Replacing a fuel gauge sending unit is a task that requires careful attention to detail and a systematic approach. This process involves removing the old unit and installing a new one, ensuring that the vehicle's fuel level is accurately monitored. The sending unit is a crucial component of the fuel gauge system, responsible for transmitting the fuel level data to the gauge. By following a step-by-step guide, you can efficiently replace this unit, ensuring your vehicle's fuel monitoring system functions correctly. Understanding the process and having the necessary tools and knowledge will make this task manageable for any DIY enthusiast or mechanic.

| Characteristics | Values |

|---|---|

| Tools Required | Wrenches, screwdrivers, fuel gauge sending unit, new sending unit (if replacing), safety equipment (gloves, goggles) |

| Location | The fuel gauge sending unit is typically located near the fuel tank, often accessible by removing the tank or a panel in the dashboard. |

| Fuel Tank Drain | If the fuel gauge sending unit is inside the fuel tank, you may need to drain the tank to access it. |

| Diagnosis | Check for any visible signs of damage or corrosion. Use a multimeter to test the resistance of the sending unit's wiring harness. |

| Removal | Disconnect the electrical connections. Carefully remove the sending unit, taking note of its position and orientation. |

| Installation | Align the new sending unit with the mounting holes. Secure it in place and reconnect the electrical connections. |

| Testing | Start the vehicle and check the fuel gauge operation. Ensure it reads accurately and responds to changes in fuel level. |

| Safety Precautions | Work in a well-ventilated area. Wear protective gear to avoid contact with fuel and electrical components. |

| Cost | The cost of replacing the sending unit can vary depending on the make and model of your vehicle, ranging from $50 to $200 or more. |

| Difficulty Level | Medium to difficult, depending on your mechanical skills and access to the sending unit. |

What You'll Learn

- Location and Removal: Identify the gauge's location and carefully remove the sending unit

- Diagnosis: Check for faulty readings and confirm the need for replacement

- Tools and Preparation: Gather necessary tools and prepare the workspace

- Installation: Insert the new sending unit and secure it in place

- Testing and Calibration: Verify functionality and calibrate the gauge if needed

Location and Removal: Identify the gauge's location and carefully remove the sending unit

To begin the process of replacing the fuel gauge sending unit, you must first locate the fuel gauge itself. This gauge is typically found on the dashboard, often near the speedometer. It provides an indication of the vehicle's fuel level, allowing the driver to monitor the remaining fuel. The sending unit is a crucial component that sends electrical signals to the gauge, indicating the fuel level.

