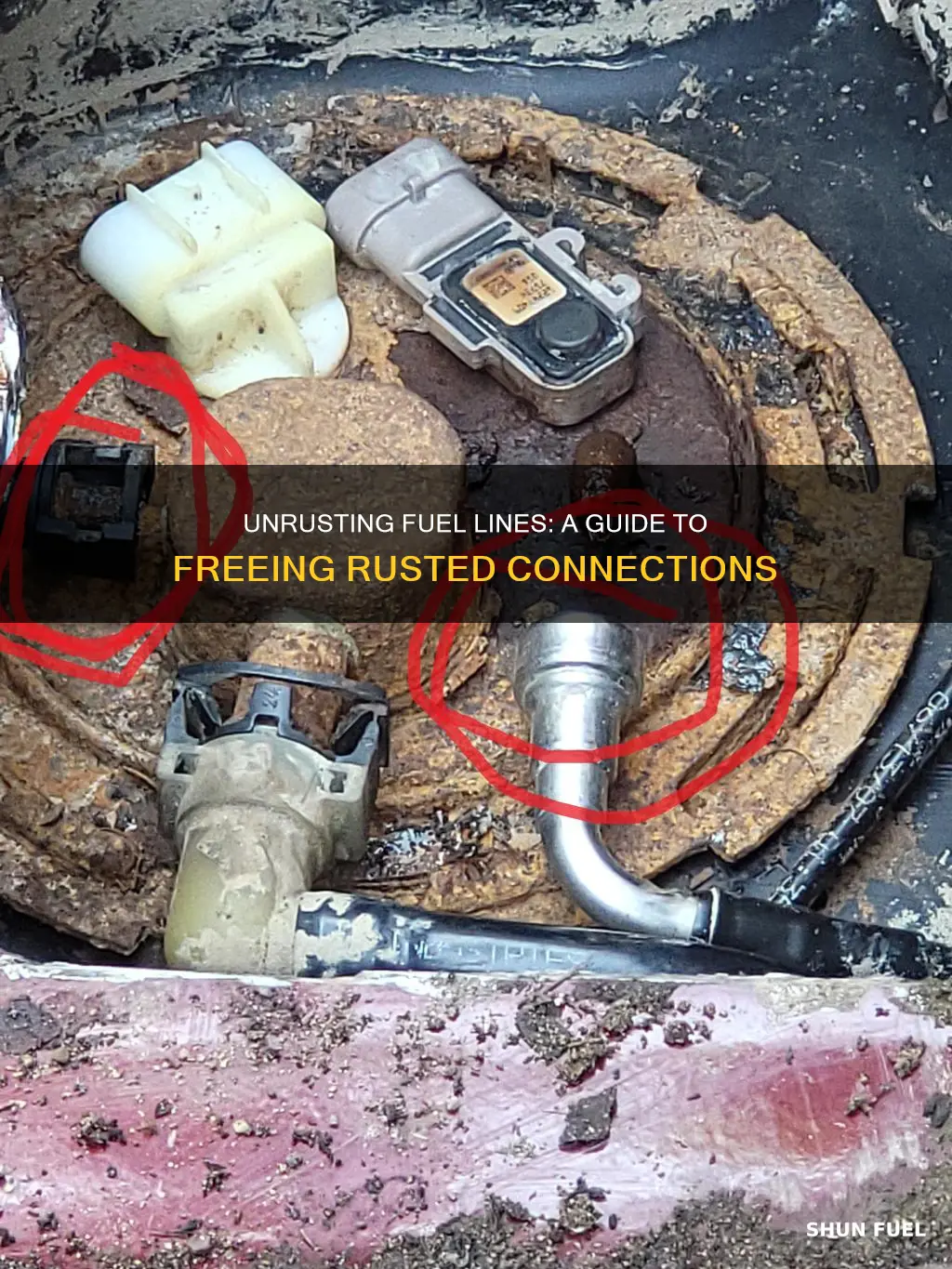

Freeing a rusted fuel line connection can be a challenging task, but with the right tools and techniques, it's definitely achievable. This guide will provide a step-by-step approach to safely and effectively remove rust and corrosion from the fuel line, ensuring a secure and reliable connection. We'll cover essential safety precautions, the necessary tools, and methods to clean and protect the fuel line, allowing you to restore its functionality and maintain your vehicle's performance.

