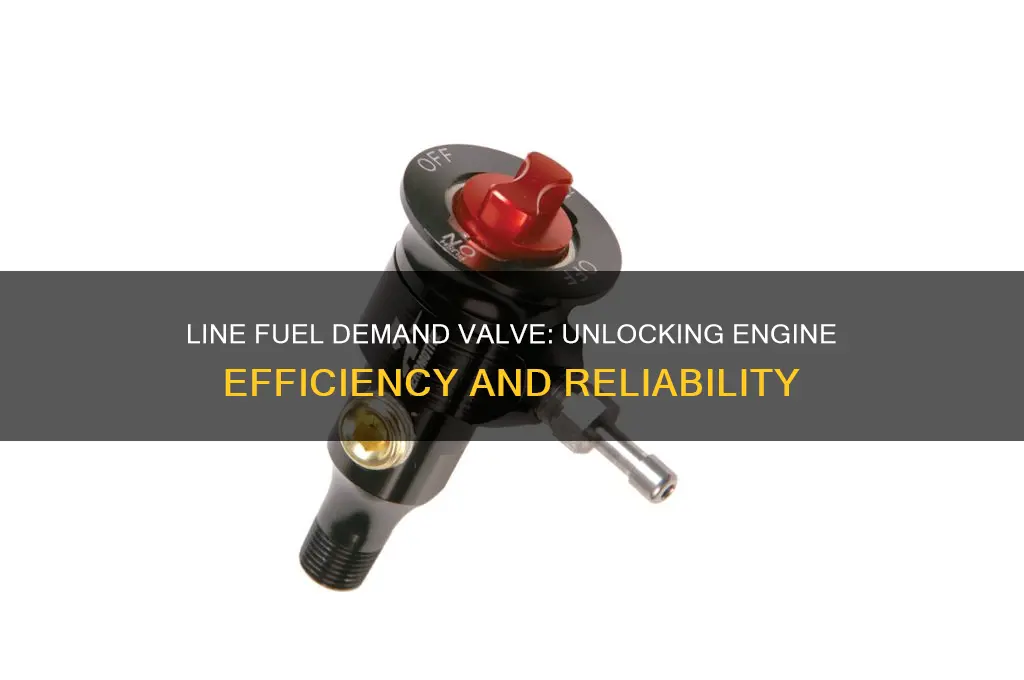

A line fuel demand valve is a crucial component in the fuel system of an engine, designed to regulate the flow of fuel from the tank to the engine. It operates based on the engine's demand for fuel, ensuring that the correct amount of fuel is supplied to meet the engine's needs. This valve is essential for optimizing fuel efficiency, maintaining engine performance, and preventing fuel wastage. By adjusting the fuel flow rate, it helps to balance the engine's power output with the available fuel, contributing to a more efficient and environmentally friendly operation.

| Characteristics | Values |

|---|---|

| Definition | A line fuel demand valve is a type of fuel injection component used in internal combustion engines, specifically in automotive applications. It regulates the fuel flow to the engine based on its demand, ensuring efficient and precise fuel delivery. |

| Function | The primary function is to control the fuel pressure and flow rate according to the engine's requirements. It opens and closes in response to engine load, allowing for optimal fuel-air mixture and power output. |

| Operation | It operates by using a solenoid or electric actuator to control the valve's position. When the engine demands more fuel, the valve opens, and when the demand decreases, it closes, thus managing the fuel supply. |

| Benefits | - Improved engine performance and power output. - Enhanced fuel efficiency and reduced emissions. - Better throttle response and overall drivability. - Ability to adapt to varying engine loads. |

| Applications | Commonly found in gasoline and diesel engines of cars, trucks, motorcycles, and other vehicles. It is also used in some marine and agricultural equipment. |

| Construction | Typically consists of a valve body, solenoid or actuator, and a spring. The valve body houses the moving parts and controls the fuel flow, while the solenoid or actuator provides the necessary force to open or close the valve. |

| Maintenance | Regular maintenance involves checking for leaks, ensuring proper solenoid operation, and replacing worn-out components to guarantee optimal performance. |

| Manufacturers | Various automotive and engine component manufacturers produce line fuel demand valves, including Bosch, Delphi, and Continental. |

