Measuring fuel lines is an essential step in ensuring the proper functioning of your vehicle's fuel system. It involves determining the length and diameter of the fuel hose to ensure a secure and efficient fuel supply. This process is crucial for maintaining optimal engine performance and preventing potential issues like fuel leaks or reduced fuel flow. By following a systematic approach, you can accurately measure the fuel line, ensuring a reliable and safe driving experience.

What You'll Learn

- Visual Inspection: Check for cracks, brittleness, and signs of wear

- Pressure Testing: Use a gauge to measure pressure at different points

- Flexibility Assessment: Test hose flexibility with a pull or bend

- Length Measurement: Measure the hose's length accurately

- Material Analysis: Examine the hose's material for durability

Visual Inspection: Check for cracks, brittleness, and signs of wear

When it comes to inspecting fuel line hoses, a visual examination is a crucial step in identifying potential issues. This process involves a thorough and careful assessment of the hose's condition, ensuring it is in optimal shape to prevent any leaks or failures. Here's a detailed guide on how to perform this inspection:

Start by laying the hose on a clean, flat surface. This allows for a clear view of the entire length, making it easier to spot any abnormalities. Inspect the hose for any visible cracks or fractures. These defects can occur due to age, wear, or exposure to harsh chemicals or heat. Look for any signs of brittleness, which might indicate that the hose has lost its flexibility and could be on the verge of breaking. Pay close attention to the connections and fittings as well. Cracks or damage around these areas can lead to fuel leaks, which are a serious concern.

Wear and tear are common issues with hoses, especially those exposed to the elements. Inspect the hose for any signs of deterioration, such as frayed edges, worn-out insulation, or discolored areas. These signs of wear can compromise the hose's integrity and its ability to contain fuel. Additionally, check for any bulges or distortions in the hose's shape. This could be an early indicator of internal damage or the presence of a foreign object that might have caused a kink or bend.

The color of the hose can also provide valuable insights. Over time, hoses may change color due to fuel exposure or environmental factors. Look for any unusual discoloration, as this could suggest the presence of contaminants or the hose's deterioration. It is essential to compare the hose's condition with a known good hose to identify any deviations.

During the visual inspection, take note of any unusual noises or vibrations when the engine is running. These sounds might indicate that the hose is not securely attached or is experiencing internal damage. A thorough inspection will help identify potential issues before they escalate, ensuring the safety and reliability of your vehicle's fuel system. Remember, regular maintenance and prompt attention to any visual defects are key to preventing costly repairs and maintaining optimal vehicle performance.

Understanding the Choke Fuel Line: A Car's Essential Component

You may want to see also

Pressure Testing: Use a gauge to measure pressure at different points

Pressure testing is a critical step in ensuring the integrity and reliability of fuel lines in vehicles. This method involves using a pressure gauge to measure the pressure at various points along the fuel line system. By doing so, you can identify potential issues, such as leaks, blockages, or weak points, which may not be immediately apparent during a visual inspection. Here's a detailed guide on how to perform this test:

Start by locating the fuel lines in your vehicle. These are typically found under the hood and may be connected to various components like the fuel tank, engine, and fuel injectors. Identify the points where you want to measure pressure. Common locations include the fuel pump, the engine rail, and the fuel injectors. Mark these points with tape or labels to ensure accurate measurements.

Next, you'll need a pressure gauge suitable for the task. Ensure it is calibrated and can measure the pressure range specific to your fuel system. Connect the gauge to the fuel line at each marked point. Make sure the gauge is securely attached to avoid any data discrepancies. When measuring, observe the gauge's reading and record the pressure at each location. Compare these readings to the expected pressure values for your vehicle's fuel system.

Ideally, you should have a baseline pressure reading for a healthy fuel line system. This can be obtained by consulting your vehicle's manual or a professional mechanic. Any significant deviations from the expected pressure indicate a potential issue. For instance, a lower-than-expected pressure might suggest a restriction or leak in the fuel line, while a higher pressure could indicate a problem with the fuel pump or injectors.

It's important to note that pressure testing should be conducted with the engine off and the vehicle in a stationary position. This ensures accurate measurements and prevents any potential hazards associated with fuel system pressure. Additionally, always follow safety protocols when working with fuel lines, and consider using a fuel line pressure tester kit, which often includes the necessary tools and instructions for a comprehensive test.

Hyundai Accent Fuel Line Repair: A Step-by-Step Guide

You may want to see also

Flexibility Assessment: Test hose flexibility with a pull or bend

To assess the flexibility of a fuel line hose, a practical and straightforward method involves a simple pull or bend test. This test is designed to evaluate the hose's ability to conform to various shapes and withstand tension without permanent deformation. Here's a detailed guide on how to perform this assessment:

Setting Up the Test: Begin by securing the hose at one end using a clamp or a fixed point. Ensure that the hose is taut and straight at this point. Then, carefully apply a controlled force to the free end of the hose, pulling or bending it. The goal is to simulate a scenario where the hose might need to accommodate movement, such as when it's routed through a tight space or under a vehicle's engine compartment.

