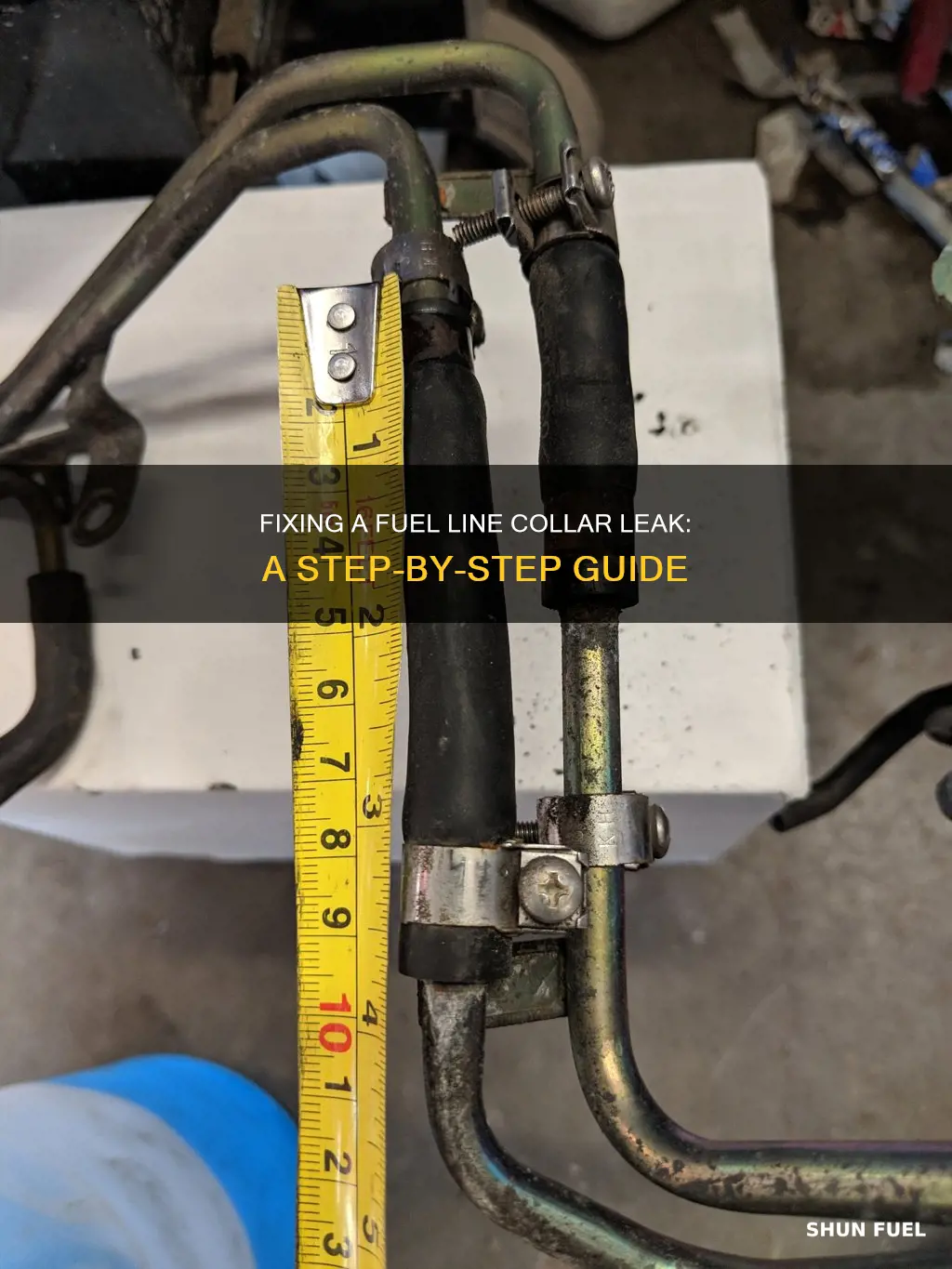

Fixing a leaking fuel line collar can be a straightforward process if you follow the right steps. Start by ensuring you have the necessary tools and safety equipment, such as gloves and safety goggles. Locate the leaking collar and inspect it for any visible damage or debris. Clean the area around the collar to ensure a proper seal. Then, use a fuel line collar repair kit, which typically includes a collar and a sealing compound, to replace the damaged part. Carefully align the new collar over the fuel line and apply the sealing compound as per the kit's instructions. Allow the compound to cure according to the manufacturer's guidelines, and test the fuel line to ensure the leak has been resolved. Remember to dispose of any used materials responsibly and seek professional help if you're unsure about any step.