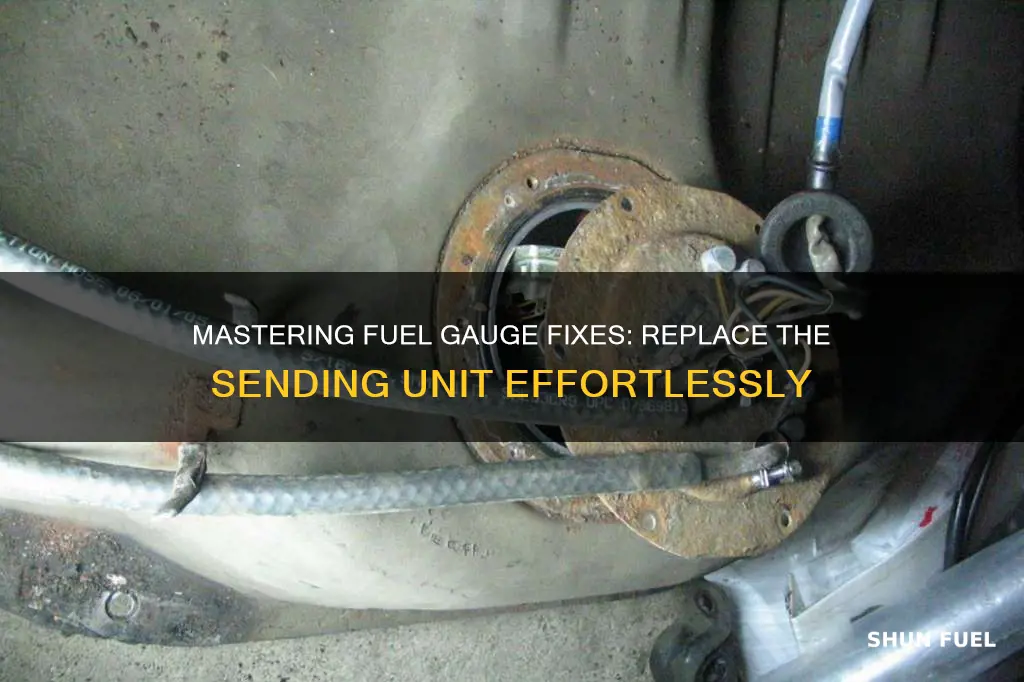

The location of the sending unit can vary depending on the vehicle make and model. It is usually positioned near the fuel tank, often along the fuel line or within the tank itself. Accessing this unit may require removing certain panels or trim pieces to expose the necessary components. Carefully inspect the vehicle's manual or online resources specific to your car model to identify the exact location and any unique features of the sending unit.

Once you have located the fuel gauge and its sending unit, it's time to proceed with the removal process. Start by disconnecting the electrical connections to the gauge. These connections are usually located at the back of the gauge or along the wiring harness. Carefully detach the wires, ensuring you note their positions for future reference.

Next, remove any retaining clips or screws that secure the sending unit in place. These fasteners are often found at the base of the unit or along the fuel line. Use the appropriate tools for removal, being cautious not to damage the surrounding components. After removing the fasteners, gently lift the sending unit out of its housing, setting it aside for later use or disposal.

When removing the sending unit, take note of any O-rings or seals that may be present. These components are crucial for maintaining a watertight seal and should be replaced if damaged or removed. Properly disposing of or replacing these seals will ensure the new sending unit functions correctly and prevents any fuel leaks.

Nissan Armada Fuel Filter Replacement: A Step-by-Step Guide

You may want to see also

Diagnosis: Check for faulty readings and confirm the need for replacement

To diagnose a faulty fuel gauge sending unit, you need to understand how it works and what can go wrong. The sending unit is a critical component in your fuel gauge system, responsible for transmitting the fuel level data to the gauge. When it malfunctions, the gauge may display incorrect or erratic readings, leading to potential issues with fuel management and awareness. Here's a step-by-step guide to help you identify and confirm the need for replacing the sending unit:

Step 1: Visual Inspection

Start by visually inspecting the fuel gauge sending unit. Check for any visible signs of damage, corrosion, or disconnection. Look for leaks or moisture around the unit, as these could indicate a failing or damaged component. If you notice any physical issues, it might be a clear indication that the sending unit needs to be replaced.

Step 2: Test the Fuel Gauge Readings

Use a multimeter or an ohmmeter to test the fuel gauge readings. Disconnect the fuel gauge sending unit from the gauge and measure the resistance across the unit's terminals. Compare the readings with the manufacturer's specifications. If the resistance values deviate significantly, it suggests a faulty sending unit. Additionally, you can test the continuity of the circuit to ensure the unit is functioning properly.

Step 3: Check for Fuel Level Accuracy

Drive the vehicle and observe the fuel gauge readings. Note the fuel level when the tank is full and when it's empty. Compare these readings with the actual fuel levels. If the gauge consistently overestimates or underestimates the fuel, it's a strong indicator of a malfunctioning sending unit. You can also try topping up the fuel tank and observing if the gauge accurately reflects the change in fuel level.

Step 4: Verify Sending Unit Functionality

In some cases, the sending unit might not be visible or accessible for direct testing. In such scenarios, you can use a fuel pressure tester or a fuel level sensor simulator to verify its functionality. Connect the tester or simulator to the sending unit's input and observe the gauge's response. If the gauge fails to provide accurate readings, it confirms the sending unit's malfunction.

