Installing a fuel pressure regulator with a return line is a crucial step in ensuring your vehicle's engine operates efficiently and safely. This process involves carefully connecting the regulator to the fuel system, allowing for precise control of fuel pressure and ensuring a steady supply of fuel to the engine. By following a step-by-step guide, you can effectively manage the fuel flow, optimize engine performance, and prevent potential issues related to fuel pressure. This guide will provide a detailed overview of the installation process, ensuring you have the necessary knowledge to complete the task successfully.

What You'll Learn

- Prepare Tools: Gather necessary tools like wrenches, sockets, and fuel pressure gauge

- Locate Components: Identify fuel pressure regulator and return line on engine

- Remove Old Parts: Carefully disconnect and remove old fuel pressure regulator and return line

- Install Regulator: Align and secure new fuel pressure regulator with return line

- Test and Adjust: Verify fuel pressure and make adjustments if needed

Prepare Tools: Gather necessary tools like wrenches, sockets, and fuel pressure gauge

Before you begin the installation process, it's crucial to have the right tools at hand to ensure a smooth and efficient job. The first step in preparing for the installation of a fuel pressure regulator with a return line is to gather the necessary tools. This includes a variety of wrenches and sockets, which are essential for tightening and loosening the various components of the fuel system. You'll need different sizes of wrenches, typically a combination of metric and standard sockets, to accommodate the various fasteners and bolts that will be encountered. Additionally, a fuel pressure gauge is a critical tool for this task. It allows you to measure and monitor the fuel pressure within the system, ensuring that it meets the required specifications. This gauge will help you verify that the fuel pressure regulator is functioning correctly and that the system is operating optimally.

Having the right tools is not just about convenience; it's about ensuring the job is done right. Wrenches and sockets provide the necessary leverage and grip to tighten or loosen connections securely, while the fuel pressure gauge offers the precision required to fine-tune the fuel system's performance. These tools are fundamental to the installation process, as they enable you to work efficiently and effectively, minimizing the risk of errors or damage to the components.

When gathering your tools, consider the specific requirements of your vehicle or engine. Different makes and models may have unique fasteners and connection points, so it's essential to have the appropriate sockets and wrenches for your particular application. This attention to detail will make the installation process smoother and more successful.

In addition to the standard tools, you might also want to have a few extra items on hand, such as a clean rag or cloth for wiping down components and ensuring a smooth installation. It's also a good idea to have some fuel system cleaner or a similar product to help remove any contaminants or old fuel that may be present in the system. These additional items can contribute to a more thorough and professional installation.

By taking the time to prepare and gather the necessary tools, you set the stage for a successful fuel pressure regulator installation. This initial step is often overlooked but is crucial for ensuring that the rest of the process goes smoothly and that the final result is a well-functioning fuel system.

Troubleshooting Clogged Fuel Lines: Common Causes and Solutions

You may want to see also

Locate Components: Identify fuel pressure regulator and return line on engine

To begin the installation process of a fuel pressure regulator with a return line, you must first locate the necessary components on your engine. The fuel pressure regulator is a critical component in your fuel system, responsible for controlling the pressure of the fuel before it enters the engine. It is typically located near the fuel tank or along the fuel lines, often in a position that allows easy access for maintenance. This component is usually a small, cylindrical device with an inlet and outlet port.

Start by inspecting your engine's fuel system. Locate the fuel tank and trace the fuel lines to identify where they connect to the engine. The fuel pressure regulator is often positioned close to the fuel injectors or the intake manifold. It might be mounted on the engine block or attached to a bracket for easy access. Carefully examine the area around the fuel lines and injectors, as this is where the regulator is commonly found.

Look for a small, cylindrical unit with a few ports. The inlet port connects to the fuel line, and the outlet port leads to the fuel injectors or the intake manifold. The return line, which is an essential part of the system, connects the outlet port of the regulator back to the fuel tank or a reservoir. This line ensures that excess fuel is returned to the tank, maintaining proper pressure and preventing fuel wastage.

Identifying the return line is crucial as it completes the fuel pressure regulation loop. The return line is usually a smaller diameter than the main fuel line and may have a different color or marking to distinguish it. It often runs parallel to the main fuel line and connects to the regulator's outlet port. Ensure you understand the layout of the fuel system in your specific engine model to accurately locate both the regulator and the return line.

