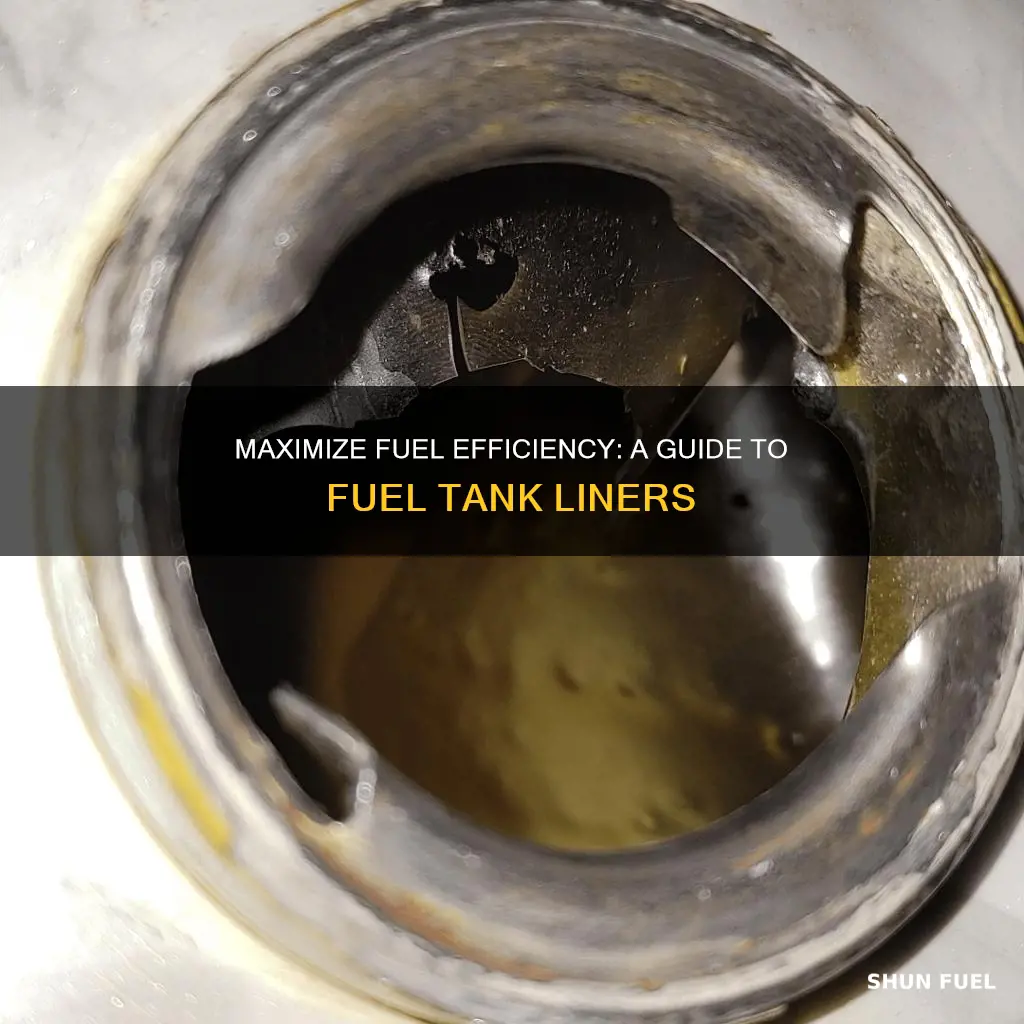

Fuel tank liners are an essential component for protecting the interior of your vehicle's fuel tank from corrosion and contamination. They are designed to line the tank's interior, providing a barrier between the metal and the fuel, which can help prevent rust and extend the life of the tank. To effectively use a fuel tank liner, it's important to follow a few key steps. First, ensure the tank is completely empty and dry to avoid any issues with the liner's installation. Then, carefully remove any existing debris or old liners from the tank. Next, measure and cut the liner to fit the tank's dimensions, allowing for some extra material to ensure a secure fit. Once the liner is cut, carefully place it into the tank, ensuring it is properly aligned and seated. Finally, secure the liner in place using the provided fasteners or by crimping the edges. By following these steps, you can ensure that your fuel tank liner is installed correctly and will provide optimal protection for your vehicle's fuel system.