Step 5: Consult Professional Help

If you're unsure about any step or the diagnosis seems complex, it's advisable to consult a professional mechanic or a specialist. They can provide expert advice and perform advanced diagnostics to confirm the sending unit's condition.

By following these steps, you can accurately diagnose a faulty fuel gauge sending unit and determine if replacement is necessary. Remember, a malfunctioning sending unit can lead to inaccurate fuel level information, potentially causing inconvenience and safety risks.

Fuel Pump and Harness: Why Replace Both?

You may want to see also

Tools and Preparation: Gather necessary tools and prepare the workspace

Before you begin the process of replacing the fuel gauge sending unit, it's crucial to gather the right tools and prepare your workspace to ensure a smooth and efficient repair. Here's a detailed guide on what you need and how to set up your work area:

Tools Required:

- Wrenches and Pliers: You'll need a set of adjustable wrenches and pliers to work on the fuel gauge sending unit. These tools will help you loosen and tighten the various nuts and bolts that secure the unit.

- Socket Set: A socket set with different sizes will be essential for removing and installing the sending unit's mounting bolts. Ensure you have a variety of socket sizes to fit the bolts.

- Fuel Gauge Tester: This tool is specifically designed to test the fuel gauge and sending unit. It will help you verify the functionality of the gauge after the replacement.

- New Sending Unit: Make sure to have a replacement fuel gauge sending unit that is compatible with your vehicle's make and model.

- Safety Gear: Safety is paramount. Wear safety goggles to protect your eyes from any potential debris or splashes. Gloves will also provide a better grip and protect your hands.

- Rags or Paper Towels: Keep these handy to wipe away any fuel or dirt that might accumulate during the process.

Workspace Preparation:

- Park Your Vehicle: Find a well-lit and spacious area to work on your vehicle. Ensure you have a stable and level surface to prevent any accidents.

- Jack and Jack Stands: Position your car on a level surface and use a jack to lift the vehicle. Place jack stands under the designated lift points to support the vehicle safely.

- Remove the Fuel Tank: This step might vary depending on your vehicle's model. In most cases, you'll need to remove the fuel tank to access the sending unit. Follow your vehicle's manual for specific instructions on this process.

- Clean and Organize: Clear the workspace of any obstacles and ensure it is well-lit. Organize your tools and parts on a flat surface to have everything within reach during the replacement process.

- Safety Reminders: Double-check that the vehicle's ignition is off and the parking brake is engaged. Ensure no one is near the vehicle during the repair process.

By gathering the necessary tools and preparing your workspace, you'll be well-equipped to tackle the replacement of the fuel gauge sending unit. This preparation ensures a safer and more efficient repair process.

Best Fuel Pump Replacements: 0388685 Upgrade Options

You may want to see also

Installation: Insert the new sending unit and secure it in place

When replacing the fuel gauge sending unit, the installation process involves a few key steps to ensure a proper and secure fit. Begin by locating the old sending unit and carefully removing it. This might require some disassembly of the fuel tank or related components, so take your time and be gentle to avoid any damage. Once the old unit is out, you'll have a clear view of the mounting points and the space it occupies.

Now, take the new sending unit and line it up with the mounting points. Ensure that the electrical connections are aligned with the vehicle's wiring harness. The new unit should have a similar shape and size to the old one, allowing for a seamless replacement. Insert the new sending unit into the designated space, pushing it gently until it clicks into place. This action should be smooth and straightforward, requiring no excessive force.

After inserting the unit, it's crucial to secure it firmly. You can use the provided mounting hardware, such as screws or clips, to fasten the sending unit in place. Tighten the screws securely, but be careful not to overtighten, as this can cause damage to the unit or the surrounding components. Ensure that all connections are tight and secure, providing a stable foundation for the fuel gauge to function accurately.

Take a moment to inspect the installation. Check that the sending unit is firmly attached and that all electrical connections are intact. A proper installation will ensure that the fuel gauge operates correctly, providing accurate fuel level readings. If everything looks good, you can proceed to test the gauge and ensure it functions as expected.

