If you're looking to modify or repair the fuel lines on your GS500F, it's important to understand the specific requirements and techniques for a proper fit. This guide will provide a step-by-step approach to ensure a secure and reliable connection for your fuel lines, covering everything from choosing the right materials to applying the necessary tools and techniques for a seamless installation.

| Characteristics | Values |

|---|---|

| Fuel Line Material | Typically made of rubber or synthetic materials like polyurethane. |

| Line Diameter | Standard size is 9mm (3/8 inch), but can vary depending on the model and year of the GS500F. |

| Length | The length of the fuel lines can vary, often ranging from 100mm to 200mm. |

| Clamps | Rubber or plastic clamps are used to secure the lines to the fuel tank and other components. |

| Fitting Methods | Common methods include crimping, clamping, and using specialized fuel line connectors. |

| Flexibility | Fuel lines need to be flexible to accommodate engine movement and vibrations. |

| Durability | High-quality fuel lines should be resistant to fuel degradation and environmental factors. |

| Compatibility | Ensure the lines are compatible with the specific GS500F model and year. |

| Installation Process | Involves removing the old lines, cleaning the fuel system, and carefully routing and securing the new lines. |

| Maintenance | Regular inspection and replacement are recommended to prevent fuel leaks and ensure optimal performance. |

What You'll Learn

- Fuel Line Material: Choose the right material for your GS500F's fuel lines, considering durability and compatibility

- Line Length: Measure and cut fuel lines to the correct length for your bike's fuel tank and engine

- Clamps and Fittings: Select appropriate clamps and fittings to secure fuel lines, ensuring a tight and leak-free connection

- Routing and Placement: Route fuel lines away from heat sources and sharp edges to prevent damage and ensure proper clearance

- Testing and Inspection: Thoroughly test and inspect fuel lines for leaks and proper functionality before final assembly

Fuel Line Material: Choose the right material for your GS500F's fuel lines, considering durability and compatibility

When it comes to modifying or replacing the fuel lines on your GS500F, choosing the right material is crucial for ensuring optimal performance and longevity. The fuel lines on your motorcycle are responsible for delivering gasoline from the tank to the engine, so any issues with these lines can lead to poor fuel delivery and potential engine problems. Here's a guide to help you select the appropriate material for your GS500F's fuel lines:

Durability and Flexibility: Fuel lines need to withstand various conditions, including temperature fluctuations, vibrations from the engine, and potential impacts during riding. Look for materials that offer excellent durability and flexibility. Rubber is a common choice for fuel lines due to its ability to absorb vibrations and provide a certain level of flexibility. However, it's important to choose a high-quality rubber that can resist cracking and degradation over time. Some manufacturers use specialized rubber compounds that are more resistant to fuel-related chemicals, ensuring the material remains intact even when exposed to gasoline.

Compatibility with Fuel Type: Consider the type of fuel your GS500F uses. If it's a standard gasoline motorcycle, then standard fuel lines made from rubber or a rubber-like material should be compatible. However, if your bike uses a different fuel type, such as ethanol-blended gasoline or even diesel, you might need to opt for materials that are more resistant to the unique properties of that fuel. For example, some fuel lines are made from materials that can withstand the higher ethanol content in certain fuels, preventing degradation and ensuring long-term reliability.

Temperature Resistance: Extreme temperatures can affect the performance and integrity of fuel lines. If you live in an area with varying climate conditions, choose materials that can handle both hot and cold temperatures without becoming brittle or losing flexibility. Some manufacturers offer fuel lines with temperature-resistant coatings or specialized compounds to ensure they remain effective in a wide range of environments.

Braiding and Reinforcement: For added strength and protection, consider fuel lines with braided construction. Braiding involves weaving multiple strands of material around the inner hose, providing additional reinforcement and making the line more resistant to punctures and abrasion. This is especially useful if you plan to modify your GS500F's fuel system or if you want to ensure the lines can handle more aggressive riding conditions.

Compatibility with the Bike's Design: Ensure that the chosen material and design of the fuel lines are compatible with your GS500F's fuel system layout. Different motorcycles may have unique fuel line routing and mounting points, so it's essential to select lines that fit seamlessly into your bike's design. Custom-made or specifically designed fuel lines for your model can ensure a perfect fit and easier installation.

