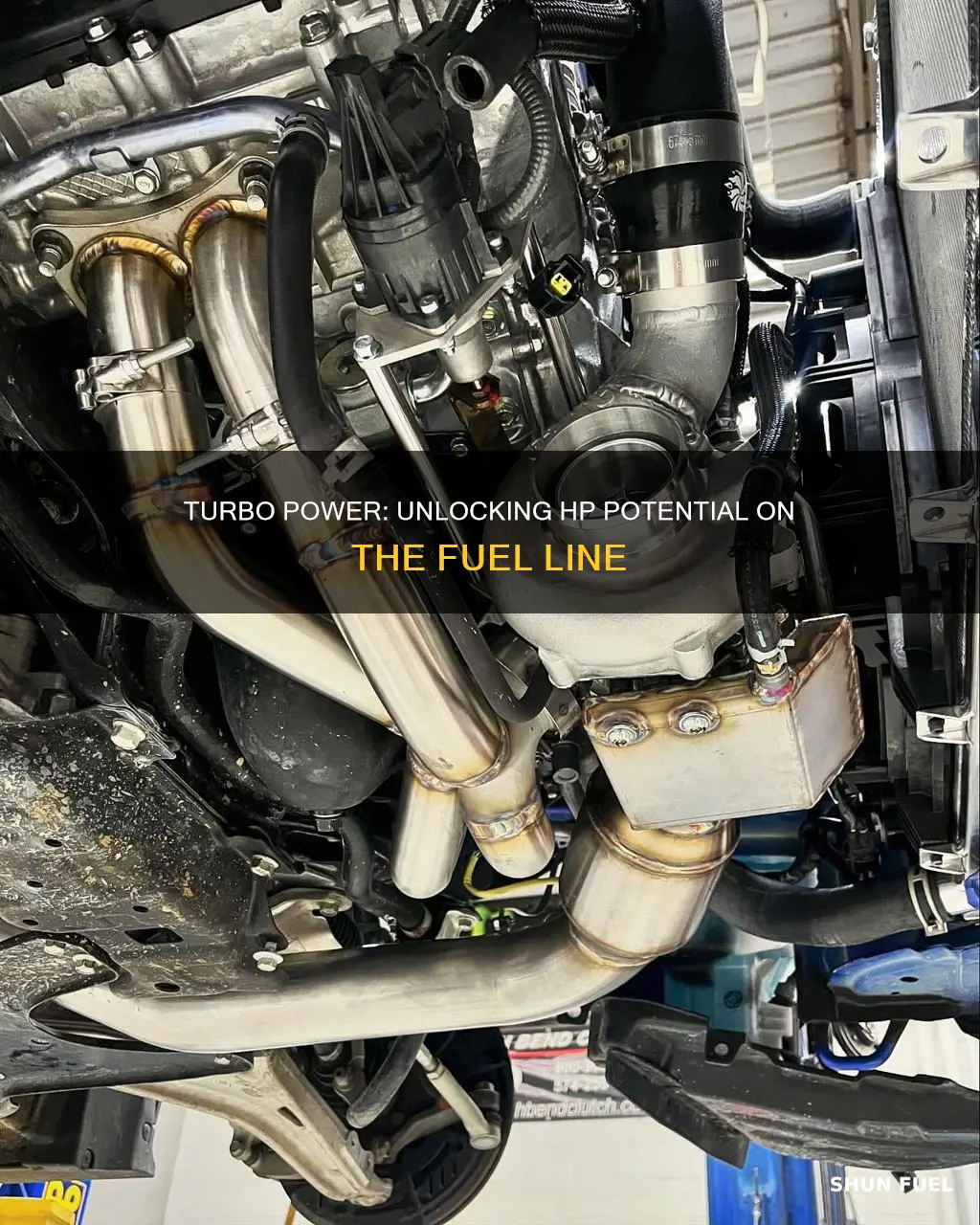

Understanding the performance of a vehicle's turbo system and its impact on horsepower (hp) is crucial for enthusiasts and mechanics alike. When discussing how much turboed hp on fuel line, we're exploring the relationship between a vehicle's turbocharged engine and the fuel delivery system. Turbochargers boost engine power by forcing more air into the combustion chamber, but the actual horsepower gain depends on various factors, including the fuel line's capacity and efficiency. This topic delves into the technical aspects of how the fuel line interacts with the turbocharger to deliver the intended power increase, ensuring optimal performance and safety.

