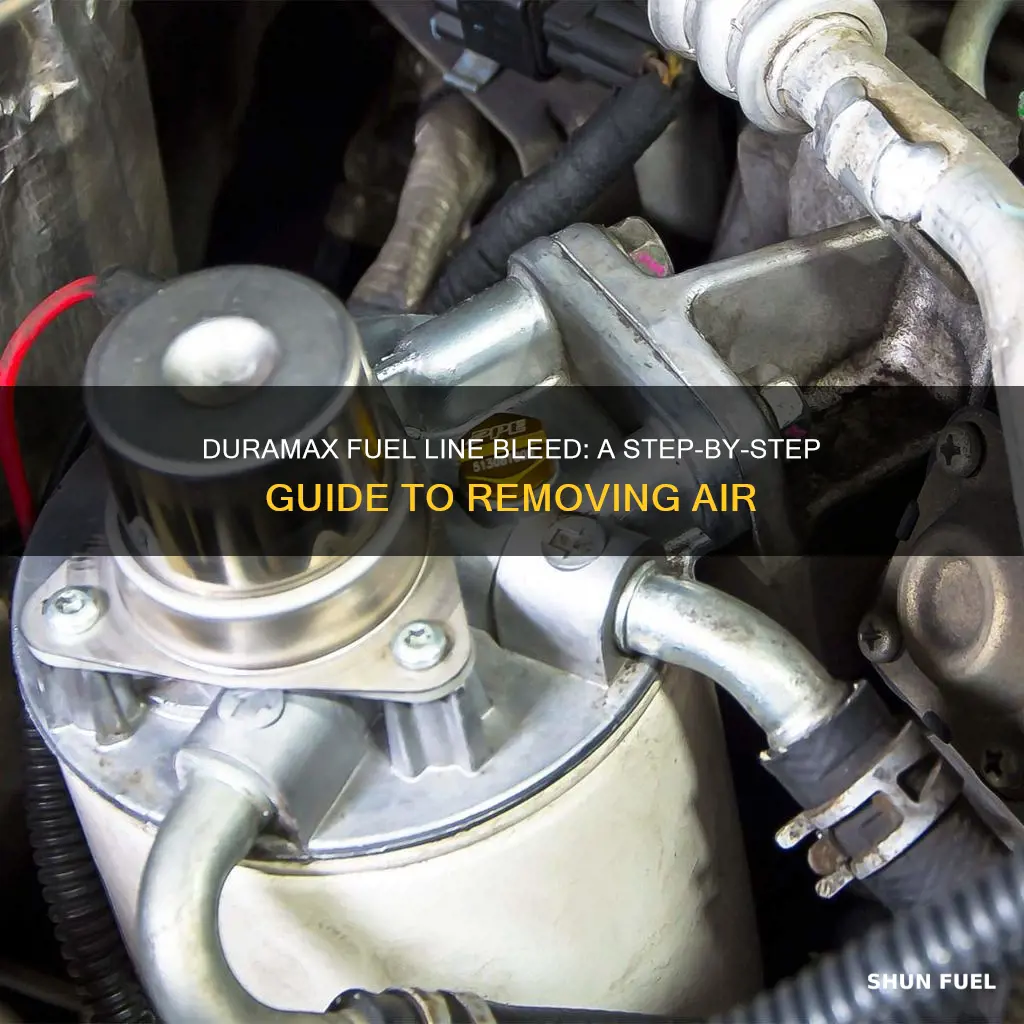

Bleed air out of your Duramax fuel lines with these simple steps. First, locate the bleeder valve, typically found near the fuel tank. Ensure the engine is off and the vehicle is in a level position. Use a flathead screwdriver to loosen the bleeder valve, allowing air to escape. Tighten the valve back in place, and start the engine. Rev the engine to its highest RPM for a few seconds, then shut it off. Repeat this process until no more air bubbles are heard. Check for any leaks around the connections and tighten them if necessary. This process ensures optimal fuel delivery and engine performance.

What You'll Learn

- Preparation: Ensure the vehicle is on a level surface, and locate the fuel lines

- Safety: Wear protective gear and ensure a well-ventilated workspace to avoid inhaling fumes

- Tools: Gather necessary tools: wrench, bleeder valve, and a container for collected air

- Locate Bleeder Valves: Identify and locate the bleeder valves on the fuel lines

- Bleeding Process: Open bleeder valves, release air, and repeat until no more air is expelled

Preparation: Ensure the vehicle is on a level surface, and locate the fuel lines

To begin the process of bleeding air from the fuel lines of a Duramax engine, it's crucial to start with the right preparation. First and foremost, ensure that your vehicle is parked on a level and stable surface. This is important to guarantee a safe and controlled environment for the procedure. Once the vehicle is securely positioned, the next step is to locate the fuel lines. These lines are typically found under the vehicle, running from the fuel tank to the engine. They are usually rubber or plastic hoses, and their exact location may vary depending on the specific model and year of your Duramax.