Measuring Flexibility: As you pull or bend the hose, observe and record the following: the angle of bend, the amount of force required to achieve the bend, and the hose's resistance to deformation. Note if the hose kinks, twists, or shows any signs of permanent distortion. The more flexible the hose, the easier it should be to manipulate without causing damage or permanent bends.

Comparing Results: Compare your findings with the hose's specifications or previous test results. If the hose can be easily bent without kinking or showing signs of stress, it likely meets the required flexibility standards. However, if the hose becomes stiff, kinks easily, or shows permanent deformation, it may need to be replaced or upgraded to ensure optimal performance.

Practical Considerations: When performing this test, it's essential to use appropriate tools and equipment to ensure accuracy. A spring scale or force gauge can help measure the force required to bend the hose. Additionally, consider the environmental conditions; hoses used in extreme temperatures or harsh environments may have different flexibility requirements.

This flexibility assessment is a critical step in ensuring the longevity and reliability of fuel line hoses, especially in automotive or industrial applications where hoses are subjected to various stresses and movements. By following this method, technicians and engineers can quickly identify potential issues and make informed decisions regarding hose selection and maintenance.

Is ISO-HEET a Fuel Line and Filter Saver?

You may want to see also

Length Measurement: Measure the hose's length accurately

To accurately measure the length of a fuel line hose, you'll need to employ a systematic approach. Start by ensuring the hose is straight and free from any bends or kinks that could affect the measurement. This is crucial for obtaining an accurate length reading.

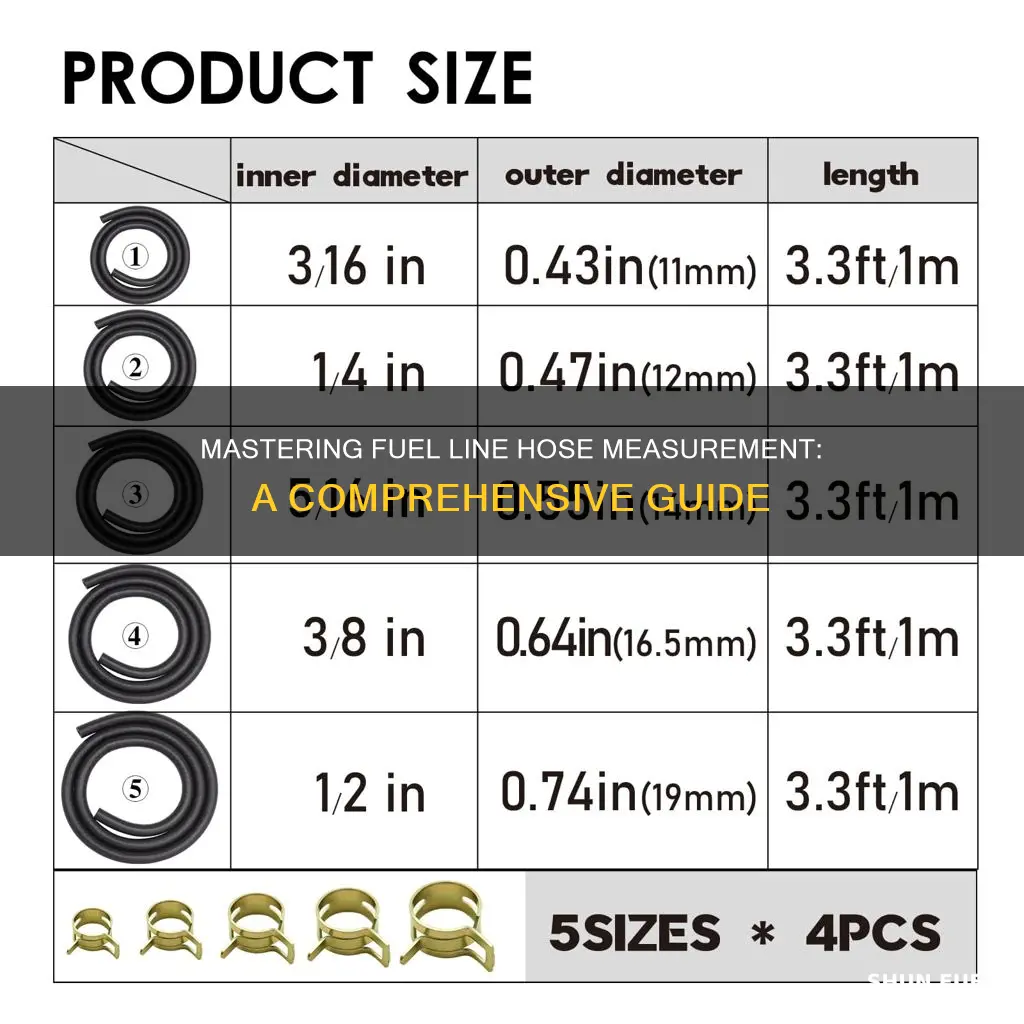

The most common method is to use a flexible measuring tape or a ruler, ensuring it is straight and aligned with the hose's length. Begin at one end of the hose and extend the measuring tool along its entire length, noting the point where the hose connects to the fuel tank or another component. Make sure to measure in a straight line, avoiding any curves or twists in the hose that might distort the reading.

