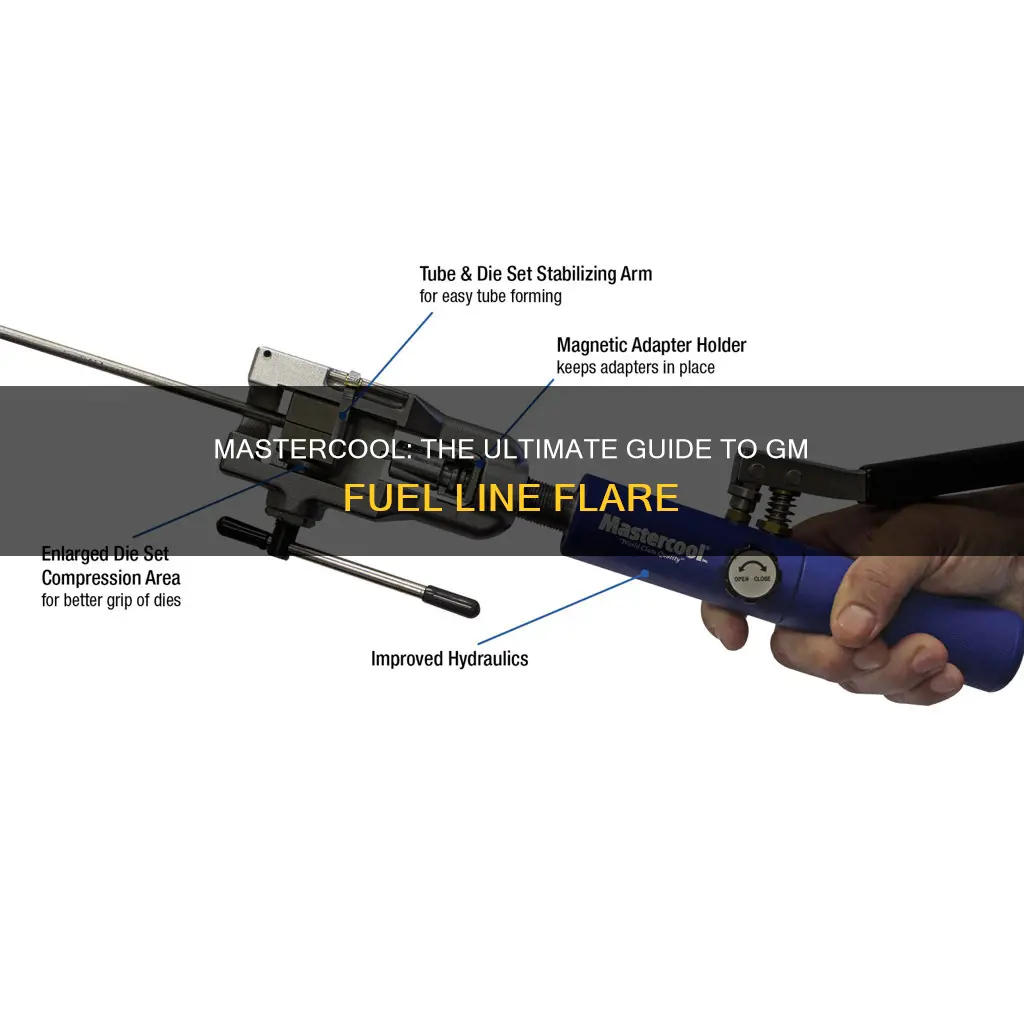

Making a fuel line flare with Mastercool can be a useful skill for anyone working on a vehicle's fuel system. This process involves creating a flare connection to join a fuel line to a fitting, ensuring a secure and leak-free connection. Mastercool, a brand known for its high-quality automotive products, offers a range of tools and techniques to make this task easier. By following a step-by-step guide, you can learn how to properly flare the fuel line, ensuring a tight seal and preventing fuel leaks. This guide will provide valuable insights into the process, making it an essential resource for anyone looking to enhance their automotive repair skills.

What You'll Learn

- Prepare Materials: Gather flare tools, GM fuel line, MasterCool, and cleaning supplies

- Clean Line: Use MasterCool to degrease and clean the fuel line

- Flare Process: Follow GM flare specifications, ensuring a tight connection

- Test Connection: Verify the flare's integrity with pressure testing

- Safety Measures: Adhere to safety protocols during the flare installation

Prepare Materials: Gather flare tools, GM fuel line, MasterCool, and cleaning supplies

To begin the process of creating a GM fuel line flare with MasterCool, it's essential to have all the necessary materials and tools ready. Start by gathering the following items:

- Flare Tools: You'll need a set of flare tools specifically designed for fuel lines. These tools typically include a flare nut, a flare die, and a mandrel. The flare nut is used to create the flare, the flare die is for shaping the fuel line, and the mandrel helps guide the process. Ensure you have the appropriate sizes of these tools to match your fuel line diameter.

