Cutting and replacing rusted fuel lines can be a necessary step in vehicle maintenance, especially for older cars or those with significant rust issues. This process requires careful planning and the right tools to ensure safety and efficiency. In this guide, we'll explore the steps involved in safely cutting and replacing rusted fuel lines, including identifying the affected lines, gathering the necessary tools, and following a step-by-step approach to minimize the risk of fuel leaks and ensure a successful repair.

What You'll Learn

- Safety Gear: Wear gloves, goggles, and a respirator to protect against rust dust and fumes

- Line Inspection: Carefully examine the fuel lines for signs of corrosion and damage

- Cutting Tools: Use a sharp, clean pair of wire cutters or a fuel line cutter

- Precision: Cut straight and at a 45-degree angle to ensure a clean, precise cut

- Disposal: Dispose of the rusted fuel line properly, following local regulations

Safety Gear: Wear gloves, goggles, and a respirator to protect against rust dust and fumes

When dealing with rusted fuel lines, prioritizing safety is crucial to avoid any potential hazards. Here's a detailed guide on the essential safety gear you should wear:

Gloves: Protecting your hands is of utmost importance. Rusted fuel lines can be extremely fragile and sharp, and any contact with the bare metal could lead to injury. Wear heavy-duty leather gloves designed for industrial use. These gloves should provide a secure grip and offer protection against cuts and punctures. Ensure they cover your entire hand and reach up to your wrist for maximum coverage.

Goggles: Eye protection is critical to prevent any potential splashes or dust from reaching your eyes. Rusted fuel lines may release small particles or corrosive substances when cut, which can cause severe irritation or even permanent damage. Choose safety goggles that fit snugly around your eyes, ensuring no gaps allow dust or debris to enter. Look for goggles with a double-lens design and an anti-scratch coating for optimal protection.

Respirator: Inhaling rust dust and fumes can have serious health consequences. Rusted metal can release harmful particles and gases, especially when cut or ground. A respirator will filter out these hazardous substances, protecting your lungs. Opt for a half-mask respirator with a high-efficiency particulate air (HEPA) filter, which can capture very fine particles. Ensure it fits comfortably over your nose and mouth, allowing for easy breathing while providing effective protection.

Additionally, consider wearing old clothing that can be easily disposed of or cleaned, as the rusted fuel lines may contain contaminants. It is also advisable to work in a well-ventilated area or outdoors to minimize the inhalation of fumes. Remember, taking these safety precautions will not only protect you but also ensure a more efficient and controlled cutting process.

