Fixing a twisted fuel line can be a straightforward process if you follow the right steps. This guide will provide a step-by-step approach to repairing a twisted fuel line, complete with detailed pictures to help you visualize the process. Whether you're a car enthusiast or a DIY mechanic, understanding how to address this common issue is essential for maintaining your vehicle's performance and safety. By following these instructions, you'll be able to efficiently resolve the problem and get your fuel line back to its original state.

What You'll Learn

- Identify the Issue: Inspect the fuel line for twists, kinks, or damage

- Gather Tools: Prepare a fuel line repair kit and safety equipment

- Locate the Twist: Pinpoint the exact location of the fuel line twist

- Unravel Carefully: Gently untwist the fuel line, avoiding sharp bends

- Secure and Test: Use clamps to secure the line and test for leaks

Identify the Issue: Inspect the fuel line for twists, kinks, or damage

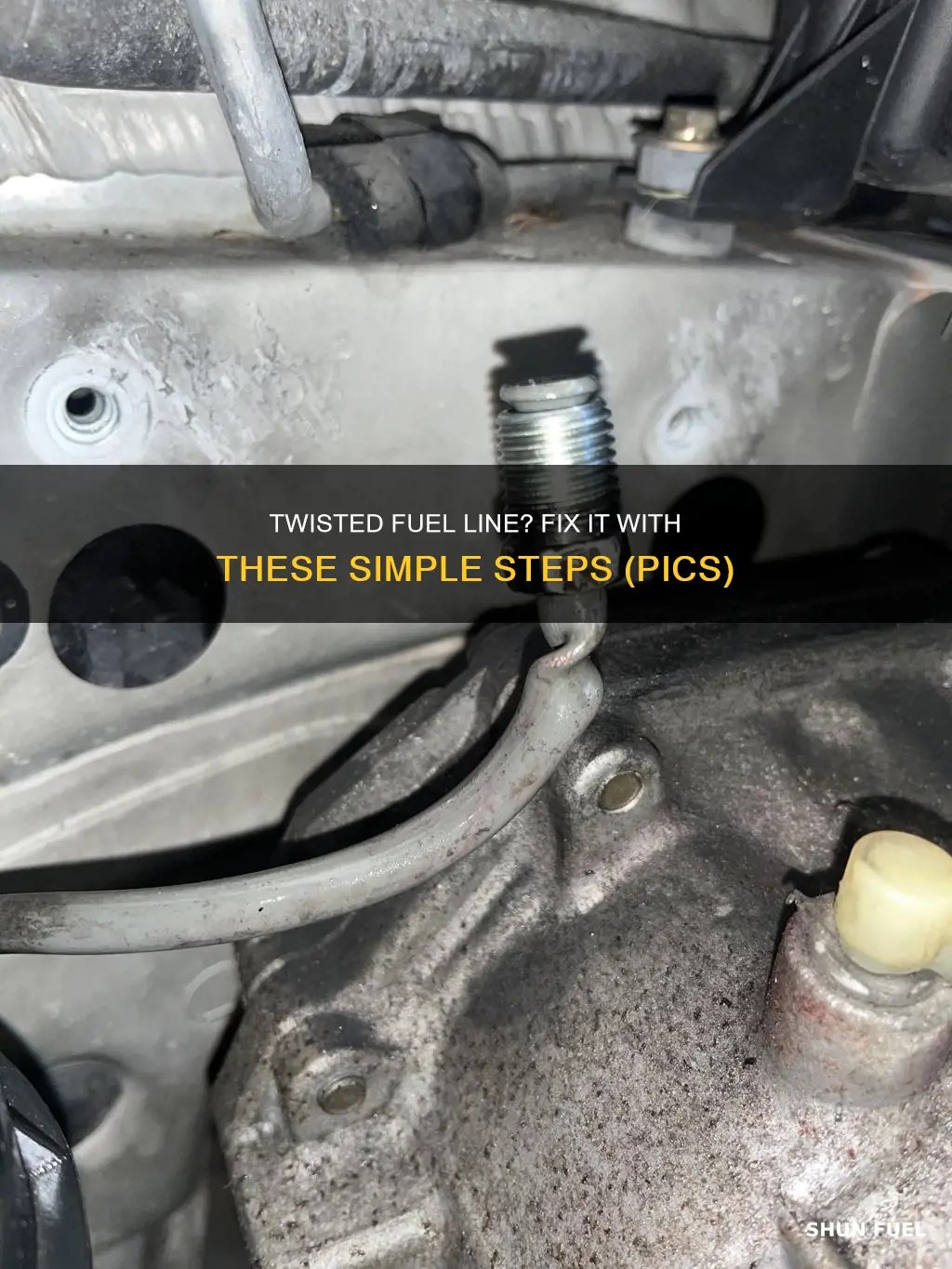

When it comes to identifying and addressing a twisted fuel line, a thorough inspection is crucial. Start by locating the fuel line, which is typically a flexible tube that runs from the fuel tank to the engine. Visually examine the line for any visible signs of damage or distortion. Look for twists, kinks, or any deviations from its natural, straight path. These issues can restrict fuel flow or even cause a complete blockage, leading to engine performance problems.

Pay close attention to the connections and bends in the fuel line. Twists or kinks at these points can be more challenging to identify but are equally important to address. Use a bright light or a flashlight to illuminate the area and ensure you can see any potential issues clearly. If the fuel line is under the vehicle or in a hard-to-reach spot, consider using a mirror or a camera to get a better view.

Check for any signs of wear and tear, such as cracks, punctures, or frayed ends. These issues can compromise the integrity of the fuel line and lead to fuel leaks or contamination. If you notice any damage, it's essential to replace the affected section promptly. Additionally, inspect the fuel line for any signs of corrosion or rust, especially if the vehicle is older or has been exposed to harsh weather conditions.

