Cutting a braided fuel line requires precision and care to ensure a clean and secure connection. This guide will provide step-by-step instructions on how to safely and effectively cut a braided fuel line, including the necessary tools and safety precautions to avoid fuel leaks and ensure a proper fit for your fuel system.

What You'll Learn

- Prepare Tools: Gather necessary tools: cutting pliers, safety gear, and a clean workspace

- Identify Line: Locate the braided fuel line, ensuring it's the correct one

- Cut Carefully: Use sharp tools to make a precise cut, avoiding damage to surrounding components

- Secure Ends: Cap or tape the ends to prevent fuel leakage

- Test: Verify the connection and functionality of the fuel system post-cut

Prepare Tools: Gather necessary tools: cutting pliers, safety gear, and a clean workspace

Before you begin the process of cutting a braided fuel line, it's crucial to ensure you have the right tools and safety measures in place. This preparation will not only make the task safer but also more efficient. Here's a detailed guide on what you need to gather:

Cutting Pliers: The primary tool for cutting braided fuel lines is a specialized cutting plier. These pliers are designed to handle the tight braiding and hard-to-reach areas of fuel lines. Look for a pair with a sharp, precision-ground cutting edge to ensure a clean cut. Ensure the pliers have a comfortable grip to provide control during the cutting process.

Safety Gear: Working with fuel lines requires taking safety seriously. Always wear safety goggles to protect your eyes from any potential splashes or debris. Additionally, consider wearing gloves to safeguard your hands and to provide a better grip on the tools. In some cases, a respirator may be necessary to avoid inhaling any fumes, especially if the fuel line contains volatile substances.

Clean Workspace: Set up your workspace in a well-ventilated area, preferably outdoors, to minimize the risk of inhaling fumes. Clear the area of any potential hazards or obstacles that could interfere with your work. Ensure you have a stable surface to place your tools and the fuel line. A clean and organized workspace will also help you work more efficiently and reduce the risk of accidents.

Having these tools and safety measures ready will set you up for a successful and safe cutting process. It's essential to take these precautions seriously, especially when working with fuel lines, as they can be hazardous if not handled properly.

Aztek Fuel Disconnect: Step-by-Step Guide to Removing the Center Line

You may want to see also

Identify Line: Locate the braided fuel line, ensuring it's the correct one

When working on a vehicle's fuel system, it's crucial to identify the correct braided fuel line before attempting to cut it. This line is often a complex network of hoses and pipes, and distinguishing the right one is essential to avoid any potential issues during the repair or replacement process. Here's a step-by-step guide to help you locate and identify the braided fuel line:

- Familiarize Yourself with the Fuel System: Begin by studying the vehicle's fuel system diagram or manual. This resource will provide a comprehensive overview of the various components, including the fuel tank, fuel pump, injectors or carburetor, and the braided fuel lines connecting these parts. Understanding the layout will help you pinpoint the specific line you need to locate.

- Inspect the Engine Bay: Open the hood of your vehicle and carefully examine the engine bay. Look for the fuel lines that are typically made of a durable, flexible material with a braided design. These lines carry fuel from the tank to the engine, and they often have distinct colors or markings to differentiate them. Identify the line that connects the fuel pump to the engine or the one that runs alongside the engine block.

- Follow the Fuel Path: Start at the fuel tank and trace the path of the fuel lines. The braided fuel line will likely run from the tank, through the engine bay, and towards the engine. It may pass through various compartments and under different components. As you trace the line, look for any unique features or attachments that could help identify it. For example, it might have a specific clip or bracket holding it in place.

- Check for Labels or Markings: Some vehicles come with labeled fuel lines, making identification easier. Look for any stickers, tags, or color-coding on the braided line. These markings can provide valuable information about the line's purpose and function. Additionally, check for any engine or vehicle-specific labels that might indicate the correct fuel line.

- Consult Professional Resources: If you're still unsure, consider consulting a vehicle repair manual or seeking guidance from a professional mechanic. They can provide detailed instructions specific to your vehicle model, ensuring you locate the correct braided fuel line.

Identifying the right braided fuel line is a critical step in any fuel system repair or modification. By following these steps, you can ensure that you're working with the correct line, minimizing the risk of errors and potential damage to the vehicle.

Unraveling the Mystery: Marine-Grade Fuel Lines Explained

You may want to see also

Cut Carefully: Use sharp tools to make a precise cut, avoiding damage to surrounding components

When it comes to cutting a braided fuel line, precision and care are paramount to ensure a clean and safe cut without causing any damage to the surrounding components. Here's a detailed guide on how to achieve this:

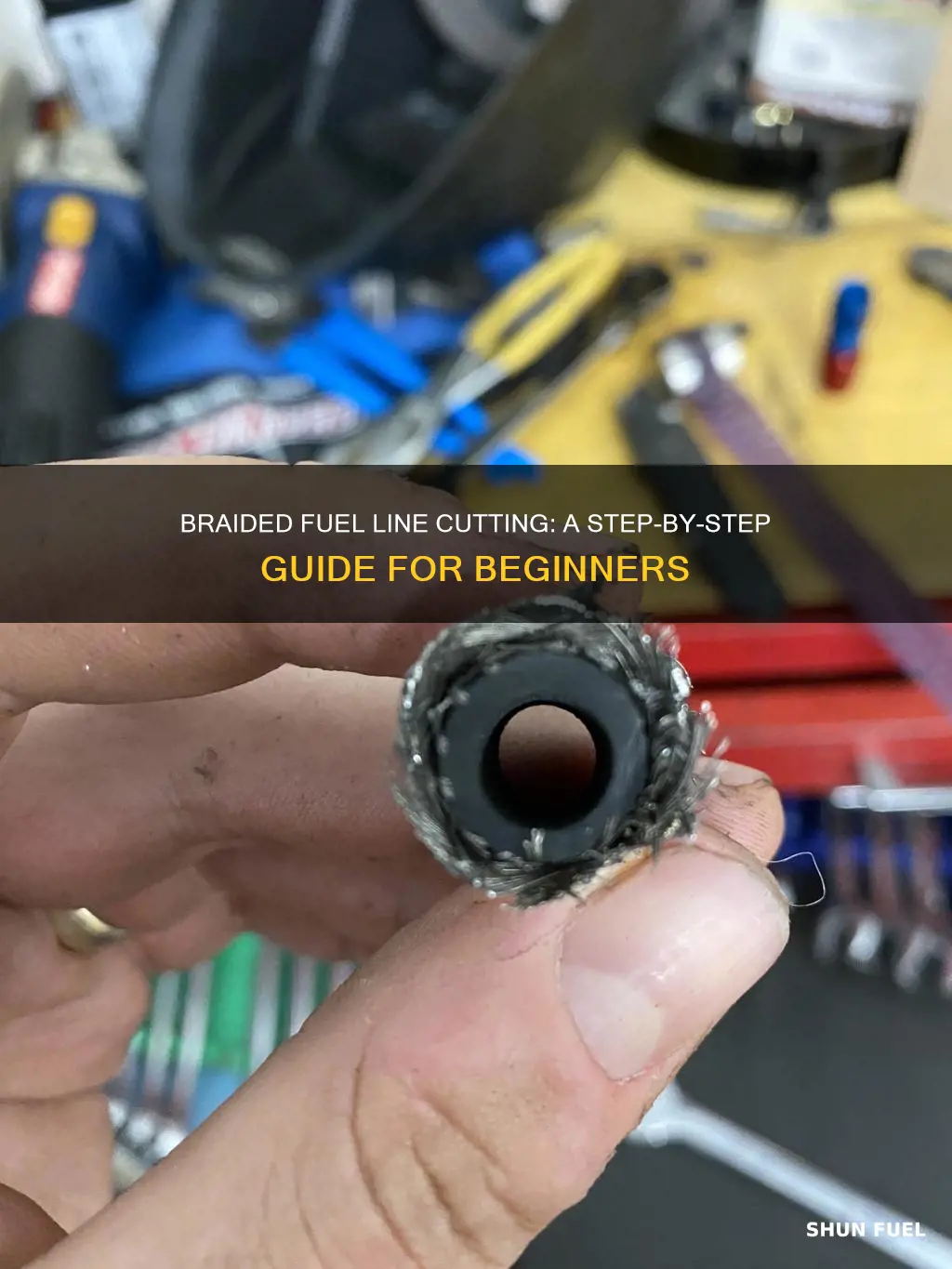

Start by gathering the necessary tools. A sharp, clean pair of wire cutters or a fuel line cutting tool is essential. These tools are designed to make clean, precise cuts without causing damage to the fuel line or nearby parts. Dull or rusty tools can lead to uneven cuts and potential damage, so ensure they are in good condition.

Position the fuel line securely. Place the braided fuel line in a stable position, ensuring it is not pinched or crushed. You want to make the cut in a location that is easily accessible and provides a clear view of the line. Avoid cutting the fuel line when it is under pressure, as this can lead to dangerous splashes and potential injury.

Now, it's time to make the cut. Hold the fuel line firmly but gently, and use the sharp tool to carefully sever the line. Apply steady pressure, moving the tool along the length of the line. Keep the cut as straight and clean as possible to minimize any potential issues. Avoid applying excessive force, as this can cause the tool to slip and potentially damage the surrounding area.

Precision is key. Take your time and ensure the cut is accurate. If the cut is not straight, the fuel line may not fit properly, leading to potential leaks or damage. Consider using a template or a marking tool to guide your cut, especially if you are cutting multiple fuel lines. This will help ensure consistency and accuracy.

After making the cut, inspect the surrounding area. Check for any signs of damage, such as frayed or exposed fibers, and ensure that the cut ends are smooth. If any damage is detected, carefully trim the affected area with the sharp tool to create a clean finish. This attention to detail will contribute to a successful and safe fuel line installation or repair.

Braided Fuel Lines: The Ultimate Upgrade for Your Vintage Beetle's Performance and Reliability

You may want to see also

Secure Ends: Cap or tape the ends to prevent fuel leakage

When cutting a braided fuel line, it's crucial to take extra precautions to ensure the ends are properly sealed to prevent any fuel leakage. The most common and effective methods to secure the ends are capping and taping.

