Fixing a leaky fuel line on your tractor can be a straightforward process if you follow the right steps. Start by identifying the source of the leak, which could be a crack or a damaged fitting. Gather the necessary tools and materials, such as a fuel line repair kit, a wrench, and a new section of fuel line if needed. Ensure you have the correct replacement parts that match the original specifications. Then, carefully disconnect the damaged section of the fuel line, being mindful of any fuel residue. Clean the area and apply a suitable adhesive or sealant to the new fuel line before reinstalling it. Finally, secure the fuel line with the appropriate fittings and torque them according to the manufacturer's guidelines. With patience and attention to detail, you can effectively repair the leak and restore your tractor's performance.

What You'll Learn

- Locate the fuel line: Identify the damaged section using a visual inspection

- Disconnect the line: Turn off the fuel supply and carefully disconnect the line

- Repair or replace: Decide whether to repair or replace the damaged fuel line

- Use the right tools: Gather the necessary tools and materials for the repair

- Reattach and test: Securely reconnect the fuel line and test for leaks

Locate the fuel line: Identify the damaged section using a visual inspection

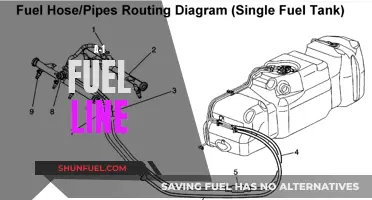

When dealing with a leaky fuel line on your tractor, the first step is to locate the damaged section. This process requires a thorough visual inspection to identify the problem area. Here's a detailed guide on how to do it:

Start by examining the fuel line for any visible signs of damage. Look for cracks, splits, or punctures along the length of the line. These defects can be caused by various factors, such as age, wear and tear, or impact damage. Pay close attention to areas where the line connects to the fuel tank, the engine, or any other components. Sometimes, the damage might be hidden beneath insulation or protective covers, so you'll need to carefully remove these to get a clear view.

Use a bright flashlight to illuminate the fuel line and its surroundings. This will help you spot any small cracks or damage that might be difficult to see with the naked eye. Inspect the line for any signs of corrosion or deterioration, especially if the fuel line is made of metal. Corrosion can weaken the line and contribute to leaks.

Check for any signs of fuel accumulation or residue around the fuel line. Leaks can cause fuel to accumulate, which may lead to further issues. If you notice any fuel residue, it could indicate a more serious problem that requires immediate attention.

If the fuel line is difficult to access or inspect, consider using a mirror or a camera with a flexible shaft to get a better view. These tools can help you reach around corners or inspect hard-to-reach areas. Take notes or take photos of the suspected damage areas for reference during the repair process.

Remember, a thorough visual inspection is crucial to accurately identifying the damaged section of the fuel line. Take your time and be meticulous in your examination to ensure you don't miss any potential issues.

Chevy Astro Fuel Line: Can It Be Pinched?

You may want to see also

Disconnect the line: Turn off the fuel supply and carefully disconnect the line

To address a leaky fuel line on your tractor, it's crucial to start by disconnecting the affected line. This process requires careful execution to ensure your safety and the proper functioning of the fuel system. Here's a step-by-step guide to help you through this task:

Step 1: Turn Off the Fuel Supply

The first and most critical step is to shut off the fuel supply to the tractor. Locate the fuel valve, which is typically found near the engine or the fuel tank. This valve controls the flow of fuel into the system. Turn it off to prevent any further fuel from entering the line, which could complicate the repair process.

Step 2: Identify the Line to Disconnect

Locate the specific fuel line that is leaking. It is usually a rubber or plastic hose that connects the fuel tank to the engine. Carefully inspect the line for any visible damage, cracks, or signs of deterioration. Mark the position of the line if necessary, so you can reconnect it in the correct orientation later.

Step 3: Disconnect the Line

Now, you can proceed to disconnect the fuel line. Use a fuel line disconnect tool or a pair of pliers to carefully loosen the fittings at both ends of the line. Be gentle to avoid damaging the fittings. Once the fittings are loose, pull the line straight off the fittings. Ensure you have a container or rag ready to catch any remaining fuel in the line to prevent spills.

Safety Precaution: When disconnecting the line, be cautious of any remaining fuel pressure. If the line is under pressure, it could spray fuel, posing a fire hazard. If you encounter pressure, release it slowly by slightly turning the fuel valve on, then turning it off again.

By following these steps, you'll be able to safely disconnect the leaky fuel line, allowing you to proceed with the necessary repairs or replacements. Remember, working with fuel requires caution, and if you're unsure, consulting a professional mechanic is always a wise decision.