What You'll Learn

- Construction: A line fuel demand valve is a mechanical device used to control fuel flow in engines

- Function: It regulates fuel pressure and flow rate based on engine load

- Operation: The valve opens and closes to manage fuel supply, optimizing performance

- Components: Key parts include a solenoid, piston, and spring

- Applications: These valves are found in automotive and marine engines

Construction: A line fuel demand valve is a mechanical device used to control fuel flow in engines

A line fuel demand valve is a crucial component in engine systems, particularly in those that utilize fuel injection technology. Its primary function is to regulate the flow of fuel from the fuel tank to the engine, ensuring that the engine receives the precise amount of fuel required for optimal performance and efficiency. This valve is an essential part of the fuel injection system, which is responsible for delivering fuel to the engine's cylinders in a controlled manner.

Construction-wise, a line fuel demand valve is typically a solenoid-operated device, which means it operates using an electromagnetic solenoid. This solenoid is energized by a control unit, which is an electronic component that receives input from various sensors in the engine. The control unit sends a signal to the solenoid, causing it to move and open or close the valve accordingly. The valve is usually located along the fuel line, close to the engine, and is designed to be compact and durable to withstand the high-pressure environment within the fuel system.

The construction of this valve involves a few key components. Firstly, the valve body is designed with precision to ensure an accurate and tight seal. It is often made from durable materials like cast iron or aluminum alloy to withstand the corrosive effects of fuel and engine heat. Inside the valve body, a spring or a diaphragm is used to provide a closing force, which is overcome by the solenoid's movement. This mechanism allows for precise control of fuel flow, as the solenoid can open or close the valve with minimal effort, ensuring quick response times.

Additionally, the valve may incorporate a check ball or a similar mechanism to prevent fuel from flowing in the reverse direction. This is important to maintain the engine's performance and to protect the fuel system from potential damage caused by fuel sloshing or backflow. The design of the valve also considers the fuel's flow rate and pressure, ensuring that the valve can handle the expected fuel volume and pressure without compromising performance.

In summary, a line fuel demand valve is a sophisticated mechanical device that plays a vital role in engine operation. Its construction involves a solenoid-operated mechanism, a durable valve body, and precise internal components to control fuel flow effectively. This valve is a critical part of modern engine systems, ensuring efficient fuel delivery and optimal engine performance.

Cold Weather's Impact: Why Diesel Gels in Fuel Lines

You may want to see also

Function: It regulates fuel pressure and flow rate based on engine load

A line fuel demand valve is a critical component in modern engine systems, specifically designed to manage fuel delivery and optimize performance. Its primary function is to regulate the fuel pressure and flow rate, ensuring that the engine receives the precise amount of fuel required for efficient operation under varying load conditions. This valve plays a crucial role in maintaining optimal engine performance, fuel efficiency, and emissions control.

The operation of a line fuel demand valve is intricate and highly responsive. It is typically located along the fuel line, positioned strategically to control the fuel supply to the engine. When the engine is at rest or operating under light load, the valve remains partially closed, restricting the fuel flow. This restriction prevents unnecessary fuel consumption, which could lead to inefficient operation and increased emissions. As the engine load increases, the valve opens wider, allowing more fuel to pass through. This dynamic adjustment ensures that the engine receives the required amount of fuel to meet the rising demand without wastage.

The valve's ability to regulate fuel pressure is equally important. It maintains a consistent fuel pressure within the engine's fuel system, ensuring a steady supply of fuel to the injectors or carburetor. Fluctuations in fuel pressure can lead to poor engine performance, misfires, and reduced power output. By precisely controlling the pressure, the line fuel demand valve contributes to the overall stability and reliability of the engine.