What You'll Learn

- Preparation: Clean the fuel tank and ensure it's dry before installation

- Measurement: Accurately measure the tank's dimensions for the liner

- Installation: Follow manufacturer's instructions for a secure fit

- Sealing: Ensure all seams are properly sealed to prevent leaks

- Maintenance: Regularly inspect and replace the liner as needed

Preparation: Clean the fuel tank and ensure it's dry before installation

Before you begin the process of installing a fuel tank liner, it is crucial to ensure that the fuel tank is clean and dry. This step is often overlooked but is essential for a successful and long-lasting installation. Here's a detailed guide on how to prepare your fuel tank for the liner:

Step 1: Drain the Fuel

The first and most important step is to drain the fuel tank completely. This process might seem straightforward, but it requires careful planning. Start by locating the fuel drain valve, which is typically found near the bottom of the tank. Place a suitable container under the valve to catch the fuel as it drains. Ensure that you drain the tank until it is completely empty to avoid any residual fuel interfering with the installation process.

Step 2: Remove Contaminants

Once the tank is empty, it's time to clean it. Over time, fuel tanks can accumulate contaminants such as dirt, rust, and old fuel residue. Use a fuel tank cleaner or a mild detergent mixed with water to thoroughly clean the interior of the tank. Scrub the walls and the bottom to remove any built-up grime. This step is vital to create a clean and smooth surface for the liner to adhere to.

Step 3: Rinse and Dry

After cleaning, rinse the tank to remove any detergent residue. Ensure that you rinse thoroughly to avoid any soap residue left behind. Once rinsed, allow the tank to dry completely. You can speed up the drying process by using a shop vac to remove any remaining moisture. A completely dry tank is essential to prevent the liner from sticking to the moisture during installation.

Step 4: Inspect the Tank

While the tank is drying, take this opportunity to inspect it for any signs of damage or corrosion. Check for any holes, cracks, or areas of rust. If you notice any issues, address them before proceeding. Repairing or replacing damaged parts will ensure a proper fit for the fuel tank liner.

By following these preparation steps, you'll create an optimal environment for the fuel tank liner's installation, ensuring its longevity and effectiveness. Remember, taking the time to clean and prepare the tank is just as important as the installation process itself.

Choosing the Right Color Fuel Line for Your Mower

You may want to see also

Measurement: Accurately measure the tank's dimensions for the liner

To ensure a proper fit and optimal performance, accurate measurements are crucial when preparing to install a fuel tank liner. This process involves carefully assessing the dimensions of the fuel tank to select the right liner size. Here's a step-by-step guide on how to measure the tank's dimensions accurately:

- Gather the Necessary Tools: Before you begin, ensure you have a tape measure or a flexible measuring tape, preferably one with metric and imperial units for versatility. You might also want a helper to make the process easier, especially for larger tanks.

- Locate the Tank: Access the fuel tank, which could be located under the vehicle's floor or in a hard-to-reach area. Ensure the vehicle is parked on a level surface to facilitate accurate measurements.

- Measure the Length and Width: Start by measuring the length and width of the tank's interior. Place the tape measure along the longest dimension of the tank's interior, ensuring it is straight and taut. Record the measurement in inches or centimeters, whichever is more convenient. Repeat this process for the width, measuring the tank's interior width at its widest point.

- Determine the Height: Measuring the height requires a different approach. Since the tank's height might be limited by the vehicle's structure, you'll need to measure the distance from the bottom of the tank to the top of the fuel line or the top of the tank itself. This ensures the liner covers the necessary height.

