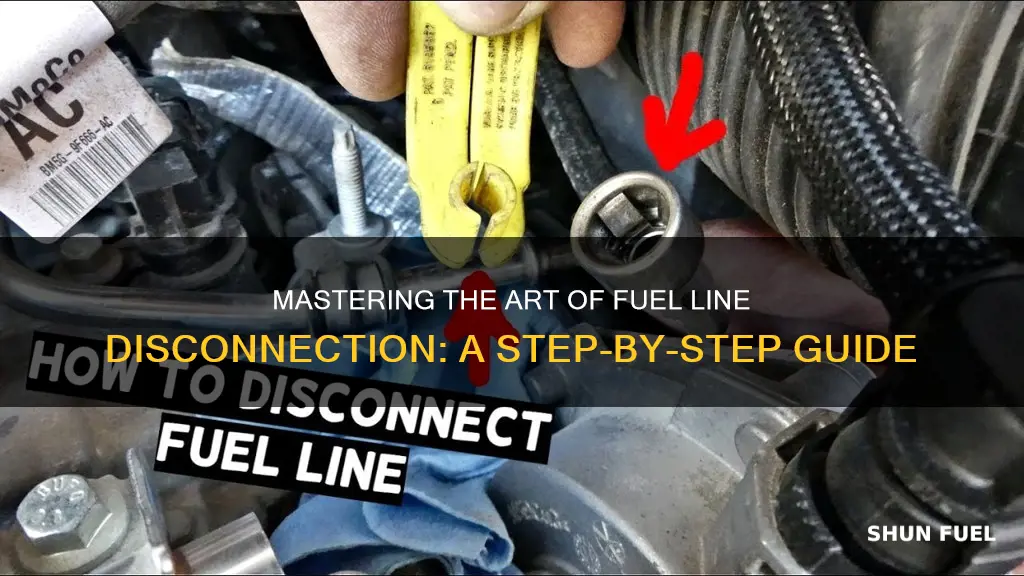

Disconnecting a fuel line is a crucial step in various automotive and mechanical projects, ensuring safety and preventing fuel leaks. This process requires careful handling to avoid accidents and requires a systematic approach. In this guide, we'll explore the step-by-step process of safely disconnecting a fuel line, covering essential tools, safety precautions, and the proper techniques to ensure a successful and secure disconnection.

What You'll Learn

- Locate the fuel line: Identify the fuel line on your vehicle, typically near the fuel tank or engine

- Turn off the fuel supply: Shut off the fuel supply valve to prevent any spills

- Disconnect the fuel line: Loosen and remove the fuel line clips or fittings

- Release pressure: Bleed the fuel line to release pressure before disconnecting

- Clean and inspect: Clean the fuel line and check for any damage or corrosion

Locate the fuel line: Identify the fuel line on your vehicle, typically near the fuel tank or engine

To begin the process of disconnecting a fuel line, you must first locate it. The fuel line is a crucial component of your vehicle's fuel system, responsible for transporting fuel from the tank to the engine. It is typically positioned near the fuel tank or engine, making it relatively accessible for maintenance and repairs.

When identifying the fuel line, look for a flexible hose or a rigid tube that connects the fuel tank to the engine. It is often made of rubber or a similar material and may have a distinctive color or marking to distinguish it from other hoses. The fuel line's path can vary depending on the vehicle's make and model, but it generally runs along the frame or under the vehicle's body to reach the engine compartment.

Near the fuel tank, you will likely find the primary fuel line, which is the main supply line. This line branches out into smaller lines that lead to various components, such as the fuel pump and injectors. Identifying the primary line is essential as it will be the starting point for your disconnection process.

In the engine compartment, locate the fuel rail or the area where the fuel injectors are mounted. This is where the fuel lines from the tank connect to deliver fuel to the engine. Carefully inspect the engine bay to find the specific fuel lines that lead to the injectors or other fuel-related components.

Remember, when working with fuel lines, it is crucial to exercise caution. Fuel is highly flammable, so ensure you are in a well-ventilated area and take the necessary safety precautions. Always disconnect the fuel line from the tank first, then carefully remove any connections to the engine components to ensure a safe and controlled process.