- GM Fuel Line: Obtain a length of GM fuel line that matches the specifications required for your vehicle. Check the manufacturer's guidelines or consult a mechanic to determine the correct size and type of fuel line. Having the right length will ensure a proper fit during the flare process.

- MasterCool: MasterCool is a brand of refrigerant and cooling system products. In this context, it likely refers to a specific product used for fuel line maintenance or repair. Research and acquire the appropriate MasterCool product that is compatible with your fuel line and vehicle system. This might include a MasterCool cleaner or a specialized fluid designed for fuel lines.

- Cleaning Supplies: Cleaning is an essential step before and after the flare process. Gather cleaning materials such as a degreaser or solvent to remove any dirt, grease, or contaminants from the fuel line and flare surfaces. You may also need a brush or scrubber for thorough cleaning. Additionally, have some rags or cleaning cloths to wipe down the area and ensure a smooth surface for the flare.

Having all these materials prepared beforehand will ensure a smooth and efficient process when creating the GM fuel line flare. It's crucial to follow the manufacturer's instructions for each product and tool to guarantee a successful and safe repair or modification.

Fuel Line Installation: A Step-by-Step Guide for Beginners

You may want to see also

Clean Line: Use MasterCool to degrease and clean the fuel line

To effectively clean and degrease your GM fuel line using MasterCool, a process that ensures optimal performance and longevity, follow these detailed steps:

Preparation:

- Gather Materials: You'll need MasterCool degreaser, a spray bottle, a clean rag or cloth, and a small brush (optional). Ensure you have the right quantities based on the length and condition of your fuel line.

- Safety First: Wear gloves and protective eyewear to safeguard your skin and eyes from potential splashes.

Cleaning Process:

- Spray and Soak: Liberally apply MasterCool to the entire length of the fuel line. Allow it to penetrate and loosen accumulated grease and grime. Let it sit for a recommended time, typically around 10-15 minutes, depending on the severity of the contamination.

- Brush and Scrub (Optional): If you encounter particularly stubborn deposits, use a small brush to gently scrub the affected areas. Be careful not to damage the fuel line's inner surface.

- Rinse Thoroughly: After the soaking period, rinse the fuel line with a steady stream of clean water. Ensure all traces of MasterCool and dislodged contaminants are removed. Use a spray bottle for controlled watering.

- Wipe Dry: Once rinsed, wipe the fuel line dry with a clean, lint-free rag. Ensure no moisture remains inside the line, as it can lead to corrosion.

Post-Cleaning Care:

- Reinstall Fuel Line: Carefully reinstall the cleaned fuel line, ensuring all connections are secure and properly aligned.

- Test Operation: Start the engine and allow it to run for a few minutes. Monitor for any unusual noises or leaks.

Important Notes:

- Always follow the manufacturer's instructions for MasterCool usage, including safety precautions and recommended application times.

- If you encounter significant corrosion or damage, consult a professional mechanic for guidance.

- Regularly inspect and clean your fuel line to prevent buildup and maintain optimal engine performance.

Ford Fuel Line Fixes: A Comprehensive Guide to Repairing Your System

You may want to see also

Flare Process: Follow GM flare specifications, ensuring a tight connection

The flare process is a critical step in creating a secure and reliable connection for your GM fuel line, especially when using MasterCool products. This method ensures a tight seal, preventing fuel leaks and potential engine issues. Here's a detailed guide on how to achieve this:

Start by gathering the necessary tools and materials, including the appropriate flare tool for your specific GM fuel line size. GM provides detailed specifications for flare connections, so it's essential to follow these guidelines. The flare process involves creating a series of bends in the fuel line to form a tight seal. Begin by cutting the fuel line to the required length, ensuring you have enough material to work with. Then, using the flare tool, carefully apply pressure to the line at the specified flare points. The goal is to create a series of 90-degree bends, forming a flare that matches the shape of the flare tool. This process requires precision and patience to ensure an accurate fit.

When flaring, maintain consistent pressure and follow the GM specifications for the number of flares and their angles. Each flare should be tight and secure, creating a robust connection. It's crucial to use the right tools and apply the correct amount of force to avoid damaging the fuel line or creating an inadequate seal. Once you've completed the flaring process, inspect the connection. Ensure that the flares are smooth and free of any sharp edges that could cause fuel leaks. A tight connection should feel secure and stable, with no visible gaps or spaces between the flares and the tool.

MasterCool products often provide specific instructions or diagrams to guide you through the flare process. Refer to these resources to ensure you are following the correct procedure. If you're unsure, consult a professional mechanic or refer to GM's official documentation for your vehicle model. Properly flaring the fuel line is essential for maintaining the integrity of your fuel system and the overall performance of your vehicle.