What You'll Learn

- Identify the leak: Inspect the fuel line collar for any visible damage or cracks

- Clean the surface: Remove dirt and corrosion using a suitable cleaner

- Apply a repair compound: Fill the gap with a suitable epoxy or silicone compound

- Reinforce with tape: Wrap the repaired area with fuel line tape for added strength

- Test for leaks: After repair, run a test to ensure the leak is sealed

Identify the leak: Inspect the fuel line collar for any visible damage or cracks

When dealing with a leaking fuel line collar, the first step is to carefully inspect the collar for any visible signs of damage or cracks. The fuel line collar is a crucial component that connects the fuel line to the engine, and any damage to this area can lead to fuel leaks, which can be dangerous and cause engine issues. Here's a detailed guide on how to identify the leak:

Start by locating the fuel line collar, which is typically found where the fuel line enters the engine compartment. It is usually a rubber or plastic collar that fits around the fuel line to create a secure seal. Inspect this collar for any visible wear and tear. Look for cracks, tears, or any deformation in the collar's structure. These defects can be caused by age, heat, or physical damage. Check for any signs of melting or softening, especially if the engine has been running at high temperatures. Even small cracks or punctures can allow fuel to leak out, so pay close attention to these potential issues.

Examine the collar for any signs of fuel contamination. If the fuel line has been exposed to contaminants or has a history of leaks, the collar may show signs of discolouration or a foul odour. Contaminated fuel can also cause engine performance issues, so identifying and addressing the leak is essential. Additionally, look for any signs of corrosion or rust around the collar's attachment points. Corrosion can weaken the collar's integrity and lead to leaks over time.

If the fuel line collar shows any visible damage, it is crucial to address the issue promptly. Even minor cracks or tears can worsen over time, leading to more significant fuel leaks and potential engine damage. If you identify any leaks or damage, it is recommended to consult a professional mechanic who can provide expert advice and ensure the necessary repairs are made. They may suggest replacing the collar or making temporary fixes to prevent further leaks while a more permanent solution is implemented.

Remember, regular maintenance and inspection of the fuel system, including the line collars, are essential to ensure the safe and efficient operation of your vehicle. By carefully examining the fuel line collar for visible damage or cracks, you can take the initial step towards resolving the leak and preventing potential engine problems.

Mastering Maintenance: How Often to Flush Your Fuel Line

You may want to see also

Clean the surface: Remove dirt and corrosion using a suitable cleaner

When dealing with a leaking fuel line collar, one of the initial steps to ensure a successful repair is to thoroughly clean the surface area. This process is crucial as it prepares the metal for proper sealing and prevents further issues. Here's a detailed guide on how to effectively clean the surface:

Identify the Cleaning Agent:

Start by selecting an appropriate cleaner. For fuel line collars, a mild acid-based cleaner or a specialized metal cleaner is ideal. These cleaners are designed to remove corrosion and grime without causing damage to the metal surface. Avoid using harsh chemicals that could strip away any existing protective coatings.

Prepare the Cleaning Process:

Before applying the cleaner, ensure the area is well-ventilated to prevent inhaling fumes. Wear protective gear, including gloves and safety goggles, to safeguard your skin and eyes. This step is essential for your safety and comfort during the cleaning process.

Application Technique:

- Begin by gently scrubbing the fuel line collar with a soft-bristled brush or a non-abrasive sponge. This mechanical action helps loosen and remove dirt and corrosion.

- Apply the cleaner directly to the surface, ensuring an even coating. Allow the cleaner to sit for the recommended time on the product's packaging, as this allows it to penetrate and break down the contaminants.

- For stubborn deposits, you may need to apply more cleaner and scrub gently again.

