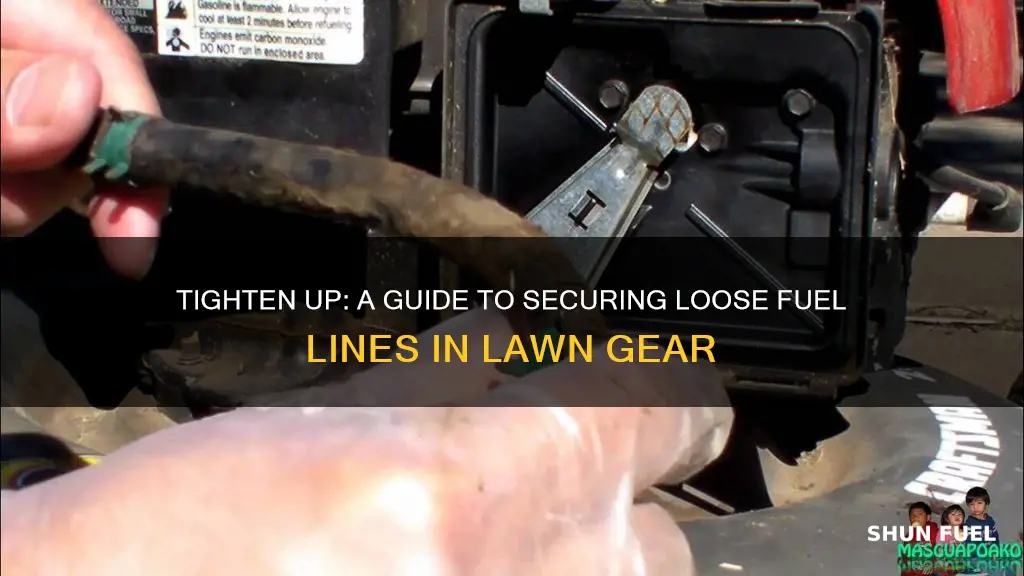

Fixing loose fuel lines in lawn equipment is a common task that can help ensure the efficient and safe operation of your outdoor power tools. Over time, fuel lines can become loose due to vibration, wear, or improper installation. This can lead to fuel leaks, engine misfires, or even dangerous situations. By following a few simple steps, you can effectively tighten and secure the fuel lines, restoring the performance of your lawnmowers, trimmers, or other equipment. This guide will provide a step-by-step approach to identifying and resolving loose fuel lines, ensuring your lawn care equipment runs smoothly and reliably.

What You'll Learn

Identify loose fuel lines with visual inspection

A visual inspection is a crucial step in identifying loose fuel lines in lawn equipment, ensuring optimal performance and safety. Here's a detailed guide on how to perform this inspection:

Start by turning off the equipment and allowing it to cool down. Safety should always be the top priority. Inspect the fuel lines for any visible signs of damage, wear, or looseness. Look for cracks, punctures, or any discolored areas along the length of the fuel lines. These could indicate potential issues. Check for any bends or kinks in the lines, especially where they connect to the fuel tank and the engine. Smooth, straight lines are ideal, and any deviations could lead to fuel leaks or reduced performance.

Pay close attention to the connections. Over time, fuel lines can become loose at their attachments, leading to potential hazards. Ensure that all connections are tight and secure. You might need to use a wrench or a fuel line tool to tighten them further. Look for any signs of corrosion or rust around the connections, as this can also cause looseness and potential fuel leaks.

Examine the fuel lines for any visible signs of deterioration. Sun exposure, temperature fluctuations, and general wear can take a toll on the lines over time. Check for any soft or brittle sections, as these may need to be replaced. Also, inspect the fuel tank for any visible damage or leaks, as this could be a result of loose fuel lines.

If you notice any of the above issues during your inspection, it's essential to address them promptly. Loose or damaged fuel lines can lead to fuel leaks, engine misfires, or even dangerous situations. Regular visual inspections can help prevent these problems and ensure your lawn equipment operates efficiently and safely. Remember, if you're unsure about any aspect of the inspection or repair process, it's always best to consult a professional.

Fixing the 2005 Chevy Blazer's Fuel Line: A Step-by-Step Guide

You may want to see also

Secure fuel lines with appropriate clamps

When dealing with loose fuel lines on lawn equipment, one of the most effective and straightforward solutions is to secure them with the right type of clamps. This method ensures a tight and reliable connection, preventing fuel leaks and potential hazards. Here's a step-by-step guide on how to achieve this:

Step 1: Identify the Clamp Type

Start by identifying the type of clamp that suits your fuel line. Different fuel lines have varying diameters, so it's crucial to choose the appropriate clamp. Common types include hose clamps, also known as spring clamps, and band clamps. Hose clamps are typically used for smaller fuel lines, while band clamps are more suitable for larger diameters. Ensure you select a clamp that fits the fuel line snugly without causing damage.