Honda Motorcycle Fuel Line: Size Guide for Optimal Performance

You may want to see also

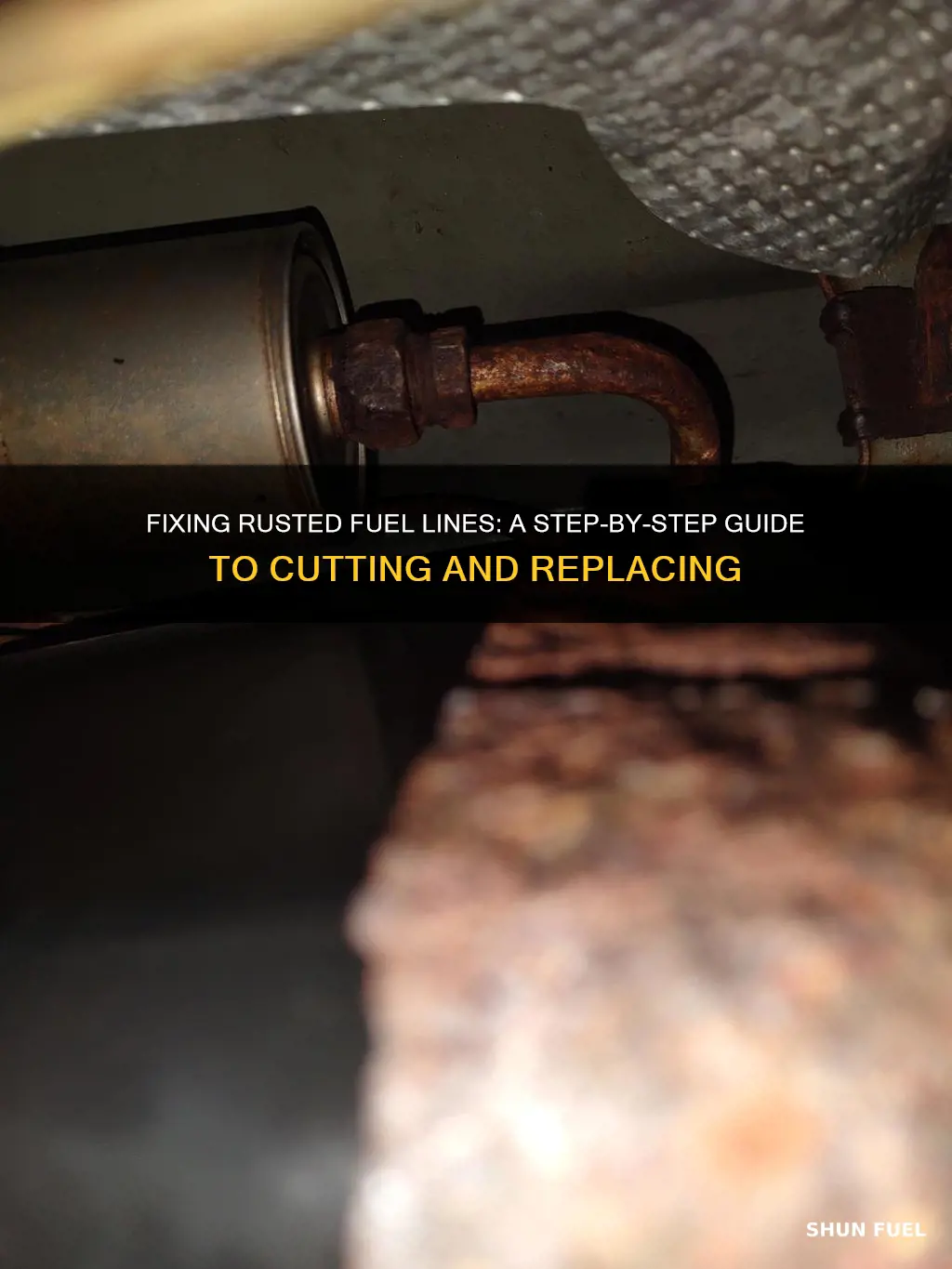

Line Inspection: Carefully examine the fuel lines for signs of corrosion and damage

When inspecting the fuel lines for signs of corrosion and damage, it's crucial to be thorough and methodical. Start by visually examining the lines for any visible signs of deterioration. Look for areas where the metal has become brittle, flaky, or has developed a reddish-brown color, which is often indicative of rust. Pay close attention to the connections and bends in the lines, as these areas are more prone to corrosion due to the increased surface area and potential for moisture accumulation.

Use a bright flashlight or a mirror to illuminate the lines and inspect hard-to-see areas. Look for any signs of leakage, which could be caused by small holes, cracks, or corrosion that has weakened the line's integrity. Also, check for any signs of distortion or kinking, as these issues can restrict fuel flow and potentially lead to engine problems.

If you notice any suspicious areas, it's essential to take a closer look. Carefully remove any protective covering or insulation around the suspected corrosion sites. This will allow you to assess the severity of the damage and determine the best course of action. Remember, the goal is to identify any compromised areas that may require cutting and replacement.

When examining the fuel lines, also consider the overall condition of the vehicle. Check for any other signs of rust or corrosion in the engine bay, as these issues can spread and affect multiple components. Additionally, inspect the fuel tank and its surroundings for any signs of leakage or damage, as these can be related to the condition of the fuel lines.

By carefully inspecting the fuel lines for corrosion and damage, you can identify potential issues early on and take the necessary steps to address them. This proactive approach ensures the longevity of your vehicle's fuel system and overall engine performance. Remember, regular maintenance and timely repairs are key to keeping your vehicle running smoothly.

Mastering Kicker Motor Fuel Line Connections: A Comprehensive Guide

You may want to see also

Cutting Tools: Use a sharp, clean pair of wire cutters or a fuel line cutter

When dealing with rusted fuel lines, using the right cutting tools is essential to ensure a clean and precise cut. One of the most effective and commonly used tools for this task is a sharp, clean pair of wire cutters. These tools are designed to cut through various materials, including metal and fuel lines, with minimal effort. Here's a step-by-step guide on how to use wire cutters for this purpose:

Start by ensuring that the wire cutters are sharp and in good condition. Dull or damaged cutters may struggle to make a clean cut, potentially causing damage to the fuel line or creating a jagged edge. Inspect the cutters and, if necessary, sharpen or replace them to maintain optimal performance.

Position the wire cutters so that the cutting edges align with the fuel line. Apply firm pressure to the handles and guide the cutters along the length of the fuel line. A sharp pair of cutters will easily slice through the rusted material, allowing you to make a clean cut. Take your time and apply steady pressure to avoid crushing or damaging the fuel line.

For more intricate or stubborn rusted sections, you might consider using a fuel line cutter, which is specifically designed for cutting fuel lines. These cutters often feature a serrated edge or a specialized blade that can easily penetrate and cut through the rusted material. When using a fuel line cutter, ensure it is the correct size for the diameter of your fuel line to avoid any potential damage.

Remember, when cutting fuel lines, it's crucial to work carefully and methodically. Take your time to make precise cuts, especially if dealing with a complex or rusted section. Always prioritize safety by wearing protective gear, such as gloves and safety goggles, to prevent any potential injuries during the cutting process.