What You'll Learn

Turbocharged Engine Power: Understanding HP Output on Fuel Line

The concept of turbocharging is an exciting advancement in engine technology, offering a powerful way to boost an engine's performance. When it comes to turbochargers, the term "HP" (horsepower) is often used to describe the engine's output, but it's important to understand what this means in the context of a fuel line. Turbocharged engines can produce significantly more horsepower than naturally aspirated engines, and this increase is directly related to the fuel delivery system.

When you hear about "turboed HP on the fuel line," it refers to the engine's ability to deliver more power by utilizing a turbocharger to compress the air-fuel mixture before it enters the combustion chamber. This process allows for a more efficient and powerful burn, resulting in increased horsepower. The fuel line plays a crucial role here, as it is responsible for supplying the necessary fuel to the engine at the right time and in the correct amount. Turbochargers require a precise fuel injection system to function optimally, ensuring that the engine receives the right amount of fuel to match the increased air pressure and density.

The amount of turbo-boosted horsepower on the fuel line can vary depending on several factors. Firstly, the engine's displacement and design play a significant role. Larger engines with more cylinders tend to produce more power, and when turbocharged, they can deliver impressive HP figures. Secondly, the type and size of the turbocharger are critical. Smaller turbos provide a gentle boost in power, while larger ones offer a more aggressive increase in performance. The engine's calibration and tuning also come into play; a well-tuned engine will ensure that the turbocharger's power is effectively harnessed and delivered through the fuel line.

Understanding the relationship between turbocharging and HP output is essential for enthusiasts and mechanics alike. When modifying or building a turbocharged engine, it's crucial to consider the fuel system's capabilities. Upgrading the fuel pump, injectors, and lines might be necessary to handle the increased fuel flow required for maximum power. Additionally, monitoring the engine's performance and adjusting the fuel management system can help optimize power delivery and ensure the engine operates within safe limits.

In summary, turbo-boosted horsepower on the fuel line represents the engine's ability to harness the power of a turbocharger and convert it into increased performance. It involves a careful balance of engine design, turbo size, and fuel system efficiency. By understanding these factors, you can unlock the full potential of a turbocharged engine and enjoy the thrill of enhanced power and acceleration. Remember, proper tuning and maintenance are key to ensuring the engine's longevity and optimal performance.

Fuel Line Routing: A Guide to Running Lines to Your YS 60 Motor

You may want to see also

Turbo Boost Pressure: Impact on Horsepower Delivery

The concept of turbo boost pressure and its direct correlation with horsepower delivery is a fascinating aspect of engine performance. When an engine is equipped with a turbocharger, it introduces an additional layer of complexity and efficiency to the power generation process. Turbo boost pressure refers to the force generated by the turbocharger, which compresses the air-fuel mixture before it enters the engine's cylinders. This compression results in a higher density of air, allowing for more efficient combustion and, consequently, increased power output.

The impact of turbo boost pressure on horsepower delivery is profound. As the pressure increases, the engine can inhale more air, which, when combined with fuel, creates a denser mixture. This denser mixture enables the engine to extract more energy from each combustion event, leading to a significant power gain. In simple terms, higher turbo boost pressure translates to more horsepower, as the engine can produce more power with each revolution. This relationship is often described as a direct proportionality, where a slight increase in boost pressure can result in a noticeable spike in horsepower.

However, it's important to note that the relationship between turbo boost pressure and horsepower is not linear. While higher boost pressure generally leads to more power, there are optimal ranges to consider. If the boost pressure exceeds the engine's design specifications, it can lead to issues such as engine knock, reduced efficiency, and even potential damage. Engine manufacturers carefully calibrate the turbocharger's boost levels to ensure optimal performance and longevity.

The impact of turbo boost pressure is also influenced by other factors, such as engine displacement, compression ratio, and fuel injection systems. These variables play a role in determining the overall horsepower output. For instance, a larger engine displacement might require higher boost pressure to achieve similar horsepower gains compared to a smaller engine. Additionally, the quality and precision of fuel injection systems become crucial, as they need to deliver the right amount of fuel to match the increased air density at higher boost pressures.

In summary, turbo boost pressure is a critical factor in maximizing horsepower delivery in an engine. It enables the engine to inhale more air, leading to denser mixtures and more efficient combustion. While higher boost pressure generally results in increased power, it must be carefully managed within the engine's design limits. Understanding the interplay between turbo boost pressure and other engine components is essential for engineers and enthusiasts alike to unlock the full potential of turbocharged engines.

