Removing fuel lines can be a necessary step in various automotive or mechanical projects, but it requires careful attention to detail and the right tools. Whether you're working on a classic car, a modern vehicle, or any other machinery, understanding the process for safely and effectively removing different types of fuel lines is essential. This guide will provide a comprehensive overview of the steps involved, covering various types of fuel lines, including rubber, braided steel, and plastic lines, ensuring you have the knowledge to tackle this task with confidence and precision.

What You'll Learn

- Fuel Line Identification: Locate and label all fuel lines for safe removal

- Fuel Pump Disconnection: Turn off the fuel pump before disconnecting lines

- Fuel Tank Access: Remove fuel tank straps for easy line access

- Line Removal Technique: Use pliers or cutting tools carefully to avoid damage

- Cleaning and Inspection: Clean and inspect lines for any signs of contamination

Fuel Line Identification: Locate and label all fuel lines for safe removal

Fuel line identification is a crucial step in safely removing fuel lines from a vehicle. This process ensures that you can work on the fuel system without accidentally disconnecting the wrong lines, which could lead to fuel leaks and potential hazards. Here's a step-by-step guide to help you locate and label the fuel lines effectively:

Step 1: Familiarize Yourself with the Fuel System

Before you begin, take some time to understand the layout of the fuel system in your vehicle. Consult the vehicle's manual or online resources specific to your car's make and model. This will provide you with a visual representation of the fuel lines and their connections. Identify the main fuel tank, the fuel pump, and the various fuel injectors or carburetor, if applicable. Understanding the overall structure will make the identification process much easier.

Step 2: Inspect the Engine Bay

Locate the engine bay and inspect the area thoroughly. Fuel lines are typically routed along the engine and may be connected to various components. Look for lines that appear to be made of rubber or plastic and are often a dark color, such as black or blue. These lines carry fuel from the tank to the engine. Carefully examine each line for any visible damage, cracks, or signs of deterioration.

Step 3: Labeling the Fuel Lines

As you identify each fuel line, label them accordingly. You can use a permanent marker or a small piece of colored tape to label each line. Start from the fuel tank and label each line as you move towards the engine. For example, you might label it as "Fuel Line 1," "Fuel Line 2," and so on. Ensure that the labels are clear and easily identifiable, especially if you are working on a complex engine with multiple fuel lines. This step is essential for keeping track of the lines and ensuring you reconnect them correctly during the installation process.

Step 4: Securely Fasten the Lines

Once you have labeled all the fuel lines, it's important to secure them temporarily to prevent accidental disconnection. You can use small clips or ties to fasten the lines in place. This step is crucial, especially if you need to remove the fuel lines for an extended period. Secure them away from any moving parts to avoid damage.

Step 5: Document and Take Notes

As you work, take notes and document the positions and connections of the fuel lines. This documentation will be invaluable when reinstalling the lines or if you encounter any issues during the removal process. Note any unique features or modifications to the fuel lines, as these details will help ensure a proper fit during reinstallation.

By following these steps, you can efficiently identify and label all the fuel lines, ensuring a safe and successful removal process. Remember, proper identification is key to avoiding any potential hazards associated with fuel line removal.

Fuel Rail Basics: Understanding the Line for Optimal Performance

You may want to see also

Fuel Pump Disconnection: Turn off the fuel pump before disconnecting lines

When working on fuel system repairs or maintenance, it is crucial to prioritize safety and follow proper procedures to avoid any potential hazards. One essential step in this process is the disconnection of the fuel pump, which requires careful handling to ensure a safe and efficient workflow. Here's a detailed guide on how to safely disconnect the fuel pump and lines:

Before beginning any work, it is imperative to turn off the fuel pump. This step is often overlooked but is critical for several reasons. Firstly, it prevents the flow of fuel, which can be highly flammable and dangerous if ignited. By cutting off the fuel supply, you eliminate the risk of accidental fires or explosions. Secondly, turning off the pump allows you to work without the constant pressure and potential hazards associated with an active fuel system. This simple action significantly reduces the chances of accidents and provides a safer working environment.

