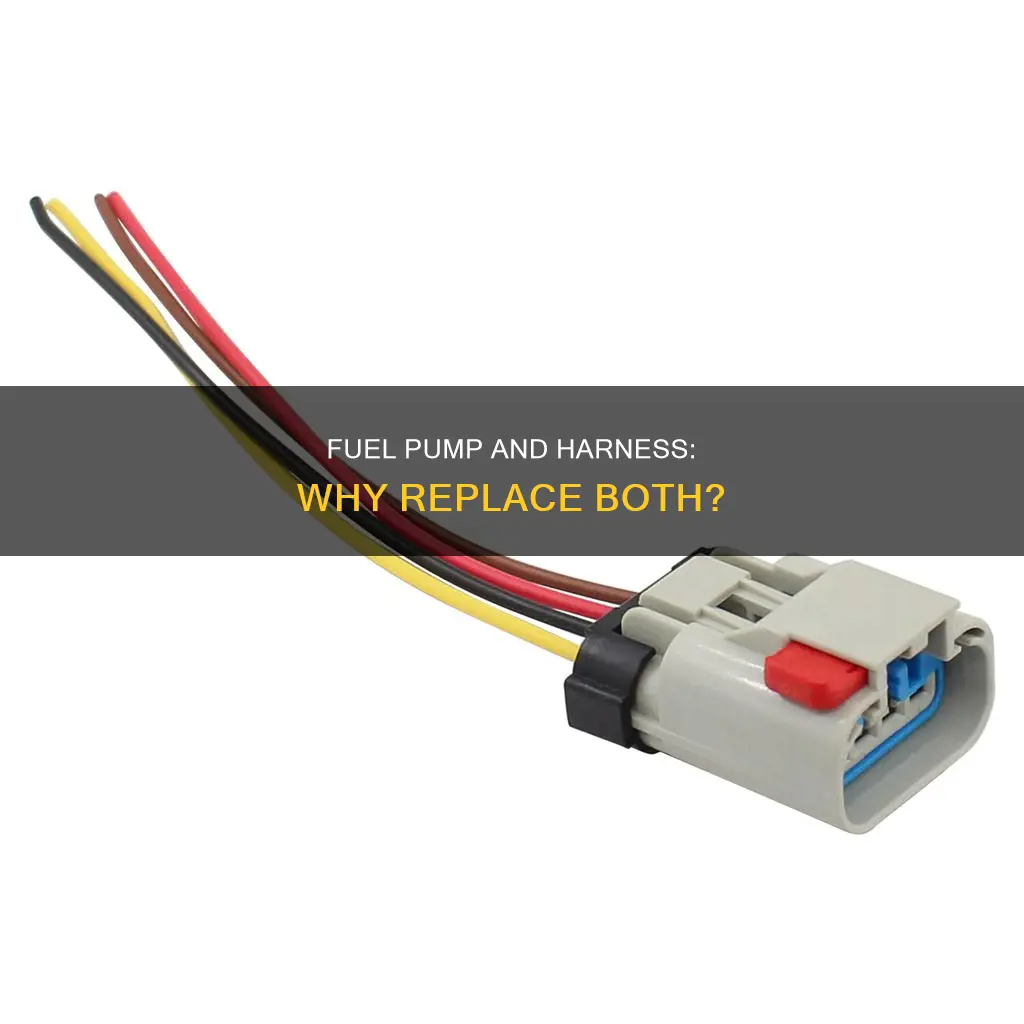

Replacing a fuel pump can be a challenging task, but it is essential to ensure your car runs smoothly. While it is possible to replace a fuel pump yourself, it is important to take the necessary precautions and consult repair manuals or online tutorials for guidance. One important consideration when replacing a fuel pump is whether to replace the fuel pump harness. Fuel pump manufacturers recommend replacing the fuel pump harness when you replace the fuel pump to ensure a secure connection and the proper functioning of the new fuel pump. However, for some vehicles, it may not be necessary to replace the harness if the connector on the wiring harness outside the tank is the same as the new pump.

