A leaky fuel line can be a frustrating and potentially dangerous issue for any vehicle owner. It's important to address this problem promptly to prevent fuel leaks, which can lead to hazardous situations and costly repairs. In this guide, we'll explore some quick and effective methods to repair a leaky auto fuel line, ensuring your vehicle remains safe and reliable.

What You'll Learn

- Locate the leak: Inspect the fuel line for visible damage, cracks, or disconnections

- Prepare tools: Gather necessary supplies: fuel line repair tape, solvent cleaner, and a rag

- Clean the area: Remove dirt and debris from the fuel line using a solvent cleaner

- Apply repair tape: Wrap the repair tape tightly around the leak, ensuring a secure seal

- Test and drive: Start the car and check for leaks. Drive the vehicle to ensure the repair is effective

Locate the leak: Inspect the fuel line for visible damage, cracks, or disconnections

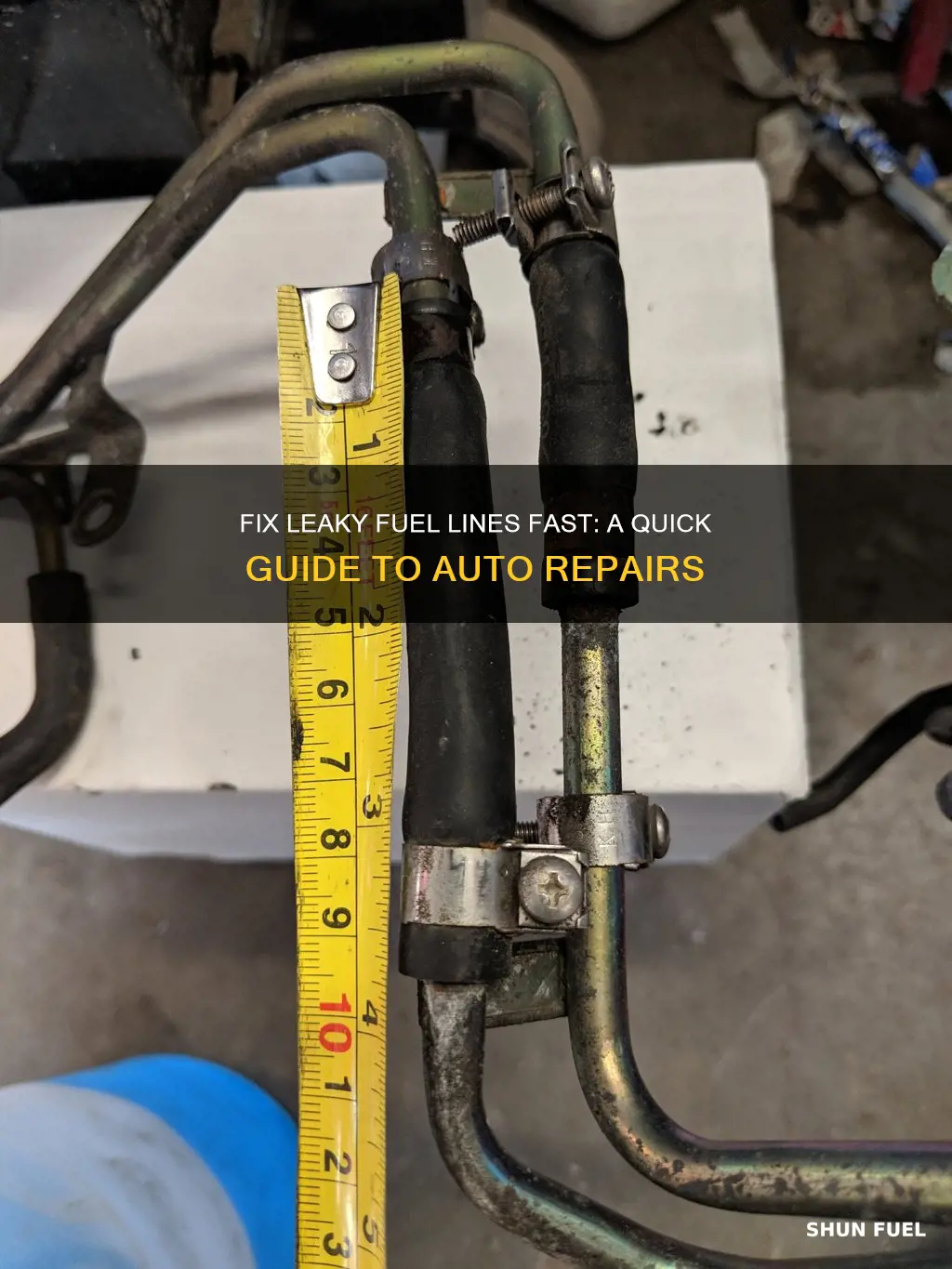

When dealing with a leaky fuel line, the first step is to locate the source of the problem. This requires a thorough inspection of the fuel line for any visible signs of damage, cracks, or disconnections. Start by tracing the fuel line from the fuel tank to the engine, paying close attention to any bends, fittings, and connections along the way. Look for any signs of corrosion, rust, or wear and tear, as these can weaken the fuel line over time.