Capping the Ends:

One of the most reliable ways to seal the ends of a braided fuel line is by using caps specifically designed for this purpose. These caps are typically made of durable materials like metal or high-quality plastic. To use this method, you'll need to carefully cut the line to the desired length, ensuring a clean and precise cut. Then, slide the cap over the end of the line, ensuring it fits snugly. The cap should have a secure mechanism to keep it in place, such as a clamp or a locking mechanism. This method provides a strong and reliable seal, especially if the caps are made of sturdy materials.

Taping the Ends:

Another simple yet effective technique is to use specialized fuel line tape. This tape is designed to create a tight seal around the end of the braided fuel line. Start by cleaning the end of the line to remove any dirt or debris. Then, apply a thin layer of fuel line primer to the end to ensure better adhesion. Wrap the tape around the end, ensuring it covers at least two layers of the line's diameter. Use a fuel line sealer or a heat source to melt the tape's adhesive, creating a secure bond. This method is convenient and can be done relatively quickly, but it may not be as durable as capping, especially in harsh conditions.

Both methods have their advantages, and the choice depends on the specific requirements of your project. Capping provides a more permanent solution, ideal for long-term use, while taping is a quick fix that can be useful for temporary repairs or when working with limited access. It's essential to follow the manufacturer's instructions for the chosen sealing method to ensure the best results and prevent any fuel-related issues. Always prioritize safety and take the necessary precautions when working with fuel lines.

Fuel Line Routing: Connecting Cylinder Heads for Optimal Performance

You may want to see also

Test: Verify the connection and functionality of the fuel system post-cut

After cutting the braided fuel line, it's crucial to thoroughly test the fuel system to ensure it is functioning correctly and safely. Here's a step-by-step guide to verifying the connection and functionality:

- Inspect the Cut Ends: Begin by carefully examining the ends of the fuel line that have been cut. Ensure that the cuts are clean and precise, with no damage to the inner fuel line. Look for any signs of fraying or exposed fibers, as these could lead to fuel leakage. If the cuts are uneven or show signs of damage, consider re-cutting the line with a sharp, dedicated fuel line cutter for a clean and precise cut.

- Reattach the Fuel Line: Securely reattach the fuel line to the fuel tank and the engine's fuel rail or injection system. Use the appropriate fuel line connectors and ensure they are tightened to the manufacturer's specifications. Double-check that all connections are tight and there are no leaks at the attachment points.

- Perform a Visual Inspection: Visually inspect the entire fuel system for any signs of damage, leaks, or unusual wear. Look for any fuel residue or contamination around the connections and fuel system components. Pay close attention to the fuel pump, fuel filter, and any fuel-related sensors or actuators. If any issues are identified, address them before proceeding.

- Start the Engine: Turn on the engine and allow it to idle. Monitor the engine's performance and listen for any unusual noises. Check for any fuel-related warning lights on the dashboard. Ensure that the engine starts and runs smoothly without any hesitation or stalling. If the engine struggles to start or exhibits erratic behavior, it may indicate a fuel system issue that requires further investigation.

- Pressure Test (Optional): For added assurance, consider performing a pressure test on the fuel system. This can be done using a fuel pressure gauge and a small amount of compressed air. Apply pressure to the fuel system and check for any leaks or abnormal pressure drops. This test can help identify potential issues with fuel line connections, fuel pump performance, or fuel tank integrity.

- Long-Term Monitoring: After the initial verification, continue to monitor the fuel system's performance over time. Regularly check for any signs of fuel leaks, especially around connections and joints. Keep an eye on engine performance and fuel consumption to ensure the system is operating efficiently.

Remember, proper testing is essential to ensure the safety and reliability of your vehicle's fuel system after making any modifications, including cutting the braided fuel line. Always follow manufacturer guidelines and consult a professional if you have any doubts or concerns during the testing process.

Diagnosing a Clogged Fuel Line: A Step-by-Step Guide

You may want to see also

Frequently asked questions

When cutting a braided fuel line, it's important to use a sharp, clean pair of shears or a fuel line cutter. Start by identifying the point where you want to make the cut, ensuring you have a clear idea of the length needed. Make a precise cut, taking care to avoid any damage to the surrounding components. It's recommended to cut slightly longer than needed and then trim the excess with a file or sandpaper to ensure a clean and precise finish.

While it might be tempting to use regular scissors, they are not suitable for cutting braided fuel lines. Regular scissors can easily become dull and may not provide a clean cut, leading to potential fuel leaks. It's best to invest in specialized tools like fuel line cutters or sharp, heavy-duty scissors designed for this purpose.

After cutting the braided fuel line, it's crucial to prepare the ends properly. Use a fuel line primer or solvent to clean the ends and remove any debris. Then, apply a small amount of fuel line adhesive to the cut ends, ensuring an even coating. Allow the adhesive to dry according to the manufacturer's instructions, and then reassemble the fuel line securely. This process helps create a tight seal and prevents any fuel from leaking.