Understanding the causes of air in fuel lines is crucial for maintaining the performance and longevity of any vehicle's engine. Air in the fuel line, also known as aeration, occurs when air bubbles are introduced into the fuel system, often due to a variety of factors such as fuel pump issues, low fuel pressure, or even the natural expansion and contraction of fuel as it moves through the system. This phenomenon can lead to a range of problems, including reduced engine performance, misfires, and even engine stall. The following section will delve into the specific causes of air in fuel lines and explore effective solutions to mitigate these issues.

What You'll Learn

- Fuel Pump Issues: Pump failure or malfunction can lead to air entering the fuel line

- Fuel Tank Venting: Improper venting allows air to enter the tank and line

- Fuel Filter Clogging: Clogged filters restrict fuel flow, causing air to be drawn in

- Engine Vacuum Leaks: Leaks in the engine's vacuum system can introduce air

- Fuel Injector Design: Some injectors may not seal properly, allowing air to mix with fuel

Fuel Pump Issues: Pump failure or malfunction can lead to air entering the fuel line

Fuel pump issues are a common cause of air entering the fuel line, which can lead to a variety of performance problems in an engine. The fuel pump is responsible for delivering fuel from the tank to the engine at the required pressure. When this pump fails or malfunctions, it can result in a decrease in fuel pressure, causing air to enter the system. This phenomenon is often referred to as 'air lock' or 'air in the fuel.'

There are several reasons why a fuel pump might fail or malfunction. One common issue is electrical problems. Over time, the wiring and connections associated with the fuel pump can deteriorate, leading to intermittent or complete power loss to the pump. This can be due to corrosion, damage from rodents or pests, or simply old age. Another potential cause is a faulty pump relay, which controls the power supply to the pump. If the relay fails, the pump may not receive the necessary current to operate effectively.

Mechanical failures are another set of potential causes. The fuel pump itself can wear out due to constant operation, leading to reduced performance or complete failure. This is often a result of internal components like the impeller or diaphragm deteriorating over time. Additionally, issues with the pump's mounting or the fuel line connections can cause the pump to vibrate or become misaligned, leading to reduced efficiency or damage to the pump.

When a fuel pump fails or malfunctions, the engine may exhibit several symptoms. One of the most common signs is a decrease in engine performance, including reduced power, acceleration, and fuel efficiency. The engine may also stall or have difficulty starting, especially when the fuel tank is nearly empty. In some cases, the engine may run roughly or with a knocking sound, indicating that air is being introduced into the combustion chamber.

To address fuel pump issues, it is essential to diagnose the problem accurately. This often involves checking the electrical connections and testing the pump's power supply. If the issue is mechanical, inspecting the pump for wear and tear, replacing worn components, or realigning the pump may be necessary. In some cases, simply cleaning or replacing the fuel filter can resolve the problem, as it can trap air bubbles that may have entered the fuel line. Regular maintenance and timely attention to any fuel pump-related issues can help prevent air lock and ensure optimal engine performance.

Unraveling the Mystery: Why Motorcycles Pop Pinholes in Fuel Lines

You may want to see also

Fuel Tank Venting: Improper venting allows air to enter the tank and line

Fuel tank venting is a critical component of any vehicle's fuel system, ensuring that the fuel remains stable and free from contaminants. When a fuel tank is filled, it is under pressure, and this pressure needs to be released to prevent the tank from overfilling and to allow for the expansion of the fuel as it heats up. The venting system is designed to release this pressure and also to allow air to escape from the tank, which is essential for maintaining the proper fuel-air mixture in the engine.

Improper venting of the fuel tank can lead to several issues, primarily the entry of air into the fuel line. When the venting system fails to function correctly, it creates a vacuum in the tank, pulling in air. This air can then enter the fuel line, causing a range of problems. One of the most common issues is fuel vaporization, where the air in the fuel line causes the fuel to turn into vapor, leading to poor engine performance and potential starting difficulties. This is especially problematic in colder climates where fuel can already be more prone to vaporization.

The presence of air in the fuel line can also result in engine misfires and reduced power. As the air mixes with the fuel, it dilutes the fuel-air ratio, causing the engine to run lean. This can lead to a loss of power, reduced fuel efficiency, and even engine damage over time. In some cases, the engine may hesitate or stall, making it difficult to start or operate.