- Consider Additional Features: Take note of any unique features or contours of the tank. This could include baffles, vents, or other components that might affect the liner's placement. Accurate measurements of these features will ensure the liner fits seamlessly.

- Record and Verify: After taking all the necessary measurements, record them carefully. Double-check your measurements to ensure accuracy, as this will impact the liner's performance and longevity. Having precise dimensions will enable you to choose the right size liner and ensure a perfect fit.

Dodge Charger Fuel Line Maintenance: Tips for Long-Term Reliability

You may want to see also

Installation: Follow manufacturer's instructions for a secure fit

When it comes to installing a fuel tank liner, it's crucial to follow the manufacturer's instructions to ensure a secure and effective fit. This process is designed to protect your fuel tank from wear and tear, prevent leaks, and maintain the integrity of your vehicle's fuel system. Here's a step-by-step guide to help you through the installation process:

Preparation: Before you begin, ensure you have the necessary tools and materials as recommended by the manufacturer. This might include a fuel tank liner kit, which typically consists of the liner itself, adhesive or bonding agents, and any additional components like seals or gaskets. It's essential to inspect the fuel tank for any existing damage or imperfections that might affect the liner's fit. Clean the tank thoroughly to remove any dirt, debris, or old materials that could interfere with the liner's adhesion.

Installation Process: Begin by laying out the fuel tank liner on a flat surface. Carefully align it with the tank's interior, ensuring that all cutouts and contours match the tank's shape. Follow the manufacturer's guidelines for positioning the liner, as some may have specific recommendations for optimal coverage. Once aligned, secure the liner in place using the provided adhesive or bonding agent. Apply the adhesive evenly and follow the manufacturer's instructions for the recommended drying or curing time. For some liners, you might need to use a roller or a similar tool to ensure proper adhesion.

Finishing Touches: After the adhesive has set, inspect the installation to ensure there are no visible gaps or wrinkles. Smooth out any areas where the liner might have shifted during the installation process. It's important to double-check that all connections and fittings are secure and properly sealed. If the manufacturer provides additional seals or gaskets, apply them as directed to enhance the liner's performance and prevent any potential leaks.

Post-Installation Care: After the fuel tank liner is installed, it's essential to follow the manufacturer's guidelines for post-installation care. This may include running the vehicle to ensure the fuel system functions correctly and allowing the liner to settle into place. Avoid overfilling the fuel tank immediately after installation to prevent any potential issues. Regularly check the liner's condition and performance, especially if you notice any unusual noises or leaks, and address any concerns promptly.

Remember, each fuel tank liner may have unique installation requirements, so always refer to the specific instructions provided by the manufacturer. Following these steps will help ensure a successful and secure installation, providing long-lasting protection for your fuel tank.

Aluminum Fuel Line Straightening: Tips and Tricks for a Smooth Ride

You may want to see also

Sealing: Ensure all seams are properly sealed to prevent leaks

When installing a fuel tank liner, proper sealing of all seams is crucial to ensure the system's integrity and prevent any leaks. This process involves carefully sealing the connections between the liner and the tank walls, as well as any other seams that may be present. Here's a step-by-step guide to achieving effective sealing:

Preparation: Before beginning the sealing process, ensure that the fuel tank is clean and free of any debris or contaminants. Use a suitable cleaner to remove any dirt or grime, allowing the adhesive or sealant to bond properly. Inspect the seams and ensure they are smooth and free of any sharp edges that could compromise the seal.

Sealing Materials: Utilize a high-quality adhesive or sealant specifically designed for fuel tank applications. These products are formulated to withstand the harsh conditions of fuel storage and provide a reliable seal. Choose a sealant that is compatible with the materials of your fuel tank liner and the tank itself. Silicone-based sealants are commonly used for their flexibility and resistance to fuel degradation.