During your inspection, also look for any signs of fuel accumulation or pooling around the fuel line. This could indicate a blockage or a faulty fuel pump. If you notice any liquid fuel around the line, it's a clear sign of a potential issue that requires immediate attention. Remember, a twisted fuel line can lead to various engine problems, so a careful and comprehensive inspection is the first step towards resolving the issue.

Temporary Fuel Line Solutions: Quick Fixes for Car Fuel Issues

You may want to see also

Gather Tools: Prepare a fuel line repair kit and safety equipment

Before you begin the process of repairing a twisted fuel line, it's crucial to gather the necessary tools and safety equipment to ensure a safe and efficient repair. Here's a detailed guide on what you should prepare:

Fuel Line Repair Kit:

- Fuel Line Repair Tape or Clamps: These are essential for sealing and securing the damaged fuel line. Get a kit that includes various sizes of repair tape or clamps to accommodate different fuel line diameters. Look for products designed specifically for fuel line repairs, as they often provide better adhesion and durability.

- Fuel Line Cutter: You'll need a sharp and precise tool to cut the twisted fuel line. A fuel line cutter or a sharp pair of scissors designed for this purpose will ensure a clean and accurate cut.

- Fuel Line Reinforcement Material: Consider including a reinforcing sleeve or tape to add extra strength to the repaired section. This is especially useful if the fuel line has been twisted multiple times, as it helps prevent future damage.

- Hose Clamps: Standard hose clamps can be useful for temporary fixes or to hold the repair tape in place. Ensure you have a variety of sizes to fit different fuel line sizes.

Safety Equipment:

- Safety Glasses: Protect your eyes from any potential fuel splashes or debris during the repair process. Safety goggles or glasses with side shields are recommended.

- Gloves: Wear heat-resistant gloves to protect your hands when handling hot fuel lines or tools. Nitrile or leather gloves are good options.

- Respiratory Protection: If you're working in a confined space or near a fuel source, consider a respirator or a mask to prevent inhaling fuel fumes.

- Fire Extinguisher: Keep a fire extinguisher nearby as a safety precaution. Fuel lines can be a fire hazard, especially when working with heat or flames.

- Safety Gear for Clothing: Consider wearing long sleeves and pants to minimize skin exposure to potential fuel contaminants.

