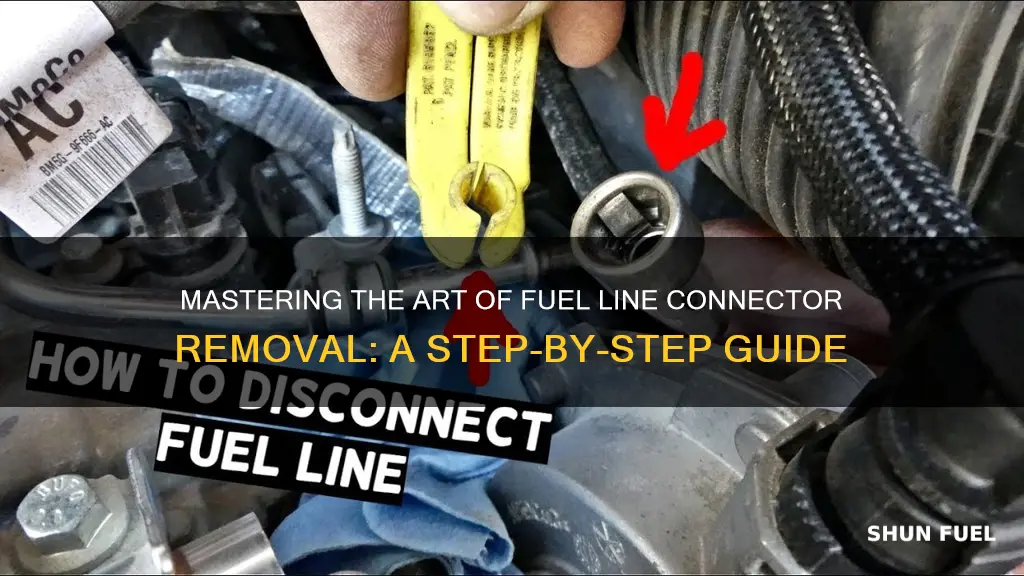

Removing the fuel line connector is a crucial step in any vehicle maintenance or repair process, ensuring you have the right tools and knowledge to do it safely and effectively. This guide will provide a step-by-step process to help you disconnect the fuel line connector, covering the necessary precautions and techniques to avoid any potential hazards. Understanding the process will enable you to tackle this task with confidence and ensure your vehicle's fuel system remains intact and functional.

What You'll Learn

- Locate the Fuel Line Connector: Identify the fuel line connector on your vehicle, typically near the fuel tank or engine

- Release the Clamp: Use a tool to release the clamp holding the connector in place, often a flathead screwdriver or a fuel line tool

- Remove the Connector: Gently pull the connector straight off the fuel line, ensuring no damage to the line

- Clean and Inspect: Clean the connector and fuel line, then inspect for any damage or debris that may affect performance

- Reinstall Properly: Reattach the connector securely, ensuring it is aligned correctly and the clamp is tightened to prevent leaks

Locate the Fuel Line Connector: Identify the fuel line connector on your vehicle, typically near the fuel tank or engine

Locate the Fuel Line Connector: Identifying its Position on Your Vehicle

The fuel line connector is a crucial component in your vehicle's fuel system, and locating it is the first step towards safely removing it. This connector is typically positioned near the fuel tank or engine, and its exact location can vary depending on the make and model of your car. Here's a detailed guide to help you find it:

Start by examining the area around your fuel tank. The fuel line, which carries gasoline from the tank to the engine, is usually visible and runs along the bottom of the tank. The connector will be attached to this line, often at a point where it changes direction or where multiple lines merge. It might be a small, cylindrical or rectangular-shaped component with threads or a quick-release mechanism.

If you have access to your vehicle's engine bay, this can provide a clearer view. The fuel lines enter the engine compartment and connect to the fuel injectors or carburetor. Look for any connections or fittings that appear to be fuel lines. The connector might be located near the front or rear of the engine, where the fuel lines converge.

In some cases, the fuel line connector might be hidden behind other components or under insulation. If you can't see it, consult your vehicle's service manual, which provides a detailed diagram of the fuel system. This manual will help you identify the exact location and any specific tools or procedures required for removal.

Remember, when locating the fuel line connector, consider the potential hazards. Fuel is flammable, so ensure your vehicle is parked in a well-ventilated area, and always exercise caution when working on any fuel-related components.

