Disassembling the fuel line on a 1996 Dodge Ram diesel engine can be a complex task, but with the right tools and a systematic approach, it is definitely achievable. This guide will provide a step-by-step process to safely and effectively disassemble the fuel line, ensuring you have all the necessary information to complete the job successfully. Understanding the process is crucial to avoid any potential damage to the engine or the fuel system.

What You'll Learn

- Fuel Line Location: Identify the fuel lines under the hood and dashboard

- Tools Required: Gather tools like a fuel line cutter and wrench

- Safety Precautions: Wear gloves and eye protection to avoid fuel spills

- Fuel Line Removal: Loosen and remove the fuel lines using the appropriate tools

- Disassembly Process: Carefully disconnect the lines, noting their positions for reassembly

Fuel Line Location: Identify the fuel lines under the hood and dashboard

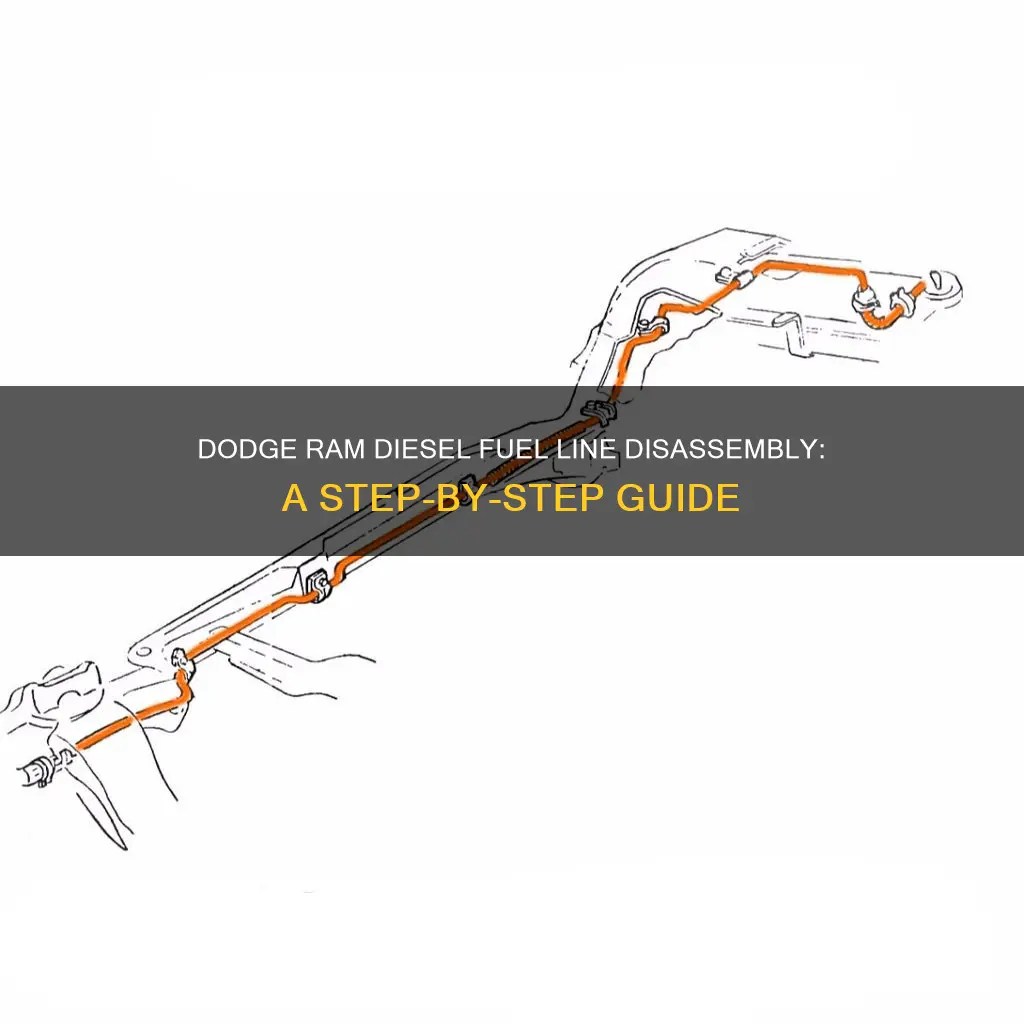

To begin the process of disassembling the fuel lines on a 1996 Dodge Ram diesel engine, it's crucial to first locate the fuel lines under the hood and dashboard. These lines are responsible for delivering fuel from the tank to the engine, and identifying their exact positions is essential for a successful disassembly.

