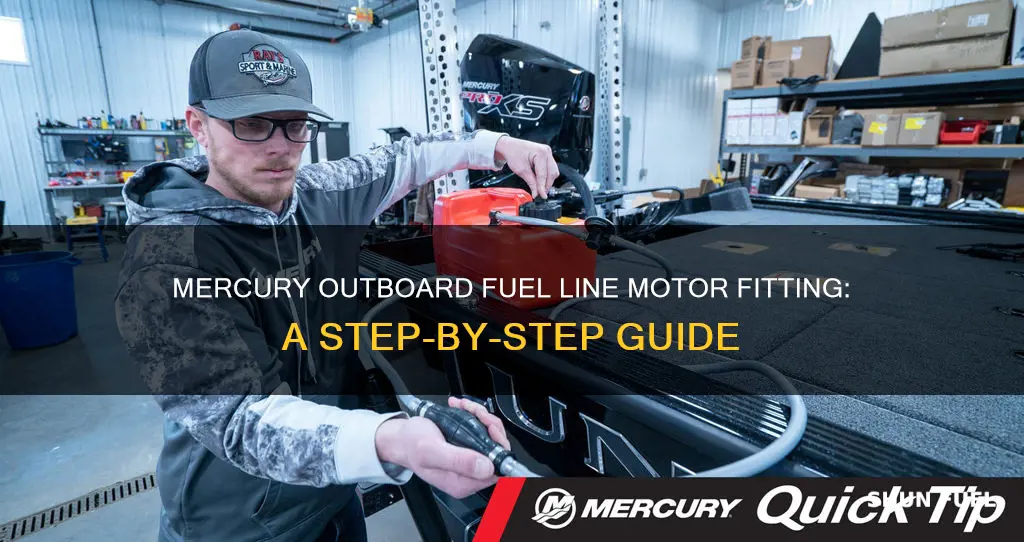

Checking the fuel line motor fitting on a Mercury outboard engine is a crucial maintenance task to ensure optimal performance and prevent potential issues. This process involves inspecting the connections and fittings for any signs of damage, leaks, or corrosion. By following a step-by-step guide, you can locate the fuel line, inspect the fittings for tightness, and verify the absence of any fuel leaks. Regular maintenance of these components is essential to maintain the engine's efficiency and longevity, especially in marine environments where corrosion and fuel contamination are common concerns.

What You'll Learn

- Fuel Line Inspection: Visually check for cracks, leaks, and damage

- Fitting Tightness: Ensure all connections are secure and tight

- Fuel Flow: Test fuel flow to confirm proper pressure and flow

- Leak Detection: Use a soapy solution to identify potential leaks

- Pressure Testing: Measure fuel pressure to ensure it meets specifications

Fuel Line Inspection: Visually check for cracks, leaks, and damage

When inspecting the fuel line of your Mercury outboard motor, a thorough visual examination is crucial to ensure optimal performance and prevent potential issues. Start by locating the fuel line, which is typically a rubber or flexible hose connecting the fuel tank to the engine. Inspect the entire length of the fuel line for any visible signs of damage or deterioration. Look for cracks, splits, or punctures in the rubber material, as these can lead to fuel leaks and potential engine problems. Check for any signs of wear and tear, especially at the points where the fuel line connects to the engine and the fuel tank. Over time, these connections can loosen or become damaged, leading to fuel leaks.

Pay close attention to the fittings and connectors. Ensure that all connections are tight and secure. If you notice any corrosion or rust around the fittings, it may indicate that the fuel line has been compromised. Corrosion can lead to reduced fuel flow and potential engine misfires. Additionally, check for any signs of fuel leakage around the fittings. Even a small leak can cause significant issues over time. If you spot any leaks, it's essential to address the problem immediately to prevent further damage.

Another critical aspect of the visual inspection is to look for any signs of fuel contamination. Check for any visible debris or contaminants in the fuel line, as this can indicate poor fuel quality or improper storage. Contaminated fuel can lead to engine performance issues and potential damage to the engine's internal components. If you notice any unusual residue or discoloration in the fuel line, it's best to consult a professional for further advice.

Remember, regular maintenance and inspections are vital to keeping your Mercury outboard motor in top condition. By visually checking for cracks, leaks, and damage, you can identify potential issues early on and take the necessary steps to ensure your engine's longevity and reliable performance on the water.

Cummins NHC 250 Fuel Return Line: What's the Deal?

You may want to see also

Fitting Tightness: Ensure all connections are secure and tight

When dealing with the fuel system of a Mercury outboard motor, ensuring that all connections are secure and tight is crucial for optimal performance and safety. Here's a detailed guide on how to check and maintain the fitting tightness:

Inspect the Fuel Lines: Start by visually inspecting the fuel lines for any signs of damage, cracks, or leaks. Look for any areas where the line might be pinched or damaged, especially where it connects to the motor and the fuel tank. If you notice any issues, it's essential to replace the affected lines to prevent fuel leaks, which can be dangerous and cause engine misfires.