What You'll Learn

Safety precautions: Wear safety gear and disconnect the battery

When replacing a fuel pump, it is important to take safety precautions to protect yourself and your vehicle. Here are some detailed instructions to ensure a safe and successful fuel pump replacement:

Wear Safety Gear

It is crucial to wear appropriate safety gear when working on your vehicle, especially when handling flammable liquids like fuel. Always wear safety glasses to protect your eyes from any debris or fuel splashes. Gloves are also recommended to protect your hands and provide a secure grip when handling tools and components. Appropriate clothing, such as long sleeves and pants, can shield your skin from fuel spills and provide an additional layer of protection.

Disconnect the Battery

Before beginning any work on your vehicle's fuel system, it is essential to disconnect the battery. Locate the negative battery terminal and disconnect it first. This step is crucial for your safety and can help prevent short circuits or unintended activation of electrical components. By disconnecting the battery, you reduce the risk of sparks or electrical surges that could potentially ignite fuel vapors, leading to a dangerous situation.

Additional Precautions

Working in a well-ventilated area or outdoors is highly recommended to minimise the risk of inhaling toxic fuel vapours and to reduce the chance of fire. It is also advisable to have a fire extinguisher nearby as an extra precaution. If possible, drain the fuel tank or reduce the fuel level to minimise the risk of spills and make the tank lighter and easier to handle. Always refer to your vehicle's service manual or seek guidance from a professional mechanic if you are unsure about any steps or safety precautions.

When replacing a fuel pump, it is often recommended to replace the wiring harness as well. This is because the new fuel pump may not work properly without a compatible wiring harness. By matching the old wiring to the new one, you can ensure a secure connection and proper functionality for the life of your vehicle. Additionally, a universal harness that comes with the new fuel pump may need to be spliced into the existing wiring, requiring careful cutting, stripping, and crimping of wires.

The Fossil Fuel-Free Future: America's Energy Evolution

You may want to see also

Disconnect the fuel pump harness from the tank

When replacing a fuel pump, it is recommended to replace the harness as well, as the new fuel pump may not work properly if the old harness is used. The fuel pump harness should be disconnected from the tank as one of the first steps in the replacement process. This can be done by first disconnecting the negative battery terminal, then removing about a foot of the tape and black plastic conduit from the harness. It is important to ensure that you are not dealing with the fuel pressure sensor connector.

There are several types of fuel line fittings that may be encountered when disconnecting the fuel pump harness from the tank. These include the push-type connector, the push-and-lock style connector, the pinch-type connector, the spring-style retainer fitting, the hose and clamp style fitting, and the horseshoe-type fitting. Each type of connector has its own method of disconnection, which should be carefully followed to avoid damage.

For example, for the push-type connector, you may need to push from both directions to release it, or simply push it down and pull it off, depending on the version. For the push-and-lock style connector, release the safety latch and push the connector back through. To disconnect the pinch-type connector, pinch the retainers on each side together. The spring-style retainer fitting can be removed by pulling back on the black ring release tool and then pulling the fitting off.

Additionally, when disconnecting the fuel pump harness, it is important to take safety precautions, such as wearing safety glasses and gloves, and having a fire extinguisher nearby.

Replacing Fuel Pump Wiring Harness: Step-by-Step Guide

You may want to see also

Match old wiring to new

When replacing a fuel pump wiring harness, it is essential to match the old wiring to the new wiring to ensure the new fuel pump works properly. If the old wiring is not identical to the new wiring, refer to the diagram that comes with the new wiring to help you match them.

- Disconnect the negative battery terminal and the fuel pump harness from the tank. Remove about a foot of the tape and black plastic conduit from the harness, ensuring you are not dealing with the fuel pressure sensor connector.

- If the old wiring is not identical to the new wiring, refer to the diagram that comes with the new wiring. This diagram will help you match the wires correctly.

- Cut the first pair of wires about two inches away from the electrical connectors. Stagger the rest of the cuts by about an inch and a half, and strip the wires.

- Crimp the vehicle's wiring to the new wiring harness with the supplied connectors on all wires. Ensure that no insulation is trapped between the electrical connector crimp.