Dodge Fuel Line Clip Removal: A Step-by-Step Guide

You may want to see also

Turn off the fuel supply: Shut off the fuel supply valve to prevent any spills

To safely disconnect a fuel line, the first crucial step is to turn off the fuel supply. This process ensures that no fuel is released during the disconnection, preventing potential spills and associated hazards. Here's a detailed guide on how to do this:

Locate the fuel supply valve, which is typically found near the fuel tank or the engine. This valve is designed to control the flow of fuel into the system. It might be a simple on/off switch or a more complex valve with a handle or knob. Identify the correct valve and ensure you are turning it off at the source.

Once you've located the valve, turn it clockwise or counterclockwise, depending on its design, to shut off the fuel supply. You should feel a distinct click or hear a mechanism engage when it's properly closed. If you're unsure, consult your vehicle's manual for specific instructions.

After turning off the valve, it's essential to confirm that the fuel supply is indeed disconnected. You can do this by checking for any fuel flow. If you've disconnected the fuel line correctly, you should not observe any fuel dripping or flowing from the line. This step is crucial to ensure that the fuel system is secure and safe to work on.

Remember, this process requires caution and attention to detail. Always work in a well-ventilated area and wear protective gear when handling fuel to minimize any potential risks. By following these steps, you can safely disconnect the fuel line and proceed with the necessary repairs or maintenance.

Evo Fuel Line Size: Essential Guide for Optimal Performance

You may want to see also

Disconnect the fuel line: Loosen and remove the fuel line clips or fittings

To safely disconnect a fuel line, you must first identify the specific clips or fittings that secure the fuel line to the vehicle's engine or other components. These clips or fittings are typically made of metal and are designed to be easily removable. The process begins by locating the fuel line clips or fittings, which are usually positioned along the length of the fuel line. These clips or fittings are often made of metal and may be secured with a screw or a simple clip.

Once the clips or fittings are identified, you can proceed to loosen them. Start by using a pair of pliers or a fuel line tool to grip the clip or fitting and turn it counterclockwise. The amount of force required may vary depending on the tightness of the connection, but it's important to apply steady pressure to avoid damaging the fuel line. Loosen the clip or fitting until it is no longer tight, ensuring that you do not strip the threads or damage the fuel line.

After loosening the clips or fittings, you can now remove them. Gently pull the fuel line away from the engine or component it was connected to. Take note of the position of the fuel line to ensure proper reattachment later. Be cautious not to tug or pull too hard, as this can cause damage to the fuel line or other components.

It's important to handle the fuel line with care throughout this process. Fuel lines can be delicate, and any damage could lead to fuel leaks, which pose a serious safety hazard. If you encounter any resistance or difficulty while disconnecting the fuel line, it is recommended to consult a professional mechanic or refer to the vehicle's manual for specific instructions.

Remember, when working with fuel lines, always prioritize safety. Ensure that the engine is turned off and the vehicle is in a secure location before beginning any disconnection process. By following these steps and exercising caution, you can safely disconnect the fuel line from your vehicle.

Unclog Your Fuel Line: Quick Tips for a Smooth Ride

You may want to see also

Release pressure: Bleed the fuel line to release pressure before disconnecting

Before attempting to disconnect a fuel line, it is crucial to release the pressure to avoid any potential hazards. Fuel lines carry pressurized fuel, and disconnecting them without proper precautions can lead to fuel spraying or even an explosion. Here's a step-by-step guide on how to release pressure and safely disconnect the fuel line:

Locate the fuel line that you intend to disconnect. It is typically a black or dark-colored line running from the fuel tank to the engine or fuel injectors. Identify the correct line to avoid any unnecessary disconnections. Once located, find the bleeder valve or port, which is usually a small opening or screw on the fuel line itself or on the fuel tank. This valve is designed to allow air to enter the line, thus releasing the pressure.

Using a flat-head screwdriver or a similar tool, carefully pry the bleeder valve open. You might need to apply some force, but be gentle to avoid damaging the valve. As you open it, you should hear a slight hissing sound, indicating that air is entering the line. Continue to hold the valve open for a few seconds to ensure a steady flow of air. This process allows the fuel to vent and the pressure to be released gradually.