For more precise measurements, consider using a laser measuring tool or a tape measure with a larger scale. These tools can provide more accurate readings, especially for hoses with complex shapes or those that are difficult to access. When using a laser measure, simply point the device at the end of the hose and it will automatically calculate the distance.

Another tip is to measure the hose in sections if it's too long to handle all at once. Measure each section carefully, then add the lengths together to get the total length. This is particularly useful for hoses that are coiled or have multiple bends.

Finally, always record the measurement accurately. Note the unit of measurement (e.g., inches, centimeters) and ensure the reading is clear and unambiguous. This documentation will be essential for future reference and can help identify any discrepancies or changes in the hose's length over time.

Mastering the Art of Bending 3/8 Fuel Lines: A Comprehensive Guide

You may want to see also

Material Analysis: Examine the hose's material for durability

When it comes to ensuring the longevity and performance of fuel lines, examining the material is a critical step in the process. The material of the hose plays a pivotal role in its durability, flexibility, and resistance to various environmental factors. Here's a detailed guide on how to analyze the material for durability:

Visual Inspection: Begin by visually examining the fuel line hose. Look for any visible signs of wear and tear, such as cracks, brittleness, or discolored areas. These visual cues can indicate potential material degradation. Check for any bulging or softening in the hose's walls, as this might suggest internal damage or compromised structural integrity. Pay close attention to the connections and fittings, as these areas are prone to stress and can reveal signs of material fatigue.

Flexibility Testing: Durability is closely tied to flexibility. Test the hose's flexibility by gently bending it at various points along its length. A durable material should exhibit a good range of motion without permanent deformation. Apply pressure and observe if the hose retains its shape or if it becomes stiff or brittle. This test helps identify hoses that might be prone to cracking or breaking under stress.

Material Composition: Understanding the material composition is essential. Different materials offer varying levels of durability. Common materials used for fuel lines include rubber, silicone, and various synthetic compounds. Rubber hoses are known for their flexibility and resistance to heat and chemicals. Silicone hoses provide excellent temperature stability and are less prone to cracking. Synthetic compounds offer enhanced durability and resistance to abrasion. Identify the specific material used in your hose and research its known properties to assess its durability.

Abrasion Resistance: Examine the hose for any signs of abrasion or wear. This is particularly important if the hose is exposed to rough surfaces or moving parts. Inspect the inner and outer surfaces for any frayed edges or worn-out areas. Abrasion resistance is crucial to ensure the hose can withstand the mechanical stresses it may encounter during its lifetime.

Temperature and Chemical Resistance: Evaluate the hose's performance under varying temperature conditions. Extreme temperatures can affect material properties. Heat-resistant hoses should maintain their flexibility and integrity even in high-temperature environments. Similarly, check for chemical resistance by exposing the hose to different substances, such as fuel, coolant, or cleaning agents. Ensure that the hose does not degrade or become brittle when exposed to these chemicals.

By following these material analysis steps, you can assess the durability of fuel line hoses and make informed decisions regarding their maintenance and replacement. This process ensures that the hoses meet the required standards and can withstand the demands of their intended use.

Mastering the Art of Soldering: Pinhole Repairs in Metal Fuel Lines

You may want to see also

Frequently asked questions

Measuring the fuel line hose is a straightforward process. First, ensure the engine is cool and the car is parked on a level surface. Locate the fuel line hose, which is typically a rubber or plastic tube connected to the fuel tank and the engine. Use a flexible measuring tape or a ruler to measure the length of the hose from the point where it connects to the fuel tank to the point where it connects to the engine. Make sure to measure in a straight line and record the measurement in inches or centimeters.

You can use a few simple tools to measure the fuel line hose. A flexible measuring tape, such as a tape measure or a ruler, is essential. It should be long enough to reach the hose's full length. Additionally, a pen or marker is useful for marking the measurement point on the hose. Some mechanics might also use a straight edge or a level to ensure accurate measurements.

Yes, you can measure the fuel line hose without removing it. The hose is usually accessible without any major disassembly, especially if you have a hood that provides easy access to the engine bay. Simply locate the hose, ensure it is straight and not kinked, and then measure it as described in the previous answer. It's important to measure when the engine is off to avoid any potential hazards from the fuel system.