To prevent these issues, it is crucial to ensure that the fuel tank venting system is functioning correctly. Regular maintenance and inspection of the venting mechanism can help identify any blockages or damage. If the venting system is blocked or damaged, it should be repaired or replaced immediately to prevent air from entering the fuel line. Additionally, keeping the fuel tank full can also help, as a full tank creates less pressure differentials, reducing the likelihood of air entering the system.

In summary, improper fuel tank venting can lead to air entering the fuel line, causing fuel vaporization, engine misfires, and reduced performance. Proper maintenance and attention to the venting system are essential to ensure the longevity and optimal operation of the vehicle's fuel system.

Unveiling the Material Secrets of Car Fuel Lines

You may want to see also

Fuel Filter Clogging: Clogged filters restrict fuel flow, causing air to be drawn in

Fuel filters are an essential component of any vehicle's fuel system, designed to prevent contaminants from entering the engine. Over time, these filters can become clogged, leading to a variety of performance issues, including the presence of air in the fuel line. Understanding the causes and effects of fuel filter clogging is crucial for maintaining a vehicle's optimal performance.

One of the primary causes of fuel filter clogging is the accumulation of contaminants in the fuel. Fuel itself contains impurities, such as water, sediment, and small particles, which can be drawn into the fuel system during the fueling process. Over time, these contaminants can build up within the filter, narrowing the passages and restricting fuel flow. This is especially common in older vehicles or those with poor fuel quality.

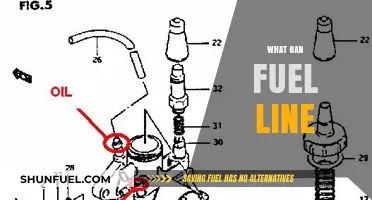

Another factor contributing to fuel filter clogging is the presence of air in the fuel line. When a fuel filter becomes clogged, it can create a restriction in the fuel flow, leading to a condition known as 'air lock'. This occurs when air is drawn into the fuel line due to the reduced pressure caused by the clogged filter. As a result, the engine may start to run roughly, lose power, or even stall.

To address this issue, it is essential to regularly inspect and replace the fuel filter. Clogged filters can be cleaned or replaced, but in some cases, the filter may need to be replaced entirely. Regular maintenance, including fuel system flushes and the use of fuel additives, can also help prevent clogging and maintain the integrity of the fuel system.

In summary, fuel filter clogging is a common issue that can lead to air being drawn into the fuel line. Contaminants in the fuel and air lock are the primary causes, resulting in reduced engine performance. Regular maintenance and filter replacement are essential to ensure the vehicle's fuel system operates efficiently and avoids potential breakdowns.

Unveiling the Causes: Why Fuel Line Leaks Happen

You may want to see also

Engine Vacuum Leaks: Leaks in the engine's vacuum system can introduce air

Engine vacuum leaks are a common issue that can significantly impact the performance and efficiency of your vehicle's engine. These leaks occur when there is an unintended passage for air to enter the engine's vacuum system, often due to worn-out or damaged components. The vacuum system plays a crucial role in maintaining the engine's optimal performance by ensuring a precise air-fuel mixture for combustion. When this system is compromised, it can lead to a variety of problems, with one of the most noticeable being the presence of air in the fuel line.

The primary cause of engine vacuum leaks is the deterioration of various components within the vacuum system. These components include hoses, gaskets, and seals, which are designed to create an airtight connection. Over time, these parts can crack, dry out, or become brittle, leading to small tears or gaps. As a result, air can seep into the system, disrupting the intended vacuum pressure. This intrusion of air can have several detrimental effects. Firstly, it dilutes the fuel in the fuel line, leading to a less concentrated mixture. This can cause the engine to run rich, resulting in decreased performance, reduced fuel efficiency, and potential engine damage over time.

Secondly, the presence of air in the fuel line can lead to a condition known as 'vacuum surge'. When air enters the system, it creates a temporary increase in pressure, causing the engine to surge or hesitate during operation. This surge can be felt as a sudden lurch or hesitation when accelerating, making the vehicle feel unresponsive. Moreover, the air bubbles in the fuel line can cause the engine to misfire, especially during high-load conditions, such as climbing steep inclines or towing heavy loads.

