A leaking fuel line can be a serious issue, but there are temporary solutions to keep your vehicle running until a more permanent fix can be implemented. This guide will provide a step-by-step approach to addressing a leaking fuel line, ensuring you can safely and effectively manage the problem until you can seek professional help.

What You'll Learn

- Identify the leak: Locate the damaged section of the fuel line using a visual inspection and a fuel odor

- Temporary seal: Wrap the leak with a rubber hose clamp or electrical tape for an immediate stopgap

- Use a fuel line repair kit: Apply a temporary fix with a kit that includes a sealant and a clamp

- Secure with a clamp: Tighten a hose clamp firmly around the leak to hold the line in place

- Temporary bypass: Route the fuel line around the leak and secure it with a clamp until a permanent fix is made

Identify the leak: Locate the damaged section of the fuel line using a visual inspection and a fuel odor

When dealing with a temporary fix for a leaking fuel line, the first crucial step is to identify the exact location of the leak. This process involves a careful visual inspection and an understanding of the fuel line's path within the vehicle. Start by examining the fuel line for any visible signs of damage, such as cracks, punctures, or frayed sections. These visual cues can often indicate where the leak is originating from. Look for any discolored or wet areas along the line, as these could be signs of fuel leakage. Pay close attention to the areas where the fuel line connects to the engine, as these points are common sources of leaks.

In addition to visual inspection, you can use your sense of smell to assist in the identification process. Fuel lines carry gasoline or diesel, and a strong, distinct odor of fuel can indicate a leak. If you notice a sweet or gasoline-like smell around the fuel line, it's a strong indicator that there is a leak present. This method is particularly useful if the leak is not immediately visible.

If you're unable to pinpoint the exact location of the leak with the naked eye, consider using a fuel-safe dye or a temporary sealant. Add a small amount of fuel-safe dye to the fuel tank and start the engine. The dye will flow through the fuel system, allowing you to visually identify the path of the fuel. Any section that appears discolored or has a visible dye trail is likely the damaged area. Alternatively, you can temporarily seal the fuel line with a non-permanent sealant, which can provide a quick fix to contain the leak while you plan for a more permanent solution.

Remember, this temporary fix is just that—temporary. It's essential to address the underlying issue promptly to prevent further damage and ensure the vehicle's safe operation. Once the damaged section is identified, you can proceed with the appropriate repairs or replacements to ensure the fuel line's integrity.

Mastering GM Fuel Line Disconnect Wrench Sizes: A Comprehensive Guide

You may want to see also

Temporary seal: Wrap the leak with a rubber hose clamp or electrical tape for an immediate stopgap

If you find yourself dealing with a leaking fuel line, it's important to act quickly to prevent further damage and potential safety hazards. While a permanent solution is ideal, a temporary fix can provide immediate relief until you can get the issue properly addressed. One simple and effective method is to use a rubber hose clamp or electrical tape to seal the leak.