Once you have identified the fuel pressure regulator and the return line, you can proceed with the installation process, ensuring that all components are correctly connected and secured. Properly locating these parts is the first step towards a successful fuel pressure regulator installation.

Unclogging the Miata: A Step-by-Step Guide to Removing the Fuel Line Filter

You may want to see also

Remove Old Parts: Carefully disconnect and remove old fuel pressure regulator and return line

To begin the process of installing a new fuel pressure regulator and return line, you must first remove the old components. Start by locating the fuel pressure regulator, which is typically found near the engine's fuel injection system. It is often connected to the fuel rail or the fuel pump via a return line. Carefully inspect the connections and take note of the positions of the old parts to ensure a smooth reinstallation.

The return line is an essential component that directs excess fuel back to the tank or the fuel pump. It is usually a flexible hose or a rigid tube. Disconnect the return line from the fuel pressure regulator by loosening the retaining clips or screws that hold it in place. Be gentle to avoid damaging the surrounding components. Once the line is free, carefully pull it away from the regulator, ensuring you don't twist or kink the hose.

Now, focus on the fuel pressure regulator itself. It is often secured with a few screws or clips. Loosen these fasteners, but do not remove them completely yet. Gently lift the regulator away from the engine, being mindful of any electrical connections or sensors that may be attached. You might need to pry it slightly to break the seal, but be cautious not to damage the surrounding components.

With the old regulator and return line removed, you'll have a clear view of the engine's fuel system. Take this opportunity to clean the mounting surfaces and any debris that may have accumulated. Ensure that the old parts are properly disposed of or recycled. This step is crucial to guarantee a secure and proper installation of the new fuel pressure regulator and return line.

Remember, when removing parts, take your time and be methodical. Properly disconnecting and removing the old components is essential to avoid any potential issues during the installation process. By following these steps, you'll be well-prepared to install the new fuel pressure regulator and return line, ensuring optimal engine performance.

Troubleshooting a Clogged Fuel Line: Quick Fixes for Car Owners

You may want to see also

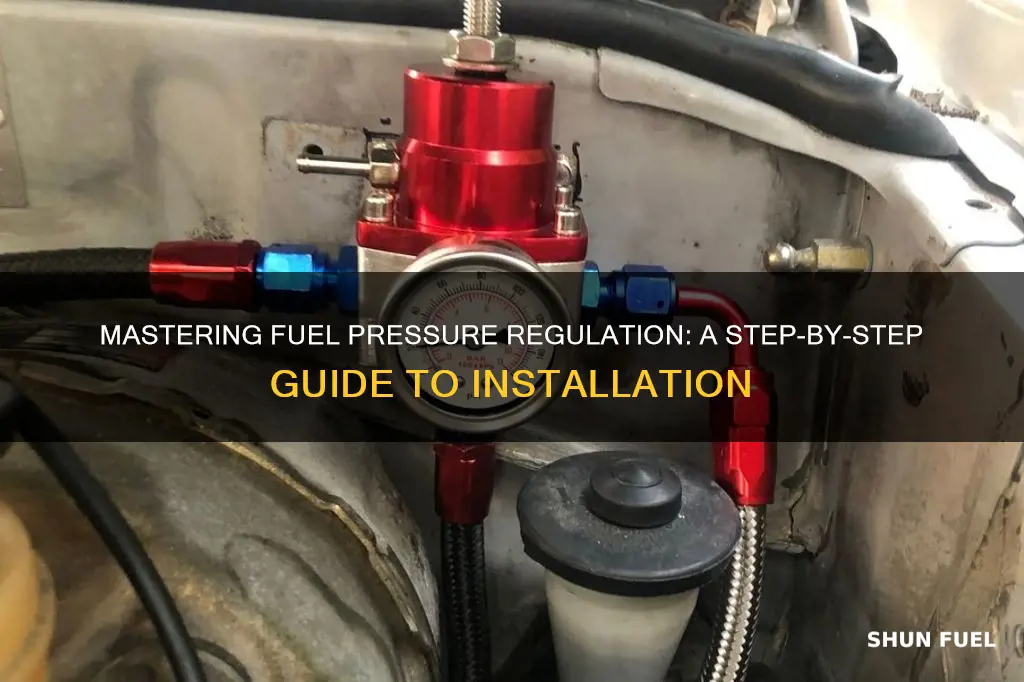

Install Regulator: Align and secure new fuel pressure regulator with return line

To install the new fuel pressure regulator with the return line, you'll need to carefully align and secure the components. Start by locating the mounting points on your engine block or fuel rail, ensuring they match the new regulator's mounting pattern. Use the appropriate-sized screws or bolts to fasten the regulator securely. It's crucial to tighten these fasteners by hand first, then check for tightness with a torque wrench to avoid over-tightening.