Cold Fuel Lines: When Winter Hits the Road

You may want to see also

Line Length: Measure and cut fuel lines to the correct length for your bike's fuel tank and engine

To ensure a proper fit for your GS500F's fuel lines, accurate measurements are crucial. Begin by carefully examining the existing fuel lines on your bike to understand their length and routing. Take note of any bends or kinks in the lines, as these may need to be replicated in the new lines. This initial assessment will provide valuable insights into the specific requirements of your bike.

Once you have a clear understanding of the existing setup, it's time to measure. Use a flexible measuring tape or a ruler to determine the exact length needed for each fuel line. Measure from the fuel tank's inlet port to the engine's fuel injection system, ensuring you account for any bends or changes in direction. Make precise notes of these measurements to guide the cutting process.

With the measurements in hand, it's time to cut the new fuel lines. Use a sharp, clean pair of scissors or a fuel line cutter to make straight, precise cuts. Ensure that the cuts are aligned with the measured lengths to avoid any unnecessary lengthening or shortening. Take your time with this step to ensure accuracy.

After cutting the lines, consider the routing and positioning. Fuel lines should be routed away from moving parts to prevent damage and ensure longevity. Plan the path of the new lines, allowing for any necessary bends or adjustments to accommodate the bike's frame and components. Secure the lines in place using appropriate ties or clips to maintain tension and prevent tangling.

Finally, inspect the installed fuel lines to ensure they are secure, properly routed, and free of any kinks or obstructions. Test the fuel system to confirm that the lines are functioning correctly and that fuel is being delivered efficiently to the engine. This meticulous approach to measuring, cutting, and installing fuel lines will result in a well-fitted system that ensures optimal performance and longevity for your GS500F.

Unplugging Fuel Lines: A Step-by-Step Guide to a Smooth Process

You may want to see also

Clamps and Fittings: Select appropriate clamps and fittings to secure fuel lines, ensuring a tight and leak-free connection

When it comes to ensuring a secure and leak-free fuel line setup for your GS500F, selecting the right clamps and fittings is crucial. The first step is to identify the specific fuel lines and their corresponding fittings that are compatible with your motorcycle's model. Different motorcycles may have unique fuel line configurations, so it's essential to consult the manufacturer's guidelines or seek advice from experienced mechanics.

For the GS500F, you'll typically need to choose clamps and fittings that match the diameter and material of your fuel lines. Common materials for fuel lines include rubber, vinyl, or synthetic compounds, and the fittings are often made of metal or plastic. Measure the inside diameter of your fuel lines accurately to determine the appropriate clamp size. Clamps should be tight enough to provide a secure hold but not so tight that they cause damage to the fuel lines.

Look for high-quality clamps and fittings designed for fuel lines to ensure durability and reliability. Metal clamps with adjustable screws are popular choices as they offer a customizable grip and can accommodate slight variations in fuel line thickness. Rubber or vinyl fuel lines often use compression fittings, which involve inserting the fuel line into a fitting and then tightening a clamp around it to create a tight seal.

Consider the environment in which your motorcycle will operate. If you anticipate extreme temperatures or exposure to harsh conditions, opt for clamps and fittings with enhanced corrosion resistance and flexibility. This is particularly important for outdoor enthusiasts or those in regions with varying weather patterns.

Additionally, ensure that the clamps and fittings are compatible with the mounting points on your GS500F. Some motorcycles may require specific mounting holes or brackets for the fuel lines. Proper alignment and secure mounting will prevent fuel lines from moving or becoming damaged during operation. Always follow the manufacturer's instructions for installation to guarantee a professional and safe fuel line setup.