In automatic transmission vehicles, this valve often works in conjunction with other engine management systems. It communicates with the engine control unit (ECU) to receive real-time data on engine speed, load, and temperature. Based on this information, the ECU sends signals to the valve, instructing it to adjust its opening and, consequently, the fuel flow and pressure. This closed-loop system ensures that the engine receives the optimal fuel-air mixture for efficient combustion, regardless of the driving conditions.

In summary, the line fuel demand valve is a sophisticated device that plays a vital role in engine management. Its function of regulating fuel pressure and flow rate based on engine load is essential for maintaining performance, fuel efficiency, and emissions standards. This valve's dynamic response and integration with engine control systems contribute to the overall reliability and responsiveness of modern vehicles.

Unleash Power: Understanding the Cutlass Dual Fuel Line System

You may want to see also

Operation: The valve opens and closes to manage fuel supply, optimizing performance

A line fuel demand valve is a critical component in fuel injection systems, particularly in automotive applications. Its primary function is to regulate the fuel supply to the engine, ensuring optimal performance and efficient combustion. This valve operates based on the engine's demand for fuel, adjusting its position to control the flow rate accordingly.

The operation of this valve is a precise process. When the engine is started or requires an increase in power, the engine control unit (ECU) sends a signal to the valve. This signal triggers the valve to open, allowing fuel to flow from the fuel tank to the engine's injectors. The opening and closing of the valve are rapid and controlled, ensuring a steady and accurate fuel supply. As the engine operates, the ECU continuously monitors the engine's performance and adjusts the valve's position to maintain the desired fuel-air mixture.

The valve's mechanism is designed to optimize fuel usage. It employs a solenoid or an electric actuator to open and close, which is controlled by the ECU. When the valve is open, fuel is delivered at a rate that matches the engine's demand, preventing over-fuelling and potential engine damage. Conversely, when the engine's demand decreases, the valve closes, stopping the fuel supply and preventing wastage. This dynamic process ensures that the engine receives the exact amount of fuel required for efficient combustion, thereby improving performance and fuel efficiency.

In the event of a sudden increase in engine load, such as during acceleration, the valve responds rapidly. It opens wider to supply additional fuel, allowing the engine to meet the higher demand without hesitation. This quick response is crucial for maintaining smooth power delivery and overall engine performance. Similarly, during deceleration or when the engine is idling, the valve closes partially or fully, reducing fuel consumption and optimizing fuel economy.

The line fuel demand valve's operation is a delicate balance of precision and responsiveness. It plays a vital role in modern engine management systems, ensuring that engines run efficiently, deliver optimal power, and meet emissions standards. By managing the fuel supply dynamically, this valve contributes to the overall performance and longevity of the engine.

Scooter Fuel Lines: Powering the Engine's Heart

You may want to see also

Components: Key parts include a solenoid, piston, and spring

A line fuel demand valve is a critical component in fuel injection systems, particularly in automotive applications. It is designed to regulate the flow of fuel from the fuel tank to the engine, ensuring precise control and efficient operation. This valve plays a vital role in managing the fuel supply, especially during varying engine loads and speeds.

The construction of a line fuel demand valve involves several key components that work in harmony. Firstly, the solenoid is an electromagnetic device that acts as the valve's actuator. When an electric current is applied, the solenoid generates a magnetic field, which pulls or pushes a piston, depending on the design. This piston is a crucial element, as it directly controls the opening and closing of the valve.

The piston is typically made of a durable material, such as aluminum or brass, and is designed to fit snugly within the valve body. When the solenoid is energized, the piston moves, either extending or retracting, depending on the direction of the current. This movement allows fuel to pass through the valve or blocks it, respectively. The spring is another essential component, providing the necessary force to return the piston to its resting position when the solenoid is de-energized. This spring action ensures a quick response time and accurate fuel control.