Under the hood, you'll typically find the primary fuel lines running from the fuel pump to the engine. The fuel pump is usually located near the front of the engine compartment, and the lines will extend from it to various injectors or the fuel rail. These lines are often made of rubber or a flexible material and can be quite long, making them easier to spot. Look for any connections or fittings that might indicate where the lines split to serve different parts of the engine.

Moving to the dashboard area, you might find additional fuel lines that are less visible but still crucial. These lines are often part of the fuel injection system and can be more delicate due to their proximity to the engine's control unit and other sensitive components. The lines in this area may be shorter and more numerous, and they might be bundled together for better organization. Carefully inspect the dashboard and any surrounding panels to locate these lines.

When identifying the fuel lines, pay attention to their color, thickness, and any unique markings or identifiers. Different colors or thicknesses can indicate various functions, such as high-pressure lines or return lines. Markings or labels might also provide clues about the specific components they connect to. It's important to take your time and carefully examine each line to ensure you don't mistake one for another.

Remember, the goal is to understand the layout of the fuel lines before you start the disassembly process. This will help you plan the removal process and ensure that you don't damage any other components during the procedure. Proper identification will also make it easier to reassemble the system once you're done.

Mastering the Art of Fuel Line Replacement: A Step-by-Step Guide

You may want to see also

Tools Required: Gather tools like a fuel line cutter and wrench

To begin the process of disassembling the fuel line on your 1996 Dodge Ram diesel engine, it's crucial to have the right tools at hand. The primary objective is to safely and effectively cut through the fuel line to facilitate the disassembly process. Here's a detailed breakdown of the tools you'll need:

Fuel Line Cutter: This specialized tool is designed to cut through fuel lines without causing damage to the surrounding components. It's essential to use a cutter that can handle the thickness and material of the fuel line you're working with. Look for a cutter with adjustable settings to ensure a clean and precise cut.

Wrenches: Wrenches are fundamental for tightening or loosening various components during the disassembly process. You'll require a set of different sizes to accommodate the various nuts and bolts that secure the fuel line system. Ensure you have a combination of metric and imperial wrenches to cover a wide range of bolt sizes.

Pliers: Pliers can be handy for gripping and turning small fasteners or for applying pressure to certain areas while cutting the fuel line. Consider getting a pair of adjustable pliers for added versatility.

Safety Gear: While not a tool per se, safety gear is crucial for your well-being. Safety goggles protect your eyes from any potential fuel or debris, and gloves provide a better grip and protect your hands during the process.

Additional Tips: Before starting, ensure you have a clear understanding of the fuel line layout and the specific components you need to access. It's also a good idea to have a diagram or reference material specific to your 1996 Dodge Ram diesel model. This will help you identify the exact locations of the fuel lines and the corresponding fasteners.

Mastering Fuel Line Bleeding: A Guide to Perkins Diesel Maintenance

You may want to see also

Safety Precautions: Wear gloves and eye protection to avoid fuel spills

When working on a vehicle's fuel system, especially on a diesel engine like the 1996 Dodge Ram, it is crucial to prioritize safety to prevent any accidents or injuries. One of the most important safety measures is to wear appropriate personal protective equipment (PPE). In this case, the key focus is on protecting yourself from potential fuel spills.

Fuel lines can contain hazardous substances, and any spillage can lead to skin irritation, respiratory issues, or other health problems. Therefore, it is essential to take the following precautions:

Gloves: Wear heavy-duty gloves made of durable materials such as leather or rubber. These gloves will act as a barrier between your skin and the fuel, preventing direct contact. Ensure the gloves fit well to allow for dexterity while still providing adequate protection. Look for gloves specifically designed for automotive work or industrial applications, as they will offer the necessary grip and durability.

Eye Protection: Protect your eyes with safety goggles or a face shield. Diesel fuel can splatter and spray, and any debris or contaminants in the fuel could cause irritation or damage to your eyes. Goggles designed for chemical protection or automotive work will provide the required shield and impact resistance. Ensure a secure fit to prevent any fuel from entering your eyes.

By wearing gloves and eye protection, you create a safe working environment, reducing the risk of fuel-related injuries and ensuring a more controlled and safe disassembly process. It is a simple yet crucial step to follow before beginning any fuel system work.

E85 Fuel's Impact: Does It Cause Dry Rot in Fuel Lines?

You may want to see also

Fuel Line Removal: Loosen and remove the fuel lines using the appropriate tools

To begin the process of disassembling the fuel line on a 1996 Dodge Ram diesel engine, you'll need to locate the fuel lines and prepare the necessary tools. The fuel lines on this vehicle are typically made of rubber or plastic and are connected to the fuel tank and the engine. Start by identifying the fuel lines, which are usually black or dark-colored hoses. They can be found running from the fuel tank to the engine compartment, often near the front of the vehicle.