Return Fuel Line: Understanding the Primer Bulb's Path

You may want to see also

Release the Clamp: Use a tool to release the clamp holding the connector in place, often a flathead screwdriver or a fuel line tool

To remove a fuel line connector, you'll need to start by releasing the clamp that holds it in place. This clamp is typically a metal or plastic piece with a screw or bolt mechanism to secure it. The process might vary slightly depending on the make and model of your vehicle, but the general steps remain the same.

The most common tool used for this task is a flathead screwdriver. You'll want to insert the screwdriver's tip into the small slot or indentation on the clamp, often located near the fuel line connector. Apply gentle but firm pressure to the screwdriver, turning it counterclockwise to loosen the clamp. Be careful not to apply too much force, as you might strip the screw or damage the clamp. Once the clamp is loosened, you can carefully remove it from the connector.

Alternatively, you might use a fuel line tool, which is specifically designed for this purpose. These tools often have a curved or L-shaped handle with a flat, sharp edge. The sharp edge is inserted into the slot on the clamp, and you apply pressure to release it. Fuel line tools are particularly useful for tight or hard-to-reach clamps.

When using either method, ensure you have a stable and secure grip on the tool. It's important to work slowly and carefully to avoid any accidental damage to the fuel line or surrounding components. Once the clamp is released, you should be able to easily remove the fuel line connector by pulling it straight off the fuel line. Remember to replace the connector with a new one after cleaning or replacing the old one to ensure optimal performance and safety.

Choosing the Right Primer for Boat Fuel Tanks Below Waterline

You may want to see also

Remove the Connector: Gently pull the connector straight off the fuel line, ensuring no damage to the line

To safely remove the fuel line connector, start by identifying the specific connector you need to detach. These connectors are typically located near the fuel tank or along the fuel lines, often with a visible clip or tab for easy access. Once located, use your fingers or a small tool to carefully release the clip or tab, allowing the connector to detach from the fuel line.

Gently pulling the connector straight off the fuel line is crucial. Avoid twisting or pulling at an angle, as this can damage the fuel line or the connector itself. Ensure you have a firm grip on the connector and apply steady pressure to remove it. If the connector is stubborn and doesn't come off easily, you may need to apply a small amount of lubricant to the connector and fuel line interface to reduce friction. However, use lubricants sparingly and only on the affected areas to prevent contamination.

When removing the connector, be mindful of any fuel that may have accumulated around the connection. Fuel can be messy and difficult to clean up once spilled, so take extra care to avoid any splashes or drips. If you notice any fuel leaks during the process, stop immediately and address the issue before proceeding.

After successfully removing the connector, inspect the fuel line and connector for any signs of damage or wear. Clean the connector and fuel line if necessary, ensuring there is no debris or old fuel residue left behind. Properly disposing of any fuel-related waste is essential for environmental safety.

Remember, the key to successfully removing the fuel line connector is patience and a gentle approach. Take your time, and ensure you are working in a well-ventilated area to avoid inhaling any fuel vapors. With these steps, you can safely disconnect the fuel line connector without causing any unnecessary damage.

Mastering Fuel Line and Steering Repairs: A Comprehensive Guide

You may want to see also

Clean and Inspect: Clean the connector and fuel line, then inspect for any damage or debris that may affect performance

To ensure optimal performance and longevity of your fuel system, it's crucial to regularly clean and inspect the fuel line connector. This process involves a few simple steps that can be easily accomplished with basic tools and some cleaning agents.

Cleaning the Connector and Fuel Line:

Start by gathering the necessary supplies: a fuel line cleaner, a soft cloth, and a small brush. Ensure you have a well-ventilated workspace and wear protective gloves to avoid skin irritation. Begin by disconnecting the fuel line from the fuel tank and the engine. This step is crucial for safety and to prevent fuel spills. Once disconnected, use the fuel line cleaner to spray and coat the entire length of the fuel line. Allow the cleaner to sit for the recommended time, which is typically around 10-15 minutes, to ensure it penetrates and loosens any built-up debris. After the specified time, use the brush to gently scrub the fuel line, removing any stubborn deposits. Rinse the fuel line thoroughly with clean water to eliminate any remaining cleaner and debris.