Once the fuel pump is turned off, proceed with disconnecting the fuel lines. Start by identifying the lines that supply fuel to the pump and the engine. These lines are typically made of durable materials like rubber or plastic and are often color-coded for easy identification. Carefully locate the fuel pump module, which is usually found near the engine or in the fuel tank area. Disconnect the electrical connections to the pump, ensuring you have a clear understanding of the wiring diagram to avoid any mistakes.

After securing the electrical connections, focus on the fuel lines. Loosen the clamps or fittings holding the lines in place, being cautious not to damage the lines during this process. Gently pull the lines away from the pump and engine, taking note of their positions to facilitate reinstallation. It is essential to handle the lines with care to prevent any punctures or damage, especially if they contain fuel.

When you have successfully disconnected all the lines and electrical connections, you can safely proceed with the rest of your fuel system repairs or maintenance. Remember, this process requires patience and attention to detail to ensure a successful outcome. Always refer to your vehicle's manual for specific instructions and safety guidelines tailored to your make and model.

Harley's Fuel Injection: The Role of Vacuum Lines

You may want to see also

Fuel Tank Access: Remove fuel tank straps for easy line access

To gain access to the fuel lines, it's crucial to first locate and remove the fuel tank straps. These straps are designed to secure the fuel tank in place and can be quite challenging to remove due to their robust construction. Here's a step-by-step guide to help you through this process:

Step 1: Identify the Straps: Start by inspecting the fuel tank and locating the straps. These straps are typically made of sturdy materials like steel or heavy-duty rubber and are often positioned around the tank's circumference. They might be visible on the outside of the tank or could be concealed beneath protective covers.

Step 2: Gather the Necessary Tools: Removing the straps requires specific tools to ensure you don't damage the fuel tank or surrounding components. You will need a set of adjustable wrenches or a fuel tank strap removal tool, which is designed to grip and release the straps. Additionally, have a jack or a sturdy lift to support the weight of the fuel tank if it's not already accessible from below.

Step 3: Loosen the Straps: Begin by loosening the straps. Use your tools to carefully turn the straps counterclockwise, working your way around the tank. Apply steady pressure to release the tension, but be cautious not to overtighten the straps, as this can lead to damage. If the straps are particularly tight, consider using a lubricant to ease the process.

Step 4: Remove the Straps: Once the straps are loosened, carefully lift them off the fuel tank. You might need to wiggle and adjust the straps to free them from their mounting points. Take your time to avoid any sudden movements that could cause the straps to snap.

Step 5: Access the Fuel Lines: With the straps removed, you now have access to the fuel lines. Carefully inspect the lines for any signs of damage, leaks, or blockages. This step is crucial for ensuring the overall health of your fuel system and identifying potential issues before they become major problems.

Remember, working on fuel lines requires caution and attention to detail. Always refer to your vehicle's manual for specific instructions tailored to your make and model. If you're unsure about any step, consult a professional mechanic to ensure the job is done safely and correctly.