Craftsman Fuel Line Sizes: A Guide to the Perfect Fit

You may want to see also

Fuel Injection Efficiency: Optimizing Turbocharged HP

Optimizing fuel injection for turbocharged engines is a critical aspect of maximizing horsepower (HP) and overall performance. When dealing with turbocharged engines, the fuel injection system plays a pivotal role in ensuring efficient combustion and power delivery. Here's a detailed guide on how to optimize fuel injection for turbocharged HP:

Understanding Turbocharged Fuel Injection:

Turbocharged engines require precise fuel injection management due to the unique challenges they present. Turbochargers increase engine power significantly, but they also demand more efficient fuel delivery to maintain optimal performance. The goal is to provide the right amount of fuel at the right time to match the increased power output while ensuring efficient combustion.

Fuel Pressure and Injection Timing:

One of the key factors in optimizing fuel injection is adjusting fuel pressure and injection timing. Higher turbo boost pressures mean the engine requires more fuel, and the fuel injection system must respond accordingly. Advanced fuel injectors with precise control can deliver the required fuel quantity at the optimal time. This involves calibrating the fuel pressure regulator and ensuring the injectors have the capability to atomize fuel effectively under increased pressure.

Fuel Pump and Line Considerations:

The fuel pump and lines are essential components in the fuel injection system. For turbocharged engines, a high-capacity fuel pump is often necessary to maintain sufficient fuel pressure under boost conditions. Upgrading to a larger-capacity pump and ensuring the fuel lines can handle the increased pressure are crucial steps. Additionally, consider using fuel filters and lines that can withstand the heat and pressure generated by the turbo system to prevent fuel degradation and ensure consistent performance.

Fuel Injector Calibration:

Calibrating the fuel injectors is a critical process. Each injector should be programmed to deliver the precise amount of fuel required for the specific engine speed and load. This calibration ensures that the engine receives the right fuel-air mixture, promoting efficient combustion and maximizing HP. Professional tuning tools and equipment are often used to adjust the injector pulse width and duty cycle for optimal performance.

Advanced Fuel Injection Technologies:

Modern fuel injection systems offer advanced technologies to optimize turbocharged engines. Direct fuel injection, for instance, delivers fuel directly into the combustion chamber, allowing for more precise control and improved power output. Additionally, electronic fuel management systems can continuously monitor and adjust fuel parameters, ensuring the engine operates at its most efficient state. These technologies enable tuners and enthusiasts to fine-tune the fuel injection setup for maximum HP.

In summary, optimizing fuel injection for turbocharged HP involves a comprehensive approach, including adjusting fuel pressure, timing, and injector calibration. By fine-tuning these aspects, enthusiasts can unlock the full potential of their turbocharged engines, achieving impressive power gains while maintaining efficient combustion. It is essential to consult manufacturer guidelines and seek professional advice when making modifications to ensure the system operates safely and effectively.

Will Heet Unfreeze Fuel Line? A Guide to Winter Car Care

You may want to see also

Turbocharged Engine Tuning: Adjusting for Maximum HP

When it comes to turbocharging an engine, the goal is often to maximize power output, and this involves careful tuning to ensure optimal performance. The process of adjusting a turbocharged engine to achieve its maximum horsepower (HP) is a complex but rewarding endeavor. Here's a breakdown of the key considerations and steps involved in this tuning process:

Understanding the Basics: Turbocharged engines rely on forced induction, where a turbocharger compresses air, which is then mixed with fuel and ignited in the cylinders. This process allows for more efficient combustion and higher power output compared to naturally aspirated engines. However, the power gain is not just a simple matter of adding more fuel; it requires precise calibration.

Fuel Line Considerations: The fuel line plays a critical role in turbo-HP adjustments. When increasing turbo boost, the engine demands more fuel to maintain power. The fuel line must be able to handle the increased pressure and volume of fuel, ensuring a consistent and precise delivery to the injectors. Upgrading the fuel line to a higher-capacity model is often necessary to accommodate the higher flow rates required for maximum power.

Tuning the Engine Management System (EMS): The EMS is the brain of the engine, controlling fuel injection, ignition timing, and other critical parameters. When turbocharging, the EMS needs to be calibrated to account for the altered engine dynamics. This involves adjusting the fuel injection timing, spray angles, and the overall fuel-air mixture to optimize power output while maintaining drivability. Advanced tuning tools and software are used to make these precise changes.

Boost Control and Safety: Turbocharged engines operate at much higher pressures, and managing boost levels is crucial. Overboosting can lead to engine damage, so boost control systems are employed. These systems monitor engine pressure and adjust the turbo's operation to prevent excessive boost. Additionally, safety measures like blow-off valves and wastegates are installed to release excess pressure and protect the engine.