By assembling this kit and ensuring you have the appropriate safety gear, you'll be well-prepared to tackle the fuel line repair. Remember, safety should always be a top priority when working with fuel systems.

An6 Fuel Line Compatibility: 1997 Ford F150 Upgrade Guide

You may want to see also

Locate the Twist: Pinpoint the exact location of the fuel line twist

To begin the process of fixing a twisted fuel line, you need to first locate the exact spot where the twist has occurred. This step is crucial as it helps you understand the extent of the damage and guides your repair efforts. Here's a detailed guide on how to pinpoint the location of the twist:

Step 1: Visual Inspection

Start by visually inspecting the fuel line. Look for any visible signs of damage, such as kinks, bends, or twists. Use a bright light source to illuminate the area and make it easier to spot any irregularities. Pay close attention to the points where the fuel line connects to other components, such as the fuel pump, engine, or fuel tank. These areas are more prone to twisting due to the movement and pressure of the fuel flow.

Step 2: Feel for Resistance

Run your fingers along the length of the fuel line, feeling for any areas of resistance or unusual texture. Twists in the fuel line can cause localized areas of increased thickness or rigidity. This tactile inspection can help you identify the exact location of the twist, especially if it's not immediately visible.

Step 3: Check for Fuel Flow Disruption

Start the engine and listen for any unusual noises, such as hissing or roaring sounds, which could indicate a twisted fuel line. If the engine struggles to start or runs roughly, it might be due to the fuel line issue. In some cases, you might notice a change in the engine's performance, such as reduced power or fuel efficiency, which could be a result of the twist.

Step 4: Use a Mirror or Camera

If the fuel line is located in a hard-to-reach area, consider using a mirror or a camera to get a better view. Insert the camera or mirror into the engine compartment and aim it at the fuel line. This can provide a more comprehensive view, allowing you to identify the twist more accurately.

Step 5: Mark the Location

Once you've located the twist, mark its position with a small piece of tape or a permanent marker. This will serve as a reference point during the repair process, ensuring that you don't accidentally cut or damage the fuel line at the wrong spot.

By following these steps, you can precisely locate the twist in the fuel line, which is the first crucial step towards a successful repair. Remember to exercise caution when working with fuel lines to avoid any accidents or further damage.

Subaru Fuel Hanger Conundrum: Identifying the Right Lines

You may want to see also

Unravel Carefully: Gently untwist the fuel line, avoiding sharp bends

When dealing with a twisted fuel line, it's crucial to approach the repair with patience and precision. The goal is to carefully unravel the twist without causing further damage to the fuel line or the surrounding components. Here's a step-by-step guide to help you navigate this delicate process:

Step 1: Assess the Situation

Before you begin, take a moment to evaluate the extent of the twist. Inspect the fuel line for any visible signs of damage, such as cracks or leaks. Understanding the severity of the issue will help you determine the appropriate course of action.

Step 2: Gather the Right Tools

You'll need a few essential tools to assist in the repair. Firstly, a pair of pliers or a fuel line tool can provide the necessary grip to hold the line steady. Additionally, a soft cloth or rag will come in handy for protecting the fuel line during the untwisting process.

Step 3: Locate the Twist

Identify the section of the fuel line that is twisted. This may require you to follow the line from its source to the destination, tracing its path through the engine bay or other compartments. Once you've located the twisted portion, mark its starting and ending points for reference.

Step 4: Gently Untwist

Now, carefully start unraveling the twist. Use your hands or the pliers to gently pull and straighten the fuel line. Avoid applying excessive force, as this can lead to further damage. Take your time, working slowly and methodically to ensure you don't miss any twists.

Step 5: Avoid Sharp Bends

As you untwist the fuel line, pay close attention to the bends and turns. Sharp bends can cause additional stress on the line and potentially lead to further twisting. Instead, aim for smooth, gradual curves. If you encounter a particularly stubborn twist, consider using a fuel line brush to carefully guide the line into a straighter position.