Rinsing and Drying:

After the cleaning process, rinse the area thoroughly with clean water to remove any remaining cleaner. Ensure no traces of the cleaning agent are left, as they might attract dirt in the future. Dry the surface completely using a clean cloth or paper towel. Moisture can lead to further corrosion, so a thorough drying is essential.

Final Inspection:

Once the surface is clean and dry, inspect it closely. Look for any remaining corrosion or dirt, and if present, repeat the cleaning process. A thorough cleaning ensures that the repair process will be more effective and long-lasting. This step is often overlooked but is critical to the overall success of fixing a leaking fuel line collar.

Mastering the Art of Cutting Steel Fuel Intake Lines: A Comprehensive Guide

You may want to see also

Apply a repair compound: Fill the gap with a suitable epoxy or silicone compound

When dealing with a leaking fuel line collar, one of the most effective methods to ensure a secure and long-lasting repair is to apply a repair compound. This process involves filling the gap or damage area with a specialized material that will create a strong bond and seal. Here's a step-by-step guide on how to achieve this:

Step 1: Prepare the Area

Start by ensuring the leaking collar is clean and dry. Use a fine-grit sandpaper to gently roughen the surface around the damage. This rough surface will provide better adhesion for the compound. Take care not to over-sand, as you want to maintain the integrity of the fuel line.

Step 2: Choose the Right Compound

Select a repair compound that is compatible with the material of your fuel line. Epoxy and silicone compounds are popular choices for this task. Epoxy resins are known for their strong bonding properties and can provide a robust repair. Silicone compounds, on the other hand, offer flexibility and are suitable for applications where some movement is expected. Ensure you follow the manufacturer's instructions for the specific compound you choose.

Step 3: Apply the Compound

Carefully inject or brush the chosen compound into the gap or damaged area. Take your time to ensure complete coverage. For small leaks, a syringe can be used to precisely fill the void. If the leak is more extensive, you might need to apply the compound in multiple layers, allowing each layer to cure before adding more. Always refer to the product instructions for the optimal application technique and curing time.

Step 4: Secure and Protect

Once the compound is applied and cured, ensure the fuel line is properly secured. Reattach the collar or any other components that were removed during the repair process. Use appropriate fasteners or clamps to hold everything in place temporarily until the compound sets. After the compound has cured, test the fuel line for leaks to ensure a successful repair.

By following these steps, you can effectively repair a leaking fuel line collar, ensuring the system's integrity and preventing further fuel leaks. Remember, the key to a successful repair is choosing the right compound and taking the time to apply it correctly.

Optimizing Fuel Delivery: Choosing the Right Size for Your 99 Ford Ranger

You may want to see also

Reinforce with tape: Wrap the repaired area with fuel line tape for added strength

When dealing with a leaking fuel line collar, one effective method to ensure a secure and long-lasting repair is to reinforce the area with tape. This technique provides an additional layer of protection and strength to the connection, preventing further leaks. Here's a step-by-step guide on how to achieve this:

Start by ensuring the fuel line is completely dry and free from any debris or contaminants. Clean the area around the leak to create a smooth surface for the tape to adhere to. It's crucial to use the right type of tape for this task. Fuel line tape, also known as fuel line repair tape or hose repair tape, is specifically designed to withstand the harsh conditions of fuel exposure. These tapes are typically made from a durable material that can resist fuel's corrosive properties.

Now, carefully wrap the tape around the repaired area. Begin by applying a small amount of tape, ensuring it covers the entire circumference of the fuel line collar. You can use a steady hand or a tape dispenser for this step to ensure an even application. Wrap the tape tightly, making sure it overlaps slightly with the previous layer to create a secure bond. Continue wrapping the tape in a circular motion, overlapping each layer slightly, until you've covered the entire repaired area. The goal is to create a smooth, continuous layer of tape that provides structural integrity.

For optimal results, ensure that the tape is applied firmly and securely. Press down on the tape as you wrap it to ensure good adhesion. You can also use a heavy object, like a weighted tool, to apply pressure and further secure the tape. This extra step will guarantee a tight seal, minimizing the risk of any future leaks.

