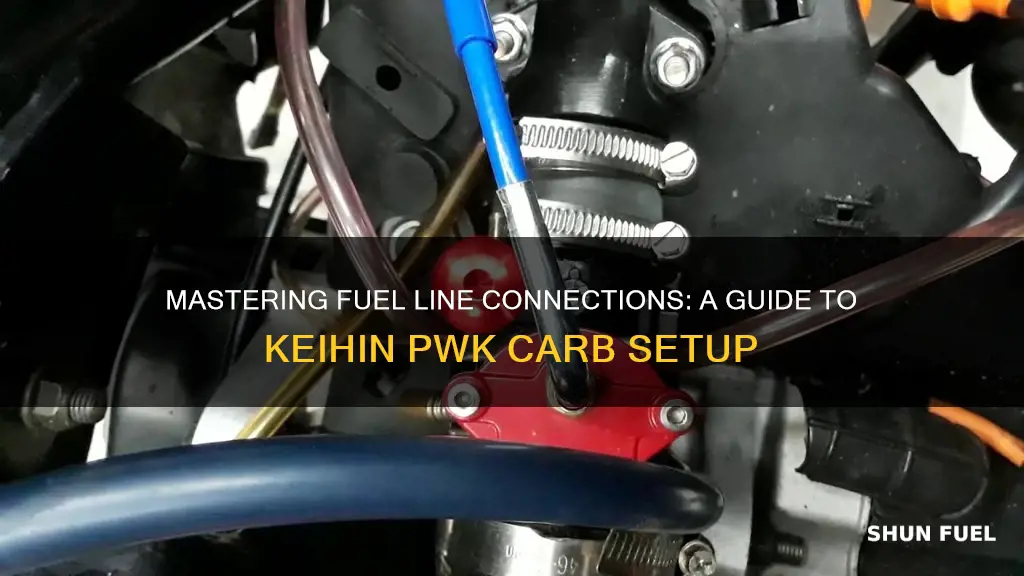

Connecting fuel lines to a Keihin PWK carburetor requires careful attention to detail and adherence to specific steps to ensure optimal performance. This process involves understanding the carburetor's components, including the float bowl, jetting, and the fuel lines' roles in delivering fuel to the engine. By following a structured approach, you can effectively connect the fuel lines, ensuring a smooth and efficient fuel supply to the engine, which is crucial for maintaining the carburetor's performance and overall engine health.

| Characteristics | Values |

|---|---|

| Fuel Line Material | Typically made of rubber or vinyl, with some modern versions using synthetic materials for improved durability. |

| Line Diameter | Usually 3/8" or 1/4" ID (inside diameter) for standard applications. |

| Length | Varies depending on the specific carb and engine setup. |

| Connection Type | Often features a quick-connect fitting or a clamp-style coupling for easy installation. |

| Color Coding | May be color-coded to differentiate between primary and secondary fuel lines. |

| Pressure Rating | Should be compatible with the fuel pressure generated by the carburetor and engine. |

| Flexibility | Needs to be flexible enough to accommodate engine movement without kinking or restricting flow. |

| Compatibility | Specific to the Keihin PWK carburetor model and engine type. |

| Installation | Requires careful alignment and secure attachment to ensure proper fuel flow and prevent leaks. |

What You'll Learn

- Prepare Tools: Gather necessary tools: fuel line, carb cleaner, wrench, and pliers

- Inspect Lines: Check for damage, kinks, or leaks in existing fuel lines

- Clean Connections: Ensure all connections are clean and free of debris

- Secure Lines: Use clamps or brackets to firmly attach fuel lines to carb

- Test Fuel Flow: Verify proper fuel flow by starting engine and checking for leaks

Prepare Tools: Gather necessary tools: fuel line, carb cleaner, wrench, and pliers

Before you begin the process of connecting fuel lines for your Keihin PWK carburetor, it's crucial to ensure you have the right tools and materials ready. This will make the task easier and more efficient. Here's a step-by-step guide on preparing the necessary tools:

Fuel Line: Start by acquiring a fuel line that is compatible with your Keihin PWK carburetor. Measure the length required to connect the fuel source (such as the fuel tank) to the carburetor. It's essential to get the correct size and material to ensure a secure and leak-free connection. You can find fuel lines at auto parts stores or online retailers.

Carb Cleaner: Carburetor cleaner is a must-have tool for this process. It helps remove any dirt, grime, or deposits that might be present in the carburetor and fuel lines. Carb cleaner will ensure a clean and smooth connection. Look for a high-quality carburetor cleaner that is safe for use with fuel systems.

Wrench and Pliers: You'll need a set of wrenches and pliers to tighten connections and adjust fuel line fittings. Wrenches are essential for turning nuts and bolts, while pliers can be used for gripping and turning smaller components. Ensure you have a variety of sizes to accommodate different fuel line fittings and carburetor parts.

