Installing a new fuel line is a crucial task for vehicle maintenance, ensuring optimal performance and safety. This process involves replacing the existing fuel line with a new one, which can be a challenging but rewarding DIY project. It requires careful planning, the right tools, and a systematic approach to ensure a successful installation. The guide will provide a step-by-step process, covering everything from preparing the necessary materials to testing the new fuel line for leaks, ensuring a reliable and safe fuel supply for your vehicle.

What You'll Learn

- Prepare Tools and Materials: Gather necessary tools, fuel line, and safety equipment

- Locate Old Line: Identify and mark the old fuel line for removal

- Remove Old Line: Disconnect and carefully remove the old fuel line, ensuring no damage

- Prepare New Line: Inspect and prepare the new fuel line for installation

- Connect and Secure: Attach the new line, tighten connections, and secure it in place

Prepare Tools and Materials: Gather necessary tools, fuel line, and safety equipment

Before you begin the installation process, it's crucial to gather all the necessary tools, materials, and safety equipment to ensure a smooth and safe fuel line replacement. Here's a step-by-step guide on what you need to prepare:

Tools and Equipment:

- Wrenches and Pliers: You'll need various sizes of wrenches and pliers to tighten and loosen fittings and connections. Make sure to have adjustable wrenches for different sizes.

- Fuel Line Cutter: A specialized fuel line cutter or a sharp utility knife with a guard will help you cut the old fuel line and create new connections.

- Hacksaw or Pipe Cutter: For cutting through thicker fuel lines, a hacksaw or a pipe cutter is essential.

- Sandpaper or Embers: Use these to smoothen any rough edges on the fuel line and fittings, ensuring a clean and secure connection.

- Rags or Cloths: Keep these handy to wipe away any fuel residue and ensure a clean work area.

- Safety Gear: Safety should always be a priority. Wear safety goggles to protect your eyes from any potential fuel splashes. Gloves will also provide a better grip and protect your hands.

Materials:

- New Fuel Line: Ensure you purchase the correct size and type of fuel line that matches your vehicle's specifications. Check the vehicle's manual or consult a professional to get the right part.

- Fuel Line Fittings: Gather the necessary fittings, such as elbows, tees, and couplings, to connect the new fuel line to the engine and other components.

- Fuel Line Adhesive or Sealant: Some fuel lines may require an adhesive or sealant to ensure a secure and leak-proof connection.

- Fuel Filter: If your vehicle's fuel filter needs replacement, make sure to have a new one ready.

Safety Precautions:

- Always work in a well-ventilated area, especially when dealing with fuel.

- Keep a fire extinguisher nearby as a safety measure.

- Be cautious when cutting through fuel lines to avoid any accidental fuel leaks.

- Ensure you understand the location of all fuel lines and components to prevent damage during the installation.

By gathering these tools, materials, and safety equipment, you'll be well-prepared to tackle the fuel line installation process, ensuring a successful and safe outcome. Remember, proper preparation is key to a smooth DIY project.

Railroads Revolution: Unlocking Investment Potential and Shaping the Future

You may want to see also

Locate Old Line: Identify and mark the old fuel line for removal

When replacing a fuel line, the first crucial step is to locate the old one. This process requires careful inspection and a systematic approach to ensure you don't miss any crucial connections or components. Start by consulting your vehicle's manual or online resources to understand the layout of the fuel system, including the location of the old fuel line. This initial research will provide valuable insights into the path the fuel line takes, the components it connects, and any potential obstacles or challenges you might encounter.

Once you have a general idea of the fuel line's route, it's time to physically inspect the vehicle. Locate the fuel tank and trace the path of the old fuel line from the tank to the engine. Look for any visible signs of damage, corrosion, or wear along the line. Check for any connections, such as fittings or clamps, that secure the line to other components. Take note of these locations, as they will be crucial for the installation of the new fuel line.

As you trace the fuel line, mark its path with temporary indicators or labels. This step is essential to ensure that you can easily identify the old line during the removal process. You can use tape, chalk, or even a permanent marker to create a clear and visible trail. Mark the starting point at the fuel tank and continue marking along the entire length of the line, noting any significant bends or changes in direction. This visual aid will make the removal process more efficient and less prone to errors.

Pay close attention to any valves, pumps, or fuel injectors connected to the old fuel line. These components are critical to the vehicle's fuel system, and their correct identification is essential for a successful installation. Mark these connections clearly, ensuring you know where they are located and how they are secured. This detailed approach will make the removal and subsequent installation of the new fuel line much smoother.