Mastering Fuel Line Pressure: A Comprehensive Testing Guide

You may want to see also

Precision: Cut straight and at a 45-degree angle to ensure a clean, precise cut

When dealing with rusted fuel lines, precision is key to ensuring a safe and effective repair. Cutting these lines requires a careful approach to avoid any potential hazards. Here's a detailed guide on how to achieve a clean and precise cut:

Start by identifying the section of the fuel line that needs to be replaced. Inspect the line for any visible signs of damage or corrosion. It's crucial to locate the exact point where the cut will be made, ensuring you remove only the affected portion. Use a sharp utility knife or a specialized fuel line cutter for this task. The goal is to make a straight and clean cut to prevent any jagged edges that could lead to further issues.

To achieve a straight cut, hold the fuel line firmly with one hand, providing support and stability. With the other hand, guide the cutting tool along the line, ensuring a consistent and straight path. Apply gentle pressure to the cutting tool, allowing it to glide smoothly along the line's surface. Take your time with this step to ensure accuracy.

For a 45-degree angle cut, you'll need to adjust your technique slightly. Hold the fuel line at a slight angle, creating a 45-degree slope. Then, carefully guide the cutting tool along this angle, maintaining a steady hand. This technique ensures that the cut is both precise and clean, minimizing the risk of any sharp, protruding edges that could cause damage or injury.

Practice and patience are essential when cutting fuel lines. Take your time, and don't rush the process. A precise cut will not only ensure the safety of your vehicle but also provide a neat and professional finish to your repair work. Remember, taking the extra time to get it right is always preferable to rushing and potentially causing further complications.

Understanding Fuel Line Sizes: Supply and Return Fuel Lines Explained

You may want to see also

Disposal: Dispose of the rusted fuel line properly, following local regulations

When dealing with a rusted fuel line, proper disposal is crucial to ensure environmental safety and compliance with local regulations. Here's a step-by-step guide on how to handle the disposal process:

- Identify Local Regulations: Begin by researching and understanding the waste management guidelines provided by your local government or environmental agency. Different regions may have specific requirements for disposing of hazardous materials, including rusted metal parts. Contact your local waste management department or visit their website to gather this information. They can provide details on designated disposal sites, collection methods, and any necessary permits.

- Prepare for Disposal: Before transporting the rusted fuel line to the disposal site, ensure it is securely packaged to prevent any potential leaks or spills. Use sturdy containers or bags that are designed to contain hazardous waste. If the fuel line is still attached to the vehicle or machinery, carefully disconnect it, taking note of its position and any specific connections. This preparation step is essential to avoid any accidental release of contaminants.

- Transport and Delivery: Transport the packaged rusted fuel line to an authorized disposal facility or recycling center. Follow the instructions provided by your local waste management authorities regarding transportation methods. Some areas may require specialized vehicles or containers for hazardous waste. Upon arrival at the disposal site, present the waste to the staff, who will guide you through the process and ensure proper handling.

- Disposal Methods: The disposal process may vary depending on your location and the specific regulations. Common methods include:

- Landfilling: Rusted metal, including fuel lines, can be disposed of in designated landfills. These sites are designed to manage and contain hazardous waste.

- Incineration: In some cases, especially for small amounts of rusted fuel line, incineration may be an option. This method involves burning the waste at high temperatures, reducing it to ash and minimizing environmental impact.

- Recycling: If the fuel line is made of recyclable materials, such as certain types of metal, it can be sent to specialized recycling facilities. These facilities will process the waste and recover valuable materials for reuse.

Documentation and Records: Keep records of the disposal process, including the date, location, and method of disposal. This documentation is essential for compliance and can be required by regulatory bodies. It also ensures that you have a record of the proper handling of hazardous waste, which is crucial for future reference and any potential audits.

Remember, improper disposal of rusted fuel lines can lead to environmental contamination and legal consequences. Always prioritize safety and adhere to local regulations to protect both the environment and yourself.

NHRA Fuel Line Routing: Engine Compartment Rules Explained

You may want to see also

Frequently asked questions

When dealing with rusted fuel lines, it's crucial to prioritize safety and use the right tools. Start by wearing protective gear, including gloves and safety goggles, to shield yourself from any potential hazards. Use a sharp, clean pair of fuel line cutters or a utility knife designed for cutting fuel lines. Make sure the tool is sharp to get a clean cut. Cut the line at a 90-degree angle, ensuring you don't compromise the integrity of the connection.

If the fuel line is severely rusted or damaged, it might be best to replace it entirely. Rust can weaken the line, leading to potential leaks or even explosions. Locate the nearest fuel line fitting or connector and cut the line at that point. Then, use a fuel line adapter or a new section of fuel line to reconnect the two ends, ensuring a secure and leak-free connection.

In some cases, you might be able to temporarily bypass the damaged section of the fuel line. Use a length of fuel line that is slightly longer than the damaged part and attach it to the fuel tank and the engine's fuel rail or carburetor. Secure the connection with fuel line clips or tape. This is a short-term solution and should not be left for an extended period, as it may lead to fuel leaks and potential safety hazards.