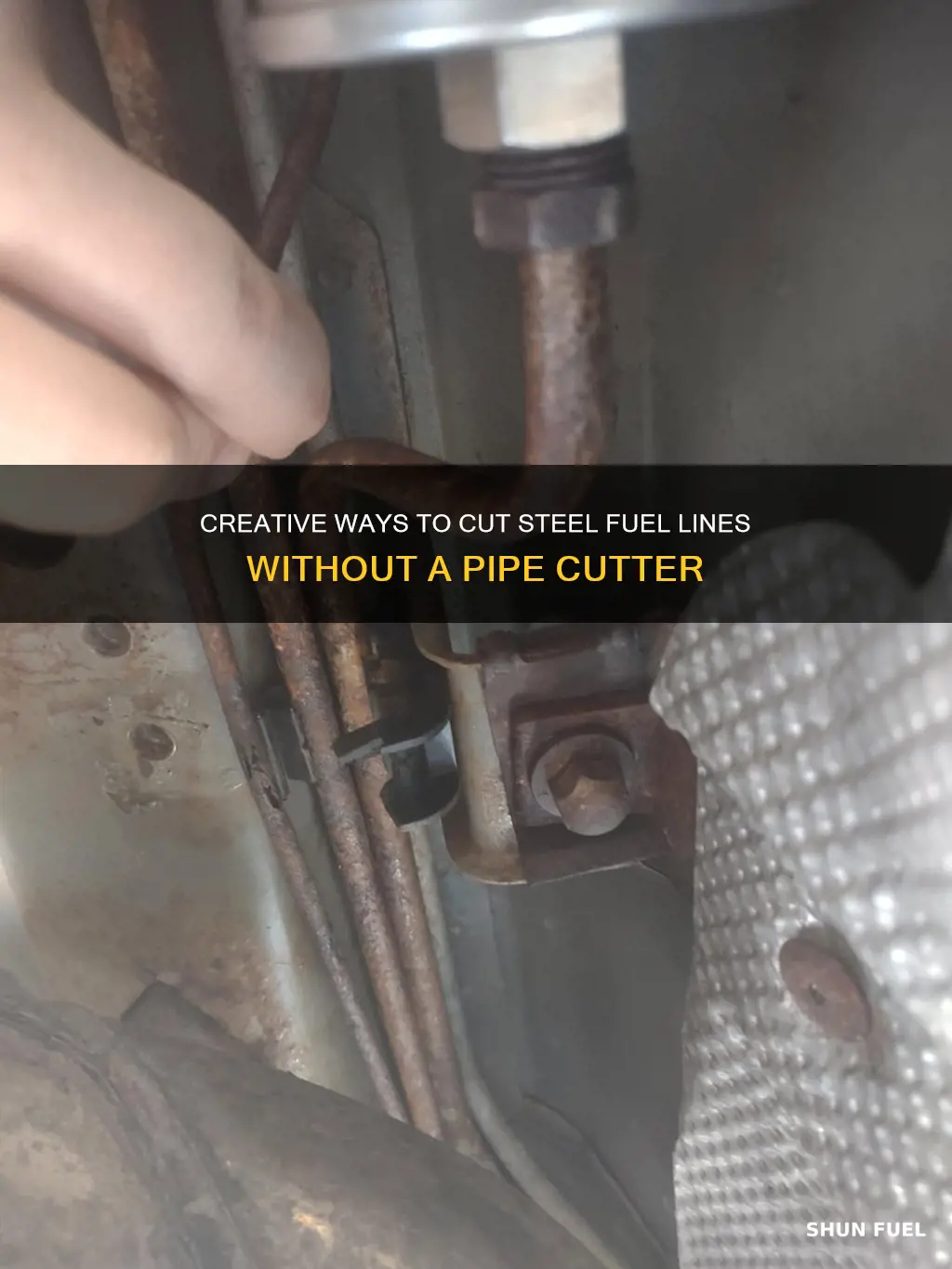

Cutting steel fuel lines without a pipe cutter can be a challenging task, but it's possible with the right tools and techniques. Here's a guide on how to achieve this: First, ensure you have the necessary safety gear, including gloves and safety goggles. Then, use a pair of sharp, heavy-duty scissors or a utility knife to carefully cut through the line, making sure to avoid any damage to the surrounding components. It's crucial to measure and mark the line accurately before cutting to ensure a precise fit. Additionally, consider using a heat gun to soften the steel slightly, making it easier to cut, but be cautious not to overheat the line. Finally, test the new connection by running the fuel through the line to ensure there are no leaks.