Step 2: Gather the Necessary Tools

You'll need a few essential tools to secure the fuel lines effectively. A pair of pliers or a clamp tool will help you apply the necessary pressure to tighten the clamp. Additionally, a wire brush or a small brush can be useful for cleaning the fuel line and removing any debris before clamping.

Step 3: Locate the Loose Fuel Line

Locate the section of the fuel line that is loose or disconnected. Carefully inspect the area to ensure there are no visible signs of damage or corrosion. Clean the fuel line and the surrounding area to ensure a proper connection.

Step 4: Apply the Clamp

Place the chosen clamp over the fuel line, ensuring it is centered and aligned with the fuel line's diameter. Use the pliers or clamp tool to tighten the clamp securely. Start by applying gentle pressure and gradually increase it until the clamp is snug and firm. Avoid over-tightening to prevent damage to the fuel line.

Step 5: Test and Inspect

After securing the clamp, test the fuel line's integrity by checking for any leaks. Run the lawn equipment and monitor for any unusual noises or signs of fuel escaping. If everything is functioning correctly, inspect the clamp to ensure it is firmly in place and not at risk of loosening over time.

By following these steps, you can effectively secure loose fuel lines with appropriate clamps, ensuring the safe and efficient operation of your lawn equipment. Regular maintenance and inspection of fuel lines are essential to prevent potential issues and maintain optimal performance.

Mastering Copper Fuel Lines: A Comprehensive Guide

You may want to see also

Use fuel line connectors for a tight fit

When dealing with loose fuel lines on lawn equipment, one effective solution is to utilize fuel line connectors. These connectors are designed to provide a secure and tight fit, ensuring that the fuel lines remain firmly in place. By employing this method, you can effectively address the issue of loose connections and prevent potential fuel leaks, which can be both dangerous and detrimental to the performance of your lawn equipment.

The process of using fuel line connectors is straightforward and can be accomplished with a few simple steps. Firstly, ensure that the fuel lines are clean and free from any debris or contaminants. This is crucial to guarantee a proper connection. Next, prepare the fuel line connectors by cleaning them and ensuring they are in good condition. Look for any signs of damage or wear, and replace them if necessary.

Now, it's time to connect the fuel lines. Start by aligning the connectors with the fuel lines, ensuring that they match the specific size and type of your equipment. Carefully slide the connectors onto the fuel lines, making sure they are fully inserted and seated correctly. Apply firm pressure to the connectors to create a tight seal, ensuring that there is no movement or play in the connection.

For optimal results, consider using fuel line connectors with a locking mechanism. These connectors often feature a bayonet or screw-lock design, providing an extra layer of security. By engaging the locking mechanism, you can further reinforce the connection, making it even more resistant to movement and potential fuel leaks. This added feature is particularly useful for outdoor equipment that may be exposed to varying environmental conditions.

In summary, using fuel line connectors is a practical and reliable method to fix loose fuel lines in lawn equipment. It ensures a tight fit, prevents fuel leaks, and promotes the overall safety and performance of your outdoor power tools. By following these simple steps and investing in quality connectors, you can effectively resolve the issue of loose fuel lines and maintain the efficiency of your lawn care equipment.

Can Fuel Lines Be Used as Vacuum Lines?

You may want to see also

Tighten fuel line fittings with wrenches

When dealing with loose fuel lines on lawn equipment, tightening the fittings with a wrench is a crucial step to ensure a secure and safe connection. Here's a step-by-step guide to help you through this process:

Step 1: Gather the Right Tools

Before you begin, ensure you have the necessary tools. You'll need a wrench that fits the size of the fuel line fittings. Wrenches come in various sizes, so it's essential to measure the fittings to determine the appropriate size. Additionally, have a pair of pliers or a fuel line tool kit, which can provide better grip and control during the tightening process.

Step 2: Locate the Fuel Line Fittings

Identify the loose fuel line fittings on your lawn equipment. These fittings are typically located where the fuel line connects to the engine or other components. Carefully inspect the fittings for any signs of damage, corrosion, or wear, as these issues may require additional attention.

Step 3: Prepare the Wrench

Place the wrench over the fuel line fitting, ensuring it is positioned correctly and securely around the fitting. Apply firm pressure to the wrench handle to begin tightening. Start with a gentle force and gradually increase it, being careful not to overtighten. Tighten the fitting until it is snug and secure, but be cautious not to strip the threads or damage the fitting.