Gathering these tools beforehand will ensure you have everything readily available when you start the connection process. It's a simple yet crucial step to make the task more manageable and efficient, especially if you're working in a limited space or under time constraints. Remember to inspect each tool for any damage or wear before use to ensure optimal performance.

F150 Fuel Line: Understanding Proper Ratings and Safety

You may want to see also

Inspect Lines: Check for damage, kinks, or leaks in existing fuel lines

When inspecting the fuel lines for your Keihin PWK carburetor, it's crucial to ensure they are in optimal condition to prevent any potential issues. Start by visually examining the lines for any signs of damage, such as cracks, punctures, or frayed ends. These issues can lead to fuel leaks, which can cause poor engine performance or even stall. Look for any visible wear and tear, especially at the points where the lines connect to the carburetor and the fuel tank. Check for any kinks or bends in the lines. Fuel lines should maintain a straight and flexible position to allow for engine movement without restriction. Any kinks can restrict fuel flow, leading to engine misfires or reduced power.

Leakage is a critical concern during this inspection. You can perform a simple test to check for leaks by removing the fuel line connections and applying a small amount of diesel fuel or a suitable fuel line sealer to the threads. Then, reattach the lines and observe if any fuel drips or seeps. Leaks can occur at the connections, where the lines are joined, or at the ends where they attach to the carburetor and fuel tank. If you notice any leaks, it's essential to address them immediately. Tighten any loose connections and consider replacing the affected lines if the damage is extensive.

In addition to visual inspection, it's beneficial to feel the fuel lines for any unusual textures. Smooth and flexible lines are ideal, but if you encounter lines that feel brittle or overly soft, they may require replacement. Also, pay attention to the length of the lines. Ensure they are not too short or too long, as this can affect the engine's performance. The lines should be long enough to reach the carburetor without excessive tension but not so long that they create unnecessary drag.

Remember, the goal of this inspection is to identify and rectify any issues before attempting to reconnect the fuel lines. By thoroughly checking for damage, kinks, and leaks, you can ensure a smooth and safe fueling process for your Keihin PWK carburetor.

Outboard Fuel Line Slack: The Ultimate Guide to Finding the Right Amount

You may want to see also

Clean Connections: Ensure all connections are clean and free of debris

When working on the fuel system of a vehicle equipped with a Keihin PWK carburetor, ensuring that all connections are clean and free of debris is crucial for optimal performance and reliability. Here's a detailed guide on how to achieve clean connections:

Prepare the Tools and Materials: Before you begin, gather the necessary tools and materials. You'll need a fine-bristle brush, compressed air, a soft cloth, and a small container of carburetor cleaner. These items will help you clean and prepare the connections effectively.

Locate the Fuel Lines: Identify the fuel lines connected to the Keihin PWK carburetor. These lines typically run from the fuel tank to the carburetor. Carefully inspect each connection point, including the carburetor body, fuel bowl, and any intermediate hoses or fittings.

Clean the Carburetor Body: Start by cleaning the carburetor body. Use the fine-bristle brush to gently remove any visible dirt, corrosion, or debris from the surface. Pay close attention to the areas where fuel lines connect to the carburetor. Ensure that all contaminants are cleared away, providing a smooth and clean surface for the fuel lines to connect to.

Remove and Clean Fuel Lines: Carefully detach the fuel lines from the carburetor and fuel tank. Inspect the interior of the fuel lines for any blockages or debris. Use compressed air to blow out any loose particles. If necessary, use a small brush to gently scrub the inside of the lines, ensuring a thorough clean. For external fuel line connections, wipe them down with a soft cloth to remove any dirt or grime.

Apply Carburetor Cleaner: After cleaning, apply a small amount of carburetor cleaner to the fuel lines and connections. This will help dissolve any remaining contaminants. Allow the cleaner to sit for a few minutes, then wipe away any residue with a clean cloth. Ensure that no cleaner remains on the fuel lines, as it can attract dirt over time.

Reassemble and Test: Once all connections are clean, carefully reconnect the fuel lines to the carburetor and fuel tank. Ensure that all fittings are securely tightened. Start the engine and allow it to run, monitoring for any unusual noises or behavior. A clean and debris-free connection will contribute to a smooth fuel flow, ensuring your engine operates efficiently.

By following these steps, you can guarantee that your Keihin PWK carburetor fuel connections are free from debris, promoting optimal performance and longevity. Remember, regular maintenance and cleaning of these connections will contribute to a reliable and efficient fuel system.

Mastering the Art of Bending Auto Fuel Lines: A Kink-Free Guide

You may want to see also

Secure Lines: Use clamps or brackets to firmly attach fuel lines to carb

When working with fuel lines for a Keihin PWK carburetor, ensuring a secure and reliable connection is crucial to maintain optimal engine performance. One essential step in this process is properly securing the fuel lines to the carburetor using appropriate fasteners. This ensures that the lines remain in place even under varying engine conditions, preventing leaks and potential hazards.

