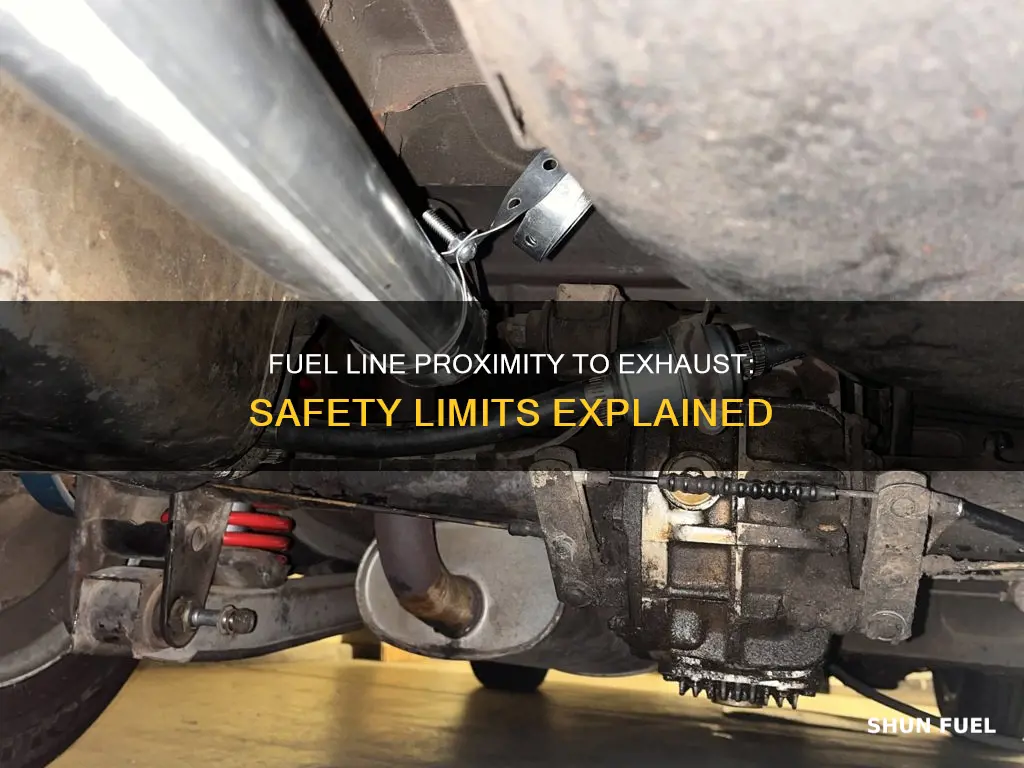

When designing or maintaining a vehicle's fuel system, it's crucial to consider the proximity of the fuel lines to the exhaust system. The exhaust system, with its high temperatures and potential for dangerous emissions, poses a significant risk to fuel lines, which can cause leaks, fires, or other hazardous situations. This paragraph will explore the optimal distance and protective measures required to ensure the safety and efficiency of the fuel system while minimizing the risk of damage from the exhaust.

| Characteristics | Values |

|---|---|

| Distance from Exhaust | According to the latest guidelines, the fuel line should be at least 6 inches (15.24 cm) away from the exhaust system. This distance is crucial to prevent fuel vaporization and potential fire hazards. |

| Material Compatibility | The fuel line material should be compatible with the fuel type. For gasoline, rubber or synthetic rubber-coated lines are commonly used. For diesel, fuel-resistant materials like nylon or braided steel are preferred. |

| Flexibility and Routing | Fuel lines should be flexible to accommodate engine movement. They should be routed away from hot surfaces and sharp bends to avoid damage and potential fuel leaks. |

| Clamping and Support | Proper clamping and support are essential to maintain the fuel line's position and prevent leaks. Clamps should be tightened securely, and the line should be supported at regular intervals. |

| Fuel Line Diameter | The diameter of the fuel line depends on the engine's fuel requirements and flow rate. Typically, 3/8" to 1/2" (9.5-12.7 mm) diameter lines are used for most automotive applications. |

| Regulations and Standards | Adherence to local and industry regulations is vital. Standards like ISO 22214 and SAE J1762 provide guidelines for fuel system design and installation. |