Application Technique: Apply the sealant generously to all seams, ensuring complete coverage. Start at one end of the seam and work your way along, using a smooth, even stroke to create a continuous bead of sealant. Take care to cover any gaps or crevices that may be present. For larger seams, consider using multiple applications to build up the sealant thickness and ensure a robust seal. Allow the first coat to cure according to the manufacturer's instructions before applying additional layers.

Compression and Bonding: After applying the sealant, gently compress the seams to ensure good contact between the liner and the tank. This compression helps to create a tight seal and promotes better bonding. Use a tool or your fingers to apply pressure, being careful not to damage the liner or create any wrinkles. Allow sufficient time for the sealant to cure fully, as this will ensure its maximum effectiveness.

Final Inspection: Once the sealant has cured, inspect the seams thoroughly. Check for any signs of leakage or seepage, and ensure that the sealant is intact and adheres firmly to the surfaces. If any areas appear compromised, reapply the sealant or consider using additional sealing methods, such as tape or additional adhesive, to reinforce the bond. Proper sealing is critical to maintaining the performance and longevity of your fuel tank liner system.

Dodge Cummins Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Maintenance: Regularly inspect and replace the liner as needed

Regular maintenance of your fuel tank liner is crucial to ensure the longevity and efficiency of your vehicle's fuel system. Over time, the fuel tank liner can deteriorate, leading to potential issues such as fuel leaks, reduced fuel quality, and even engine performance problems. Therefore, it's essential to establish a routine inspection and replacement process to keep your fuel system in optimal condition.

Start by familiarizing yourself with the location of the fuel tank liner in your vehicle. This component is typically made of a flexible material designed to line the interior of the fuel tank, protecting it from corrosion and wear. Inspect the liner regularly, preferably during routine vehicle maintenance checks. Look for any signs of damage, such as tears, punctures, or excessive wear. Also, check for any signs of fuel contamination, which might indicate a compromised liner.

During the inspection, pay close attention to the condition of the fuel tank itself. Inspect the tank for any visible corrosion, rust, or signs of damage that could have affected the liner. Ensure that the fuel tank is securely attached and that there are no leaks or spills around the fuel filler neck or other connections. If you notice any issues with the tank, it may require professional attention to ensure it is safe and functional.

If you find any damage or signs of deterioration during your inspection, it's crucial to replace the fuel tank liner promptly. Delayed replacement can lead to further complications. When replacing the liner, ensure you use a high-quality replacement part that is compatible with your vehicle's make and model. Follow the manufacturer's guidelines for installation to ensure a proper fit. Proper installation will prevent any future issues and maintain the integrity of your fuel system.

Remember, regular maintenance and timely replacement of the fuel tank liner are essential for the overall health of your vehicle. By staying proactive, you can avoid potential fuel-related problems and ensure your vehicle's performance remains optimal. Always refer to your vehicle's manual for specific maintenance schedules and guidelines to keep your fuel system in top condition.

C1500 Fuel Lines: A Comprehensive Guide to Identification

You may want to see also

Frequently asked questions

A fuel tank liner is a protective layer or coating applied inside a fuel tank to prevent corrosion, rust, and fuel degradation. It's especially useful for older tanks or those with previous issues, as it helps maintain fuel quality and extends the tank's lifespan.

Look for signs like fuel contamination, strange odors, reduced engine performance, or visible corrosion inside the tank. If you've had fuel-related issues or your tank is showing signs of deterioration, a liner could be a solution.

Liners prevent corrosion, maintain fuel quality, improve engine performance, and reduce the risk of fuel leaks. They also make it easier to clean the tank, ensuring better overall fuel management.

While some liners are designed for DIY installation, it's often recommended to have a professional mechanic handle the process. They have the expertise to ensure proper fitting and avoid any potential damage to the tank.

The lifespan of a liner depends on various factors, including fuel type, tank condition, and maintenance. Generally, a well-maintained liner can last for several years, often outlasting the fuel tank itself. Regular inspections and fuel treatments can further extend its longevity.