Mastering the Process: Extracting Fuel Lines from Transfer Pumps

You may want to see also

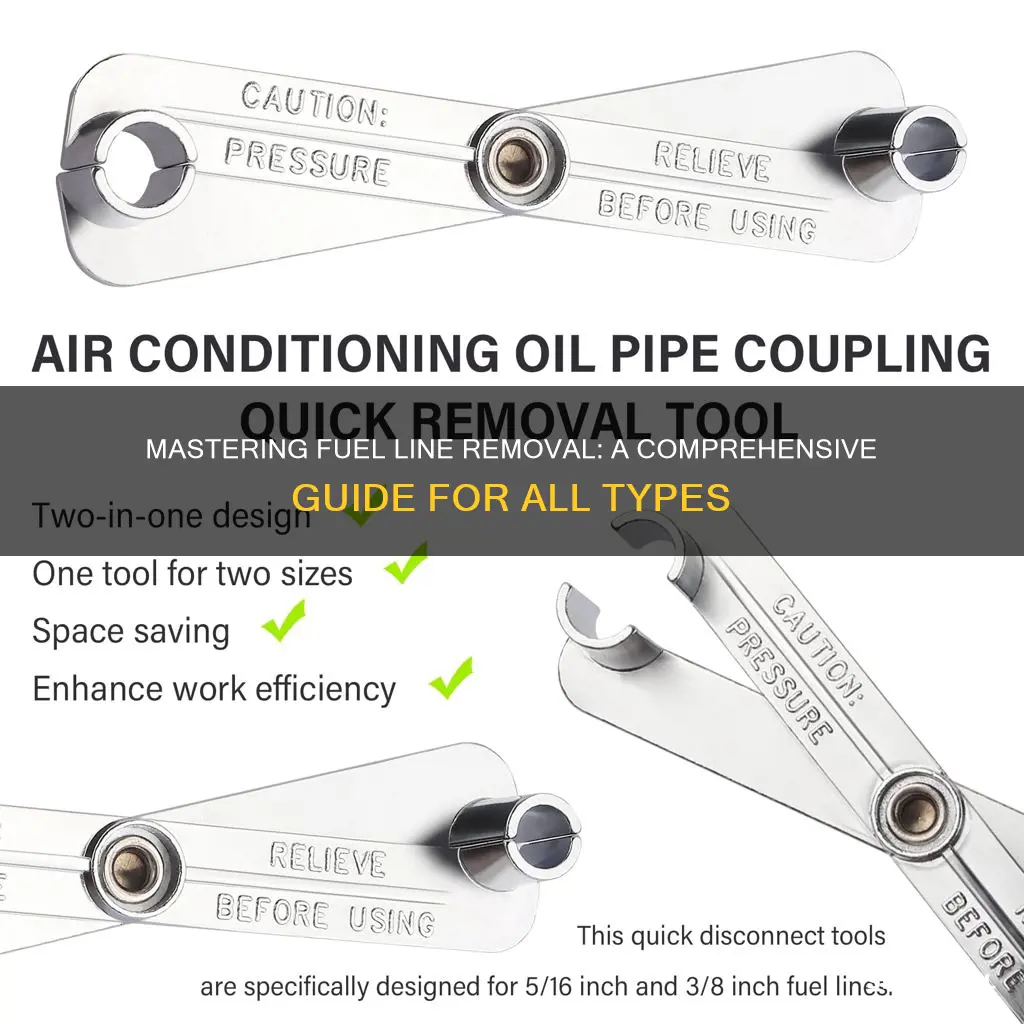

Line Removal Technique: Use pliers or cutting tools carefully to avoid damage

When dealing with fuel lines, it's crucial to employ the right techniques to ensure a safe and efficient removal process. One effective method is to use pliers or cutting tools with precision to minimize the risk of damage. Here's a step-by-step guide on how to achieve this:

Start by identifying the specific fuel line you need to remove. Different types of fuel lines may require varying approaches, so understanding the line's material and structure is essential. For example, some fuel lines are made of rubber or plastic, while others might be metal or composite. This initial assessment will help you choose the appropriate tools and technique.

Grasp the fuel line with a pair of pliers, ensuring you get a firm hold. The key is to apply controlled pressure to avoid slipping and causing potential damage. If the line is made of a flexible material, you might need to adjust your grip to accommodate its movement. Be cautious not to twist or bend the line excessively, as this could lead to cracks or tears. For more stubborn or tightly secured lines, consider using a pair of adjustable pliers to get a better grip and apply more force without risking damage.

In some cases, you may need to cut the fuel line to remove it. When using cutting tools, such as wire cutters or a sharp knife, exercise extreme caution. Always cut away from yourself and ensure the line is securely held in place to prevent it from springing back and causing injury. Make precise, clean cuts, and consider using a fuel line cutter if available, as these tools are designed to make clean, accurate incisions. After cutting, take extra care to avoid any sharp edges that could cause harm during the removal process.