What You'll Learn

- Fuel Line Placement: Keep fuel lines at least 1 inch away from exhaust pipes to prevent heat damage

- Distance and Insulation: Maintain a safe distance, using insulation if necessary, to avoid fuel line overheating

- Flexibility and Routing: Route fuel lines with flexibility to avoid sharp bends near exhaust systems

- Vibration Resistance: Ensure fuel lines are secured to withstand engine vibrations without damage

- Regular Inspection: Periodically check fuel lines for wear and ensure they're not too close to exhaust heat

Fuel Line Placement: Keep fuel lines at least 1 inch away from exhaust pipes to prevent heat damage

When it comes to vehicle maintenance, one crucial aspect often overlooked is the proper placement of fuel lines. The proximity of fuel lines to exhaust systems can lead to potential issues, primarily due to the intense heat generated by the exhaust pipes. This heat can cause significant damage to the fuel lines, resulting in costly repairs and potential safety hazards.

Exhaust pipes, particularly those in high-performance vehicles, emit a considerable amount of heat. This heat can transfer to nearby components, including fuel lines, if they are not adequately spaced. Fuel lines are responsible for transporting gasoline or diesel from the tank to the engine, and any damage to these lines can lead to fuel leaks, which pose a fire risk and can cause engine misfires or complete failure.

To ensure the longevity of your vehicle and prevent potential accidents, it is essential to maintain a safe distance between fuel lines and exhaust systems. The recommended spacing is a minimum of one inch. This simple yet effective measure can be easily overlooked during vehicle assembly or maintenance, but it is a critical aspect of vehicle design and maintenance.

Proper fuel line placement is not just about preventing heat damage; it also ensures optimal engine performance. When fuel lines are close to exhaust pipes, the heat can cause the fuel to vaporize, leading to inefficient combustion. This inefficiency can result in reduced engine power, increased fuel consumption, and even potential engine damage over time.

In summary, keeping fuel lines at least one inch away from exhaust pipes is a simple yet vital practice in vehicle maintenance. It helps prevent heat-related damage, ensures efficient fuel delivery, and contributes to the overall safety and performance of your vehicle. Regular inspections and maintenance can help identify any potential issues, ensuring your vehicle remains reliable and safe on the road.

Maximizing Performance: Understanding the Benefits of Double Lines on Dual Action Fuel Pumps

You may want to see also

Distance and Insulation: Maintain a safe distance, using insulation if necessary, to avoid fuel line overheating

When it comes to the placement of fuel lines in relation to exhaust systems, maintaining a safe distance is crucial to prevent potential issues. The proximity of these components can lead to overheating of the fuel line, which may result in fuel degradation, reduced performance, and even potential fire hazards. Therefore, it is essential to understand the recommended guidelines for spacing and insulation to ensure optimal engine operation and safety.

The distance between the fuel line and exhaust system should be sufficient to prevent direct heat transfer. As a general rule, it is advised to keep the fuel line at least 6 inches (approximately 15 cm) away from the exhaust manifold or any hot components of the exhaust system. This spacing helps to create a thermal barrier, reducing the risk of fuel line damage due to excessive heat. Insulation materials, such as heat shields or protective sleeves, can be employed to further enhance the safety margin.

Insulation plays a vital role in maintaining the integrity of the fuel line. It acts as a protective barrier, absorbing and reflecting heat, thus preventing the fuel line from coming into direct contact with hot exhaust components. There are various types of insulation available, including metal heat shields, ceramic coatings, and flexible insulation sleeves. These materials can be applied to the fuel line or installed as a separate component to ensure a safe and efficient setup.

