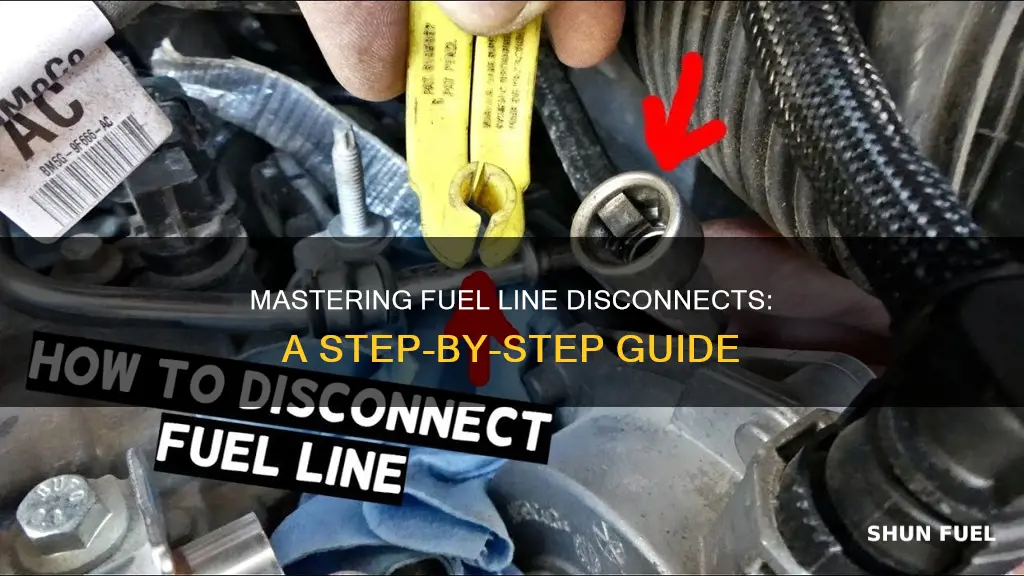

Disconnecting fuel line fittings can be a crucial step in vehicle maintenance or when replacing fuel components. It requires careful execution to avoid spills and ensure a safe working environment. This guide will provide a step-by-step process for safely disconnecting fuel line fittings, including identifying the correct tools, understanding the fitting types, and following proper safety protocols to prevent fuel leaks and potential hazards.

What You'll Learn

- Prepare the Vehicle: Ensure the engine is off and the vehicle is in a safe, stable position

- Locate the Fittings: Identify the fuel lines and their respective fittings under the hood

- Use the Right Tools: Gather wrenches, pliers, or a fuel line disconnect tool

- Loosen Connections: Apply gentle force to loosen the fittings without stripping threads

- Remove Carefully: Pull the fittings straight off, avoiding twists that can damage lines

Prepare the Vehicle: Ensure the engine is off and the vehicle is in a safe, stable position

Before you begin the process of disconnecting fuel line fittings, it is crucial to ensure the vehicle is in a safe and secure state. This step is essential to prevent any accidents or injuries during the procedure. Firstly, turn off the engine and allow it to cool down. This is important as the fuel lines may still contain residual heat, and cutting into hot lines can be dangerous. Once the engine is off, engage the parking brake to stabilize the vehicle. This will prevent the car from moving unexpectedly while you work on it.

Next, locate the fuel tank and identify the fuel lines that need to be disconnected. Typically, there are two main fuel lines: one for the intake and one for the return. The intake line brings fuel from the tank to the engine, while the return line sends unused fuel back to the tank. It is important to identify the correct lines to avoid any fuel spillage or engine damage.

To further ensure safety, place a large container or drain pan under the vehicle to catch any fuel that may spill during the disconnection process. This step is crucial to prevent fuel from contaminating the surrounding area and to make cleanup easier. Additionally, wear protective gear, such as gloves and safety goggles, to protect yourself from any potential fuel splashes or debris.

With the vehicle secure and the necessary safety measures in place, you can now proceed with the actual process of disconnecting the fuel line fittings. Remember to work systematically, ensuring that you have the right tools and that each connection is properly sealed before moving on to the next. This will help prevent fuel leaks and ensure a smooth and safe procedure.