| Characteristics | Values |

|---|---|

| Safety Precautions | Wear safety gear, including gloves, goggles, and a respirator. Ensure proper ventilation in the work area. |

| Tools Required | Heat source (torch or flame), protective gloves, safety glasses, respirator, steel cutting fluid, and a suitable cutting method (e.g., using a file, sandpaper, or a sharp knife). |

| Steps | 1. Clean the fuel line to remove any dirt or debris. 2. Apply a cutting fluid to the line to prevent overheating and warping. 3. Use a heat source to carefully melt and weaken the steel at the desired cut point. 4. Once the line is weakened, use a sharp tool to carefully cut through the steel, taking care not to damage the surrounding material. 5. Repeat the process for any additional cuts needed. |

| Tips | - Practice on a similar material beforehand to get a feel for the process. - Take your time and work carefully to avoid accidents. - Ensure the fuel line is completely cooled before handling to prevent burns. |

| Alternatives | Consider using a pipe cutter designed for steel if available, as it provides a more precise and controlled cut. However, if a pipe cutter is not accessible, the above method can be employed with caution. |

What You'll Learn

Use a hacksaw for clean, precise cuts

When it comes to cutting steel fuel lines without a pipe cutter, a hacksaw is a versatile and accessible tool that can provide clean and precise cuts. Here's a step-by-step guide on how to achieve this:

Prepare the Hacksaw: Start by ensuring your hacksaw is in good condition. Check the blade for any signs of wear or damage, and if necessary, replace it with a fresh blade. A sharp and sturdy blade is crucial for a clean cut. Adjust the blade tension to a moderate setting, allowing for some flexibility while maintaining control. This adjustment will enable you to guide the blade smoothly along the line you intend to cut.

Mark the Line: Before making the cut, mark the steel fuel line with a permanent marker or a piece of chalk. Measure and mark the desired length, ensuring you account for any necessary allowances or adjustments. A clear mark will serve as a visual guide, making it easier to follow the line with the hacksaw.

Position the Hacksaw: Hold the hacksaw with one hand, using the handle for control, and place the blade against the marked line. Position the blade at a slight angle, ensuring it is stable and secure. This angle will help guide the blade through the material without causing it to wander. Apply gentle pressure with your hand holding the blade, maintaining a steady pace.

Cutting Technique: As you guide the hacksaw along the marked line, apply steady and even pressure. Keep the blade at a consistent angle to ensure a straight cut. Avoid applying excessive force, as it may lead to an uneven or jagged cut. Instead, let the blade do the work, and adjust your hand position to maintain control. Take your time and be patient, as rushing may result in mistakes.

Finishing the Cut: Continue the cutting process until you have reached the desired length. Once you've completed the cut, inspect the edges to ensure they are smooth and clean. If any roughness is present, carefully file the edges with a fine-grit file or sandpaper to create a precise and professional finish. This step is essential to ensure a secure connection for any subsequent plumbing work.

By following these steps and utilizing a hacksaw effectively, you can achieve clean and precise cuts in steel fuel lines without the need for specialized pipe cutters. It is a practical method for various plumbing and automotive projects, offering an affordable and accessible solution for cutting steel materials.

Unleash Your Potential: Understanding Your Unique Fuel Line

You may want to see also

Heat the line slightly for easier bending

When working with steel fuel lines, you might encounter the challenge of needing to cut and bend the line without a pipe cutter. While a pipe cutter is the most efficient tool for this task, there are alternative methods to achieve the desired result. One effective technique is to heat the steel fuel line slightly, which can make the bending process much easier and less prone to damage.