Check for any visible cracks or punctures in the fuel line itself. These can be caused by various factors, such as age, impact damage, or chemical corrosion. Inspect the line for any areas where it has become brittle or has developed small cracks. Even a small crack can lead to a significant leak, so it's essential to identify and address these issues promptly.

In addition to physical damage, look for any signs of disconnections or loose fittings. Fuel lines are typically secured in place with clamps or brackets, and over time, these can loosen or become damaged. Inspect the clamps and brackets to ensure they are intact and securely holding the fuel line in place. If you find any loose connections, tighten them carefully and ensure they are properly secured.

It's also important to check for any signs of fuel contamination or degradation. Over time, fuel can absorb moisture or become contaminated with debris, leading to corrosion and potential leaks. If you suspect fuel contamination, it may be necessary to drain and flush the fuel system to remove any impurities.

If you're unable to locate the leak yourself, or if the damage appears extensive, it's best to consult a professional mechanic. They have the tools and expertise to identify and repair fuel line issues effectively, ensuring your vehicle's safety and performance.

Unclogging Fuel Lines: A Step-by-Step Guide for Snowblower Maintenance

You may want to see also

Prepare tools: Gather necessary supplies: fuel line repair tape, solvent cleaner, and a rag

Before you begin the repair process, it's crucial to gather the right tools and supplies to ensure a successful fix. Here's a step-by-step guide on preparing the necessary items:

Fuel Line Repair Tape: This is the primary material you'll use to seal the leak. Opt for a tape specifically designed for fuel line repairs, as it is engineered to withstand the pressure and temperature variations associated with fuel systems. Look for a tape with a strong adhesive backing and a flexible, durable construction.

Solvent Cleaner: A good solvent cleaner is essential for removing any dirt, grime, or old tape residue from the fuel line. Choose a cleaner that is safe for use on rubber and plastic components. It should effectively dissolve grease and oil without causing damage. Ensure you have enough solvent to cover the entire length of the fuel line that needs attention.

Rag or Cleaning Cloth: You'll need a clean rag or cloth to wipe down the fuel line and remove any contaminants before applying the repair tape. A soft, lint-free rag is ideal to ensure a smooth surface for the tape to adhere to.

Once you have these supplies ready, you can proceed with the repair process, which typically involves cleaning the affected area, applying the solvent, and then carefully wrapping the repair tape around the fuel line to create a secure seal. Remember, a well-prepared toolkit is the first step towards a quick and effective repair.

Fuel Line Flexibility: Adapting 1/4" to 5/8" Connections

You may want to see also

Clean the area: Remove dirt and debris from the fuel line using a solvent cleaner

To effectively address a leaky fuel line, it's crucial to start by cleaning the affected area. This initial step is often overlooked but is essential for a successful repair. Begin by ensuring you have the necessary tools and materials: a solvent cleaner specifically designed for fuel lines, a small brush or wire brush, and a clean cloth.

Locate the fuel line, which is typically a rubber or plastic hose that carries fuel from the tank to the engine. Carefully inspect the line for any visible signs of damage, cracks, or corrosion. These issues can often be the source of leaks. Once you've identified the problem area, use the solvent cleaner to remove any dirt, grime, or debris that may be present. Apply the cleaner directly to the fuel line, ensuring it comes into contact with the affected surface. Allow the cleaner to sit for a few minutes to dissolve any stubborn deposits.

For hard-to-reach areas or stubborn buildup, use the small brush to gently scrub the fuel line. This will help dislodge any particles that might be causing the leak. Be careful not to apply excessive force, as this could damage the fuel line. After cleaning, rinse the area with a clean cloth to remove any remaining solvent and ensure a thorough dry. This step is vital to prevent further contamination and ensure the effectiveness of your repair.

Remember, a clean and dry fuel line is essential for a successful temporary fix. This process will help you identify the exact location of the leak and prepare the area for any necessary repairs or replacements. It's a simple yet crucial step that can save you time and money in the long run.

Unveiling the Mystery: Where Are the Wing Tank Fuel Lines?