To address engine vacuum leaks, it is essential to inspect and replace any damaged components in the vacuum system. This includes checking for cracks or brittleness in hoses, ensuring gaskets are tight and intact, and replacing any seals that have failed. Regular maintenance and timely repairs can prevent air from entering the fuel line, ensuring your engine operates efficiently and reliably. If you suspect a vacuum leak, it is advisable to consult a professional mechanic who can diagnose and rectify the issue, ensuring your vehicle's performance remains optimal.

Unveiling the 1967 Ford LTD's Fuel Line Route

You may want to see also

Fuel Injector Design: Some injectors may not seal properly, allowing air to mix with fuel

The presence of air in a fuel line is a common issue that can significantly impact the performance of an engine. This phenomenon often occurs due to design flaws or malfunctions in the fuel injection system, particularly with fuel injectors. When a fuel injector fails to seal properly, it creates a pathway for air to enter the fuel stream, leading to a process known as "air in the fuel line." This issue is a critical concern as it can result in a variety of engine problems, including reduced power, poor fuel efficiency, and even engine misfires.

Fuel injectors are designed to precisely deliver the correct amount of fuel to the engine's combustion chamber. They operate under high pressure, ensuring that the fuel is atomized and mixed with air for efficient combustion. However, if the injector's sealing mechanism is compromised, it can lead to several adverse effects. One of the primary consequences is the introduction of air bubbles into the fuel, which can cause the fuel to become less dense and less effective in combustion. This results in a condition known as "air lock," where the engine may run roughly or stall due to the inconsistent fuel-air mixture.

The design of fuel injectors is crucial to their proper functioning. Injectors typically feature intricate internal components, including precision-engineered nozzles and valves, which are responsible for the accurate metering and injection of fuel. These components must be manufactured with tight tolerances to ensure a reliable seal. Over time, wear and tear, or manufacturing defects can cause these seals to deteriorate, leading to air leakage. This is especially critical in high-pressure systems, where even a small breach in the seal can result in significant air intrusion.

To address this issue, engineers employ various sealing mechanisms in fuel injectors. One common design is the use of O-rings or gaskets made from durable materials like rubber or silicone. These seals are designed to withstand the high pressure and temperature conditions within the injector. Regular maintenance, such as replacing worn-out seals and ensuring proper installation, is essential to prevent air leaks. Additionally, the use of fuel filters and vacuum relief valves can help mitigate the effects of air in the fuel line by removing air bubbles and maintaining a consistent fuel-air mixture.

In summary, improper sealing in fuel injectors is a significant contributor to the presence of air in fuel lines. This design flaw can lead to engine performance issues and requires careful attention during manufacturing and maintenance. Understanding the intricate relationship between fuel injector design and air intrusion is vital for optimizing engine efficiency and reliability.

Safe and Effective Methods to Thaw Frozen Car Fuel Lines

You may want to see also

Frequently asked questions

Air in the fuel line can be caused by several factors. One common reason is a poorly sealed fuel tank, allowing air to enter when the fuel level drops. Additionally, fuel pumps may introduce air if they are not functioning correctly or if there are leaks in the pump's housing.

Air bubbles in the fuel line can lead to reduced engine performance. When air enters the fuel system, it can cause fuel to spray incorrectly, leading to misfires and reduced power. This issue is often noticeable during acceleration, where the engine may hesitate or stall momentarily.

Yes, prolonged exposure to air in the fuel system can potentially damage the engine. Air bubbles can carry moisture, leading to corrosion in the fuel injectors and engine components. Over time, this can result in clogged injectors, reduced fuel efficiency, and even engine misfires.

You may notice several symptoms indicating air in the fuel line. These include erratic engine behavior, such as stalling, hesitation, or rough idling. The engine may also produce a knocking or rattling sound, especially during acceleration. Additionally, a decrease in fuel efficiency and increased emissions are common indicators.

Preventing air intrusion in the fuel line involves several maintenance practices. Ensure your fuel tank is properly sealed and consider using a fuel stabilizer to maintain the fuel's quality. Regularly checking and replacing fuel filters can also prevent contaminants, including air, from entering the system.