Finally, inspect the taped area regularly to ensure the repair holds up over time. Check for any signs of deterioration or damage, especially if the vehicle is exposed to extreme temperatures or harsh conditions. With proper care and reinforcement, the tape will provide long-lasting protection, ensuring the fuel line collar remains leak-free. This method is a practical and cost-effective solution for minor fuel line leaks, offering a quick fix without the need for extensive replacement work.

Aluminum Fuel Lines: Unlocking Reliability and Performance

You may want to see also

Test for leaks: After repair, run a test to ensure the leak is sealed

After completing the repair of a leaking fuel line collar, it is crucial to verify that the issue has been effectively resolved. A thorough leak test is essential to ensure the safety and efficiency of your vehicle's fuel system. Here's a step-by-step guide on how to conduct this test:

Step 1: Prepare the Vehicle: Park your vehicle in a well-ventilated area, preferably outdoors, to avoid inhaling any potentially harmful fumes. Ensure the engine is cool to the touch, as working on a hot engine can be dangerous. Turn off the ignition and disconnect the battery to prevent any accidental electrical discharges.

Step 2: Inspect the Repair: Before testing, inspect the repaired area. Check for any signs of damage, debris, or improper installation that might have caused the leak in the first place. Ensure all components are securely in place and aligned correctly.

Step 3: Apply a Leak Detection Fluid: A common method for leak testing is using a non-toxic, biodegradable leak detection fluid. This fluid is typically a bright-colored liquid that can be easily spotted if it escapes. Carefully apply this fluid to the repaired fuel line collar and any other suspected leak points. Take note of the specific areas you are testing to avoid confusion later.

Step 4: Start the Engine: With the leak detection fluid applied, start the engine and allow it to run for a few minutes. You can use the vehicle's idle speed control to maintain a steady engine speed. Keep an eye on the fluid's behavior; if it starts to pool or form droplets, it indicates a potential leak.

Step 5: Observe and Identify Leaks: Carefully inspect the vehicle, especially the areas where the leak detection fluid was applied. Look for any signs of fluid accumulation, especially around the fuel line collar and connections. Note the exact locations of any leaks, as this information will be valuable for further diagnosis and repair if needed.

Step 6: Document and Repair: If any leaks are detected, carefully document their locations. Take photographs if possible to provide visual evidence. Then, proceed with the necessary repairs to address the identified issues. Ensure that all components are tightened securely and that the fuel system is properly bled to remove any air bubbles.

Step 7: Repeat the Test: After the repairs, repeat the leak test to ensure that the issue has been completely resolved. This double-check is essential to guarantee the safety and reliability of your vehicle's fuel system.

Remember, regular maintenance and prompt attention to any leaks can prevent more extensive and costly repairs in the future. Always follow safety protocols when working on your vehicle, and if you are unsure about any step, consult a professional mechanic.

Fixing GM Fuel Line: A Step-by-Step Guide to Repair

You may want to see also

Frequently asked questions

Leaks in fuel line collars can occur due to several reasons, including age, corrosion, damage from vibrations, or improper installation. Over time, the collar may degrade, leading to cracks or gaps that allow fuel to escape.

For a temporary solution, you can use a fuel line clamp or a temporary repair kit. These products provide a quick fix by creating a tight seal around the leaking area, preventing further fuel loss. However, it's essential to address the root cause for a permanent repair.

Replacing a fuel line collar typically involves basic automotive tools. You will need a fuel line cutter or a set of cutting tools to remove the damaged section of the fuel line. Additionally, have a new fuel line collar, fuel line, and the necessary connectors or fittings readily available.

It is generally not recommended to repair a leaking collar without removing the fuel line. The collar is designed to secure the fuel line, and attempting to fix it in place may lead to further damage or inadequate sealing. It's best to disconnect the fuel line, clean the surfaces, and then install the new collar.

Regular maintenance and inspection of fuel lines can help prevent leaks. Ensure that fuel lines are properly routed, away from heat sources and sharp edges. Use high-quality fuel line collars and fittings, and follow manufacturer guidelines for installation. Keep an eye out for any signs of wear or damage and address them promptly.