Remember, if you encounter any challenges during the installation process, it's essential to seek guidance from a professional mechanic or refer to the vehicle's manual for specific instructions tailored to your make and model. Proper installation is crucial for the reliable operation of your fuel gauge system.

Replacing Fuel Lines: Spider Injector Maintenance Guide

You may want to see also

Testing and Calibration: Verify functionality and calibrate the gauge if needed

When replacing the fuel gauge sending unit, it's crucial to test and calibrate the gauge to ensure accurate fuel level readings. Here's a step-by-step guide to help you through this process:

Testing the Fuel Gauge:

Start by testing the fuel gauge's functionality after the replacement. Ensure that the gauge is properly connected and securely mounted. Turn on the vehicle's ignition and check if the gauge needle responds to changes in fuel level. Fill the fuel tank with a known amount of fuel and observe the gauge's reading. It should accurately reflect the fuel level, rising and falling as you add or remove fuel. If the gauge doesn't respond or shows incorrect readings, there might be an issue with the gauge itself or its wiring.

Verifying Sending Unit Functionality:

The sending unit is responsible for transmitting the fuel level data to the gauge. To verify its functionality, locate the sending unit, which is typically a small float-type mechanism in the fuel tank. Ensure it is clean and free of debris. Immerse the sending unit in a container of water, adjusting the water level to simulate different fuel levels. The sending unit should move accordingly, allowing the gauge to receive accurate signals. If it doesn't respond or moves erratically, the sending unit may require adjustment or replacement.

Calibration Process:

Calibration is essential to ensure the fuel gauge provides accurate readings. Here's how to calibrate it:

- Empty Fuel Tank: Start by draining the fuel tank completely. This step is crucial as it ensures the sending unit is at its lowest position, providing a baseline reading.

- Set Initial Reading: With the tank empty, note the initial reading on the gauge. This will be your reference point.

- Fill Tank Gradually: Slowly fill the fuel tank and observe the gauge's response. As you add fuel, the gauge should accurately reflect the increasing fuel level.

- Verify Accuracy: Continue filling the tank until it is full, and check the gauge's reading. It should match the actual fuel level. If there's a discrepancy, you may need to adjust the gauge's sensitivity or consider recalibration.

Troubleshooting and Adjustments:

If the gauge doesn't calibrate correctly, check the gauge's settings and ensure they are properly configured. Some gauges have adjustable sensitivity, which can be fine-tuned to match the vehicle's specific fuel level characteristics. If adjustments don't resolve the issue, consult the vehicle's service manual or seek professional assistance for further troubleshooting.

Remember, proper testing and calibration are essential to guarantee accurate fuel level monitoring after replacing the sending unit. This process ensures your vehicle's fuel gauge provides reliable information to the driver.

The Evolution of Fuel: Coal's Replacement Revolution

You may want to see also

Frequently asked questions

The fuel gauge sending unit, also known as the fuel level sensor, is a crucial component in your vehicle's fuel management system. It's responsible for measuring the fuel level in the tank and sending this information to the fuel gauge, which then displays the fuel level to the driver. Over time, this sensor can wear out due to factors like corrosion, fuel contamination, or mechanical failure. If the sensor is faulty, the fuel gauge may read incorrectly, leading to potential fuel-related issues and inaccurate driver feedback.

There are several signs that may indicate a failing or faulty fuel gauge sending unit. These include an inaccurate fuel gauge reading, where the gauge shows a lower or higher fuel level than what's actually in the tank. You might also notice a slow or erratic response in the fuel gauge, or in some cases, the gauge may not move at all. Additionally, if you hear unusual noises from the fuel tank or experience issues with starting the vehicle, it could be related to a failing sensor.

Replacing the fuel gauge sending unit can be a complex task and may require specific knowledge and tools, especially for vehicles with advanced fuel systems. It's generally recommended to have this job done by a professional mechanic who has experience with fuel system repairs. They can ensure the correct diagnosis, remove the old unit safely, and install the new one properly. DIY attempts might void warranties or lead to further complications, especially if your vehicle has an intricate fuel system design.