By taking the time to locate and mark the old fuel line, you are setting yourself up for a successful and efficient installation of the new one. This step ensures that you have a clear understanding of the fuel system's layout and can accurately remove the old line, minimizing the risk of damage to other components. Remember, a well-prepared approach is key to a successful DIY project.

Determining the Perfect Fit: Your Fuel Line Tube Size Guide

You may want to see also

Remove Old Line: Disconnect and carefully remove the old fuel line, ensuring no damage

When replacing a fuel line, the first crucial step is to safely and meticulously remove the old one. This process requires careful attention to detail to avoid any potential hazards. Start by identifying the old fuel line's connections and attachments. Locate the fittings or clamps that secure the line to the fuel tank, engine, and other components. It's important to note the positions of these connections to ensure a proper reinstallation later.

Carefully disconnect the fuel line from the fuel tank. This might involve loosening screws or clips that hold the line in place. Gently pull the line away from the tank, being mindful of any fuel that may still be present. If there is any residual fuel, consider draining it safely into a container or using a fuel pump vacuum to extract it.

Next, remove the fuel line from the engine or other components it is connected to. This could involve unscrewing fittings or carefully prying the line away from the engine block or other parts. Take your time here, as forcing the line can cause damage. Use a gentle, steady motion to avoid putting excessive pressure on the line or the connections.

As you remove the old fuel line, be cautious of any sharp edges or protruding components that could cause punctures or tears. Fuel lines often have protective coverings, so be mindful of these and ensure they remain intact. If any damage is noticed, it's best to replace the entire line rather than risking further issues.

Once the old fuel line is completely disconnected and removed, inspect it for any signs of wear, damage, or contamination. This step is essential to ensure that the new line will not be compromised by old, potentially harmful fuel or line condition. Properly disposing of the old line or recycling it is also an environmentally responsible practice.

Crafting Diesel Fuel Lines: A Journey from Raw Materials to Engine Power

You may want to see also

Prepare New Line: Inspect and prepare the new fuel line for installation

Before you begin the installation process, it's crucial to inspect and prepare the new fuel line to ensure a successful and safe setup. Start by carefully examining the fuel line for any visible defects or damage. Look for cracks, tears, or any signs of deterioration that could compromise the line's integrity. Check for any kinks or bends that might affect the flow of fuel. Ensure that the new fuel line is free from any debris or contaminants that could cause issues during installation.

If you notice any issues with the fuel line, it's essential to address them before proceeding. For minor defects, such as small tears or cracks, you might be able to repair them temporarily. However, for significant damage, it's best to replace the entire line to avoid potential leaks and safety hazards. Keep in mind that the fuel line should be compatible with the vehicle's fuel type and system to ensure optimal performance.

Once you've inspected the fuel line, it's time to prepare the installation area. Clean the area where the fuel line will be connected to the fuel tank and any other components. Remove any old fuel line or debris to create a smooth and clean surface for the new line. Ensure that all connections are free from corrosion or debris that could hinder a secure fit.

Prepare the new fuel line by carefully uncoiling it and laying it out in a straight line. Check the length to ensure it matches the required specifications for your vehicle. If necessary, adjust the line to fit the specific layout of your engine bay. Take note of any bends or kinks you make in the line, as these should be maintained during the installation process to avoid future issues.

Additionally, consider using fuel line protective sleeves or covers to safeguard the new line from potential damage during installation and future use. These sleeves can help prevent punctures and ensure the line remains in good condition. By taking the time to inspect and prepare the fuel line, you'll set the foundation for a successful and safe installation, minimizing the risk of fuel leaks and other potential problems.

Mastering Fuel Line Hose Cutting: A Step-by-Step Guide

You may want to see also

Connect and Secure: Attach the new line, tighten connections, and secure it in place