Check Fittings and Connections: Pay close attention to the fittings and connections throughout the fuel system. Mercury outboard motors often use specific types of fittings, such as quick-connect fittings or threaded fittings. Ensure that all these connections are tight and secure. Use a wrench or the appropriate tool to tighten the fittings further if necessary. A loose fitting can lead to fuel leaks and potential engine issues.

Test for Leaks: After ensuring the fittings are tight, it's crucial to test for any leaks. You can do this by applying a small amount of diesel fuel or soapy water to the connections and observing if any leaks occur. If you notice any leaks, tighten the connections further or replace the fittings if they are worn out. Regularly checking for leaks is essential, especially before and after extended periods of use.

Use the Right Tools: When tightening fittings, use the appropriate tools to ensure you don't overtighten them, which can damage the fittings or fuel lines. Mercury may provide specific tools or recommendations for their outboard motors. Always follow the manufacturer's guidelines to avoid any potential issues.

Regular Maintenance: Make it a habit to check the fuel system regularly, especially before and after each use. Over time, fittings can loosen due to vibration and movement. Regular checks will help you identify and address any tightness issues promptly, ensuring the longevity and reliability of your Mercury outboard motor.

The Rubber Fuel Line: A Comprehensive Guide

You may want to see also

Fuel Flow: Test fuel flow to confirm proper pressure and flow

To ensure your Mercury outboard engine is running efficiently and reliably, it's crucial to check the fuel flow and pressure. Here's a step-by-step guide on how to test the fuel flow to confirm proper pressure and flow:

Step 1: Gather the Necessary Tools

Before you begin, make sure you have the following tools and equipment: a fuel pressure gauge, a fuel flow meter, a wrench or socket set, and a clean rag or cloth. It's also recommended to have a helper assist you during the testing process.

Step 2: Locate the Fuel System

Locate the fuel tank, fuel lines, and the fuel pump. The fuel pump is typically located near the engine and is responsible for sending fuel through the lines to the carburetor or fuel injection system. Identify the fuel pressure gauge port, which is usually a small opening on the fuel tank or a dedicated port on the engine.

Step 3: Disconnect the Fuel Lines

Carefully disconnect the fuel lines from the fuel pump and the carburetor or fuel injection system. Make sure to label or mark the connections for easy reattachment later. Place the disconnected fuel lines into a container to collect any fuel that may spill.

Step 4: Test Fuel Pressure

Using the fuel pressure gauge, connect it to the fuel pressure port. Turn on the engine and allow it to idle. Observe the gauge to read the fuel pressure. The pressure should be within the recommended range specified by Mercury for your engine model. If the pressure is too low, it may indicate a restricted fuel line or a faulty fuel pump. If the pressure is too high, it could suggest a clogged fuel filter or a problem with the fuel pump regulator.

Step 5: Measure Fuel Flow

With the engine running, attach the fuel flow meter to the fuel line between the fuel pump and the carburetor or fuel injection system. Ensure the meter is securely connected. Adjust the engine speed to a steady idle and record the fuel flow rate. The flow rate should be within the expected range for your engine. Low fuel flow could indicate a clogged fuel filter or a problem with the fuel pump. High flow rates might suggest a malfunctioning fuel pressure regulator or a restricted fuel line.

Step 6: Reattach and Start the Engine

Carefully reattach the fuel lines to their respective ports and secure them with the appropriate tools. Start the engine and allow it to run for a few minutes. Check for any leaks or unusual noises. If everything is functioning correctly, the engine should run smoothly and efficiently.

By following these steps, you can ensure that your Mercury outboard engine's fuel system is operating optimally, providing the necessary pressure and flow for reliable performance. Regular maintenance and testing of the fuel flow will help prevent potential issues and keep your engine in top condition.

Craftsman Push Mower Fuel Line Sizes: A Comprehensive Guide

You may want to see also

Leak Detection: Use a soapy solution to identify potential leaks

Checking for fuel line leaks on a Mercury outboard motor is an essential maintenance task to ensure optimal performance and prevent potential engine issues. One of the most effective methods to identify leaks is by using a soapy solution, which can help you pinpoint the source of the problem quickly. Here's a step-by-step guide on how to perform this leak detection process:

Start by preparing the soapy solution. Mix a few drops of dish soap or a mild detergent with water. The soap acts as a visual indicator, creating bubbles that will help you identify even the smallest leaks. Ensure the solution is not too concentrated, as it might make it challenging to see the bubbles.

Next, locate the fuel lines and fittings on your Mercury outboard motor. These are typically found near the engine and may require some disassembly of the engine's exterior panels to access them fully. It's crucial to work carefully to avoid any damage during this process.