Step 4: Check for Leaks

After tightening the fittings, it's crucial to check for any leaks. Turn on the lawn equipment's fuel supply and observe for any signs of fuel escaping. If you notice any leaks, carefully inspect the fittings and connections to identify the source. Tighten the affected fittings further or consider replacing damaged components to resolve the issue.

Step 5: Reassemble and Test

Once you've tightened all the loose fittings and addressed any leaks, reassemble the lawn equipment. Ensure all components are correctly aligned and secured. Then, start the equipment and let it run for a while. Monitor the engine's performance and listen for any unusual noises. If the engine runs smoothly and there are no leaks, your fuel line tightening task is complete.

Remember, when working with fuel lines, always prioritize safety. Wear protective gear, such as gloves and safety goggles, to avoid any potential hazards. If you're unsure about any step or encounter complex issues, consult a professional or refer to the equipment's manual for specific guidance.

Fuel Return Line Exit: Unveiling the Passenger Side Mystery

You may want to see also

Replace damaged fuel lines for long-term fix

When dealing with loose or damaged fuel lines on lawn equipment, replacing them is often the most effective long-term solution. Fuel lines can become loose over time due to wear and tear, exposure to the elements, or improper installation. Here's a step-by-step guide to help you replace damaged fuel lines and ensure your lawn equipment runs smoothly again.

Step 1: Identify the Problem

Before you begin, carefully inspect the fuel lines on your lawn equipment. Look for any signs of damage, such as cracks, leaks, or areas where the line has become detached from the fuel tank or engine. Identify the specific section of the line that needs replacement.

Step 2: Gather the Necessary Tools and Materials

You'll need a few essential tools and materials to replace the fuel lines:

- New fuel lines of the appropriate length and diameter for your equipment. Ensure they are compatible with your specific model.

- Fuel line connectors or fittings that match the old ones.

- A fuel filter (if your equipment uses one).

- A fuel pump (if the old one is faulty).

- A small wrench or pliers for tightening connections.

- Cleaning supplies, such as a brush or cloth, for preparing the fuel lines.

Step 3: Drain the Fuel Tank

Safety should always be a priority. Before replacing the fuel lines, drain the fuel tank to prevent any spills or accidents. Locate the drain valve and open it to allow the fuel to drain into a suitable container. Ensure you dispose of the fuel responsibly and in compliance with local regulations.

Step 4: Remove the Old Fuel Lines

Carefully disconnect the old fuel lines from the fuel tank and engine. Take note of the positions and connections to ensure proper reattachment of the new lines. Use a small wrench or pliers to loosen any fittings, being careful not to damage the surrounding components.

Step 5: Prepare the New Fuel Lines

Clean the fuel lines and connectors to remove any dirt or debris. Inspect the new fuel lines for any defects or damage during the installation process. Ensure they are free of bends or kinks that could affect performance.

Step 6: Install the New Fuel Lines

Start by attaching the new fuel lines to the fuel tank, following the original connections. Secure the lines with the appropriate fittings and connectors, ensuring a tight and leak-free fit. Route the lines carefully, allowing for easy access and avoiding any sharp bends that could restrict fuel flow.

Step 7: Test and Adjust

Once the new fuel lines are installed, reconnect the fuel pump and fuel filter (if applicable). Start the lawn equipment and let it run for a few minutes to ensure the fuel is flowing correctly. Check for any leaks at the connections and make adjustments as necessary.

By replacing damaged fuel lines, you can ensure a reliable and efficient fuel supply to your lawn equipment, preventing potential issues caused by loose or faulty lines. This process may require some technical skill and patience, but it is a valuable skill to have for maintaining your outdoor power equipment.

Mastering the Art of Nylon Fuel Line Connections: A Comprehensive Guide

You may want to see also

Frequently asked questions

Tightening loose fuel lines is a common issue with lawn equipment, and it can be easily fixed. Start by identifying the loose line and using a fuel line clamp or a hose clamp to secure it. Ensure the clamp is tight enough to prevent movement but not so tight that it causes damage to the line. You can also consider replacing the fuel line if it's worn out or damaged, as this might be the cause of the looseness.

Fuel lines can loosen due to various factors. Regular use and movement of the lawn equipment can cause the lines to stretch and loosen connections. Additionally, exposure to sunlight and extreme temperatures can degrade the fuel line material, making it more prone to movement. It's essential to inspect and maintain your equipment regularly to prevent such issues.

While duct tape might provide a temporary fix, it is not recommended for a permanent solution. Duct tape is not designed for fuel lines and may not be compatible with the fuel's chemical composition. It can also become brittle over time and may not offer a secure hold. Instead, opt for proper fuel line clamps or consider replacing the line to ensure a safe and effective repair.