If you're experiencing issues with your 2003 GMC Envoy, you may need to replace the fuel pump. The fuel pump is responsible for delivering gas from the fuel tank to the fuel injectors, and problems with it can cause a loss of engine power or even prevent the car from starting. This guide will outline the process of replacing the fuel pump in a 2003 GMC Envoy, including the tools and parts required, as well as safety precautions to consider.

| Characteristics | Values |

|---|---|

| Vehicle | 2003 GMC Envoy |

| Fuel Pump Location | Inside the fuel tank |

| Fuel Filter Location | Between the fuel tank and the engine |

| Fuel Pump Replacement Cost | Parts: $512-$669; Labor: $238-$300; Total: $750-$968 |

| Fuel Filter Replacement Cost | $90-$207 |

| Fuel Pump Warning Signs | Engine struggles to maintain speed, noises, backfires, sputtering engine, hesitation at start or take-off, engine overheating, "Check Engine" light |

What You'll Learn

Disconnect the battery to reduce the chance of a fire

When replacing the fuel pump in your 2003 GMC Envoy, it is important to take safety precautions to reduce the chance of a fire. Disconnecting the battery is one of the essential steps to ensure your safety and protect your vehicle from potential electrical issues. Here are some detailed instructions and information on why this step is crucial:

Safety First:

Before beginning any repairs or maintenance on your Envoy, it is imperative to prioritize safety. Disconnecting the battery is a critical step in reducing the risk of electrical fires, which can be dangerous and cause significant damage to your vehicle. By disconnecting the battery, you interrupt the electrical current and minimize the chances of sparks or short circuits that could ignite fuel vapors or fluids.

Location and Procedure:

The battery in your 2003 GMC Envoy is typically located in the engine compartment, near the front of the vehicle. To disconnect it, follow these steps:

- Locate the battery and identify the negative terminal, which is usually marked with a "-" sign.

- Loosen the nut or clamp securing the negative battery cable using a wrench or socket of the appropriate size. Do not allow the wrench to touch any other metal parts to avoid creating a short circuit.

- Carefully remove the cable from the battery terminal.

- If desired, you can also disconnect the positive cable (+) for added safety, following the same procedure.

Considerations:

When disconnecting the battery, keep the following in mind:

- Modern vehicles with electronic components may be affected by the power interruption. Some settings, such as radio presets or engine control unit parameters, may need to be reset or relearned after reconnecting the battery.

- Disconnecting the battery will disable electronic features such as power windows, power seats, and keyless entry. Ensure you have manual overrides or alternative methods to access these functions if needed.

- If your Envoy has electric seats, consult a professional or refer to the owner's manual before disconnecting the battery. In some cases, the seats may move to a default position when power is restored, potentially causing issues during the repair process.

- Always exercise caution when working around batteries and fuel systems. Wear protective gear, such as gloves and eye protection, to safeguard against battery acid and sparks.

Benefits:

Disconnecting the battery offers several advantages, including:

- Reduced risk of electrical fires: By interrupting the electrical current, you minimize the chances of sparks or short circuits that could ignite fuel vapors or fluids.

- Protection against battery drain: Disconnecting the battery prevents slow electrical drain, ensuring that your battery remains charged while your vehicle is parked for extended periods.

- Theft deterrence: A disconnected battery makes it more challenging for potential thieves to start your vehicle, providing an additional layer of security.

In conclusion, disconnecting the battery in your 2003 GMC Envoy during fuel pump replacement is a crucial safety measure to reduce the chance of electrical fires. By following the proper procedures and considerations, you can help ensure a safer and more successful repair experience.

Tecumseh Engine Fuel Line: Replacing the Right Way

You may want to see also

Remove the rear driver-side seat bottom bracket nuts

To remove the rear driver-side seat bottom bracket nuts, you will need a deep 18mm socket.

First, locate the two studs on the rear driver-side seat bottom bracket. Using the deep 18mm socket, remove the nuts from the studs. From the middle of the two studs, feel for a body seam running across the floor. This is the approximate centre point of the pump assembly. Make a small cut in the body seam so that you can feel under the carpet to find it. Be careful to make a shallow cut, as there are wiring harnesses in several places underneath the carpet.

Next, you will need to cut the carpet above this point in the body seam. The opening should be at least six inches wide and three inches in radius, so it is larger than the top of the pump. Cut the metal beneath to a similar size, being very careful as there is very little space between the body and the tank. Do not use a jigsaw for this; a Dremel with a metal-cutting disk would be a better option.

Once you have made these cuts, you can access the fuel pump and continue with the regular fuel pump replacement procedure.

Fuel Filter Replacement: Enhancing Engine Performance and Efficiency

You may want to see also

Cut the carpet and metal to access the pump assembly

To cut the carpet and metal to access the pump assembly, you will need to remove the rear driver's side seat. Move the seat forward, take off the two bolts, and pull out the seat. Then, remove the trim from the bottom of the rear driver's side door jamb and the B pillar trim. Move the front driver's seat up to give yourself more room.

