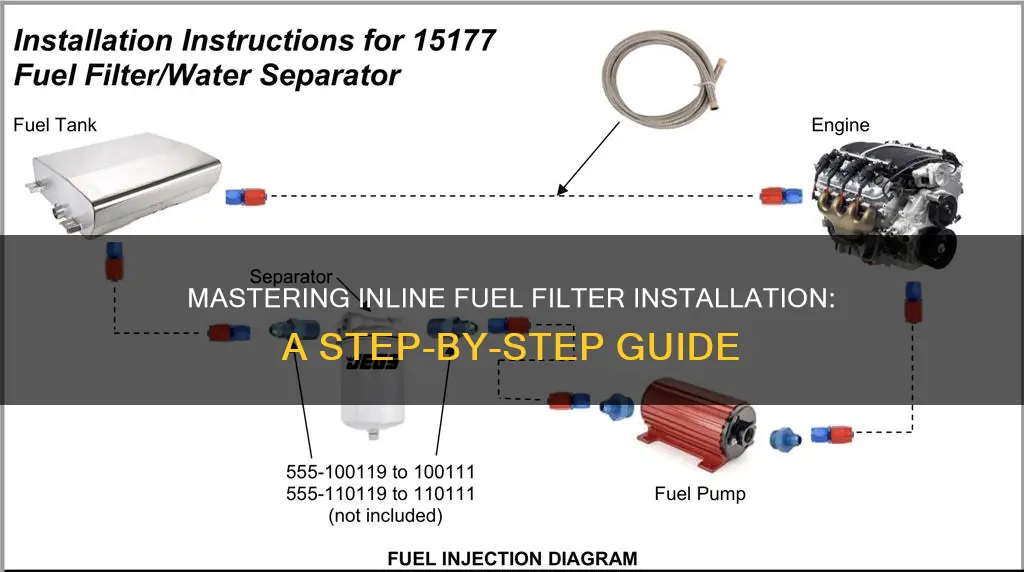

Installing an in-line fuel filter is a crucial step in maintaining your vehicle's engine performance and longevity. This process involves replacing or adding a filter to your fuel system, which helps remove contaminants and ensure clean fuel delivery to the engine. Whether you're a seasoned mechanic or a DIY enthusiast, this guide will provide a step-by-step approach to installing an in-line fuel filter, covering everything from choosing the right filter to ensuring a secure and leak-free setup. By following these instructions, you can enhance your vehicle's fuel efficiency and protect it from potential damage caused by dirty fuel.

| Characteristics | Values |

|---|---|

| Preparation | Ensure you have the necessary tools: a fuel filter, a wrench or socket, a rag or cloth, and a container to catch any spilled fuel. Also, locate the fuel line and identify the correct filter size and type for your vehicle. |

| Turn Off the Engine | Before starting the installation, turn off the engine and allow it to cool down. This is an important safety precaution to prevent fuel spills and potential hazards. |

| Locate the Fuel Line | Find the fuel line that connects to the fuel tank. It is usually a thick, black hose. Mark its position or take a picture for reference during the installation process. |

| Remove the Old Filter (if applicable) | If you're replacing an existing filter, locate the old one and carefully remove it. Keep the old filter for disposal or recycling. |

| Prepare the New Filter | Open the new fuel filter and inspect it. Ensure it is the correct size and type for your vehicle. Check the manufacturer's instructions or consult a repair manual if needed. |

| Install the Filter | Position the new filter in the fuel line, ensuring it is aligned correctly. Use the wrench or socket to tighten the filter securely, but be careful not to overtighten. |

| Bleeding the System | After installing the filter, start the engine and allow it to run. Turn it off and check for any fuel leaks. Then, restart the engine and let it run for a few minutes. Turn it off again and check for any remaining fuel leaks. |

| Final Steps | Dispose of the old filter properly. Clean any fuel residue from the surrounding area. Start the engine and check for any unusual noises or vibrations. If everything is functioning correctly, your in-line fuel filter is now installed. |

What You'll Learn

- Preparation: Gather tools and materials, ensure engine is off and cooled

- Location: Identify fuel tank, locate filter access point

- Removal: Disconnect fuel lines, carefully take out old filter

- Installation: Slide new filter into place, reconnect lines securely

- Testing: Start engine, check for leaks, ensure proper functionality

Preparation: Gather tools and materials, ensure engine is off and cooled

Before you begin the process of installing an in-line fuel filter, it's crucial to prepare and ensure you have everything you need to make the task smooth and efficient. Start by gathering the necessary tools and materials. You will typically require a new in-line fuel filter, which can be purchased from an auto parts store or online. Along with the filter, you'll need a fuel line, a wrench or socket set, and possibly a fuel pump flush solution, depending on your vehicle's setup. Having these items ready will streamline the installation process.

