightweight, allowing it to sit on top of the fuel. To remove the fuel tank sender, follow these steps:

- Locate the fuel tank by looking under the vehicle.

- Lower the fuel tank slightly using a transmission jack or similar tool.

- Disconnect the harness from the connector by reaching up to the top of the fuel tank.

- If your vehicle is a 1996 model or newer, there may be a return fuel charcoal canister attached to the vent hose. Remove the clamp and detach the hose to allow more clearance.

- Remove the fuel filler neck by twisting it out of the rubber hose and guiding it out of the area.

- Take out the clamp on the rubber hose that was attached to the fuel filler neck.

- At this point, you may need to remove fuel from the tank before proceeding. It is recommended to have a quarter tank of fuel or less when removing the fuel filler neck.

- Clean the harness and connector to the fuel pump and sending unit using electrical cleaner and a lint-free cloth to remove any debris and moisture.

- Remove any dirt and debris from the fuel pump and sender mounting area.

- Take out the mounting bolts securing the fuel pump and sender.

- Carefully pull out the fuel pump and sender from the fuel tank, being mindful not to bend the float arm, as this can affect the accuracy of the fuel gauge.

- If needed, rotate the fuel sender to free the float from the fuel tank.

Now that you have removed the fuel tank sender, you can proceed to install a new one or make any necessary repairs. Remember to work carefully and follow the safety guidelines to ensure a successful and safe procedure.

Replacing the Fuel Sending Unit in Your SL R230

You may want to see also

Install the new fuel tank sender

Before installing the new fuel tank sender, ensure that you have disconnected the negative battery cable to prevent any electrical sparks. It is also important to work in a well-ventilated area to avoid inhaling fumes.

The new fuel tank sender should be compatible with the old one. Fit the new fuel tank sender with a new gasket/O-ring, ensuring that the gasket is properly aligned between the fuel sender and the tank. If you are replacing a fuel pump sender, transfer the fuel line retainers and install the fuel pump by guiding the sending unit arm in first.

Reinstall the retaining ring if applicable. If the fuel sender uses screws, use the included washers to prevent leaks and tighten in a star pattern. Reconnect all electrical connectors and snap the fuel lines back in place.

Now, refill the tank and check for leaks. Ensure that the fuel gauge is registering correctly.

Replacing Fuel Pump on Cat C7: Step-by-Step Guide

You may want to see also

Frequently asked questions

If your fuel gauge is reading empty when there is fuel in the tank, or constantly reading full, this could be due to a faulty sender unit. However, it could also be a faulty gauge or a break in the wiring between the gauge and sender, so further testing is required.

You can test the sender unit by checking the resistance with a multimeter. If the resistance is infinite, then the sender is broken. If it has some resistance, the fault is likely in the wiring or gauge.

Before beginning, disconnect the negative battery cable to prevent electrical sparks. You should also ensure the area is well-ventilated to prevent the inhalation of fumes. The fuel tank sending unit is located at the top of the fuel tank and is accessible under the back seat or in the trunk. You will need to remove the access cover, which is usually held on with a couple of screws. Once the cover is removed, unplug the wiring harness and, if the unit is screwed or bolted in place, remove the screws or bolts. If the unit is a "twist-lock" type, you can use a sturdy, flat-head screwdriver to gently tap it counter-clockwise to loosen it.

As you are dealing with gasoline, which is highly flammable, ensure there are no sources of sparks or flames nearby. Always do this repair outside, with the windows of your vehicle rolled down.