Inspecting for Damage and Debris:

With the fuel line now clean, it's time to inspect it for any potential issues. Carefully examine the fuel line for any signs of damage, such as cracks, leaks, or corrosion. Look for any kinks or bends in the line that might restrict fuel flow. Pay close attention to the fuel line connector, as this is a critical component. Check for any signs of corrosion or damage around the threads and ensure the o-ring or gasket is intact and not worn out. Also, inspect the surrounding area for any debris or contaminants that may have accumulated during the cleaning process. Use a magnifying glass if necessary to identify small particles or contaminants that could affect the fuel line's performance.

By following these steps, you can effectively clean and inspect the fuel line connector, ensuring that your fuel system operates efficiently and reliably. Regular maintenance of this nature can help prevent fuel-related issues and extend the life of your vehicle's fuel system. Remember, if you encounter any complex issues or are unsure about any step, it's always best to consult a professional mechanic for assistance.

Mastering Harbor Freight Fuel Line Disconnect: A Comprehensive Guide

You may want to see also

Reinstall Properly: Reattach the connector securely, ensuring it is aligned correctly and the clamp is tightened to prevent leaks

When reinstalling a fuel line connector, it's crucial to follow a systematic approach to ensure a secure and leak-free connection. Here's a step-by-step guide to help you through the process:

Start by carefully examining the fuel line connector and its components. Locate the connector body, which is typically a cylindrical or oval-shaped component with a clamp or retaining mechanism at one end. Identify the fuel line, which is the flexible tube that connects the fuel source to the engine. Ensure that the fuel line is free of any damage or kinks before proceeding.

Now, take the connector and align it with the fuel line. The connector should have a specific orientation or angle that matches the fuel line's path. Carefully slide the connector onto the fuel line, ensuring it is fully inserted and seated correctly. You should feel a secure fit or hear a click as the connector locks into place.

The next step is to secure the connector with the clamp or retaining mechanism. Tighten the clamp by hand, ensuring it is snug and firmly in place. You can use a wrench or a specialized tool designed for this purpose if needed. The goal is to create a tight seal that prevents any fuel from leaking out. Be careful not to overtighten the clamp, as it may damage the fuel line or cause internal damage to the connector.

After securing the clamp, inspect the connection for any signs of leaks. You can use a small amount of soapy water or a specialized fuel leak detector to check for any potential issues. If you notice any bubbles forming around the connector or see a small amount of fuel, it indicates a potential leak. In such cases, you may need to adjust the connector's position or tighten the clamp further.

Finally, ensure that the connector is aligned correctly and that all components are in their proper positions. Double-check that the fuel line is not kinked or pinched anywhere, as this could lead to future issues. With the connector securely reattached and the clamp tightened, your fuel system should now be leak-free and ready for operation. Remember, proper reinstallation is essential to maintain the integrity of your fuel system and prevent any potential engine issues.

Unclog Your Fuel Line: A Step-by-Step Guide to a Clean Engine

You may want to see also

Frequently asked questions

When removing the fuel line connector, it's crucial to prioritize safety. Ensure the engine is cool to avoid burns, and park the vehicle on a level surface to prevent spills. Loosen the connector by hand first, then use a fuel line removal tool or a flathead screwdriver to carefully pry it off, being mindful of any fuel that may have accumulated.

It's generally not recommended to reuse a fuel line connector that has been removed and reinstalled. Over time, the connector can degrade, leading to potential fuel leaks and engine performance issues. It's best to replace it with a new one to ensure optimal functionality and safety.

You'll typically need a few basic tools to remove the fuel line connector. A fuel line removal tool, also known as a fuel line disconnecting tool, is the most common and effective option. Alternatively, a flathead screwdriver or a pair of pliers can be used, but these may require more force and careful application to avoid damage.

Yes, there are a few important steps. First, locate the fuel line connector, often found under the hood or near the fuel tank. Release any pressure by slightly loosening the connector or using a tool to break the vacuum. Then, carefully remove the connector, being mindful of any fuel that may have accumulated. Finally, clean the area and reconnect the fuel line when needed.

If the connector is stubborn, try applying a small amount of fuel line cleaner or a thin-walled object to loosen it. Be cautious not to damage the connector or surrounding areas. If the issue persists, consider seeking professional assistance to ensure the job is done safely and effectively.