Step 6: Test and Reassemble

Once you've successfully untwisted the fuel line, it's essential to test its functionality. Connect the line to its source and destination, ensuring a secure fit. Start the engine and monitor for any signs of fuel delivery issues. If everything functions correctly, you can reassemble the fuel line, securing it in place to prevent future twisting.

Optimizing Fuel Flow: Choosing the Right Line Size

You may want to see also

Secure and Test: Use clamps to secure the line and test for leaks

When dealing with a twisted fuel line, one of the crucial steps is to secure the line properly to prevent further damage and ensure the system's functionality. Clamps are an excellent tool for this purpose, providing a reliable and adjustable means of fastening the fuel line. Here's a step-by-step guide on how to use clamps to secure the twisted fuel line and test for any potential leaks:

Step 1: Identify the Clamps: Start by selecting the appropriate clamps for your fuel line. The type of clamp you choose should match the diameter of your fuel line. Common types include hose clamps, also known as "spring clamps" or "v-band clamps." Ensure you have the right size to fit snugly around the fuel line without causing damage.

Step 2: Locate the Twisted Section: Carefully inspect the fuel line to locate the twisted section. Identify the points where the line is twisted, ensuring you understand the direction of the twist. This information will be crucial for proper clamping.

Step 3: Apply Clamps: Position the clamps at strategic points along the twisted section. Typically, you would place one clamp near the fuel pump and another closer to the fuel tank. Tighten the clamps securely, but be careful not to overtighten, as this can cause damage to the fuel line. The goal is to hold the twisted section in place without restricting the flow of fuel.

Step 4: Test for Leaks: After securing the fuel line with the clamps, it's essential to test for any leaks. Here's how:

- Visual Inspection: Start by visually inspecting the fuel line and the clamps. Look for any signs of damage, such as cracks or bends, especially at the clamp points. Ensure there are no visible leaks or drips.

- Pressure Test: Use a fuel line pressure tester or a simple pump to apply pressure to the fuel system. Check for any bubbles or hissing sounds around the clamps and connections. Even a small leak can cause significant issues over time.

- Run the Engine: If possible, start the engine and let it run for a few minutes. Monitor the engine's performance and listen for any unusual noises. If the engine runs smoothly, it's a good sign, but continue to observe for any leaks.

Step 5: Fine-Tuning: If you notice any leaks or issues, adjust the clamp positions or tighten them slightly. Ensure that the clamps are secure enough to hold the fuel line in place without causing excessive pressure or damage. Repeat the testing process until you achieve a leak-free system.

Remember, proper clamping and testing are vital to ensuring the fuel line's integrity and the overall performance of your vehicle's fuel system. Always exercise caution when working with fuel lines to avoid any accidents or further complications.

Where to Find the Best Deals on Diesel Fuel Lines

You may want to see also

Frequently asked questions

Fixing a twisted fuel line can be a straightforward process. First, locate the twisted section of the line and use a pair of pliers to carefully untwist it. Take your time and be gentle to avoid further damage. Once untwisted, inspect the line for any cracks or damage. If there's no visible damage, you can reattach the line to the fuel pump and carburetor (if applicable) using the appropriate fittings and clamps. Ensure a secure connection and double-check for any leaks.

You don't necessarily need specialized tools for this task, but having a few basic items can make the job easier. A pair of adjustable pliers or fuel line cutters will be useful for untwisting and trimming the line. Additionally, having a fuel line inspection mirror can help you visualize the inside of the line to identify any blockages or damage.

If the fuel line is cracked or severely damaged, it's best to replace it entirely. Start by disconnecting the line from both the fuel pump and the carburetor (if equipped). Take pictures of the old line for reference when purchasing a replacement. When installing the new line, ensure a tight and secure connection, and use fuel line tape or clamps to prevent leaks.

Yes, a temporary fix is possible if you need to get your vehicle running again quickly. You can use a piece of fuel line that is slightly longer than the twisted section and carefully feed it through the line to untwist it. Secure the ends with temporary clamps, ensuring a tight seal. This will allow you to drive the vehicle temporarily, but it's crucial to address the issue permanently as soon as possible to avoid further complications.