Removing the fuel return line is a crucial step in any vehicle maintenance routine, especially when addressing fuel system issues. This process involves carefully disconnecting the line to ensure proper fuel flow and prevent potential leaks. It's essential to follow a systematic approach to avoid damage to the vehicle's components. The procedure typically starts with identifying the return line's location, often found beneath the vehicle, and then using the appropriate tools to carefully detach the connections. This guide will provide a step-by-step breakdown of the process, ensuring a safe and efficient removal.

What You'll Learn

- Preparation: Gather tools and materials, ensure engine is cool, and drain fuel tank

- Location: Identify fuel return line, typically near the fuel tank or pump

- Disconnection: Loosen clamps and disconnect line from fuel pump and tank

- Cleaning: Rinse and inspect line, replace if damaged, then reinstall

- Testing: Check for leaks, ensure proper flow, and reattach securely

Preparation: Gather tools and materials, ensure engine is cool, and drain fuel tank

Before you begin the process of removing the fuel return line, it's crucial to prepare the necessary tools and materials to ensure a smooth and safe procedure. Start by gathering the required equipment, which may include a fuel pump primer, a fuel filter, a fuel line disconnect tool, a wrench or socket set, and a drain pan. These tools will facilitate the removal process and help you handle any potential fuel leaks. Additionally, it's essential to have a clear understanding of the vehicle's fuel system layout to locate the return line effectively.

Once you have the tools ready, it's imperative to ensure the engine is cool to prevent any accidents or damage. Engine overheating can lead to fuel line expansion, making it challenging to remove the return line. Allow the engine to idle and cool down for a sufficient period, typically 30 minutes to an hour, to ensure it reaches a safe temperature. This step is crucial for your safety and the success of the repair.

Before proceeding, it's highly recommended to drain the fuel tank to avoid any spills or accidents during the removal process. Locate the fuel drain valve, which is usually a small opening near the bottom of the fuel tank. Place the drain pan underneath the valve and open it to release the fuel. Ensure you drain the tank completely, as residual fuel can cause issues during the removal process. This step is essential for a clean and safe working environment.

After the fuel tank is drained, double-check that the engine is still cool to the touch. This double-checking step is vital to ensure your safety and the integrity of the fuel system. With the engine cool and the fuel tank empty, you are now ready to proceed with the removal of the fuel return line, taking the necessary precautions and following the appropriate steps for your specific vehicle model.

When Fuel Lines Detach: Understanding the Consequences and Solutions

You may want to see also

Location: Identify fuel return line, typically near the fuel tank or pump

When attempting to remove a fuel return line, the first step is to locate it. This line is an essential component of your vehicle's fuel system, and it plays a crucial role in ensuring that fuel is returned to the tank after it has been used by the engine. The fuel return line is typically located near the fuel tank or fuel pump, and identifying its position is key to a successful removal process.

Start by inspecting the area around your fuel tank. The fuel return line often runs from the fuel pump, which is usually situated near the tank, and connects to the tank's inlet port. It is important to note the exact location of the fuel pump and the path the line takes. This line may be hidden under various components, such as the engine, exhaust system, or even the body panels, so a thorough inspection is necessary. Look for any signs of damage, corrosion, or obstructions that might indicate why the line needs to be removed.

If you have difficulty finding the line, consider consulting your vehicle's service manual. This manual will provide detailed diagrams and illustrations specific to your car's make and model, making it easier to identify the fuel return line's exact location. It might also offer valuable information about the tools and procedures required for the removal process.

Once you've identified the fuel return line, ensure you have the necessary tools and safety equipment. Removing this line requires careful handling to avoid any fuel spills or damage to the surrounding components. You might need a fuel drain pan to catch any spilled fuel, gloves to protect your hands, and possibly a fuel filter removal tool, depending on your vehicle's design.

Remember, when working on any fuel-related components, it is crucial to exercise caution and follow safety protocols. Always double-check your connections and ensure that all fuel has been drained or contained before proceeding with any repairs or replacements.