If you're working on a fuel tank, there might be a dedicated bleeder screw or valve. Loosen this screw by hand or with a small wrench, and then open it slightly to release the pressure. Again, hold it open for a few seconds to ensure the air and fuel are properly vented. This step is essential to prevent any sudden eruptions of fuel when you disconnect the line.

After releasing the pressure, it's a good practice to run the engine for a short period. This will help ensure that any remaining fuel in the line is burned off, reducing the risk of fuel residue causing starting issues or engine performance problems. However, always exercise caution when working with fuel and engines, and ensure proper ventilation in your workspace.

Remember, taking the time to release pressure and bleed the fuel line is a critical safety measure. It ensures that you can disconnect the fuel line without the risk of fuel spraying or an explosion. Always follow these steps and exercise caution when working with fuel systems to maintain a safe working environment.

Thawing Diesel Fuel Lines: Quick Tips for Cold Weather

You may want to see also

Clean and inspect: Clean the fuel line and check for any damage or corrosion

To ensure the proper functioning of your vehicle's fuel system, it's essential to regularly clean and inspect the fuel line. This process involves removing any debris, contaminants, or built-up residue that may have accumulated over time. Here's a step-by-step guide to help you through this task:

Step 1: Gather the Necessary Tools and Materials

Before you begin, make sure you have the required tools and supplies. You will need a fuel line cleaner, which can be purchased from auto parts stores. This cleaner is designed to dissolve and remove any fuel-related deposits. Additionally, have a set of wrenches or pliers for disconnection and a clean cloth or rag for wiping.

Step 2: Locate the Fuel Line

Identify the fuel line on your vehicle. It is typically a rubber or plastic hose that connects the fuel tank to the engine. The location may vary depending on the vehicle model, but it is usually accessible from beneath the car or in the engine compartment.

Step 3: Disconnect the Fuel Line

Carefully disconnect the fuel line from the fuel tank and the engine. Locate the fuel line clamps or fittings and use the appropriate tools to loosen and remove them. Take note of the connection points to ensure proper reattachment later. When disconnecting, be cautious as fuel lines can be under pressure, especially if the vehicle has been running.

Step 4: Clean the Fuel Line

Once the fuel line is disconnected, use the fuel line cleaner as per the manufacturer's instructions. Apply the cleaner to the inside and outside of the fuel line, allowing it to sit for the recommended time to dissolve any deposits. Then, use a cloth or rag to wipe down the fuel line, removing any residue or contaminants. Ensure you clean the entire length of the fuel line.

Step 5: Inspect for Damage or Corrosion

After cleaning, thoroughly inspect the fuel line for any signs of damage, cracks, leaks, or corrosion. Check for any visible wear and tear, especially at the points where the fuel line connects to the tank and engine. Look for any discolored or hardened areas, which may indicate corrosion. If you notice any issues, it's crucial to address them promptly to prevent further damage.

Step 6: Reattach and Test

Once you've completed the cleaning and inspection, reattach the fuel line securely, ensuring all connections are tight. Start the vehicle and check for any leaks. If everything is functioning correctly, your fuel system is now clean and ready for optimal performance.

Remember, regular maintenance of the fuel line is essential to prevent fuel-related issues and ensure your vehicle's overall reliability.

Fuel Line Experts: Who Can Fix Your 1998 F150?

You may want to see also

Frequently asked questions

To safely disconnect a fuel line, you'll need a fuel line disconnect tool or a pair of adjustable pliers. It's important to have a container nearby to catch any spilled fuel.

The fuel line is typically located near the fuel tank and runs along the frame or under the vehicle. It's often secured with clamps or fittings. Locate the specific line you want to disconnect, usually the one connected to the fuel pump or the engine.

Absolutely. Before starting, ensure the engine is off and has had enough time to cool down. Relieve any pressure by slightly opening the fuel line fitting or using a small tool to release the pressure. Always work carefully to avoid fuel spills and potential fires.

Grip the fuel line disconnect tool or pliers firmly and twist counterclockwise to loosen the fitting. Be gentle but firm to avoid damaging the line. Once loosened, carefully pull the line away from the connection. Take note of the orientation of the line to ensure proper reconnection later.

When reconnecting, align the fuel line with the fitting and insert it until it's fully seated. Tighten the fitting securely by hand, then use the tool to tighten it further. Ensure the connection is tight and there are no leaks.