Remember, the goal is to remove the fuel line without causing damage to the surrounding components or the line itself. By using pliers or cutting tools with care and precision, you can ensure a successful and safe removal process. Always take your time and double-check your work to avoid any unnecessary complications.

Mastering the Art: Connecting Plastic Fuel Lines to Braided Hose

You may want to see also

Cleaning and Inspection: Clean and inspect lines for any signs of contamination

When it comes to maintaining your vehicle's fuel system, cleaning and inspecting the fuel lines is an essential step that should not be overlooked. Over time, fuel lines can accumulate contaminants such as fuel varnish, water, and debris, which can lead to reduced performance and potential engine issues. Here's a detailed guide on how to clean and inspect your fuel lines to ensure optimal performance.

Start by removing the fuel lines from the vehicle. This process may vary depending on the make and model of your car, but generally, you'll need to locate the fuel lines, which are typically rubber or plastic hoses, and disconnect them from the fuel tank and various components like the fuel pump and injectors. Take note of the positions and connections to ensure a smooth reinstallation later. Once removed, you can begin the cleaning process.

Use a fuel line cleaner, which is a specialized cleaning agent designed to dissolve and remove contaminants. You can find these at most auto parts stores. Apply the cleaner to the inside of the fuel lines, ensuring an even coating. Allow the cleaner to sit for the recommended time, usually around 10-15 minutes, to give it time to break down any built-up gunk. After the specified time, use a high-pressure water jet or a compressed air gun to flush out the lines, removing any loose contaminants. For more stubborn deposits, you might need to use a fuel line brush to manually scrub the interior of the lines.

While cleaning, inspect the fuel lines for any signs of damage, cracks, or leaks. Look for any discolored or brittle areas, as these could indicate wear and tear or potential failure. Check for any blockages or restrictions in the flow of the fuel, as this could be a sign of contamination or debris buildup. Ensure that the lines are free-flowing and clear of any obstructions.

After cleaning and inspection, rinse the fuel lines thoroughly with clean water to remove any remaining cleaner and debris. Dry the lines completely, as moisture can lead to corrosion and further contamination. Reinstall the fuel lines, ensuring they are securely connected and aligned correctly. With the lines now clean and in good condition, your vehicle's fuel system should operate more efficiently, resulting in improved performance and potentially longer engine life. Regular cleaning and inspection of fuel lines are crucial for maintaining a healthy fuel system and avoiding costly repairs.

Fuel Line Hose: Choosing the Right Repair for FKM

You may want to see also

Frequently asked questions

Removing a fuel line requires caution and the right tools to avoid any accidents or damage. First, locate the fuel line and identify the type of connector or clamp used to secure it. Then, use the appropriate tool, such as a fuel line cutter or a pair of adjustable pliers, to carefully cut or loosen the connection. Ensure you have a clear workspace and wear protective gear, like gloves and safety goggles, to protect yourself from any potential spills or splashes.

Replacing a damaged fuel line is a complex process and should be done with care. Start by draining the fuel tank to avoid any spills during the replacement. Then, locate the old fuel line and disconnect it from the fuel pump, injectors, and the tank. Take note of the routing and any clips or brackets holding it in place. Carefully cut the old line and insert the new one, ensuring it is the correct size and routing. Secure the new line with the appropriate clamps or brackets and double-check all connections. Finally, refill the fuel tank and test the vehicle to ensure the new line is functioning properly.

Yes, using a fuel line cleaner can be an effective way to maintain and clean the fuel lines. Start by disconnecting the fuel line from the fuel pump and the tank. Then, pour the cleaner into the fuel tank and run the engine for a few minutes to allow it to circulate. This process helps to dissolve any deposits, varnish, or debris that may be present. After running the engine, drain the fuel tank and flush the lines with clean fuel to remove any remaining cleaner. Regular use of fuel line cleaner can help prevent clogs and maintain optimal fuel system performance.