Clamps and brackets are the go-to fasteners for this task. Clamps, typically made of durable materials like metal or plastic, offer a simple and effective solution. They are designed to grip the fuel lines tightly, providing a secure hold. When using clamps, it's important to choose the right size and type for the specific fuel line diameter. Ensure the clamp is tightened enough to create a snug fit but avoid over-tightening, as this can damage the line.

Brackets, on the other hand, provide a more permanent and robust solution. These are often metal and are designed to bolt or screw onto the carburetor body, offering a sturdy anchor point for the fuel lines. Brackets are especially useful when dealing with longer fuel lines or when a more discreet installation is desired. They can be positioned to route the lines in an optimal manner, minimizing the risk of damage or interference.

To install the fasteners, start by cleaning the fuel lines and carburetor surfaces to ensure a good bond. Then, carefully route the lines to the desired positions, allowing for easy access during the installation process. For clamps, slide them over the fuel lines, positioning them where needed, and tighten them using a suitable tool. For brackets, attach them to the carburetor using the appropriate hardware, ensuring they are firmly in place.

Remember, the goal is to create a tight, leak-free connection while also allowing for some flexibility to accommodate engine movement. Regularly inspect the fasteners and fuel lines for any signs of wear or damage, especially after prolonged use or exposure to harsh conditions. By following these steps, you can ensure that your Keihin PWK carburetor's fuel lines are securely attached, contributing to a reliable and efficient engine performance.

Unclogging Rusted Fuel Lines: A Step-by-Step Guide to Revive Your Gas Tank

You may want to see also

Test Fuel Flow: Verify proper fuel flow by starting engine and checking for leaks

To ensure the correct fuel flow to your Keihin PWK carburetor, a thorough testing process is essential. This involves starting the engine and carefully inspecting for any leaks, which can indicate potential issues with the fuel system. Here's a step-by-step guide to help you verify the proper fuel flow:

- Preparation: Before you begin, ensure the engine is cool to avoid any safety hazards. Locate the fuel lines connected to the carburetor and identify the fuel inlet and outlet ports. It's crucial to understand the layout to know where to check for leaks.

- Starting the Engine: Begin by starting the engine and allowing it to idle. Pay close attention to the engine's behavior and listen for any unusual noises. A properly functioning fuel system should provide a steady and smooth idle without any sputtering or hesitation.

- Visual Inspection: While the engine is running, visually inspect the fuel lines for any signs of leaks. Check for wet spots or fuel residue around the connections and joints. Leaks can occur at the carburetor, fuel pump, or any point where the fuel lines are connected or bend. Ensure that all connections are tight and secure.

- Leak Test: To further verify the fuel flow, you can perform a leak test. Turn off the fuel supply and disconnect the fuel line at the carburetor. Securely cap the end of the line to prevent fuel from escaping. Now, start the engine and observe if any fuel drips from the disconnected line. If there are no leaks, the fuel should remain contained within the system.

- Fuel Pump Check: With the engine running, locate the fuel pump, typically found near the carburetor. Ensure that the pump is functioning correctly by listening for a steady, rhythmic sound. A weak or non-functional pump may result in insufficient fuel pressure, leading to poor engine performance.

- Adjustments and Calibration: If any leaks are detected, carefully inspect the connections and make the necessary adjustments. Tighten loose fittings and ensure all components are properly aligned. Consider consulting the carburetor's manual for specific calibration instructions to optimize fuel flow.

By following these steps, you can effectively test the fuel flow to your Keihin PWK carburetor. Proper fuel delivery is critical for optimal engine performance, so taking the time to verify the system's integrity is essential for any vehicle enthusiast or mechanic.

Fixing a Fuel Line Leak: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Before connecting the fuel lines, ensure that you have the correct size and type of fuel lines that match the carburetor's specifications. Inspect the lines for any damage or leaks, and if necessary, replace them with new ones.

Start by locating the float bowl, which is typically a small chamber above the carburetor. Identify the fuel inlet on the bowl, which is where the fuel line will connect. Insert the fuel line into the inlet, ensuring a secure and tight fit. You might need to use a fuel line adapter or a small hose clamp to keep the connection in place.

When bending fuel lines, it's crucial to use a fuel line bender or a similar tool designed for this purpose. Start by placing the line over a smooth, rounded surface to create a gentle curve. Avoid sharp bends as they can cause stress and potential leaks. Gradually increase the radius of the curve, ensuring the line remains flexible and intact.

If the fuel line is too short, you can extend it using a fuel line extension kit or by splicing in a small piece of replacement line. Cut the line to the desired length, ensuring a clean and precise cut. Then, use a fuel line primer to clean the ends of the line and a fuel line solvent to remove any debris. Finally, crimp on a suitable fuel line fitting to make the connection.