In the de-energized state, the spring's tension keeps the piston in a closed position, preventing fuel from flowing. When the solenoid is energized, it overcomes this spring force, allowing the piston to move and open the valve. This process is rapid and precise, enabling the valve to respond quickly to engine demands. The design of these components is critical to the valve's performance, ensuring it can handle the required fuel flow rates and pressures while maintaining efficiency.

The line fuel demand valve's functionality is essential for modern engines, especially those with electronic fuel injection systems. It provides dynamic fuel control, optimizing engine performance and fuel economy. By precisely managing the fuel supply, this valve contributes to reduced emissions and improved overall engine operation. Understanding its components and their roles is fundamental to appreciating the complexity and efficiency of modern fuel injection systems.

Unveiling the Car Fuel Line: Visual Guide

You may want to see also

Applications: These valves are found in automotive and marine engines

A line fuel demand valve is a crucial component in modern fuel injection systems, particularly in automotive and marine applications. These valves play a vital role in ensuring efficient and precise fuel delivery to the engine, optimizing performance and fuel economy. In the context of automotive and marine engines, these valves are designed to meet the specific demands of these environments, offering a range of benefits.

In automotive engines, line fuel demand valves are commonly used in electronic fuel injection systems. These systems rely on precise fuel control to achieve optimal engine performance and emissions. The valve's primary function is to regulate the fuel pressure and flow rate, ensuring that the engine receives the exact amount of fuel required at any given operating condition. This is achieved through a sophisticated control mechanism that adjusts the valve's opening and closing based on engine speed, load, and other parameters. By maintaining a consistent and accurate fuel-air mixture, these valves contribute to improved engine efficiency, reduced emissions, and enhanced overall performance.

In marine applications, line fuel demand valves are essential for powering various types of vessels, including boats, ships, and yachts. Marine engines often operate in harsh environments, requiring reliable and robust fuel management systems. These valves are designed to handle the unique challenges of marine environments, such as varying fuel temperatures and pressures. They ensure that the engine receives the necessary fuel, even in demanding conditions, by precisely controlling the fuel flow. This precision is critical for maintaining engine performance, especially during critical operations like docking or maneuvering in tight spaces.

The design of these valves often incorporates advanced materials and technologies to withstand the rigors of automotive and marine use. They are typically constructed with durable materials that can resist corrosion and extreme temperatures, ensuring long-lasting performance. Additionally, the valves may feature advanced sealing mechanisms to prevent fuel leaks, which is crucial for both safety and environmental reasons.

Furthermore, line fuel demand valves in automotive and marine applications often include feedback systems that provide real-time data on fuel pressure and flow. This information is valuable for engine diagnostics and maintenance, allowing technicians to identify and address potential issues promptly. The ability to monitor fuel delivery accurately contributes to the overall reliability and longevity of the engine system.

In summary, line fuel demand valves are integral components in automotive and marine fuel injection systems, offering precise fuel control and management. Their design and functionality are tailored to meet the specific demands of these environments, ensuring optimal engine performance, fuel efficiency, and reliability in various operating conditions.

Unveiling the Mystery: What Are Fuel Line Connectors Called?

You may want to see also

Frequently asked questions

A line fuel demand valve is a crucial component in the fuel injection system of an internal combustion engine. It is designed to regulate the fuel pressure and ensure efficient and precise fuel delivery to the engine. This valve opens when the engine requires fuel, allowing a controlled amount of fuel to pass through and reach the injectors.

The valve operates based on the engine's demand for fuel. When the engine is started or during acceleration, a solenoid within the valve is energized, causing it to open and allow fuel to flow. The valve's opening and closing are precisely controlled to maintain the desired fuel pressure and ensure optimal engine performance.

This valve offers several advantages. Firstly, it provides accurate fuel control, ensuring the engine receives the correct amount of fuel for efficient combustion. Secondly, it helps improve engine performance by maintaining consistent fuel pressure, which results in better power output and responsiveness. Additionally, the line fuel demand valve contributes to fuel economy by optimizing fuel usage and reducing waste.