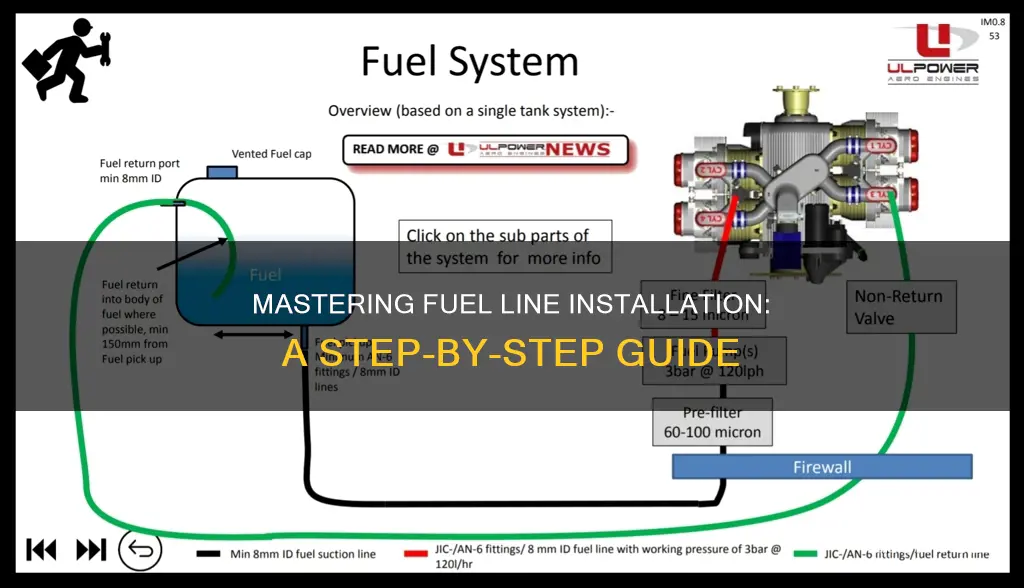

Once you've acquired the new fuel line and prepared the necessary tools, it's time to connect and secure the new line in place. This step is crucial to ensure a safe and efficient fuel supply to your engine. Here's a detailed guide on how to accomplish this:

Attaching the New Fuel Line: Start by locating the existing fuel line and identifying the points where the new line will connect. Typically, these connections are made at the fuel tank and the engine's fuel rail or carburetor. Carefully align the new fuel line with the existing one, ensuring that the fittings and clamps are properly positioned. Use the appropriate tools, such as fuel line cutters or shears, to trim the new line to the correct length, leaving a small excess for flexibility.

Tightening Connections: With the new line in place, it's time to tighten the connections securely. Begin by inserting the fuel line into the fittings, ensuring a snug fit. Use the appropriate wrenches or pliers to tighten the fittings, but be cautious not to overtighten, as this can damage the fuel line. Tighten each connection firmly, following the manufacturer's specifications for torque or pressure. This step is critical to prevent fuel leaks and ensure a reliable fuel supply.

Securing the Fuel Line: After tightening the connections, it's essential to secure the fuel line in place to prevent any movement or vibration-induced damage. Use fuel line clips, ties, or brackets to fasten the line to the vehicle's body or frame. Space the clips or ties evenly along the length of the fuel line to distribute the strain and prevent kinking. Ensure that the securing method allows for some flexibility, as the fuel line needs to move slightly with the engine's operation.

Final Checks: Once the fuel line is connected and secured, perform some final checks to ensure everything is in order. Inspect all connections for tightness and look for any signs of damage or leaks. Start the engine and check for any unusual noises or vibrations, especially around the fuel line connections. If everything is secure and functioning correctly, you can proceed with testing the fuel system and ensuring the engine runs smoothly.

Remember, proper installation and securing of the fuel line are vital for the safe operation of your vehicle. Take your time during this process, and if you're unsure about any step, consult the vehicle's manual or seek professional assistance.

Fixing a Leaking Fuel Line: A Guide for 1997 Tahoe Owners

You may want to see also

Frequently asked questions

To install a new fuel line, you will need a few essential tools and materials. These include a fuel line cutter or a pair of sharp scissors or knives, a fuel line crimping tool or a pair of pliers, a fuel line clamp, and a cleaning solution like fuel line cleaner or vinegar. Additionally, ensure you have the correct size and type of fuel line that matches your vehicle's specifications.

Achieving a proper fit and secure connection is crucial for a successful installation. Start by cleaning the fuel line and the areas where it will be connected to prevent any contamination. Cut the fuel line to the appropriate length, leaving a small excess for adjustments. Slide the fuel line into the fitting, ensuring it is aligned correctly. Use the crimping tool or pliers to secure the connection, following the manufacturer's instructions for the specific tool. Finally, attach the fuel line clamp to provide an additional layer of security.

Absolutely, safety is a top priority when working with fuel lines. Before beginning, ensure the engine is off and the vehicle is in a secure position. Wear protective gear, such as gloves and safety goggles, to prevent any potential injuries. Be cautious of hot engine components, as they can cause burns. Additionally, work in a well-ventilated area to avoid inhaling any fuel vapors. It's also essential to double-check your connections and ensure no fuel leaks occur before starting the vehicle.