Understanding Fuel Oil Line Requirements: A Comprehensive Guide

You may want to see also

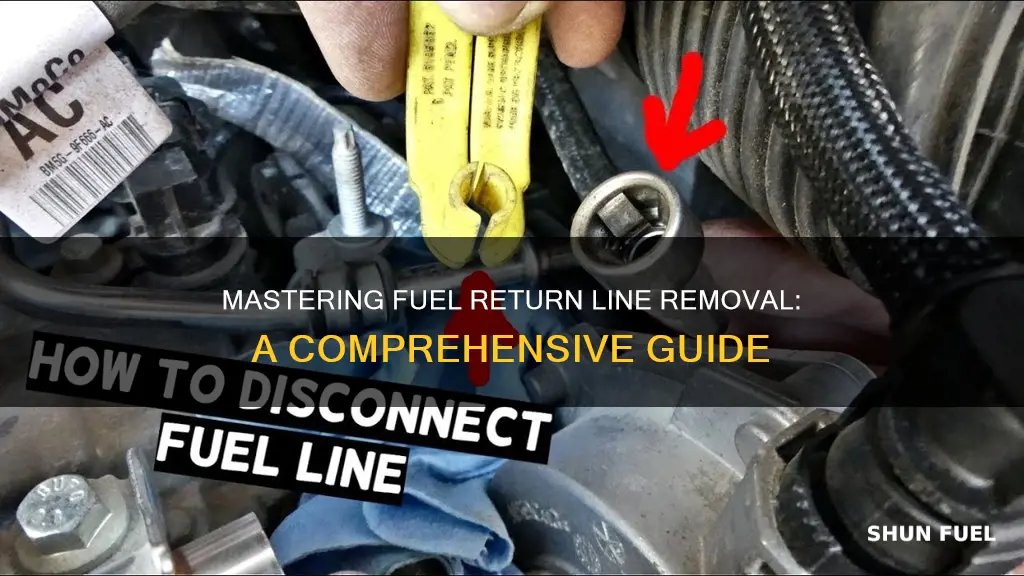

Disconnection: Loosen clamps and disconnect line from fuel pump and tank

To begin the process of removing the fuel return line, you'll need to access the line's connection points. This typically involves locating the fuel pump and the fuel tank, as these are the primary components where the return line is connected. Start by identifying the specific clamps and fittings that secure the line to both the pump and the tank. These connections are usually made with metal or plastic clamps, which can be loosened using a wrench or a pair of adjustable pliers. Be cautious when using tools to avoid damaging the clamps or the line itself.

Once the clamps are loosened, you can carefully disconnect the fuel return line from the fuel pump. Locate the line's connection point on the pump, which is often a small fitting or a quick-release coupling. Gently pull the line away from the pump, ensuring that you don't force it, as this could damage the pump or the line. After disconnecting the line from the pump, move on to the fuel tank.

The fuel return line connects to the tank via a similar fitting or coupling. Loosen the clamps securing the line to the tank and carefully disconnect it. It's important to note that the fuel tank may have a fuel level sensor or other components connected to the return line, so be cautious when removing it. You might need to refer to your vehicle's manual to understand the specific connections and ensure you don't accidentally disconnect any critical components.

After successfully disconnecting the line from both the pump and the tank, you should have the fuel return line removed. Ensure that you handle the line with care to avoid any damage, especially if it's made of flexible material. Keep the disconnected components organized and ready for potential reinstallation or further inspection. Remember, if you're unsure about any step, it's always a good idea to consult a professional mechanic or refer to your vehicle's manual for specific instructions tailored to your make and model.

Finding the Perfect Fuel Line Fit for Your 2006 Scion TC

You may want to see also

Cleaning: Rinse and inspect line, replace if damaged, then reinstall

To effectively clean and maintain your fuel return line, follow these steps:

Rinse the Line: Begin by disconnecting the fuel return line from the fuel tank and any other connected components. Use a garden hose or a dedicated fuel line cleaner to thoroughly rinse the line. Ensure you direct the water flow in a way that allows for the removal of any debris, contaminants, or built-up residue. Pay close attention to any bends or kinks in the line to ensure a complete rinse.

Inspect for Damage: After rinsing, carefully examine the fuel return line for any signs of damage, such as cracks, leaks, or corrosion. Inspect the connections and fittings as well. If you notice any damage, it is crucial to replace the line immediately to prevent further issues. Look for any signs of deterioration, especially in areas where the line is exposed to heat or vibration.