Heat Shield for Fuel Line: Top Sources Revealed

You may want to see also

Locate the Fittings: Identify the fuel lines and their respective fittings under the hood

To begin the process of disconnecting fuel line fittings, you must first locate the fuel lines and their respective fittings under the hood of your vehicle. This step is crucial as it ensures you target the correct components for disconnection. Here's a detailed guide on how to identify these fittings:

Start by examining the engine compartment and locate the fuel tank. Fuel lines typically originate from the fuel tank and extend towards the engine, where they connect to various components. Look for rubber or plastic hoses that carry fuel from the tank to the engine. These lines are often color-coded or marked with identifiers to indicate their purpose. Common fittings include quick-connect fittings, which are commonly used for fuel lines due to their ease of installation and removal.

Identify the fuel lines that lead to the engine's fuel injectors or carburetor. These lines are usually longer and may have additional fittings or clamps securing them in place. The fittings at the end of these lines are often designed to fit specific fuel injectors or carburetors, so they may have unique shapes or sizes. It's essential to match the correct fitting to the corresponding fuel injector or carburetor to ensure a proper fuel supply.

Look for any additional fuel lines that might be present, such as those connecting to fuel pumps or return lines. These lines may have different fittings and connections, so careful identification is necessary. Some vehicles may also have fuel pressure regulators, which are typically located near the engine and are connected to the fuel lines. These regulators are crucial for maintaining the correct fuel pressure, so identifying the correct fittings is essential.

When identifying the fittings, pay attention to their physical characteristics. Fittings may have different threads, connectors, or locking mechanisms. Some might have a screw-on design, while others may use a bayonet-style connection. Understanding these differences will help you select the appropriate tools for disconnection. Additionally, take note of any clamps or retaining clips used to secure the fittings, as these may need to be adjusted or removed during the disconnection process.

By carefully examining the engine compartment and identifying the fuel lines and their respective fittings, you'll be well-prepared to proceed with the next steps of disconnecting the fuel line fittings safely and efficiently.

Solid Fuel in KSP: Unlocking the Mystery of Fuel Lines

You may want to see also

Use the Right Tools: Gather wrenches, pliers, or a fuel line disconnect tool

When it comes to disconnecting fuel line fittings, having the right tools is crucial to ensure a safe and efficient process. The primary goal is to avoid any fuel spills or leaks, which can be dangerous and cause environmental damage. Here's a step-by-step guide on how to gather the necessary tools for this task:

Gather Wrenches and Pliers: Start by identifying the type of fittings you are dealing with. Fuel lines often use various types of fittings, including quick-connect fittings, compression fittings, and clamp-style fittings. For quick-connect fittings, you'll typically need a special quick-connect fitting tool or a pair of adjustable wrenches. These wrenches should be adjustable to accommodate different sizes of fittings. For compression fittings, a standard pipe wrench or a pair of channel locks (also known as adjustable spanner pliers) will suffice. Ensure you have the appropriate size to fit the fuel line.

Consider a Fuel Line Disconnect Tool: In some cases, especially with older vehicles or more complex fuel systems, a fuel line disconnect tool might be necessary. This specialized tool is designed to safely and efficiently disconnect fuel lines without the risk of spilling fuel. It often features a built-in clamp or a mechanism to grip the fitting securely. When using this tool, make sure to follow the manufacturer's instructions to avoid any damage to the fuel system.

Having the right tools will make the disconnection process much smoother. It's essential to inspect your tools before starting the job to ensure they are in good condition and suitable for the task. Additionally, always wear protective gear, such as gloves and safety goggles, to protect yourself from any potential fuel splashes or debris. Remember, taking the time to gather the appropriate tools will contribute to a safer and more successful fuel line disconnection.

E85 Fuel's Impact: Does It Cause Dry Rot in Fuel Lines?

You may want to see also

Loosen Connections: Apply gentle force to loosen the fittings without stripping threads

When dealing with fuel line fittings, it's crucial to approach the task with care and precision to avoid any damage. The goal here is to safely disconnect the fuel lines without causing any threads to strip, which can lead to costly repairs and potential safety hazards. The first step in this process is to understand the importance of applying the right amount of force.

Start by identifying the fittings you need to loosen. These are typically located where the fuel lines connect to the fuel tank, fuel pump, or other components. Use a wrench or a specialized fuel line disconnect tool, ensuring it fits the fitting's size and shape. The key is to use the tool as an extension of your hand, providing leverage without applying excessive force directly to the fitting.