The key to successful bending is to apply heat to the line in a controlled manner. Start by locating the section of the fuel line that needs bending. Use a heat gun or a torch to gently heat the line, ensuring you cover the entire length of the bend. The heat will make the steel more pliable, allowing you to manipulate it more easily. Take your time and apply the heat gradually, being careful not to overheat the line, as this can cause damage.

As you heat the line, you'll notice it becomes softer and more flexible. This is the ideal state for bending. Use a pair of pliers or a pipe bending tool to start the bending process. Apply gentle force and work the line into the desired shape. Remember, the heat has made the steel more compliant, so you won't need to exert as much force as you would without heating. Take your time and ensure the bend is accurate and smooth.

It's important to note that heating the steel fuel line is a temporary measure and should be done with caution. The line will cool down and return to its original hardness once heated. Therefore, the bend will be permanent once the line has cooled. This method is particularly useful when dealing with tight spaces or complex bends, where a pipe cutter might not fit.

By heating the steel fuel line, you can easily manipulate it to fit your desired shape, making it a valuable technique for any DIY enthusiast or professional working with fuel lines. Always prioritize safety when using heat guns or torches, and ensure proper ventilation in your workspace. With this method, you can achieve precise bends without the need for specialized tools.

The Ultimate Guide to Choosing the Right Hose Clamp for Your 3/8" Outboard Fuel Line

You may want to see also

Consider a metal shear for thicker lines

When dealing with thicker steel fuel lines, a pipe cutter might not be the most efficient or effective tool. In such cases, a metal shear can be a valuable alternative. Metal shears are designed to cut through various materials, including steel, with precision and ease. Here's a detailed guide on how to use a metal shear for this task:

Understanding the Shear: Before you begin, ensure you have a good understanding of how a metal shear works. These tools typically consist of two blades that move towards each other to cut the material. The force required to cut thicker materials can be substantial, so it's essential to have a sturdy shear with the appropriate cutting capacity.

Preparation: Start by securing the fuel line in a stable position. You can use clamps or vice-grips to hold the line firmly in place. This step is crucial to ensure that the shear can cut the line without slipping or moving.

Setting Up the Shear: Position the metal shear so that one blade is aligned with the edge of the fuel line, and the other blade is positioned slightly above it, creating a small gap. This setup allows the shear to cut through the material without causing excessive pressure on the blades. Apply firm pressure to the handle of the shear, moving it towards the fuel line. The blades should now cut through the steel, creating a clean and precise cut.

Safety Considerations: When using a metal shear, always prioritize safety. Wear appropriate personal protective equipment, such as gloves and safety goggles, to protect your hands and eyes. Ensure that the work area is clear of any obstacles or trip hazards.

Practice and Precision: Cutting thicker steel lines may require some practice and precision. Take your time, and make sure the shear is aligned correctly before applying force. A well-executed cut will result in a smooth, straight edge, which is essential for proper fuel line installation or repair.

By utilizing a metal shear, you can efficiently and accurately cut thicker steel fuel lines without relying solely on a pipe cutter. This method is particularly useful for professionals and DIY enthusiasts working with various metal pipes and hoses.

Mastering the Art of Removing Fuel Line Fittings: Tips and Tricks

You may want to see also

File and sand for a smooth finish

When it comes to cutting a steel fuel line without a pipe cutter, you can still achieve a precise and clean cut by following a few steps. One effective method is to use a file and sand combination to ensure a smooth finish. Here's a detailed guide on how to do it:

Start by laying out your tools and materials. You'll need a fine-grit file, preferably a flat or round file designed for metalwork, and a suitable type of sandpaper. The file should be chosen based on the desired cut quality; finer grits will provide a smoother finish. Additionally, have a steady hand and a well-ventilated workspace to ensure safety.

Begin by placing the fuel line on a stable surface. Mark the desired cut location with a pencil or a permanent marker. It's crucial to be precise here, as the cut will be permanent. Once marked, use the file to carefully remove material from the line, following the marked line as a guide. Apply gentle pressure and move the file in a smooth, even motion to avoid creating a jagged edge. Take your time and be patient, as rushing can lead to an uneven cut.

