Installing a 2-line fuel pump can be a useful project for anyone looking to enhance their vehicle's fuel delivery system. This process involves connecting the pump to the fuel tank and ensuring it delivers fuel efficiently to the engine. The installation requires careful planning and attention to detail to ensure the pump operates correctly and safely. This guide will provide a step-by-step approach to help you successfully install a 2-line fuel pump, covering essential components, tools needed, and safety precautions to be taken throughout the process.

What You'll Learn

- Prepare the Vehicle: Ensure the car is parked, engine off, and fuel tank empty

- Locate the Pump: Identify the fuel pump's position, often under the car

- Disconnect Old Pump: Carefully disconnect the old pump's wiring and fuel lines

- Install New Pump: Secure the new pump, connecting fuel lines and wiring

- Test and Adjust: Start the engine, check for leaks, and adjust as needed

Prepare the Vehicle: Ensure the car is parked, engine off, and fuel tank empty

Before you begin the installation process of a two-line fuel pump, it is crucial to ensure the vehicle is in a safe and controlled environment. Start by parking the car in a well-ventilated area, preferably a garage or an open space where there are no potential hazards. This step is essential for your safety and the safety of those around you. Once parked, turn off the engine and allow it to cool down. This is particularly important if you've been driving the vehicle, as a hot engine can be dangerous and may cause fuel to vaporize, leading to potential hazards during the installation process.

Next, locate the fuel tank and ensure it is empty. This is a critical step as it allows for easy access to the fuel lines and ensures that you don't accidentally spill fuel during the installation. To empty the tank, you can either drain it manually or, if you have a fuel pump already installed, turn it off and disconnect the fuel lines to release any remaining fuel. It's important to follow safety protocols and wear protective gear, such as gloves and goggles, to prevent any fuel-related accidents.

With the fuel tank empty, you can now proceed to the next step of the installation process. Ensure that the vehicle is securely parked and stable to avoid any accidental movement during the work. This preparation phase is vital to guarantee a safe and efficient installation of the two-line fuel pump. By following these simple steps, you'll be well-prepared to tackle the installation process with confidence and minimize any potential risks.

Barbed Nylon Fuel Line: Compatibility and Installation Guide

You may want to see also

Locate the Pump: Identify the fuel pump's position, often under the car

Locate the fuel pump, which is typically positioned beneath the vehicle, often near the fuel tank. This location is chosen for easy access and to ensure the pump can efficiently draw fuel from the tank. It's important to identify the correct pump, as there may be more than one in some vehicles, especially in larger cars or trucks. The primary fuel pump is usually responsible for supplying fuel to the engine, while a secondary pump might be used for auxiliary systems like the fuel gauge or the fuel pressure regulator. Understanding the vehicle's layout and the function of each pump is crucial for a successful installation.

When you've located the pump, inspect the area for any obstructions or damage. Ensure that the pump has adequate ventilation and is not blocked by other components. The pump should be securely mounted to prevent movement during operation. Check the mounting bolts or brackets for tightness and replace any that are worn or damaged. This step is essential to guarantee the pump's stability and prevent potential issues during use.

In some cases, you might need to remove the fuel tank or related components to access the pump. This process requires careful disassembly to avoid damage to the vehicle's interior. If the pump is integrated into the fuel tank, you'll need to drain the tank and remove the tank itself to gain access. Always follow the manufacturer's guidelines for the specific vehicle you're working on to ensure a proper and safe installation.

Once the pump is accessible, you can proceed with the installation process, which typically involves connecting the fuel lines and securing the pump in its new position. Ensure that all connections are tight and secure to prevent fuel leaks. After installation, test the pump's functionality to ensure it's working correctly and providing the required fuel pressure.

Mastering the Art of Fuel Line Disconnection: A Step-by-Step Guide

You may want to see also

Disconnect Old Pump: Carefully disconnect the old pump's wiring and fuel lines

When replacing a fuel pump, the first step is to safely and methodically disconnect the old pump to ensure a smooth transition to the new setup. This process requires careful attention to detail to avoid any fuel leaks or damage to the vehicle's components.

Start by locating the old fuel pump and its associated wiring and fuel lines. The pump is typically mounted near the fuel tank, and its wiring and lines will be visible. Carefully inspect the connections to identify the power supply and fuel lines. The power supply is usually a small wire or a harness that connects to the pump's electrical terminal. The fuel lines may consist of a primary line connecting the tank to the pump and a return line to ensure a continuous fuel supply.

Using the appropriate tools, carefully disconnect the wiring. This might involve loosening screws or clips that hold the wiring harness in place. Gently pull the wires away from the pump's terminals, taking note of the color-coded wiring for future reference. Ensure you label or mark the wires to maintain the correct connections during the installation of the new pump.

Next, address the fuel lines. The primary fuel line will have a larger diameter and is usually connected to the fuel tank. Use a fuel pump primer bulb or a small pump to prime the line to remove any residual fuel. Then, carefully disconnect the line from the tank and the pump, again labeling or marking the connections for future reference. For the return line, ensure it is properly secured and connected to the new pump's return port.

Once the wiring and fuel lines are disconnected, it's crucial to inspect the old pump for any signs of damage or wear. This step ensures that the new pump will be installed in a healthy system. Properly disposing of or recycling the old pump components is essential for environmental reasons and to maintain a clean workspace.