In high-performance vehicles or those with modified exhaust systems, the risk of fuel line overheating may be increased. In such cases, it is imperative to double-check the insulation and spacing to meet or exceed the manufacturer's recommendations. Custom-made insulation solutions might be required to accommodate the specific layout and design of the vehicle. Regular inspections and maintenance are also essential to identify and address any potential issues promptly.

By adhering to the suggested distance and insulation practices, vehicle owners can ensure the longevity of their fuel lines and overall engine performance. It is a simple yet effective measure to prevent costly repairs and potential safety hazards associated with fuel line overheating. Always consult the vehicle's manual or seek professional advice for specific guidelines tailored to your make and model.

Nicop Line: A Fuel Line Alternative?

You may want to see also

Flexibility and Routing: Route fuel lines with flexibility to avoid sharp bends near exhaust systems

When designing the fuel system for a vehicle, it's crucial to consider the proximity of fuel lines to the exhaust system. The exhaust system, with its high temperatures and potential for heat transfer, can pose a significant risk to the integrity and safety of fuel lines. To mitigate this risk, it is essential to route the fuel lines with flexibility, ensuring they avoid sharp bends and close proximity to the exhaust.

Flexibility in fuel line routing is key to preventing damage from heat transfer. Exhaust systems, particularly those with catalytic converters and mufflers, can reach temperatures high enough to cause fuel lines to degrade or even melt. By allowing the fuel lines to move and bend gradually, you create a buffer zone that reduces the risk of direct heat exposure. This is especially important in high-temperature areas, such as under the hood or near the engine compartment.

Avoiding sharp bends is another critical aspect of routing fuel lines. Sharp bends can lead to increased stress on the fuel lines, potentially causing cracks or leaks. By employing flexible materials and allowing for gradual curves, you ensure that the fuel lines can withstand the natural expansion and contraction of the vehicle's components during operation. This flexibility also helps in accommodating the movement of the vehicle's suspension and engine components.

The routing should be carefully planned to maintain a safe distance from the exhaust system. This distance can vary depending on the specific vehicle design and engine configuration. As a general guideline, it is recommended to keep fuel lines at least 6 inches away from the exhaust to ensure adequate protection. This distance provides a buffer zone, allowing for any potential heat transfer without compromising the integrity of the fuel lines.

In addition to flexibility and distance, consider using protective materials and coatings on the fuel lines. These materials can further enhance the line's resistance to heat and abrasion, ensuring longevity and safety. By implementing these routing practices, you can effectively manage the proximity of fuel lines to exhaust systems, reducing the risk of damage and ensuring the overall reliability of the vehicle's fuel system.

Bleed Fuel Lines: A Comprehensive Guide for Car Owners

You may want to see also

Vibration Resistance: Ensure fuel lines are secured to withstand engine vibrations without damage

When it comes to fuel lines and their proximity to exhaust systems, it's crucial to consider the impact of engine vibrations. Fuel lines play a vital role in delivering fuel to the engine, and their placement should be carefully planned to ensure optimal performance and longevity. The goal is to secure the fuel lines in a way that allows them to withstand the intense vibrations generated by the engine without compromising their integrity.

One effective method to achieve this is by using specialized fuel line mounts or brackets. These components are designed to absorb and dampen the vibrations, providing a stable and secure attachment point for the fuel lines. By utilizing these mounts, you can ensure that the fuel lines remain in their intended position, even under the most demanding engine conditions. Properly secured fuel lines will not only prevent damage to the lines themselves but also reduce the risk of fuel leaks, which could lead to dangerous situations.

The process of securing fuel lines involves careful routing and attachment to the engine frame or other sturdy components. It is essential to leave enough slack in the fuel lines to accommodate the engine's movement without causing excessive tension or stress on the lines. Over-tightening or restricting the fuel lines can lead to reduced fuel flow and potential damage over time. Therefore, a balance must be struck between keeping the lines secure and allowing for the necessary flexibility.