After filing, inspect the cut edge. If there are any rough spots or sharp edges, it's time to sand. Use the sandpaper to smooth out the area, again following the marked line as a guide. Start with a finer grit sandpaper and gradually move to a finer finish if needed. Sanding ensures that the cut is not only clean but also smooth to the touch, reducing the risk of any damage to the fuel line or surrounding components.

Repeat the filing and sanding process until you are satisfied with the cut's precision and smoothness. Remember, the goal is to create a seamless transition between the cut and the rest of the fuel line. This method may take a bit more time and effort compared to using a pipe cutter, but it allows for more control and can be especially useful when dealing with unique or hard-to-reach areas. Always prioritize safety and take the necessary precautions when working with metal and sharp tools.

Mustang Fuel Pump: Return Line Essentiality Explored

You may want to see also

Practice on scrap steel first

Before attempting to cut a steel fuel line, it's crucial to practice on scrap steel to ensure you have the necessary skills and confidence. This practice will help you understand the unique challenges of cutting steel and refine your technique. Here's a step-by-step guide on how to practice cutting steel without a pipe cutter:

Gather Materials: Start by collecting some scrap steel pieces of various sizes. You can find these at a local scrapyard or even use old metal objects you have at home. The key is to have a range of sizes and thicknesses to practice with.

Mark the Lines: Take your scrap steel and mark the spots where you want to make the cuts. Use a pencil or a permanent marker to draw straight lines. Ensure the lines are precise and aligned with the edges of the steel. This step is crucial for practice as it helps you understand the importance of accuracy.

Use a Hammer and Chisel: Begin by practicing with basic tools like a hammer and chisel. Start by gently tapping the chisel along the marked line, creating a small indentation. Gradually increase the force to create a deeper cut. This method allows you to control the depth and precision of the cut. Remember to wear safety gear, including gloves and eye protection.

Experiment with Different Techniques: Try various cutting techniques on the scrap steel. For example, you can use a file to create a smooth edge along the cut line, ensuring a clean finish. Practice making multiple cuts at different angles to understand how the steel behaves under different conditions. This experimentation will help you develop a feel for the material.

Study the Results: After making several cuts, carefully examine the edges and surfaces. Look for any signs of damage, such as burrs or uneven cuts. This inspection will help you identify areas for improvement and refine your technique. Remember, the goal is to achieve a clean, precise cut without damaging the surrounding material.

By practicing on scrap steel, you'll gain a better understanding of the material's properties, the importance of precision, and the various techniques required for successful cutting. This foundation will build your confidence when it's time to tackle the actual steel fuel line.

Fixing a Steel Fuel Line: A Step-by-Step Guide

You may want to see also

Frequently asked questions

No, regular wire cutters are not suitable for cutting steel fuel lines. They may not provide a clean and precise cut, and the steel's hardness can cause the cutters to wear out quickly.

You can use a few alternative methods. One option is to use a hacksaw, which can provide a relatively clean cut. Another method is to use a metal-cutting band saw, which offers more precision and control. For smaller lines, a pair of sharp shears or a utility knife can be used, but it may require more effort and could result in an uneven cut.

Absolutely! When working with steel fuel lines, it's crucial to prioritize safety. Always wear protective gear, including gloves and safety goggles, to protect your hands and eyes from any potential hazards. Ensure you are in a well-ventilated area, especially if you are using a flame-cutting method, to avoid inhaling fumes. Additionally, be cautious of any nearby flammable materials and keep a fire extinguisher close by.

Achieving a precise cut without a pipe cutter can be challenging but possible. One technique is to use a mandrel or a solid metal rod as a guide. Place the fuel line over the mandrel and then use a hacksaw or a band saw to cut along the line, following the mandrel's path. This method helps to ensure a straight and accurate cut.

Yes, applying heat to the steel fuel line can make it more pliable and easier to cut. You can use a heat gun or a torch to heat the line, but be cautious and ensure you have proper ventilation. After heating, the line will become softer, and you can use a hacksaw or a file to make the cut. Remember to allow the heated area to cool before handling to avoid burns.