Spray Test: A Simple Way to Check Fuel Line Leaks

You may want to see also

Repair or replace: Decide whether to repair or replace the damaged fuel line

When dealing with a damaged fuel line on your tractor, the decision to repair or replace it is crucial and depends on several factors. Firstly, assess the extent of the damage. If the leak is minor and limited to a small section of the line, repairing it might be a viable option. You can start by cleaning the area around the leak to ensure there is no dirt or debris obstructing the repair process. Then, use a suitable adhesive or sealant designed for fuel lines to seal the leak temporarily. This method can provide a quick fix, allowing you to continue using your tractor until a more permanent solution is found.

However, if the damage is more extensive, with multiple leaks or significant wear and tear, replacement might be necessary. Over time, fuel lines can deteriorate due to exposure to fuel, heat, and mechanical stress. If the line is old and the damage is widespread, it's likely that the line has compromised its structural integrity, making it unsafe to continue using. In such cases, replacing the entire fuel line is recommended to ensure the safety and reliability of your tractor's fuel system.

Another factor to consider is the availability of replacement parts. If the specific make and model of your tractor are no longer in production, finding an exact replacement fuel line might be challenging. In this scenario, you may need to consider modifying the existing line or using an aftermarket replacement that is compatible with your tractor. It's essential to ensure that any replacement part meets the required specifications to maintain the performance and safety standards.

Furthermore, the cost of repair versus replacement should be evaluated. Minor repairs might be more economical in the short term, but if the damage is extensive, the cost of replacement could be more justified. Consider the overall condition of the fuel line and the potential risks associated with continued use. If the line is crucial for the tractor's operation and poses a safety hazard, investing in a replacement is a prudent decision.

In summary, the decision to repair or replace a damaged fuel line on your tractor should be based on a thorough assessment of the damage, the age and condition of the line, the availability of replacement parts, and the associated costs. By carefully considering these factors, you can make an informed choice that ensures the safe and efficient operation of your tractor's fuel system.

Fuel Injector Line Disconnect: A Step-by-Step Guide for 98 S-10 Owners

You may want to see also

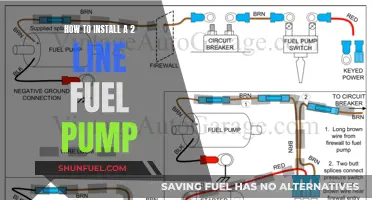

Use the right tools: Gather the necessary tools and materials for the repair

Before you begin any repair work on a tractor's fuel line, it's crucial to ensure you have the right tools and materials to complete the task efficiently and effectively. Here's a step-by-step guide on gathering the necessary items:

- Basic Hand Tools: Start by equipping yourself with some essential hand tools. You'll need a set of screwdrivers, preferably a flathead and a Phillips head, to remove any screws that might secure the fuel line in place. A pair of adjustable pliers will be invaluable for gripping and manipulating various components. Additionally, a utility knife or a sharp blade will help you carefully cut any excess fuel line if needed.

- Fuel Line Repair Kit: Invest in a fuel line repair kit specifically designed for tractor fuel lines. These kits typically include a range of components such as fuel line connectors, clamps, and replacement sections of fuel line. Look for a kit that includes the appropriate size and type of fuel line for your tractor model. This kit will provide you with everything you need to make a proper repair.

- Cleaning Supplies: It's essential to have cleaning supplies to prepare the fuel line for repair. Gather some diesel fuel or gasoline to flush out any remaining fuel in the line. You'll also need a fuel line cleaner or a degreaser to remove any built-up contaminants and ensure a clean repair surface.

- Safety Gear: Don't forget the importance of safety. Wear safety goggles to protect your eyes from any potential fuel splashes. Gloves are also recommended to safeguard your hands during the repair process.

- Additional Materials: Depending on the specific issue, you might need additional materials. For instance, if the fuel line is damaged beyond repair, you may require a length of replacement fuel line that matches the original specifications. Always refer to your tractor's manual or online resources to determine the exact parts needed for your particular model.

By gathering these tools and materials, you'll be well-prepared to tackle the repair of a leaky fuel line on your tractor. Having the right equipment ensures that the job is done correctly and efficiently, minimizing the risk of further damage or complications.