- Shrink the insulation with a heat gun to secure the connections, keeping it away from any fuel. A sign that your seals are weather-tight is when the glue begins to come out of the connector.

- Finally, install the black plastic conduit and re-tape the wires.

Now you can be confident that your new fuel pump will have a secure connection for the rest of the vehicle's life.

It is important to note that electrical fluctuations in older wiring can damage modern appliances or devices. It is recommended to use surge protectors to divert excess electricity to a grounding wire. Additionally, old wiring should not be left in place, even if it is disconnected, as it can lead to mistakes with future wiring jobs.

The Future of Energy: Sustainable Alternatives to Fossil Fuels

You may want to see also

Cut and strip wires, crimp new harness, and shrink insulation

When replacing a fuel pump, it is essential to also replace the old wiring harness with the new one supplied with your new fuel pump module. The new fuel pump may not work properly if you don't.

To cut and strip wires, crimp the new harness, and shrink the insulation, follow these steps:

Cutting and Stripping Wires

- Disconnect the negative battery terminal.

- Disconnect the fuel pump harness from the tank. Remove about a foot of tape and black plastic conduit from the harness. Ensure you are not dealing with the fuel pressure sensor connector.

- Match the old wiring to the new. If they are not identical, refer to the diagram that comes with the new wiring.

- Cut the first pair of wires about two inches away from the electrical connectors. Stagger the rest of your cuts by about an inch and a half and strip the wires.

Crimping the New Harness

Crimp the vehicle wiring to the new wiring harness with the supplied connectors on all wires. Ensure you don't trap any insulation between the electrical connector crimp.

Shrinking the Insulation

- Shrink the insulation with a heat gun to secure the connections. Keep this away from any fuel.

- When the glue begins to come out of the connector, your seals are weather-tight.

- Install the black plastic conduit and re-tape the wires.

Now you can be confident that the new fuel pump you’re about to install will have a secure connection for the rest of the vehicle's life.

Replacing Ski-Doo Fuel Tank Grommets: A Step-by-Step Guide

You may want to see also

Reinstall the black plastic conduit and re-tape the wires

Reinstalling the black plastic conduit and re-taping the wires is a crucial step in ensuring a secure connection for your vehicle's fuel pump. Here's a detailed guide on how to approach this task:

Before beginning, ensure you have the necessary tools, such as safety glasses, gloves, and a fire extinguisher. It is also important to disconnect the negative battery terminal for safety.

Firstly, you will need to remove the tape and black plastic conduit from the harness. Be cautious to avoid dealing with the fuel pressure sensor connector. This step will expose the wires that need to be worked on.

Now, carefully reinstall the black plastic conduit over the wires. Ensure that it is securely fitted and aligned correctly. Once the conduit is in place, you can start re-taping the wires.

Use electrical tape to securely fasten the wires within the conduit. Make sure to wrap the tape tightly and smoothly to avoid any gaps or loose areas. This will help protect the wires and ensure they remain in place.

Finally, double-check your work to ensure that the conduit is securely installed and the wires are properly taped. This will help prevent any issues with wire connections and ensure the fuel pump operates optimally.

By following these steps, you will have successfully reinstalled the black plastic conduit and re-taped the wires, contributing to a reliable and safe fuel pump system in your vehicle.

Golf Cart Fuel Vent: Replacing the Essential Part

You may want to see also

Frequently asked questions

It is recommended by fuel pump manufacturers to replace the fuel pump harness when you replace the fuel pump. This is because the new fuel pump may not work properly if the old wiring harness is used.

First, disconnect the negative battery terminal and then disconnect the fuel pump harness from the tank. Remove the tape and black plastic conduit from the harness. Next, cut and strip the wires, crimp the vehicle wiring to the new wiring harness, and shrink the insulation with a heat gun. Finally, install the black plastic conduit and re-tape the wires.

Some common symptoms of a faulty fuel pump include difficulty starting the car, a sudden loss of power while driving, a rough run or stalling, and strange, high-pitched whining noises coming from the fuel tank area.