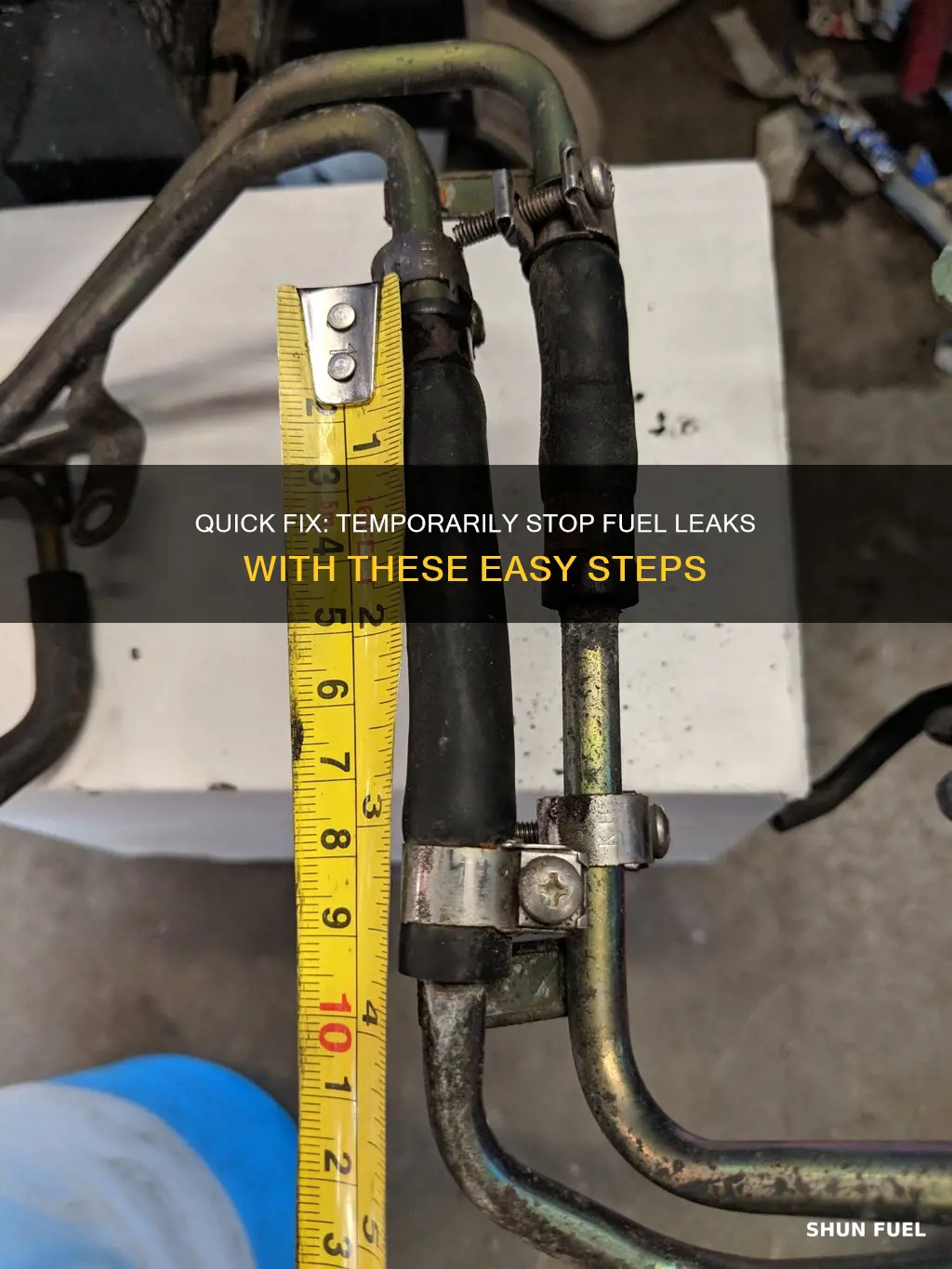

For the hose clamp method, start by ensuring the clamp is the right size for the fuel line. You want it to be snug but not too tight, as this could restrict flow. Locate the leak and position the clamp directly over it. Tighten the clamp firmly, making sure it covers the entire damaged area. This physical barrier will prevent fuel from escaping and provide a temporary seal. Remember to test the clamp's effectiveness by gently pressing around the area to ensure no fuel seeps through.

Electrical tape, commonly known as duct tape, can also be utilized for this purpose. Cut a piece of tape slightly wider than the leak, ensuring it's long enough to completely cover the damaged section. Carefully apply the tape, starting at one end and overlapping it slightly as you work your way around the leak. Press the tape firmly to create a tight seal. This method is particularly useful for quick fixes, as electrical tape is readily available and easy to apply.

Both of these temporary solutions are best used as a stopgap measure. They provide an immediate fix, allowing you to safely transport your vehicle or equipment to a mechanic for a more permanent repair. It's crucial to remember that these fixes are not meant to be long-term solutions. The underlying issue causing the leak must be addressed by a professional to ensure the safety and reliability of your fuel system.

Understanding the Key Differences: Heet Gas vs. Fuel Lines

You may want to see also

Use a fuel line repair kit: Apply a temporary fix with a kit that includes a sealant and a clamp

A fuel line repair kit is a handy tool to have in your automotive toolbox when faced with a temporary fix for a leaking fuel line. These kits are designed to provide a quick and effective solution to contain the issue until a more permanent repair can be carried out. The primary components of such a kit typically include a high-quality sealant and a sturdy clamp.

When you purchase a fuel line repair kit, you'll find that it is often compact and easy to store in your vehicle. The kit's contents are carefully selected to ensure they can be used in various fuel line repair scenarios. The sealant is a critical element, as it is designed to create a strong, flexible bond that can withstand the pressure and heat associated with fuel lines. This sealant is typically applied directly to the damaged area, filling any gaps or holes to prevent further leaks.

The clamp, another essential part of the kit, serves to secure the sealant in place. It is made from durable materials to ensure it can withstand the rigors of the fuel system. This clamp is designed to be easy to use, often featuring a simple tightening mechanism that allows for a secure and tight fit around the fuel line. By combining the sealant and clamp, the repair kit provides a robust temporary fix.

To apply this temporary fix, start by cleaning the damaged area of the fuel line to ensure the sealant has a good surface to adhere to. Then, carefully follow the instructions provided with the kit to apply the sealant, ensuring it is applied evenly and in sufficient quantity. Once the sealant is set, position the clamp over the sealed area and tighten it securely. This process will create a reliable barrier that prevents fuel from leaking.

It's important to remember that this is a temporary solution, and a more permanent repair should be sought as soon as possible. However, the fuel line repair kit can provide peace of mind and ensure your vehicle remains safe and functional until professional assistance is available. Always follow the manufacturer's guidelines for the specific kit you use to ensure the best results.