Remember, the key to a successful flare is precision and adherence to GM specifications. Take your time, use the right tools, and double-check your work to ensure a tight connection that will stand the test of time. This process might require some practice, but with patience and attention to detail, you'll master the art of flaring GM fuel lines.

Line Fuel Demand Valve: Unlocking Engine Efficiency and Reliability

You may want to see also

Test Connection: Verify the flare's integrity with pressure testing

Before proceeding with the pressure testing, it's crucial to ensure that the flare connection is properly assembled and aligned. Start by double-checking the flare fitting's orientation and make sure it is securely attached to the fuel line and the mastercool unit. Use a wrench to tighten the flare nut, but be cautious not to over-tighten, as this can damage the threads or the flare fitting itself. The goal is to achieve a snug fit without forcing anything.

Now, it's time to prepare for the pressure test. Gather the necessary tools, including a pressure gauge, a source of compressed air or nitrogen, and a supply of mastercool. Ensure that the pressure gauge is calibrated and suitable for the expected pressure range. Connect the pressure gauge to the flare connection, making sure it is securely attached and aligned.

With the setup complete, initiate the pressure test. Gradually increase the pressure in the system using the compressed air or nitrogen source. Start with a low pressure and gradually build up to the recommended operating pressure specified for the mastercool system. Monitor the pressure gauge closely during this process. The goal is to observe if there are any leaks or abnormalities in the system.

As you increase the pressure, pay close attention to the flare connection. Check for any signs of leakage around the flare nut and the mating surfaces. A slight hiss or the formation of a small bubble around the connection indicates a potential issue. If you notice any leaks, immediately release the pressure and inspect the flare connection for damage or improper assembly. Ensure that all components are clean and free of debris before attempting to reassemble and retest.

If the pressure test is successful and no leaks are detected, you can conclude that the flare connection is intact and functioning correctly. However, it is essential to remember that this test provides a snapshot of the system's integrity at that moment. Regular maintenance and inspections are recommended to ensure the long-term reliability of the flare connection and the overall fuel system.

Online Fuel Assistance: Applying for Help in Winchester, VA

You may want to see also

Safety Measures: Adhere to safety protocols during the flare installation

Before beginning any work on your vehicle's fuel system, it is crucial to prioritize safety. Flare installation, especially when using MasterCool products, requires careful adherence to safety protocols to ensure the process is carried out without incident. Here are some essential safety measures to follow:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, safety goggles, and a respirator mask. This is vital to protect against potential hazards like fuel spills, fumes, and any sharp edges or debris that might be present during the installation process.

- Ventilation: Ensure the work area is well-ventilated to minimize the inhalation of harmful fumes. If working in a confined space, consider using a fume hood or working outdoors. Proper ventilation is key to preventing respiratory issues and maintaining a safe environment.

- Fuel System Isolation: Before starting the flare installation, locate and shut off the fuel supply to the engine. This step is critical to prevent accidental fuel release and potential fires. Use the appropriate tools to isolate the fuel line and ensure no fuel is flowing through the system.

- Tool and Equipment Safety: Familiarize yourself with the tools and equipment you will be using. Ensure they are in good working condition and properly maintained. Check for any damage or defects that could compromise their functionality. For example, flare guns should be checked for proper alignment and functionality to avoid misfires or damage to the fuel line.

- Fire Safety: Keep a fire extinguisher nearby and ensure you know how to use it. Fuel lines, especially when heated, can become flammable. Be cautious when using heat sources or tools that generate sparks, and always have a fire safety plan in place.

- Training and Expertise: If you are not familiar with the process, consider seeking guidance from a professional mechanic or referring to detailed tutorials specific to your vehicle's make and model. Proper training ensures that you understand the procedure and can identify potential risks.

By strictly following these safety measures, you can significantly reduce the risks associated with flare installation, ensuring a safer working environment and a successful outcome. Remember, safety should always be the top priority when working on any vehicle-related projects.

Mastering Motorcycle Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Frequently asked questions

MasterCool is a specialized refrigerant and lubricant used in the flare process to ensure a secure and leak-free connection between the fuel line and the engine. It helps to create a tight seal, reducing the risk of fuel leaks and ensuring optimal engine performance.

Before flaring, ensure the fuel line is clean and free of any debris or contaminants. Use a suitable solvent to clean the line, and then rinse it thoroughly. Dry the line with compressed air to remove any moisture. This preparation step is crucial for a successful flare.

It is recommended to use fresh MasterCool for each flare operation. Over time, the refrigerant can absorb impurities from the air, reducing its effectiveness. Reusing old MasterCool may lead to decreased performance and potential leaks. Always start with fresh MasterCool for the best results.