Locate the fuel lines by following their path from the fuel tank. They will likely be running along the frame rail or under the vehicle's body, depending on the design of your truck. It's essential to identify both the primary fuel line, which carries the main supply of fuel, and any secondary lines that may be present, as these could also contain air bubbles. Take note of any clips or ties that secure the fuel lines to the vehicle's structure, as you will need to temporarily release these to access the lines for bleeding.

When you've identified the fuel lines, it's time to gather the necessary tools. You will need a fuel line bleeding kit, which typically includes a specialized tool for creating a vacuum in the line and a container to collect any air or fuel that is released. Additionally, have a supply of clean, fresh fuel on hand to refill the tank after the bleeding process. This is important to ensure that the fuel system is not contaminated with air or old fuel.

Before proceeding, it's a good idea to consult the vehicle's manual or online resources specific to your Duramax model. These sources can provide detailed diagrams and instructions tailored to your vehicle, ensuring that you locate the correct fuel lines and use the appropriate tools for bleeding. Taking the time to prepare and gather the necessary resources will make the bleeding process smoother and more efficient.

Locating the Fuel Line: A 2005 Mazda 6 Guide

You may want to see also

Safety: Wear protective gear and ensure a well-ventilated workspace to avoid inhaling fumes

When working on any vehicle, especially one with a complex fuel system like the Duramax, it's crucial to prioritize safety. One common issue that Duramax owners might encounter is air bubbles in the fuel lines, which can lead to poor performance and potential engine damage. To address this, you'll need to bleed the air out of the fuel lines, but doing so requires caution and preparation.

First and foremost, ensure you are working in a well-ventilated area. The fuel system of a Duramax, like any diesel engine, operates under high pressure and can release potentially harmful fumes. Inhaling these fumes can be dangerous and should be avoided. Open the garage door or work outside if possible to allow fresh air to circulate. If you must work indoors, use a fan to draw out any fumes and ensure proper ventilation.

Protective gear is essential for this task. Wear safety goggles to protect your eyes from any potential splashes or debris. Gloves are also recommended to safeguard your hands from sharp edges or hot surfaces. Additionally, consider wearing a respirator mask to filter out any harmful fumes that might be present. This is a critical step to ensure your safety during the process.

Before you begin, it's a good idea to familiarize yourself with the specific steps for your Duramax model. Different models may have slightly varying procedures, so consult your vehicle's manual or online resources for detailed instructions. Understanding the process will help you identify potential hazards and ensure you're prepared for any challenges that might arise.

Remember, taking the necessary safety precautions is non-negotiable. By wearing the appropriate protective gear and working in a well-ventilated environment, you can minimize the risks associated with this task and ensure a safe and successful outcome when bleeding air out of your Duramax's fuel lines. Always stay cautious and informed when working on your vehicle to avoid any unnecessary complications.

Brake Line Placement: Can They Run Alongside Fuel Lines?

You may want to see also

Tools: Gather necessary tools: wrench, bleeder valve, and a container for collected air

To effectively bleed air from your Duramax fuel lines, it's crucial to have the right tools at hand. The primary tools you'll need include a wrench, a bleeder valve, and a container to collect the air that is released during the process. Here's a detailed breakdown of why each tool is essential:

Wrench: A wrench is a fundamental tool for any automotive repair, and it becomes especially important when dealing with fuel lines. You'll use the wrench to loosen and tighten the nuts or fittings that connect the fuel lines to various components of the engine. This step is critical to accessing the areas where air can accumulate and needs to be bled out.

Bleeder Valve: This specialized tool is designed to allow controlled release of air from the fuel lines. It is typically located at key points along the fuel system, such as where the fuel lines connect to the engine block or the fuel pump. The bleeder valve provides a safe and efficient way to remove air bubbles without causing any fuel to spill or damage the engine.

Container for Collected Air: Having a container ready to collect the air that is bled out is essential for two reasons. Firstly, it prevents the air from re-entering the fuel system, which could lead to performance issues. Secondly, it allows you to measure the amount of air removed, ensuring that you've successfully bled the system. This container can be a simple bucket or a specialized collection vessel designed for automotive use.

By gathering these tools in advance, you'll be well-prepared to tackle the task of bleeding air from your Duramax fuel lines. Each tool plays a specific role in ensuring a smooth and efficient process, contributing to the overall health and performance of your vehicle's fuel system.