What You'll Learn

- Safety First: Wear gloves, goggles, and protective clothing to avoid injury from rust and fuel

- Prepare the Line: Disconnect the line, drain fuel, and clean rust with a wire brush

- Use a Lubricant: Apply a suitable lubricant to the inner surface of the line to prevent sticking

- Reattach Carefully: Reinsert the line, ensuring a tight, secure connection, and avoid over-tightening

- Test Thoroughly: Check for leaks, pressure, and functionality before using the fuel line

Safety First: Wear gloves, goggles, and protective clothing to avoid injury from rust and fuel

When dealing with rusted fuel lines, prioritizing safety is paramount. Rusted fuel lines can be hazardous due to the potential for fuel leaks and the risk of injury from sharp edges or broken pieces. Here's a detailed guide on how to safely tackle this issue:

Personal Protective Equipment (PPE): Before you begin any work, ensure you have the necessary safety gear. Always wear gloves to protect your hands from sharp edges and potential fuel contact. Opt for heavy-duty gloves designed for mechanical work, offering both durability and grip. Additionally, safety goggles are essential to shield your eyes from any debris, rust particles, or potential fuel splashes. Consider wearing a full-face respirator mask to avoid inhaling any hazardous fumes that may be present.

Protective Clothing: Covering your body is crucial to minimize the risk of injury. Wear long sleeves and pants to protect your skin from sharp objects and potential fuel spills. Opt for clothing made from breathable materials to ensure comfort during prolonged work. Consider wearing a full-body apron or coverall for added protection, especially if you anticipate coming into contact with heavy rust or fuel.

Work Environment: Ensure you are working in a well-ventilated area, preferably outdoors, to minimize the risk of fuel inhalation. Keep a fire extinguisher nearby as a precaution, especially when dealing with fuel. It's also a good idea to have a bucket of water or a fire blanket readily available in case of emergencies.

Precautionary Measures: Before starting, inspect the fuel line for any visible signs of damage or corrosion. If the line is severely rusted or damaged, it may be best to consult a professional mechanic to avoid further complications. Always work carefully to avoid applying excessive force, as this can lead to fuel line breakage or damage.

Remember, taking these safety precautions is essential to ensure your well-being and the success of your project. By wearing the appropriate protective gear, you can effectively manage the risks associated with rusted fuel lines and complete the task with confidence.

Fitting the Right Fuel Line: 2004 F150 Fuel Filter Guide

You may want to see also

Prepare the Line: Disconnect the line, drain fuel, and clean rust with a wire brush

To begin the process of freeing a rusted fuel line connection, you must first ensure that the line is properly prepared. Start by disconnecting the fuel line from the fuel tank or the engine. This step is crucial as it allows you to work on the line without the risk of fuel spillage or damage to the engine. Use a suitable fuel line disconnect tool or a pair of pliers to carefully separate the line from its connection points. Once disconnected, place the line in a secure location to prevent any accidental contact with the ground or other surfaces.

Next, it is essential to drain any remaining fuel from the line. This step helps to prevent further corrosion and ensures that the line is free of any residual fuel that could cause issues during the cleaning process. Locate the fuel line's drain valve, which is typically found near the fuel tank or the engine. Open the valve and allow the fuel to flow out into a suitable container. Ensure that you catch any fuel that drips from the line to avoid wastage and potential hazards.

Now, focus on cleaning the rust from the fuel line. Rust can be stubborn and may require some effort to remove. Start by using a wire brush, preferably a steel wire brush with a handle, to scrub the inside of the fuel line. Begin at the point of disconnection and work your way along the length of the line. Apply firm pressure and move the brush in a circular motion to loosen and remove the rust. Take care not to damage the inner walls of the line, as this could lead to fuel leaks. If the rust is particularly stubborn, you may need to repeat the brushing process or use a stronger cleaning agent.