You may want to see also

Apply repair tape: Wrap the repair tape tightly around the leak, ensuring a secure seal

When dealing with a leaky auto fuel line, one of the quickest and most effective solutions is to use a repair tape. This method is especially useful for temporary fixes or when you need a rapid solution before a more permanent repair can be carried out. Here's a step-by-step guide on how to apply the repair tape to seal the leak:

Start by ensuring the area around the leak is clean and dry. Remove any dirt, debris, or old tape from the surface. This step is crucial to ensure the tape adheres properly and creates a tight seal. Use a small amount of fuel line cleaner or isopropyl alcohol to further prepare the area, especially if there is any corrosion or residue. Allow the cleaner to evaporate before proceeding.

Next, carefully cut a piece of repair tape slightly longer than the diameter of the fuel line. The tape should be wide enough to cover the leak and provide a secure seal. Ensure you have enough tape to wrap around the leak at least three to four times, overlapping the previous layer by about 50%. This overlapping technique creates a stronger bond and ensures the leak is completely covered.

Now, begin wrapping the tape around the leak, starting from one side and working your way around the fuel line. Apply firm pressure as you wrap to ensure the tape adheres well. Make sure the tape is tight enough to prevent any movement or shifting, but be careful not to overtighten, as this could damage the fuel line. The goal is to create a snug fit that will hold the tape in place until a more permanent repair can be made.

As you wrap the tape, ensure that it is smooth and free of any wrinkles or creases. Overlapping the tape layers is essential for a strong bond. If the leak is near the end of the fuel line, you might need to adjust the wrapping to ensure the tape covers the entire length. Once you've completed the wrapping, test the repair by starting the engine and checking for any further leaks.

Remember, this is a temporary solution, and it's important to have the fuel line repaired professionally as soon as possible. The repair tape provides an immediate seal, allowing you to continue using your vehicle while addressing the underlying issue. Regularly inspect the repair and consider reapplying the tape if necessary until a more permanent fix is implemented.

Mastering the Art: Fuel Line Removal Guide for 05 WRX

You may want to see also

Test and drive: Start the car and check for leaks. Drive the vehicle to ensure the repair is effective

Before you begin the test and drive procedure, it's important to ensure that the car is in a safe and controlled environment. Park the vehicle on a level surface, preferably an empty parking lot or a garage, to minimize the risk of accidents. Engage the parking brake to prevent any unintended movement.

Now, let's proceed with the test and drive protocol:

- Start the Engine and Check for Initial Signs: Begin by starting the car's engine. Pay close attention to any unusual noises, such as hissing or roaring sounds, which could indicate fuel escaping. Also, look for any visible signs of fuel around the engine bay, especially near the suspected leak points. If you notice any immediate leaks, address them first before proceeding.

- Visual Inspection: After the engine has warmed up, conduct a thorough visual inspection of the vehicle. Check for any wet patches on the ground, which could be an indication of fuel leaks. Inspect the fuel lines for any visible damage, cracks, or bulges. Look for any signs of corrosion or deterioration, especially around the fuel tank and lines. Take note of any areas where the fuel lines are exposed and could potentially come into contact with hot surfaces or sharp objects.

- Drive and Monitor: Start driving the vehicle at a moderate speed, ensuring you can control it easily. Keep an ear out for any unusual sounds, especially during acceleration and deceleration. Pay attention to the fuel gauge and listen for any changes in the engine's performance, such as a drop in power or a change in idle speed. If the repair was successful, you should notice a significant improvement in the vehicle's performance and a reduction in fuel consumption.

- Park and Re-inspect: After driving for a reasonable distance, park the car and re-inspect the engine bay and undercarriage for any new leaks. Check the fuel lines again for any signs of damage or deterioration. If everything appears stable, you can conclude that the repair was effective. However, if any new issues arise, it's crucial to identify and address them promptly.

Remember, this test and drive procedure is a critical step in ensuring the longevity of your vehicle and your safety. Always drive with caution and be mindful of your surroundings during this process.

Poulan Prolink P335 Fuel Line Size: Essential Guide for Optimal Performance

You may want to see also

Frequently asked questions

In case of a minor leak, you can use a temporary fix by wrapping the fuel line with a piece of rubber hose or a temporary clamp to stop the leak. This is a quick solution to prevent fuel loss and should be done by a professional mechanic for a more permanent repair.

Fuel lines can leak due to various reasons such as age, corrosion, damage from road debris, or improper installation. Over time, the fuel lines can deteriorate, especially if they are made of rubber, which can crack and split. Additionally, fuel lines may be susceptible to damage from sharp objects on the road, leading to leaks.

While some minor leaks can be temporarily fixed, it is highly recommended to have a professional mechanic handle the repair. Fuel lines are crucial for the proper functioning of the engine, and an incorrect repair could lead to more serious issues. Professionals have the tools and expertise to identify the root cause and provide a safe and effective solution.