Gently insert the tool onto the fitting, ensuring it is properly aligned. Apply a steady, even pressure to begin loosening the connection. It's important to move the tool in a smooth, continuous motion rather than forcing it, as this can strip the threads. If you feel resistance, stop and check the alignment. Adjust your grip and try again, ensuring the tool is correctly positioned.

As you loosen the fitting, you might encounter some resistance due to the fuel line's internal pressure. This is normal and indicates that you are on the right track. Continue applying gentle, even pressure, and the fitting should gradually come loose. Remember, the goal is to avoid any sudden, forceful movements that could damage the threads or the fuel line itself.

Once the fitting is loosened, you can now disconnect it by hand. Carefully pull the fitting away from the connection, ensuring you don't strip any remaining threads. If the fitting is stubborn, you can use a small amount of thread locker or anti-seize compound to help loosen it further without causing damage. Always take your time and be patient, as rushing this process can lead to mistakes.

Evap Line's Role in Fuel Filter Maintenance

You may want to see also

Remove Carefully: Pull the fittings straight off, avoiding twists that can damage lines

When disconnecting fuel line fittings, it's crucial to approach the task with precision and care to avoid any potential damage to the fuel lines. The process involves gently removing the fittings without applying excessive force or twisting, as this can lead to cracks or tears in the delicate fuel lines. Here's a step-by-step guide to ensure a safe and successful disconnection:

Start by identifying the specific fittings you need to remove. These are typically located near the fuel tank and are connected to the fuel lines that supply fuel to the engine. Locate the fittings securely attached to the fuel lines and prepare the necessary tools, such as a fuel line disconnect tool or a pair of adjustable pliers, to facilitate the process.

Gently loosen the fittings by turning them counterclockwise. Ensure you do not overtighten, as this can create unnecessary tension and make removal more challenging. Once loosened, you should be able to create a small gap between the fitting and the fuel line.

Now, the critical step is to pull the fittings straight off, maintaining a consistent and direct force. Avoid any twisting or rotational movements, as these can cause the fuel lines to kink or damage the inner lining. Apply steady pressure and carefully extract the fittings from the fuel lines. Take your time with this step to ensure a clean and safe disconnection.

After removing the fittings, inspect the fuel lines for any signs of damage or wear. Cracks, tears, or kinks in the lines could lead to fuel leaks or reduced performance. If any damage is detected, it is essential to replace the affected fuel lines to ensure the safety and efficiency of your vehicle's fuel system.

Remember, patience and a gentle approach are key when dealing with fuel line fittings. By following these instructions, you can effectively disconnect the fittings without causing any unnecessary harm to the fuel lines, ensuring a smooth and safe process for your vehicle's maintenance.

Fuel Line Furnace Bleeding: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Disconnecting a fuel line fitting requires caution and the right tools to avoid any accidents. First, ensure the engine is cool and parked on a level surface. Locate the fuel line fitting, which is typically a metal or rubber hose connected to a fuel tank or fuel pump. Use a fuel line disconnect tool, also known as a fuel line cutter or fuel line disconnect kit, to carefully cut the fitting. These tools provide a safe and controlled way to separate the fitting without damaging the fuel line.

While it is possible to disconnect a fuel line fitting without specialized tools, it is not recommended for beginners or those without experience. Using the right tools ensures a clean and safe cut, reducing the risk of fuel spills and potential fires. If you lack the necessary equipment, consider borrowing or renting a fuel line disconnect tool from a local auto parts store or mechanic.

If the fuel line fitting is corroded or damaged, it is essential to replace it to ensure safe operation. Attempting to disconnect a damaged fitting may lead to fuel leaks and potential hazards. In such cases, consult a professional mechanic who can advise on the appropriate replacement parts and ensure the fuel system is properly repaired.

Absolutely. Working with fuel lines requires strict adherence to safety protocols. Always wear protective gear, including gloves and safety goggles, to prevent any fuel-related injuries. Ensure proper ventilation in the work area to avoid inhaling fuel vapors. Keep a fire extinguisher nearby, as fuel is highly flammable. Additionally, be cautious when using power tools or heat sources, as they can ignite fuel.

To prevent fuel line damage, use the appropriate size and type of fuel line disconnect tool for your specific fitting. Apply gentle force and avoid excessive pressure, as this can cause the fuel line to kink or rupture. Take your time and work carefully to avoid any sudden movements that might lead to accidents. After disconnecting, inspect the fuel line for any signs of damage and replace it if necessary.