Thawing Diesel Fuel Lines: Quick Tips for Cold Weather

You may want to see also

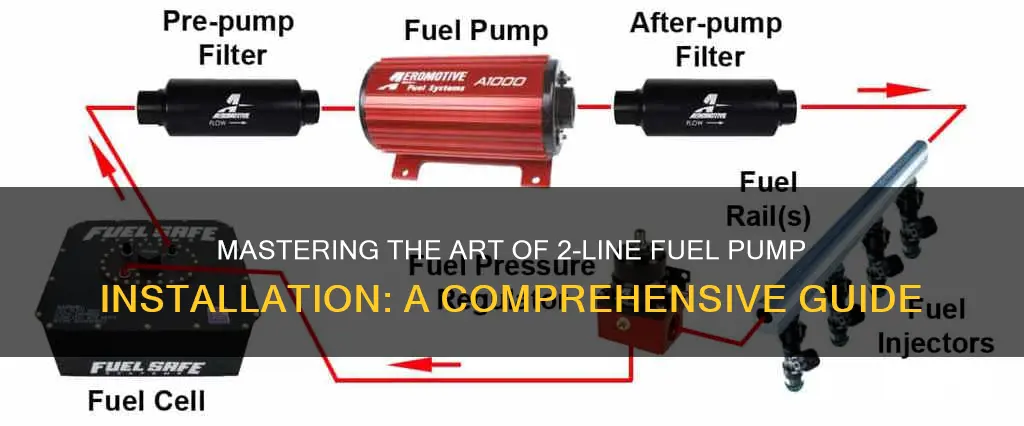

Install New Pump: Secure the new pump, connecting fuel lines and wiring

Before you begin the installation, ensure you have the necessary tools and components, including the new fuel pump, fuel lines, wiring harnesses, and any required fasteners. It's crucial to have a well-lit and spacious work area to facilitate the process.

Start by locating the old fuel pump and its mounting bracket. Carefully remove the old pump and set it aside. Identify the mounting holes on the engine block or the designated mounting surface. Secure the new fuel pump using the appropriate fasteners. Ensure the pump is positioned correctly and securely attached to avoid any movement during operation.

Next, connect the fuel lines. The new pump will typically have two fuel lines: one for the low-pressure side and another for the high-pressure side. Attach the low-pressure line to the low-pressure port on the pump and secure it with a clamp or a fitting. Similarly, connect the high-pressure line to the high-pressure port and fasten it accordingly. Make sure the connections are tight and there are no leaks.

Now, it's time to wire the fuel pump. Locate the wiring harness and identify the correct wires for power and ground. Connect the power wire to the positive terminal of the fuel pump's electrical connector and secure it in place. Similarly, connect the ground wire to the appropriate ground point on the engine or the fuel tank. Ensure all connections are tight and insulated to prevent any short circuits.

Finally, double-check all connections and secure any loose components. Test the fuel pump's functionality by starting the engine and monitoring the fuel flow. Ensure that the pump operates smoothly and delivers fuel to the engine as expected. If everything is in order, you can now proceed with the final steps of your installation process.

Understanding Marine Fuel Lines: A Comprehensive Guide

You may want to see also

Test and Adjust: Start the engine, check for leaks, and adjust as needed

Once you've installed the 2-line fuel pump, it's crucial to test and adjust its performance to ensure optimal functionality. Here's a step-by-step guide to help you through this process:

Starting the Engine: Begin by starting the engine. This initial test will give you an idea of the pump's ability to deliver fuel. Turn the ignition key to the 'on' position, ensuring the engine doesn't start immediately. You might need to prime the pump by slightly accelerating the engine or using the throttle body to create a vacuum. Once the engine starts, let it run for a few minutes to allow the fuel system to stabilize.

Checking for Leaks: After the engine has been running for a while, it's time to inspect for any leaks. Park the vehicle on a level surface and engage the parking brake. Check the fuel lines and connections for any signs of fuel leakage. Pay close attention to the pump's housing and the connections between the pump, the fuel filter, and the fuel rails or injectors. If you notice any fuel dripping or pooling, it indicates a potential leak, and you should address it immediately.

Adjustments: If there are no leaks, the next step is to make any necessary adjustments to optimize the fuel delivery. Adjust the fuel pressure regulator if you have one. This component controls the pressure of the fuel entering the engine. You can typically adjust it by turning a screw or using a tool provided with the pump. The goal is to achieve the manufacturer's recommended fuel pressure. Additionally, check the fuel filter and replace it if it appears clogged or dirty. A clean fuel filter ensures that contaminants don't enter the engine, promoting better performance.

Fine-Tuning: During this adjustment phase, you might also want to fine-tune the fuel pump's performance. This could involve checking and adjusting the timing of the pump's operation. Some fuel pumps have adjustable timing, allowing you to optimize the fuel delivery based on engine speed. Consult the pump's manual or online resources for specific instructions on adjusting the timing.

Remember, proper testing and adjustment are essential to guarantee the fuel pump's longevity and the overall performance of your vehicle's fuel system. Always refer to the manufacturer's guidelines and seek professional advice if you're unsure about any step during this process.

Challenger RT Fuel Lines: A 1970s Classic's Fuel System Breakdown

You may want to see also