Now, apply the soapy solution to the fuel lines and fittings. Use a spray bottle or a small brush to ensure the entire area is covered. Pay close attention to the connections and joints, as these are the most common areas for leaks. Allow the soap to sit for a few minutes, giving it time to create bubbles and coat the surfaces.

After the soapy solution has been applied, inspect the area thoroughly. Look for any bubbles forming on the fuel lines or around the fittings. Bubbles indicate the presence of a leak, as the fuel or air in the system is reacting with the soap. If you notice any bubbles, carefully examine the surrounding area to locate the exact source of the leak. This might require further investigation and potentially removing certain components to access the affected area.

Remember, regular maintenance and leak detection can save you from potential engine damage and costly repairs. By following this simple yet effective method, you can ensure the longevity and reliability of your Mercury outboard motor. Always take your time and be meticulous in your approach to identify and address any fuel line issues promptly.

Sportsters' Secret: Unveiling the Reserve Fuel Line Mystery

You may want to see also

Pressure Testing: Measure fuel pressure to ensure it meets specifications

Pressure testing is a critical step in ensuring the proper functioning of your Mercury outboard motor's fuel system. It helps identify potential issues with the fuel lines, fittings, and pumps, ensuring optimal performance and preventing costly repairs. Here's a detailed guide on how to perform this test:

Understanding the Importance of Pressure Testing:

Before diving into the process, it's essential to understand why pressure testing is necessary. Over time, fuel lines can develop cracks, leaks, or damage, leading to reduced fuel pressure. Insufficient pressure can result in poor engine performance, including reduced power, hesitation, and even stalling. By testing the pressure, you can pinpoint these issues and take corrective action.

Gathering the Required Tools:

To measure fuel pressure, you'll need a few essential tools. Firstly, a fuel pressure gauge is a must-have. These gauges are specifically designed to measure the pressure in fuel lines and are available at most automotive or marine supply stores. Ensure you get a gauge compatible with your Mercury outboard motor's fuel system. Additionally, you'll need a fuel pump primer bulb or a small hand pump to prime the fuel system temporarily.

Step-by-Step Pressure Testing:

- Park your boat on a level surface and allow the engine to cool down. This is important to ensure accurate readings.

- Locate the fuel pressure gauge port, which is typically a small opening on the fuel rail or near the fuel pump.

- Securely attach the fuel pressure gauge to the port. Make sure it is tight and sealed properly.

- Start the engine and allow it to idle for a few minutes to reach operating temperature.

- Using the primer bulb or hand pump, prime the fuel system. This step ensures that the fuel lines and pump are filled with fuel, providing an accurate pressure reading.

- Release the primer bulb or pump slowly while observing the gauge. The needle should rise to a specific pressure value, which varies depending on your Mercury outboard model and specifications.

- If the pressure is below the recommended range, it indicates a potential issue with the fuel pump, lines, or fittings.

Interpreting the Results:

The ideal fuel pressure for a Mercury outboard motor depends on the specific model and year. Consult your owner's manual or a technical guide for the recommended pressure range. If the measured pressure is significantly lower or higher than the specified value, it may indicate a problem. For example, low pressure could suggest a faulty fuel pump or clogged lines, while high pressure might be due to a malfunctioning pressure regulator.

Troubleshooting and Repairs:

After pressure testing, if you identify any issues, it's best to consult a qualified marine mechanic or refer to your Mercury outboard's service manual for troubleshooting steps. Common solutions include replacing damaged fuel lines, cleaning or replacing the fuel pump, or adjusting the pressure regulator. Regular pressure testing as part of your maintenance routine will help ensure your motor's longevity and reliable performance.

Briggs Fuel Line: Finding the Perfect Fit for Your Engine

You may want to see also

Frequently asked questions

To ensure a tight and leak-free connection, you can use a simple visual inspection. Start by removing the fuel line from the engine and examining the fitting for any signs of damage, cracks, or corrosion. If you notice any issues, it's best to replace the fitting. Additionally, you can use a soapy water solution and gently apply it around the fitting to check for bubbles, which would indicate a potential leak.

For this task, you'll require a few basic tools. Firstly, a fuel line removal tool or a pair of pliers can help you take off the fuel line. You might also need a wrench or a socket to loosen and tighten the fitting. It's recommended to have a new replacement fitting ready, as well as some fuel line sealant, in case you need to make any adjustments.

Regular maintenance is key to preventing problems. Ensure that you keep the fuel line and fittings clean and free from debris. After each use, inspect the fuel line for any signs of wear or damage. It's also a good practice to check the engine's manual for recommended maintenance intervals and any specific guidelines for your Mercury outboard model. Properly securing the fuel line with the appropriate fasteners can also help maintain a tight seal.