Performance Testing and Validation: After making adjustments, thorough testing is essential. This involves dyno testing, where the engine's power output is measured under controlled conditions. The tuning process is iterative, with adjustments made based on test results. The goal is to find the sweet spot where power is maximized while maintaining a healthy engine operation. This may require fine-tuning various parameters, including fuel pressure, ignition advance, and turbo boost levels.

In summary, turbo-HP adjustments require a meticulous approach, considering fuel delivery systems, engine management, and safety measures. It's an art and science that allows enthusiasts and engineers to unlock the full potential of turbocharged engines while ensuring reliable and powerful performance.

Fuel-Lone Tool: A Viable Option for Transmission Line Maintenance?

You may want to see also

Turbocharged Engine Maintenance: Keeping HP Consistent

Maintaining a consistent power output from a turbocharged engine is crucial for optimal performance and longevity. Here's a comprehensive guide to ensuring your turbo-charged vehicle delivers the horsepower (HP) you expect:

Fuel Quality: The foundation of consistent power starts with the fuel you inject into your engine. Opt for high-octane gasoline, as it provides the necessary energy for efficient combustion. Lower-grade fuels may not fully utilize the turbo's potential, leading to reduced power. Regularly check your fuel filter and lines for contamination or blockages that could restrict fuel flow, impacting performance.

Air Intake and Exhaust: Efficient air intake is vital. Ensure your air filter is clean and free of debris. A clogged air filter restricts airflow, hindering the turbo's ability to deliver its full potential. Similarly, a well-maintained exhaust system is essential. Inspect for any leaks or damage to the exhaust manifold and pipes, as these can lead to backpressure, reducing engine efficiency. Regularly replacing the exhaust gases with fresh air is key to maximizing power.

Turbocharger Maintenance: The turbocharger is the heart of your power gain. Regular servicing is critical. This includes replacing the turbo oil seal and ensuring the turbo is lubricated properly. Over time, turbochargers can accumulate deposits and contaminants, leading to reduced performance. Consider using a turbo cleaner additive to maintain cleanliness and prevent performance degradation.

Engine Management System (EMS): Your vehicle's EMS plays a pivotal role in optimizing power delivery. It controls fuel injection, ignition timing, and other critical parameters. Regularly update your EMS software to ensure it's calibrated for your specific turbo setup. This ensures the engine operates efficiently across various driving conditions, maintaining consistent HP.

Performance Tuning: Fine-tuning your engine's performance can further enhance power output. This involves adjusting the air-fuel mixture, ignition timing, and other parameters to optimize power delivery. Professional tuners can provide valuable insights and adjustments tailored to your turbo setup. However, be cautious with extreme modifications, as they may void warranties and require additional maintenance.

Remember, consistent HP is a result of meticulous maintenance and attention to detail. By following these guidelines, you can ensure your turbocharged engine delivers the power you desire while extending its lifespan.

Understanding Fuel Pump and Injection Line Connections

You may want to see also

Frequently asked questions

Turbocharging your fuel line can significantly boost your engine's performance. The exact gain in horsepower depends on various factors, including your vehicle's make and model, engine specifications, and the type of turbo system installed. Generally, a well-tuned turbo setup can add anywhere from 50 to 300 horsepower or more, depending on the specific modifications and the engine's original state.

Turbocharging your fuel line might void your manufacturer's warranty, especially if the modifications are not performed by an authorized dealership or a reputable mechanic. It is essential to check your vehicle's warranty terms and conditions before making any significant changes. If you're unsure, consulting a professional mechanic or a dealership can provide clarity and ensure your warranty remains intact.

There are several indicators that your fuel line may benefit from turbocharging:

- Increased Engine Load: If your engine frequently feels underpowered, especially during high-load conditions like overtaking or climbing hills, turbocharging could provide the extra boost.

- Limited Power Band: A naturally aspirated engine may have a narrow power band, meaning it delivers power only within a specific RPM range. Turbocharging can expand this band, providing more power across a broader range of engine speeds.

- Engine Noise: A roaring or whining sound from the engine, especially at higher RPMs, could be a sign that it's struggling to breathe and could benefit from forced induction.

Turbocharging is a complex process that requires specialized knowledge and skills. While some enthusiasts might attempt DIY turbo kits, it is generally recommended to seek professional assistance. A qualified mechanic or performance specialist can ensure the installation is done correctly, safely, and in compliance with your vehicle's specifications. They can also fine-tune the system for optimal performance and reliability.