The Ultimate Guide to Choosing the Right Hose Clamp for Your 3/8" Outboard Fuel Line

You may want to see also

Secure with a clamp: Tighten a hose clamp firmly around the leak to hold the line in place

If you're dealing with a temporary fix for a leaking fuel line, one of the most straightforward and effective methods is to secure the line with a hose clamp. This simple technique can provide a quick solution to contain the leak and prevent further fuel loss. Here's a step-by-step guide on how to do it:

Start by ensuring you have the right tools and materials. You'll need a hose clamp, which is a type of metal or rubber clamp designed to secure hoses and pipes. Choose a clamp that is slightly larger than the diameter of the fuel line to ensure a snug fit. Additionally, have a pair of pliers or a wrench handy to tighten the clamp effectively.

Locate the leaking section of the fuel line. Carefully inspect the line to identify the source of the leak. It could be a small puncture, a crack, or a loose connection. Once you've identified the problem area, prepare the hose clamp by ensuring it is clean and free of any debris.

Place the hose clamp around the leaking fuel line, positioning it directly over the leak. Make sure the clamp is centered and aligned properly. Then, using the pliers or wrench, tighten the clamp firmly. Apply steady pressure to ensure it is secure and will not come loose. The goal is to create a tight seal that holds the fuel line in place, effectively stopping the leak.

After tightening the clamp, check the pressure and ensure there is no further fuel leakage. You might need to adjust the clamp's position slightly to find the optimal fit. Once satisfied, you can consider this temporary fix complete. Remember, this method is best for short-term use, and it's crucial to have the leaking section of the fuel line repaired or replaced as soon as possible to ensure the safety and reliability of your vehicle's fuel system.

Fuel Line Removal: A Guide for 87 Crown Victoria Owners

You may want to see also

Temporary bypass: Route the fuel line around the leak and secure it with a clamp until a permanent fix is made

When faced with a leaking fuel line, a temporary bypass can be a quick and effective solution to prevent further fuel loss and potential engine damage. This method involves redirecting the fuel flow around the damaged area, ensuring that the fuel continues to reach the engine without the leak. Here's a step-by-step guide on how to achieve this:

Locate the leak: Start by identifying the exact spot where the fuel line is leaking. This could be a small puncture, a crack, or a loose connection. Understanding the source of the leak is crucial for a successful temporary fix.

Prepare the necessary tools: You'll need a few essential items for this repair. First, get a length of fuel line that is slightly longer than the damaged section. Ensure it is compatible with the existing fuel line material. Additionally, have a fuel line clamp or a suitable hose clamp ready, which will be used to secure the bypass.

Create the bypass: Carefully cut the fuel line a few inches away from the leak, creating a clean and straight cut. Then, take the new length of fuel line and connect it to the original line, ensuring a secure and tight fit. Route the new line around the leak, preferably in a way that avoids any sharp bends or kinks, as these can cause further issues. Secure the connection with the hose clamp, tightening it firmly but being careful not to overtighten, as this can damage the fuel line.

Test the bypass: After securing the bypass, start the engine and monitor the fuel flow. Check for any signs of continued leakage and ensure that the engine runs smoothly. This temporary fix should provide a reliable solution until a more permanent repair can be carried out.

Remember, this is a temporary measure, and it's essential to address the root cause of the leak as soon as possible. A professional mechanic should be consulted for a permanent solution to ensure the safety and reliability of your vehicle's fuel system.

Understanding Fuel Crossovers: A Comprehensive Guide to Efficient Systems

You may want to see also

Frequently asked questions

In the event of a leaking fuel line, there are a few quick fixes to consider. Firstly, you can use a fuel line clamp to secure the line and prevent further leakage. Ensure the clamp is the correct size and fits snugly around the line. Alternatively, if the leak is minor, you can try wrapping the affected area with electrical tape or duct tape. This provides a temporary seal, but it's important to note that this method is not a long-term solution and should be replaced with a proper repair as soon as possible.

While it's not the most effective or safe method, using a rubber band to hold the fuel line in place might provide a temporary stopgap. However, it is crucial to understand that this approach is not recommended for several reasons. Rubber bands can stretch and lose their grip over time, leading to potential fuel leakage. Additionally, the heat generated by the engine or exposure to sunlight might cause the rubber to degrade, resulting in a more significant issue. It's always best to use specialized tools and materials designed for fuel line repairs.

If the fuel line is severely damaged and the leak is substantial, it is essential to address the issue immediately. Do not attempt a temporary fix in this case. Instead, locate the nearest safe area and shut off the fuel supply to the engine. Contact a professional mechanic or a repair shop to have the fuel line replaced or repaired. Attempting to fix a major leak without proper expertise and tools can be dangerous and may lead to further complications, including potential fires or explosions.