Gather the appropriate tools for this task. You will need a fuel line disconnect tool, which is a specialized tool designed to release the pressure and disconnect the fuel lines. This tool is crucial to avoid any fuel spills and ensure a safe removal process. Additionally, have a set of wrenches or pliers handy, as you may encounter some resistance when loosening the connections.

Now, carefully inspect the fuel lines for any signs of damage or wear. Look for cracks, leaks, or any areas where the line might be pinched or restricted. It's important to address any issues before proceeding with the disassembly. If you notice any problems, take the necessary steps to repair or replace the affected fuel line before continuing.

Once you have confirmed that the fuel lines are in good condition, proceed with the removal process. Locate the fuel line disconnect tool and insert it into the connection point of the fuel line. Apply firm pressure to release the pressure and disconnect the fuel line from the engine or fuel tank. Be cautious as you disconnect, as fuel can spill if not handled properly.

After disconnecting one fuel line, repeat the process for the remaining lines. Take your time and ensure that each connection is properly loosened and removed. It is essential to follow the correct sequence to avoid any confusion during the reassembly process. Once all the fuel lines are disconnected, you can safely remove them from the vehicle, making note of their positions for future reference.

Chevy Fuel Line Reversal: A Step-by-Step Guide

You may want to see also

Disassembly Process: Carefully disconnect the lines, noting their positions for reassembly

The disassembly process for the fuel lines on a 1996 Dodge Ram diesel engine requires a systematic approach to ensure an efficient and safe procedure. Here's a detailed guide on how to carefully disconnect the fuel lines and prepare for reassembly:

Start by locating the fuel lines that need to be disassembled. These lines are typically found along the engine's fuel rail and may require some access to the engine bay. It is crucial to identify the correct lines to avoid any confusion, as the positions of the lines might vary depending on the specific engine configuration.

Carefully inspect each fuel line for any signs of damage, corrosion, or wear. This step is essential to ensure that the lines are in good condition and can be safely reassembled. Look for any cracks, leaks, or signs of deterioration that might indicate a need for replacement.

Now, begin the disassembly process by using the appropriate tools to carefully disconnect the fuel lines from their respective connections. This step requires patience and a gentle approach to avoid any damage to the lines or the surrounding components. Locate the clamps or fittings securing the lines and release them, taking note of the positions of the lines as you disconnect them. It is important to keep track of the connections to ensure a smooth reassembly process.

As you disconnect the lines, carefully set aside each line and its corresponding fittings. Label or mark the lines with their respective positions to avoid confusion during reassembly. Proper organization of the components will save time and ensure an accurate restoration of the fuel system.

By following these steps, you can systematically disassemble the fuel lines of a 1996 Dodge Ram diesel engine, ensuring that the process is thorough and prepared for the next phase of reassembly. Remember, taking the time to carefully disconnect and note the positions of the lines will contribute to a successful and efficient repair or maintenance task.

Polaris Ranger 570 Fuel Line Fittings: A Comprehensive Guide

You may want to see also

Frequently asked questions

Disassembling the fuel line on a diesel engine requires caution and a systematic approach. Start by locating the fuel line connections, typically found under the hood and near the engine. Use a fuel line disconnect tool or a pair of adjustable pliers to carefully release the fittings and remove the fuel line. Take note of the positions of any clips or fasteners to ensure proper reassembly.

You will need a set of wrenches or socket tools to loosen and remove the fuel line fittings. A fuel line disconnect tool, also known as a fuel line cutter or bender, can be helpful for safely cutting and bending the fuel line. Additionally, have a clean workspace and some rags ready to catch any spills.

Yes, safety is crucial when working with fuel lines. Ensure the engine is cool to the touch before starting the disassembly process. Wear protective gloves and goggles to prevent fuel from splashing. Work in a well-ventilated area, and be aware of potential fuel leaks. If you notice any fuel escaping, stop the process immediately and seek professional advice.

To minimize the risk of fuel spillage, gently loosen the fittings and avoid sudden movements. Use a rag to cover the ends of the fuel line when removing them to catch any residual fuel. Keep the fuel line as straight as possible during disassembly to prevent kinking. If you encounter any resistance, do not force it; instead, check for obstructions or corrosion that may require further investigation.

If you encounter any difficulties or suspect a problem, it's best to consult a professional mechanic. They can provide expert guidance and ensure the process is done safely. Additionally, refer to the vehicle's manual for specific instructions and diagrams related to your 1996 Dodge Ram diesel model.