As you clean, keep an eye out for any signs of damage or wear and tear in the fuel line itself. Over time, the line can develop cracks or small holes due to corrosion or general wear. If you notice any such issues, it is best to replace the fuel line to ensure a safe and efficient fuel supply. Additionally, consider using a rust inhibitor or a protective coating to prevent future corrosion, especially if the line will be exposed to the elements.

Once you have thoroughly cleaned the fuel line and removed all visible rust, it is essential to inspect the line for any remaining corrosion or damage. Reattach the fuel line to the fuel tank or engine, ensuring a secure and tight connection. Test the line by starting the engine and checking for any leaks. If everything is in order, you can now reconnect the fuel line to the rest of the fuel system, completing the preparation process.

Fuel Line Connection: DIY Tips for a Seamless Installation

You may want to see also

Use a Lubricant: Apply a suitable lubricant to the inner surface of the line to prevent sticking

If you're dealing with a stubbornly rusted fuel line connection, one effective method to free it up is by using a lubricant. This technique is particularly useful when the rust has caused the connection to become tight and difficult to disconnect. Here's a step-by-step guide on how to proceed:

Start by acquiring a suitable lubricant. There are various options available, such as white lithium grease, petroleum jelly, or even a specialized fuel line cleaner. Choose a product that is compatible with your fuel system and ensure it is designed for the specific application of rust removal and prevention.

Once you have the lubricant, it's time to apply it. Clean the inner surface of the fuel line where it connects to the fuel pump or filter. Use a clean cloth or rag to wipe away any loose rust particles, ensuring a smooth and clean surface. Then, generously coat the inner diameter of the fuel line with the lubricant. Make sure to cover the entire length of the connection, paying extra attention to any particularly rusted areas.

The lubricant acts as a protective barrier, preventing the rusted surfaces from sticking together. By applying it, you create a slippery layer that allows the fuel line to move freely without the resistance caused by rust. This method is often successful in freeing up stubborn connections and can be a quick fix for minor rust-related issues.

After applying the lubricant, allow it to sit for a short period, usually a few minutes, to ensure it has a chance to work its way into the rusted areas. Then, attempt to disconnect the fuel line. The lubricant should make the process smoother, and you may find that the connection comes apart more easily than before. Remember to wipe away any excess lubricant to prevent mess and potential contamination of the fuel system.

Optimizing Performance: Choosing the Right Fuel Line for Your Go Devil Engine

You may want to see also

Reattach Carefully: Reinsert the line, ensuring a tight, secure connection, and avoid over-tightening

Reattaching a fuel line that has become rusted and stuck can be a delicate process, and it requires patience and careful execution to ensure a secure and leak-free connection. Here's a step-by-step guide to help you through this task:

Step 1: Preparation

Before you begin, make sure you have the necessary tools, including a fuel line cleaner, a lubricant (such as white lithium grease), a pair of channel locks or a wrench, and a rag or cloth. Clean the fuel line and the connection points thoroughly to remove any dirt, rust, or debris. This step is crucial to ensure a proper bond between the new connection and the existing line.

Step 2: Reinserting the Line

Take the fuel line and carefully reinsert it into the connection port. Ensure that the line is aligned correctly and that the male and female ends are properly aligned. You want to create a tight, secure fit, but be cautious not to force it. Use your hands or a pair of channel locks to gently tighten the connection. Apply steady pressure and feel for the connection to click or snap into place. This indicates a secure attachment.

Step 3: Avoid Over-Tightening

It's important to distinguish between a secure connection and over-tightening. Over-tightening can damage the fuel line, causing cracks or permanent deformation. If you feel excessive resistance or hear a loud snap, you've likely over-tightened. In this case, carefully back off the connection slightly and try again, ensuring you maintain a gentle, controlled force. The goal is to achieve a snug fit without applying excessive pressure.

Step 4: Testing and Verification

Once you've reattached the fuel line, it's essential to test the connection. Turn on the fuel supply and check for any leaks. Inspect the connection point for any signs of damage or excessive movement. If everything appears secure and there are no leaks, you've successfully reattached the fuel line.

Remember, taking your time and being gentle during the reattachment process will help ensure a long-lasting and reliable connection. Always prioritize safety and avoid forcing connections to prevent any potential damage to the fuel line or surrounding components.