Next, connect the return line to the regulator. This line is typically a small diameter hose that directs fuel back to the tank or a reservoir. Ensure a tight, leak-free connection by inserting the hose into the regulator's return port and using an appropriate clamp or fitting. You might need to adjust the position of the regulator slightly to ensure the return line is straight and free of kinks.

With the regulator and return line connected, it's time to check for any leaks. Inspect all connections and fittings for any signs of fuel escaping. If you notice any leaks, tighten the connections further or consider using a fuel-resistant sealant to ensure a secure bond.

Once all connections are secure and leak-free, double-check the alignment of the regulator. Ensure it is positioned correctly and securely attached to the engine. You may need to refer to your vehicle's manual or online resources for specific alignment instructions, as this can vary depending on the make and model of your engine.

Finally, start the engine and check for any unusual noises or vibrations. If everything is properly installed and aligned, the fuel pressure regulator should function smoothly, ensuring optimal engine performance. Remember to regularly inspect and maintain your fuel system to keep your vehicle running efficiently.

Sugar's Impact: How Fast Does It Affect Fuel Lines?

You may want to see also

Test and Adjust: Verify fuel pressure and make adjustments if needed

Once you've installed the fuel pressure regulator and return line, it's crucial to test and adjust the fuel pressure to ensure optimal performance. This process involves verifying the pressure and making any necessary adjustments to fine-tune the system. Here's a step-by-step guide to help you through this critical phase:

Testing Fuel Pressure: Start by locating the fuel pressure gauge, which is typically connected to the fuel rail or the regulator itself. Ensure the engine is off and the vehicle is in a stable position. Connect the gauge securely and note the initial reading. The ideal fuel pressure range can vary depending on your vehicle's specifications, so consult your vehicle's manual for the correct target pressure. If the pressure is significantly lower or higher than the recommended range, adjustments are required.

Adjusting Fuel Pressure: Adjusting the fuel pressure often involves turning a screw or adjusting a valve on the fuel pressure regulator. Turn the screw clockwise to increase pressure or counterclockwise to decrease it. Make small adjustments and recheck the pressure after each turn. Fine-tuning the pressure might require multiple iterations to achieve the desired level. It's essential to be patient and methodical during this process. Once you reach the target pressure, secure the regulator and move on to the next step.

Fine-Tuning and Verification: After making adjustments, start the engine and let it idle. Monitor the fuel pressure gauge to ensure it remains stable within the desired range. Check for any unusual noises or vibrations that might indicate improper fuel pressure. If the engine runs roughly or stalls, it may indicate too much or too little fuel pressure, respectively. Adjustments might be necessary, and you should repeat the testing process until the engine runs smoothly and consistently.

Safety Precautions: When working with fuel systems, always exercise caution. Ensure the engine is cool to prevent burns, and be mindful of any fuel spills. If you encounter any issues or are unsure about any step, consult a professional mechanic for guidance. Proper testing and adjustment of fuel pressure are vital to prevent engine performance issues and potential damage to the fuel system.

Remember, each vehicle may have unique requirements, so always refer to your vehicle's manual for specific instructions and target pressure ranges. This detailed approach to testing and adjusting fuel pressure will help ensure a reliable and efficient fuel system.

Painting Fuel Lines: A Pre-Install Guide

You may want to see also

Frequently asked questions

You will need a fuel pressure gauge, a fuel line kit, a fuel filter, a wrench, a socket, and a fuel pressure regulator. Ensure you have the correct size and type of fuel lines that match your vehicle's specifications.

The installation process typically involves mounting the regulator near the fuel tank, ensuring it is positioned where the fuel lines can be connected easily. The return line should be routed back to the fuel tank, usually via a small opening or port on the side of the tank.

Yes, in most cases, you can install the regulator and return line without completely removing the fuel tank. However, you may need to drain some fuel to access the necessary connections and ensure a proper fit.

One common issue is ensuring a tight and secure connection between the fuel lines and the regulator. Leaks can occur if the connections are not properly tightened. Additionally, check for any obstructions or interference with other components during the installation to avoid damage or improper function.