Cadillac Deville Fuel System: Uncovering Hidden Lines

You may want to see also

Locate Bleeder Valves: Identify and locate the bleeder valves on the fuel lines

To begin the process of bleeding air from your Duramax fuel lines, you'll need to locate the bleeder valves. These valves are strategically placed along the fuel lines to allow for the release of air pockets. Here's a step-by-step guide to help you identify and locate these valves:

Start by inspecting the fuel lines under the hood of your Duramax vehicle. The bleeder valves are typically small, screw-capped openings along the length of the fuel lines. They are often located at regular intervals, making it easier to identify them. Look for any visible caps or small openings along the fuel lines. These are the potential bleeder valves.

In some cases, the bleeder valves might be less obvious and require a more thorough inspection. If you're having trouble finding them, refer to your Duramax's owner's manual. The manual will provide detailed diagrams or illustrations specific to your vehicle model, showing the exact locations of the bleeder valves. This is especially useful if your fuel lines have been modified or if you're working with a different generation of the Duramax.

When you've identified the potential bleeder valves, it's essential to double-check their placement. Ensure that they are not located in areas that might be difficult to access during the bleeding process. Some valves might be positioned near the fuel tank or under the engine, requiring you to lift or remove certain components to gain access. Take your time to carefully examine each fuel line and mark the locations of the valves if needed.

Remember, the key to successful air bleeding is proper valve identification. Take your time, refer to the manual if necessary, and ensure you locate all the bleeder valves along the fuel lines. This will make the subsequent steps of bleeding the air much more manageable and efficient.

Fuel Line Straightening: A Step-by-Step Guide to a Smooth Ride

You may want to see also

Bleeding Process: Open bleeder valves, release air, and repeat until no more air is expelled

The process of bleeding air out of Duramax fuel lines is a crucial step in maintaining the engine's performance and longevity. This procedure ensures that the fuel system operates efficiently, delivering clean and pressurized fuel to the engine. Here's a detailed guide on how to perform this task:

When you start the bleeding process, locate the bleeder valves, which are typically small openings or ports on the fuel lines. These valves are strategically placed to allow access to different sections of the fuel system. It's important to identify the correct bleeder valves for the specific area where air needs to be bled out. Start by opening one of these valves, usually located near the fuel tank or the engine block. This action will release any air trapped in the line. Listen for the hissing sound of air escaping, and feel for any bubbles that may come out. The goal is to expel any air bubbles that could cause issues.

After opening the first valve, you might notice that air continues to be released even after a few minutes. This is a good sign, as it indicates that the air is being properly bled out. However, if no air is expelled, you may need to adjust the valve slightly and try again. It's a process of trial and error, ensuring that you're targeting the right section of the fuel line. Once you've released as much air as possible from the initial valve, move on to the next section by opening another bleeder valve. Repeat this process until you've addressed all areas of the fuel system where air accumulation is suspected.

The key to successful bleeding is patience and persistence. Take your time to systematically go through each bleeder valve, ensuring that you've addressed all potential air pockets. If you encounter any resistance or difficulty in opening a valve, it might indicate a more complex issue, and you should consult the Duramax owner's manual or seek professional advice. Remember, the goal is to create a smooth and continuous flow of fuel, free from any air bubbles that could lead to engine performance problems.

In summary, bleeding air from Duramax fuel lines involves a methodical approach to opening and closing bleeder valves, ensuring that air is released from various sections of the fuel system. This process requires attention to detail and a systematic approach to identify and address all air pockets. By following these steps, you can effectively maintain the Duramax engine's fuel system, ensuring optimal performance and longevity.

Dorman Fuel Line Sizes: A Comprehensive Guide for 55240

You may want to see also

Frequently asked questions

Bleeding air from the fuel lines in a Duramax is a process that ensures proper fuel flow and engine performance. Here's a step-by-step guide: First, locate the fuel filter and remove it. Then, identify the bleeder screws, which are typically located near the fuel filter. Loosen these screws slightly to allow air to escape. You might hear a hissing sound as air is released. Tighten the screws back in place once the hissing stops. Reinstall the fuel filter and start the engine. Let it run for a few minutes, and check for any leaks.

Air bubbles in the fuel lines can occur due to a few reasons. One common cause is the fuel system not being properly bled during the initial fueling process. When the fuel pump is engaged for the first time, it can draw in air if the lines are not fully saturated with fuel. Additionally, fuel line damage or kinking can lead to air entering the system. Regular maintenance and ensuring the fuel system is bled correctly can prevent this issue.

While you may not need specialized tools, having a few basic items can make the job easier. A fuel line bleeder kit, which includes various-sized bleeder screws and a fuel line clamp, is useful. These screws are designed to fit into the bleeder ports and allow for controlled air release. Additionally, a fuel pump primer bulb can help prime the system and ensure proper fuel flow during the bleeding process.