Cleaning and Maintenance: If the line appears intact, proceed with cleaning. You can use a fuel line cleaner or a mild detergent mixed with water. Apply the cleaner to the line and let it sit for a few minutes to dissolve any stubborn deposits. Then, rinse the line again to ensure all cleaning agents are removed. This process helps to restore the line's functionality and prevent clogs.

Replacement and Reinstallation: In some cases, despite your efforts, the line may be too damaged to clean effectively. If this is the case, replace the fuel return line with a new one that is compatible with your vehicle. Ensure you follow the manufacturer's guidelines for the correct size and type of replacement. After installing the new line, reconnect all fittings and secure them properly. Test the system to ensure there are no leaks and that the fuel flow is optimal.

Remember, regular maintenance and cleaning of the fuel return line are essential to prevent fuel system issues and ensure optimal engine performance. By following these steps, you can keep your fuel system in good condition and avoid potential problems.

Saito 180 Fuel Line: Size Guide for Optimal Performance

You may want to see also

Testing: Check for leaks, ensure proper flow, and reattach securely

When you've completed the removal and replacement of the fuel return line, it's crucial to thoroughly test the system to ensure it's functioning correctly and safely. This testing process involves several key steps to verify the integrity of the fuel system.

Checking for Leaks: Begin by inspecting the entire fuel system for any signs of leaks. This includes the fuel return line, the fuel tank, and all connections. Use a soapy water solution to carefully test each joint and connection. If you notice any bubbles forming, it indicates a leak. Leaks can lead to fuel contamination, engine performance issues, and potential safety hazards. Address any leaks immediately by tightening connections or replacing damaged components.

Ensuring Proper Flow: After confirming there are no leaks, it's essential to check the flow of fuel through the system. Start the engine and monitor the fuel gauge to ensure it operates as expected. Listen for any unusual noises, such as hissing or roaring, which could indicate a restriction or blockage in the fuel flow. Proper flow ensures that the engine receives the required amount of fuel for optimal performance. If you notice any issues, you may need to clean or replace certain components to restore normal fuel flow.

Reattachment and Security: Once you've verified the absence of leaks and confirmed proper flow, securely reattach the fuel return line. Ensure that all connections are tight and secure to prevent any potential dislodging during operation. Double-check the installation to make sure there are no obstructions or interference with other components. Proper reattachment is vital to maintain the structural integrity of the fuel system and prevent any further issues.

Final Testing and Operation: After reattachment, start the engine and let it run for a while. Monitor the engine's performance, including its idling, acceleration, and overall behavior. Check for any unusual smells or sounds, as these could indicate potential issues. If the engine operates smoothly and without any anomalies, your fuel return line replacement and testing have been successful. This final step ensures that the entire fuel system is functioning correctly and safely.

Air in Fuel Lines: Will Your Pump Fail?

You may want to see also

Frequently asked questions

Removing the fuel return line requires caution to prevent fuel spillage and potential hazards. First, ensure the engine is cool to avoid burns. Locate the return line, typically a rubber or plastic hose, and use a fuel line cutter or a sharp tool to carefully cut it at the desired point. Take note of the connection points and any fittings. If possible, replace the line with a new one to ensure a proper seal.

You will need a few essential tools to remove the fuel return line. A fuel line cutter or a pair of sharp scissors/knives will help make clean cuts. A wrench or pliers might be necessary to loosen any fittings or connections. Additionally, have a container ready to catch any spilled fuel, and consider wearing protective gear like gloves and safety goggles.

Absolutely, safety is crucial when dealing with fuel lines. Always work in a well-ventilated area and ensure proper ventilation to avoid inhaling fuel vapors. Be cautious of hot engine components to prevent burns. If you're unsure, consult the vehicle's manual or seek professional assistance to ensure you follow the correct procedure for your specific make and model.

It is generally recommended to replace the old fuel return line, especially if it shows signs of wear, damage, or cracking. Over time, the line can degrade, leading to potential fuel leaks and reduced performance. Replacing it with a new line ensures a secure connection and optimal fuel flow, promoting better engine operation and fuel efficiency.