In addition to the physical attachment, the material of the fuel lines itself should be considered. High-quality, flexible materials that can withstand vibrations and temperature fluctuations are ideal. These materials ensure that the fuel lines can move with the engine while maintaining their structural integrity. Regular inspections and maintenance are also recommended to identify and address any signs of wear or damage, especially in areas where the fuel lines are close to the exhaust system.

By implementing these vibration-resistant measures, you can ensure that your fuel lines remain in optimal condition, providing reliable fuel delivery to the engine. This attention to detail is crucial for maintaining the overall performance and reliability of the vehicle, especially in high-performance or heavy-duty applications where engine vibrations are more pronounced. Properly secured fuel lines contribute to a safer and more efficient driving experience.

Unveiling the Mystery: What Exactly is 6AN Fuel Line?

You may want to see also

Regular Inspection: Periodically check fuel lines for wear and ensure they're not too close to exhaust heat

Regular maintenance and inspections are crucial for ensuring the safety and efficiency of your vehicle's fuel system. One critical aspect often overlooked is the proximity of fuel lines to the exhaust system. While it might seem like a minor detail, the placement of fuel lines in relation to the exhaust can significantly impact the vehicle's performance and longevity.

When performing routine checks, it is essential to inspect the fuel lines for any signs of wear and tear. Over time, fuel lines can degrade due to various factors, including heat, vibration, and chemical exposure. Inspecting these lines periodically can help identify potential issues before they become major problems. Look for any cracks, brittleness, or signs of corrosion along the length of the fuel lines. Even a small tear can lead to fuel leaks, which, when in close proximity to the exhaust, can result in dangerous situations.

The primary concern with placing fuel lines near the exhaust is the risk of heat damage. Exhaust systems generate a significant amount of heat, and prolonged exposure can cause the fuel lines to deteriorate. This can lead to reduced fuel pressure, poor engine performance, and, in extreme cases, fuel leaks that may ignite. It is recommended to maintain a safe distance between the fuel lines and the exhaust to prevent such issues. A general guideline is to keep the fuel lines at least a few inches away from the exhaust pipes to ensure they are not subjected to excessive heat.

During your inspections, pay close attention to the connections and fittings of the fuel lines. These points are more susceptible to damage and can be a source of leaks if not properly secured. Ensure that all connections are tight and free from corrosion. Additionally, check for any signs of fuel contamination, as this can also be an indicator of potential issues with the fuel lines.

In summary, regular inspections of fuel lines are an essential part of vehicle maintenance. By checking for wear and tear and ensuring they are not too close to the exhaust, you can prevent potential hazards and maintain optimal engine performance. Remember, a little preventative care can go a long way in keeping your vehicle safe and reliable.

Honda XR50 Fuel Line: Understanding the OD and OEM Specs

You may want to see also

Frequently asked questions

The proximity of a fuel line to an exhaust system is a critical consideration for vehicle safety. It is essential to maintain a safe distance to prevent potential hazards. Generally, it is recommended to keep the fuel line at least 6 inches (15 cm) away from the exhaust system. This spacing helps reduce the risk of fuel line damage from heat, flames, or sparks generated by the exhaust, which could lead to fuel leaks and potential fire hazards.

Placing a fuel line too close to an exhaust system can pose several risks. Exhaust components, such as catalytic converters and mufflers, can reach high temperatures, and direct contact with the fuel line may cause damage, including melting or warping. Additionally, the high heat can lead to fuel evaporation and potential fuel leaks, which can be a fire hazard. In some cases, the fuel line's material may not withstand the heat, leading to deterioration over time.

Yes, there are often specific regulations and guidelines provided by vehicle manufacturers and local safety standards. These guidelines may vary depending on the vehicle's make and model. It is crucial to consult the vehicle's manual or seek professional advice to ensure compliance with these standards. Proper fuel line routing and spacing are essential to meet safety requirements and avoid potential legal issues.