Fuel Injection Line Repair: A Step-by-Step Guide to Fixing Leaks

You may want to see also

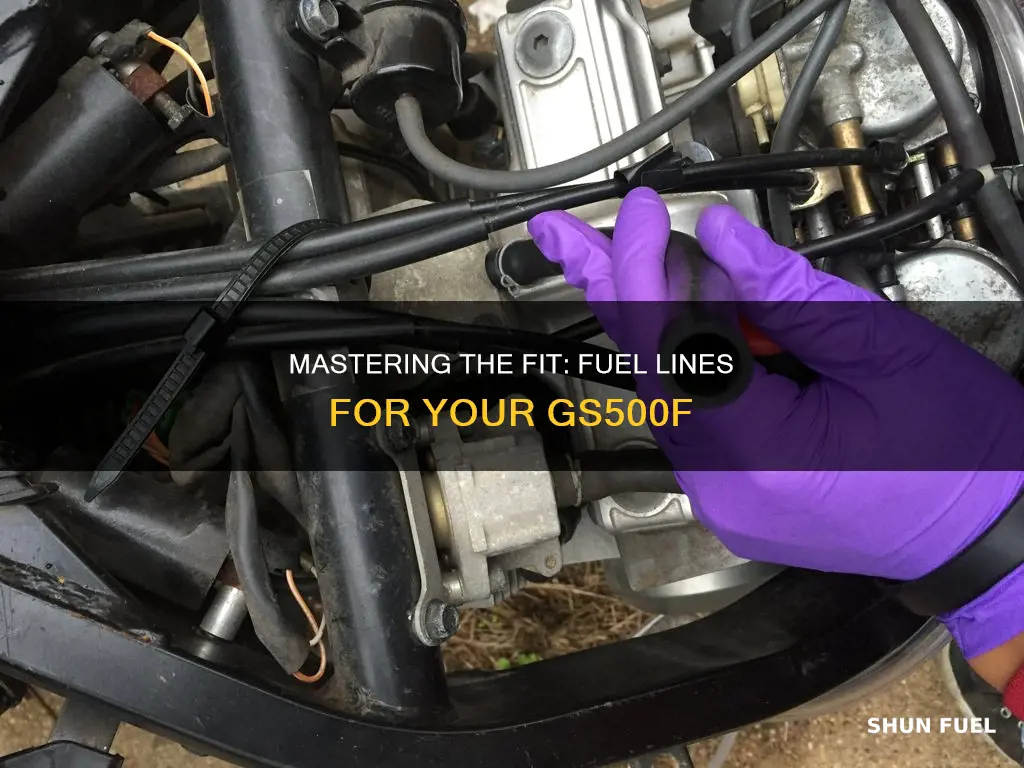

Routing and Placement: Route fuel lines away from heat sources and sharp edges to prevent damage and ensure proper clearance

When installing fuel lines on a GS500F, proper routing and placement are crucial to ensure the system's longevity and performance. The primary goal is to protect the fuel lines from potential sources of damage, such as heat and sharp objects. Here's a step-by-step guide on how to achieve this:

Start by referring to the manufacturer's instructions or online resources specific to your GS500F model. These resources will provide detailed diagrams and guidelines for fuel line installation. Identify the optimal path for the fuel lines, ensuring they are routed away from engine components that generate significant heat, such as the exhaust system, headers, or the engine block itself. Heat can cause fuel lines to expand and contract, leading to potential damage or reduced performance.

Next, consider the placement of the fuel lines in relation to sharp edges and protruding components. Fuel lines should be kept away from sharp corners, edges, or any sharp objects that could cause punctures or tears. For example, avoid routing the lines near the frame rails, suspension components, or any other sharp-edged parts of the motorcycle. Proper clearance is essential to prevent damage during normal operation and movement.

A good practice is to use protective sleeves or shields along the length of the fuel lines, especially in areas where they might come into contact with other components. These sleeves can be made of durable materials like rubber or plastic and should be securely fastened to the motorcycle's body or frame to ensure they remain in place. This simple addition provides an extra layer of protection against potential hazards.

Additionally, when bending or routing the fuel lines, ensure smooth and gentle curves to avoid stress concentrations that could lead to cracks or leaks. Tight bends or sharp turns might compromise the integrity of the fuel lines over time. Allow the lines to follow the natural contours of the motorcycle's body, providing ample space for movement and flexibility during acceleration and deceleration.