Now, you need to locate the centre point of the pump assembly. Go forward from the middle of the two studs until you feel a body seam running across the floor. Make a small cut in the carpet so you can feel under it to find the seam. Be careful to only make a shallow cut, as there are wiring harnesses in several places under the carpet. You will need to cut the carpet in a three-inch radius so it's larger than the top of the pump—the opening should be at least six inches wide. Cut the metal beneath to a similar size, being very careful as there is very little distance to the tank. Do not use a jigsaw for this—a Dremel with a metal-cutting disk would be best.

From this point, you can continue with the regular fuel pump replacement procedure.

Replacing the Fuel Pump in Your Jeep Liberty: Step-by-Step Guide

You may want to see also

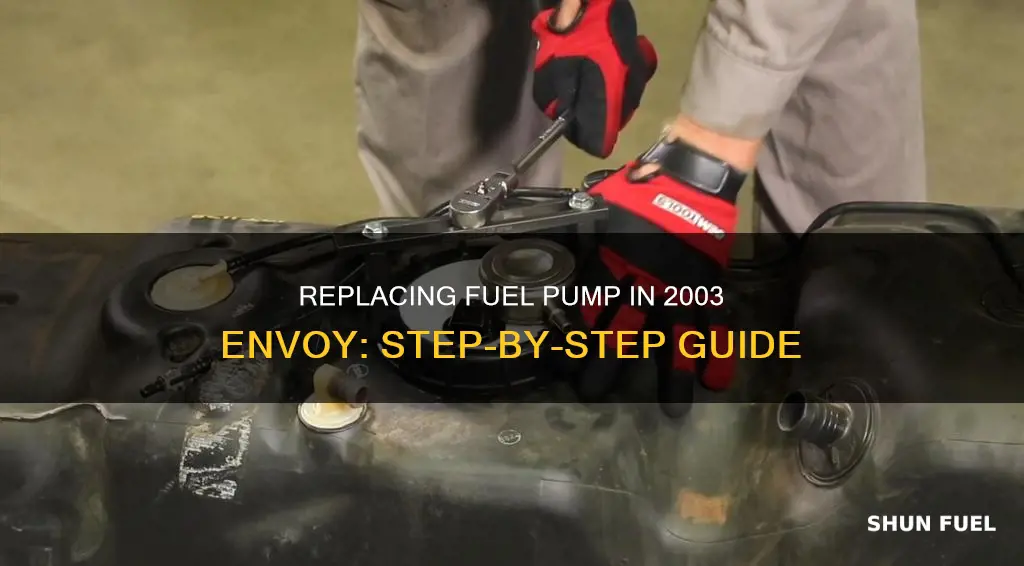

Remove the access cover to the fuel tank

To remove the access cover to the fuel tank of a 2003 GMC Envoy, you will first need to disconnect the battery to reduce the risk of fire.

Next, you will need to remove the rear driver's side seat bottom bracket nuts with a deep 18mm socket. From the middle of the two studs, go forward until you feel a body seam running across the floor. This is the approximate centre point of the pump assembly. Make a small cut so you can feel under the carpet to find the seam. Be careful to make a shallow cut since there are wiring harnesses in several places under the carpet. You will have to cut the carpet above this point in a three-inch radius so it's larger than the top of the pump - the opening should be at least six inches wide. Cut the metal beneath to a similar size, being very careful as there is very little distance to the tank.

Now, lower yourself into the space above the fuel tank. You should be able to see the access cover to the fuel tank. It will be secured with a plastic ring that screws on and off. Use a crowbar and a dead blow hammer to gently tap the ring and loosen it. Be careful not to strip the threads. Once the ring is removed, you can lift the access cover.

When to Replace Your Fuel Rail?

You may want to see also

Drain the fuel and replace the pump and pre-pump filter screen

To drain the fuel and replace the pump and pre-pump filter screen in a 2003 GMC Envoy, follow these steps:

First, you will need to relieve the pressure from the fuel lines. Open the fuse box and locate the fuel pump relay. Once you've found it, start the vehicle and pull out the relay. The engine will shut off as it runs out of fuel. Make sure you do not turn the key on again, as this will re-pressurize the system.

Next, place a drip pan underneath the fuel lines to catch any remaining fuel. Remove the cap from the fuel line and push in on the tabs to drain the gas. Now, disconnect the hoses from the fuel filter by pushing the tabs on either side and pulling the hoses free.

With the hoses disconnected, you can now remove the fuel filter. Loosen the Phillips screw at the top of the fuel filter to loosen the clamp, then pull the fuel filter up and out.

To install the new fuel filter, insert it into the clamp and replace the Phillips screw. Reinsert the hoses into the fuel filter and replace the caps on the fuel lines.

Finally, you can reconnect the fuel pump relay and start the vehicle.

It is important to note that working with fuel can be dangerous, and one should exercise caution and ensure a safe working environment. It is recommended to consult a certified mechanic or a service center for guidance or to perform the replacement.

Tecumseh Carb Fuel Inlet: DIY Replacement Guide

You may want to see also