Next, locate your vehicle's fuel tank and engine compartment to identify the fuel lines and connections. It's important to understand the layout to ensure you can access the necessary points without causing any accidental damage. Ensure that you have a clear understanding of the fuel system's layout to avoid any confusion during the installation.

Now, it's time to ensure the engine is off and cooled. This step is critical for your safety and the success of the installation. Turn off the engine and allow it to cool down for at least 30 minutes. This precaution prevents any potential fuel system issues and ensures you can work on the fuel lines without the risk of fuel spray or overheating. Additionally, it's advisable to put on safety gear, such as gloves and eye protection, to safeguard yourself from any potential fuel splashes or debris.

While the engine is off, locate the fuel line that connects to the fuel pump and the one that leads to the engine. These lines are usually identified by their color-coding or labels. Carefully disconnect the fuel lines, ensuring you have a container or drain pan ready to catch any fuel that may spill. This step is crucial to prevent fuel wastage and potential environmental hazards.

Once the fuel lines are disconnected, you can proceed with the installation of the new in-line fuel filter. Ensure that you have a clean workspace and take the necessary precautions to avoid any fuel-related accidents. By following these preparation steps, you'll be well-equipped to tackle the installation process with confidence and efficiency.

Nissan Maxima Fuel Line: Location Guide for 2007 Models

You may want to see also

Location: Identify fuel tank, locate filter access point

To begin the process of installing an in-line fuel filter, you need to identify the fuel tank and locate the access point for the filter. This step is crucial as it ensures you can access the necessary components without causing any damage to the vehicle.

Start by locating the fuel tank. In most vehicles, the fuel tank is typically positioned at the rear or side of the engine compartment. It is usually a large, cylindrical container with a cap or lid that can be opened to access the fuel. If your vehicle has a separate fuel tank, it might be located under the floor or in the trunk. Once you've identified the tank, ensure you have a clear view and easy access to it.

Next, you need to find the filter access point. This is the location where you can remove the old filter and install the new one. The access point is usually a small opening or port on the fuel tank. It might be a dedicated screw or a fitting that is specifically designed for filter replacement. Check your vehicle's manual or consult the manufacturer's guidelines to locate the exact access point. This information is vital to ensure you don't damage any other components during the installation process.

Look for any visible signs of wear or damage around the access point. If there are any leaks or signs of corrosion, it might indicate that the filter has already been replaced or that the area requires additional attention. In some cases, you might need to remove certain panels or trim pieces to gain access to the filter. Take your time and be gentle when removing any parts to avoid any further complications.

Remember, the key to a successful installation is proper identification and access. Take your time to locate the fuel tank and the filter access point, ensuring you have a clear understanding of the vehicle's layout. This will make the entire process smoother and reduce the risk of any errors during the installation of the in-line fuel filter.

Miata Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Removal: Disconnect fuel lines, carefully take out old filter

When it comes to removing an in-line fuel filter, the process is relatively straightforward, but it requires careful attention to detail to avoid any fuel spills or damage to the system. Here's a step-by-step guide on how to safely and effectively remove the old filter:

- Prepare Your Workspace: Before you begin, ensure you have a clean and well-lit workspace. Gather the necessary tools, including a fuel drain pan or container to catch any spilled fuel. It's also a good idea to wear protective gear, such as gloves and safety goggles, to safeguard yourself from any potential fuel splashes.

- Locate the Fuel Lines: Identify the fuel lines connected to the in-line filter. These lines are typically made of rubber or plastic and are often color-coded for easy identification. Locate the filter's mounting points, which are usually secured with brackets or screws.

- Disconnect the Fuel Lines: Carefully disconnect the fuel lines from the filter. Start by loosening the fittings or clips that hold the lines in place. Be gentle to avoid damaging the lines. Once the lines are free, set them aside, making sure to note their positions for reattachment later.

- Remove the Old Filter: With the fuel lines disconnected, you can now safely remove the old filter. Locate the mounting brackets or screws and carefully detach them. Lift the filter out of its position, being mindful of any residual fuel that may still be present. Place the old filter in the drain pan or container to catch any remaining fuel.

- Clean and Inspect (Optional): If you plan to reuse the fuel lines or the engine bay, consider cleaning the filter housing and any connected components. This step ensures that any contaminants or old fuel are removed, promoting a smooth installation of the new filter.

By following these steps, you can efficiently remove the old in-line fuel filter, making way for a fresh filter installation. Remember, when working with fuel, always prioritize safety and take the necessary precautions to protect yourself and your surroundings.

The Ultimate Guide to Choosing the Right Hose Clamp for Your 3/8" Outboard Fuel Line

You may want to see also

Installation: Slide new filter into place, reconnect lines securely

Before you begin the installation process, ensure you have the necessary tools and components ready. You'll need the new in-line fuel filter, which should be compatible with your vehicle's fuel system, and a set of tools such as wrenches, pliers, and possibly a fuel pump primer if needed. It's also a good idea to have a clean workspace and some rags or paper towels to handle any spills.