By following these routing and placement guidelines, you can ensure that the fuel lines on your GS500F are well-protected, maintaining optimal performance and extending the life of the fuel system. Remember, proper installation and care will contribute to a reliable and efficient motorcycle.

Inline Fuel Filter Direction: A Comprehensive Guide

You may want to see also

Testing and Inspection: Thoroughly test and inspect fuel lines for leaks and proper functionality before final assembly

Before finalizing the assembly of the fuel lines on your GS500F, it is crucial to conduct a comprehensive testing and inspection process to ensure optimal performance and safety. This step is often overlooked but is essential to guarantee that the fuel lines are leak-free and function correctly. Here's a detailed guide on how to approach this task:

Leak Testing: Start by preparing the fuel lines for testing. Ensure that the lines are clean and free of any debris or contaminants that could affect the test results. Use a suitable cleaning agent recommended for the fuel lines' material to remove any old fuel or residue. Then, apply a small amount of a leak detection liquid, such as a proprietary fuel line sealer or a soapy water solution, along the entire length of each fuel line. This liquid will help identify any potential leaks. Allow the lines to dry completely, and then perform the leak test. Use a spray bottle to gently mist the fuel lines with water or the leak detection liquid. Inspect the lines thoroughly for any bubbles or drips, which indicate leaks. Pay close attention to the connections and fittings, as these areas are prone to developing leaks. If any leaks are detected, carefully disassemble the affected section and re-install it, ensuring proper sealing.

Functionality Check: After confirming the fuel lines are leak-free, it's time to test their functionality. Start the engine and carefully observe the fuel lines under operation. Listen for any unusual noises, such as hissing or roaring, which could indicate a restriction or malfunction. Check for any vibrations or movements in the lines, ensuring they are secure and not rubbing against any components. Monitor the fuel gauge to ensure the engine is receiving the correct amount of fuel. If the gauge reads abnormally low or high, it may indicate a problem with the fuel lines or the fuel system as a whole. Additionally, check for any signs of overheating or excessive pressure in the fuel lines, as these can be caused by blockages or faulty components.

Pressure Testing: To further ensure the integrity of the fuel lines, perform a pressure test. This is especially important if the fuel lines are made of flexible materials. Attach a pressure gauge to the fuel line and gradually increase the pressure to a specified level, typically the maximum operating pressure of the fuel system. Monitor the gauge for any drops in pressure, which could indicate leaks or faulty fittings. Release the pressure and repeat the test to ensure consistent results.

Final Inspection: Before closing the fuel line assembly, conduct a final visual inspection. Check for any signs of damage, such as cracks, punctures, or kinks, that may have occurred during the testing process. Ensure that all connections are tight and secure, with no signs of corrosion or deterioration. Verify that the fuel lines are routed correctly and do not interfere with other engine components during operation.

By following these testing and inspection procedures, you can ensure that the fuel lines on your GS500F are installed correctly and will function reliably, providing peace of mind and optimal engine performance.

Is Aluminum Fuel Line Legal for NHRA Competition?

You may want to see also

Frequently asked questions

When installing fuel lines on your GS500F, it's crucial to measure and cut the lines to the correct length for your specific bike model. Use a flexible measuring tape to determine the exact length required, ensuring you account for any bends or angles in the line's path.

Opt for fuel line connectors that are compatible with your GS500F's fuel system. Common types include barbed connectors with ferrules or quick-connect style fittings. Ensure the connectors are made from durable materials like stainless steel or aluminum to withstand fuel pressure.

Reusing old fuel lines is generally not recommended as they may have deteriorated over time. New fuel lines are designed to meet the specific requirements of your GS500F and ensure optimal fuel flow and safety.

To minimize the risk of leaks, inspect the fuel lines for any signs of damage or wear before installation. Ensure all connections are tight and secure. Use fuel line tape or protective sleeves to cover any sharp bends or potential stress points, providing an extra layer of protection against leaks.

Yes, you'll need a few essential tools for the job. These include a fuel line cutter or a pair of sharp scissors/knives for precise cutting, a fuel line crimper or a pair of pliers to secure barbed connectors, and a fuel line cleaner to ensure a clean and leak-free installation.