Choosing the Right Fuel Line: A Guide for 9N Cobalt Owners

You may want to see also

Reattach and test: Securely reconnect the fuel line and test for leaks

When dealing with a leaky fuel line on your tractor, one of the most crucial steps is to ensure a secure and leak-free reattachment. Here's a detailed guide on how to achieve this:

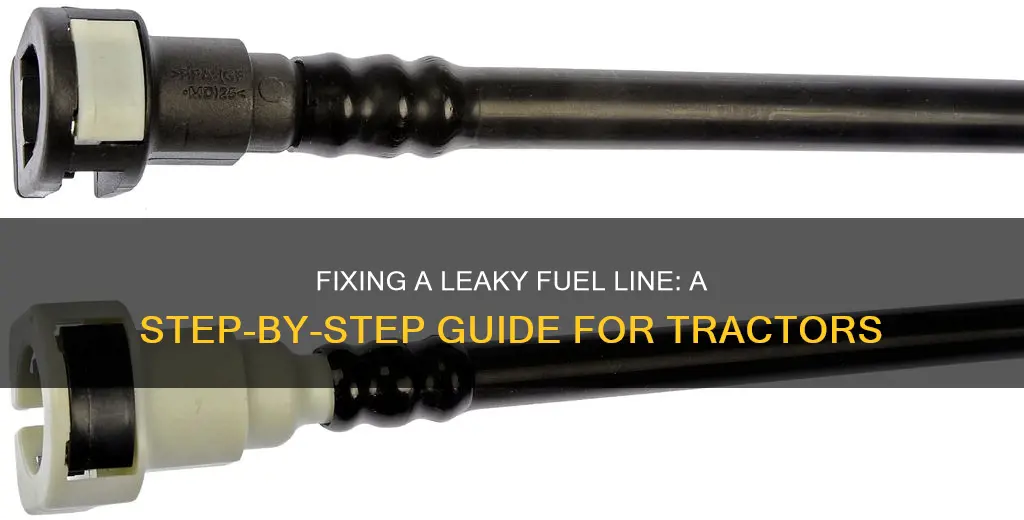

Start by identifying the specific area where the fuel line has come loose. Carefully inspect the connection points and the line itself for any signs of damage or wear. If there are any visible tears or cracks, it's best to replace the fuel line rather than attempting a repair. Once you've located the issue, gather the necessary tools, including fuel line connectors, a fuel line clamp, and a rag or cloth for cleaning.

Now, proceed with reattaching the fuel line. Clean the ends of the fuel line and the connectors to ensure a proper seal. Apply a small amount of fuel line adhesive or tape to the connectors, following the manufacturer's instructions. Slide the connectors onto the fuel line, ensuring they are aligned correctly. Use the fuel line clamp to secure the connection firmly. Make sure the clamp is tight enough to prevent any movement but avoid over-tightening to prevent damage to the fuel line.

After reattaching the fuel line, it's essential to test for leaks. Park your tractor in a well-ventilated area and turn it on. Listen carefully for any hissing or bubbling sounds, which could indicate a leak. Check for any fuel residue or stains around the connection points, as these could be signs of a leak. If you detect any leaks, immediately shut off the engine and tighten the connection further or consider replacing the fuel line.

If no leaks are found, you can reassess the engine's performance. Start the engine and monitor its behavior. Check for any unusual noises, vibrations, or changes in idling speed. If the engine runs smoothly and without issues, you've successfully resolved the leaky fuel line problem. However, if any problems persist, it's advisable to consult a professional mechanic for further assistance.

Remember, proper reattachment and testing are vital to ensuring the longevity of your tractor's fuel system. By following these steps, you can effectively fix a leaky fuel line and maintain the overall performance and reliability of your tractor.

Colorado Fuel Pump Line: Quick Disconnect Guide

You may want to see also

Frequently asked questions

A leaky fuel line can be identified by noticing fuel dripping or pooling around the tractor, especially near the fuel tank, lines, and connections. You might also see fuel stains on the engine or nearby components.

Fuel lines can leak due to various reasons, including age, corrosion, damage from sharp objects, improper installation, or the use of low-quality fuel. Over time, fuel lines can degrade, develop cracks, or become brittle, leading to leaks.

Temporary fixes are possible but not recommended for long-term use. You can use fuel line tape or rubber fuel line repair tape to seal small leaks. However, for more significant leaks, it's best to replace the entire fuel line to ensure a proper and safe repair.

Replacing a fuel line requires careful disassembly and reassembly of the fuel system. Start by draining the fuel tank and disconnecting the fuel lines from the engine and tank. Then, remove the old fuel line, cut it to the desired length, and install the new line, ensuring proper connections and secure fittings. Reassemble the system and refill the fuel tank. It's recommended to consult a tractor repair manual or seek professional assistance for a successful replacement.