Locate the in-line fuel filter on your vehicle. This filter is typically positioned along the fuel line, often near the engine or the fuel tank. Carefully inspect the existing filter (if there is one) to understand its orientation and any unique features. This will help you identify the correct way to install the new filter.

Now, slide the new filter into place. Ensure it is aligned correctly with the fuel line. You might need to use a small amount of force to push it in, but be careful not to force it too much, as this could damage the filter or the fuel line. Once the filter is in place, check that it is secure and cannot be easily moved.

After the filter is installed, reconnect the fuel lines. Make sure the lines are properly aligned and securely attached to both the filter and the fuel source. Tighten any connections with a wrench, being careful not to overtighten, as this could damage the threads. Ensure all connections are tight and leak-free.

Finally, test the system to ensure it is functioning correctly. Start the engine and check for any signs of fuel leaks. Listen for any unusual noises, and monitor the engine's performance. If everything is in order, you can now enjoy the benefits of a clean and efficient fuel supply to your vehicle's engine. Remember to regularly replace the filter to maintain optimal engine performance and longevity.

Fitech Fuel Injection: Return Line Size Guide

You may want to see also

Testing: Start engine, check for leaks, ensure proper functionality

Once you've installed the in-line fuel filter, it's crucial to test its functionality to ensure it's working correctly and providing the necessary protection for your engine. Here's a step-by-step guide on how to test the filter:

Starting the Engine: Begin by starting the engine. This initial test will help you identify any immediate issues with the fuel system. Ensure that the engine starts without any issues and runs smoothly. Pay attention to any unusual noises or vibrations, as these could indicate potential problems.

Leak Check: After the engine is running, it's essential to check for any leaks. Locate the in-line fuel filter and inspect it for any signs of fuel leakage. Fuel leaks can be dangerous and may lead to engine misfires or even a fire hazard. Check the connections and the filter itself for any cracks or damage. If you notice any leaks, tighten the connections or replace the filter as necessary.

Functionality Assessment: Now, let's ensure the filter is functioning properly. You can do this by monitoring the engine's performance and behavior. Here are a few things to look out for:

- Engine Performance: Observe if the engine's performance is consistent and stable. There should be no noticeable changes in power, acceleration, or fuel efficiency.

- Fuel Consumption: Check the fuel gauge to see if the fuel consumption aligns with your expectations. The filter should not cause any significant changes in fuel usage.

- Engine Sensors: Modern engines have various sensors that monitor performance. Check if these sensors provide accurate readings. For example, the mass airflow sensor should read correctly, and the oxygen sensors should detect the correct air-fuel ratio.

Long-Term Monitoring: Testing the filter's performance doesn't end after the initial check. It's beneficial to monitor the engine's behavior over time. Keep an eye on the engine's health, and if any issues arise, investigate further. Regularly checking for leaks and ensuring the filter's functionality will help maintain a healthy engine and prevent potential problems.

Remember, proper testing and maintenance of the in-line fuel filter will contribute to the overall reliability and longevity of your vehicle's fuel system.

Mastering Fuel Sending Unit: Tips to Trim Extra Lines

You may want to see also

Frequently asked questions

An in-line fuel filter is a device installed directly in the fuel line of your vehicle, typically between the fuel tank and the engine. It is designed to filter contaminants and impurities from the fuel before it reaches the engine, ensuring cleaner combustion and potentially improving engine performance and longevity. This is especially beneficial for vehicles that use lower-grade fuels or are prone to fuel-related issues.

Signs that your vehicle might benefit from an in-line fuel filter include engine misfires, reduced power, increased fuel consumption, and the presence of fuel-related error codes. If you notice any of these symptoms, especially after using lower-grade fuel or if your vehicle is older, it's a good idea to consult a mechanic to determine if an in-line filter is necessary.

While some in-line fuel filters are designed for DIY installation, it is generally recommended to have a professional mechanic perform the installation. Fuel systems can be complex, and improper installation may lead to fuel leaks or other issues. A qualified mechanic will ensure the filter is installed correctly and securely, maintaining the integrity of your vehicle's fuel system.

High-quality in-line fuel filters offer several advantages. They provide superior filtration, capturing a wide range of contaminants, including water, sediment, and small particles. This can lead to improved engine performance, reduced maintenance costs, and increased fuel efficiency. Additionally, some filters have built-in pressure relief valves, ensuring that the fuel system operates at optimal pressure.

The replacement interval for an in-line fuel filter depends on various factors, including the filter's quality, your vehicle's usage, and the type of fuel used. As a general guideline, it is recommended to replace the filter every 30,000 to 50,000 miles or as per the manufacturer's instructions. Regular maintenance ensures that the filter remains effective in protecting your engine from contaminants.