Echo PB 200 Fuel Line Size: A Comprehensive Guide

You may want to see also

Test Thoroughly: Check for leaks, pressure, and functionality before using the fuel line

Before reassembling or using a fuel line that has been affected by rust, it is crucial to perform a thorough test to ensure its integrity and prevent potential issues. Here's a step-by-step guide on how to test the fuel line for leaks, pressure, and functionality:

Leak Detection: Start by inspecting the fuel line for any visible signs of damage or corrosion. Look for cracks, holes, or areas where the line has separated from its fittings. If you notice any damage, it's essential to replace the affected section. Next, use a soapy water solution as a leak detection method. Apply the solution to all connections and fittings, including the fuel pump, fuel tank, and any valves or sensors in the line. If you see bubbles forming, it indicates a leak. This simple test can help you identify weak points in the fuel line that may need repair or replacement.

Pressure Testing: Fuel lines should be able to withstand the pressure of the fuel system. To test this, you can use a pressure gauge and connect it to the fuel line. Ensure the engine is off and the fuel pump is not running. Apply pressure gradually and check for any leaks or signs of damage. The pressure should be within the recommended range specified by the vehicle manufacturer. If the pressure is too low, it might indicate a blockage or a damaged section of the line. Conversely, excessive pressure could suggest a weak connection or a potential failure point.

Functionality Check: After ensuring there are no leaks, it's time to test the fuel line's functionality. Start the engine and monitor its performance. Check for any unusual noises, such as hissing or whistling, which could indicate a leak. Listen for any abnormal sounds coming from the fuel line, as these might be signs of damage or disconnection. Additionally, observe the engine's behavior. A healthy fuel line should supply the engine with the required fuel volume and pressure, resulting in smooth operation and optimal performance. If the engine stalls, surges, or exhibits erratic behavior, it may indicate a problem with the fuel line's functionality.

Visual Inspection: While testing, pay close attention to the overall condition of the fuel line. Look for any signs of rust or corrosion that might have accumulated during the rusting process. Remove any visible rust deposits and ensure the line is clean and free of debris. Check for any bends or kinks in the line, as these can affect the flow of fuel and potentially cause issues during operation.

Remember, thorough testing is essential to ensure the fuel line is safe and functional. By following these steps, you can identify and address any issues before reassembling the fuel system, ultimately preventing potential problems and ensuring the vehicle's performance and reliability.

Craftsman Chainsaw Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Frequently asked questions

To address a rusted fuel line connector, start by soaking the affected area in a mixture of white vinegar and water. This will help dissolve the rust. After soaking, use a wire brush or a rust remover tool to scrub away the rust and any remaining debris. Ensure you wear protective gear, like gloves and goggles, during this process. Once cleaned, apply a lubricant to the connector to make it easier to reconnect.

Yes, using a heat gun can be an effective method. Apply the heat gun to the rusted area, keeping it in motion to avoid overheating the surrounding metal. The heat will cause the rust to loosen and flake off. Be cautious not to overheat the connector, as it may damage the fuel line. After removing the rust, clean the area thoroughly and apply a rust inhibitor to prevent future issues.

Absolutely! There are various chemical rust removers available that can be highly effective. Look for products containing phosphoric acid or citric acid, which are commonly used for this purpose. Follow the manufacturer's instructions carefully, as these chemicals can be corrosive. Wear protective clothing and ensure proper ventilation when using these products. After treatment, rinse the fuel line thoroughly to remove any residue.

Regular maintenance and cleaning are key to preventing rust. Keep the fuel lines and connectors clean by using a fuel line cleaner or a mild detergent. Ensure the fuel lines are dry after cleaning to avoid moisture-related rust. Applying a thin layer of rust-inhibiting oil or grease to the connectors can also provide protection. Additionally, consider using fuel line covers or protective sleeves to shield the lines from environmental factors.

In some cases, yes. If the rust has caused significant damage to the connector, leading to cracks or holes, it may be best to replace the entire fuel line. Rust can compromise the integrity of the fuel system, potentially causing leaks or engine performance issues. However, if the damage is minimal, you can focus on removing the rust and reinstalling the connector with proper maintenance to prevent further issues.