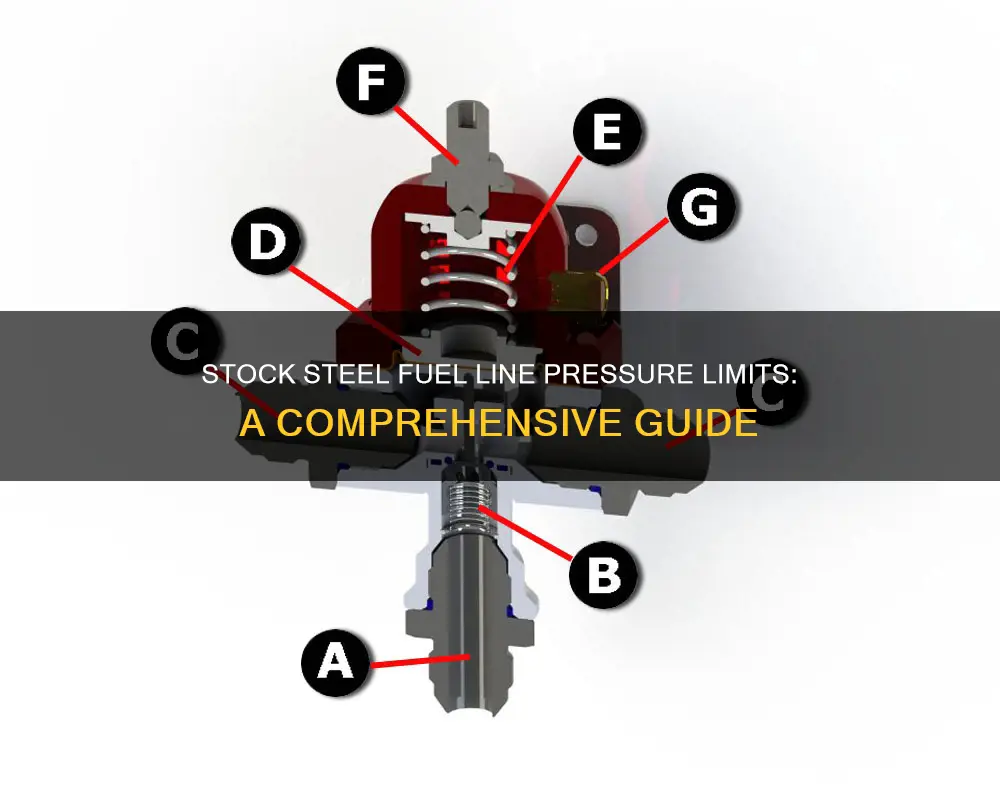

Understanding the pressure capacity of a stock steel fuel line is crucial for ensuring the safe and efficient operation of any vehicle's fuel system. The term psi refers to pounds per square inch, a unit of measurement for pressure. Stock steel fuel lines are designed to withstand a specific amount of psi, which varies depending on the make and model of the vehicle. Knowing this limit is essential for preventing potential issues such as fuel leaks, pump damage, or even engine failure. This knowledge is particularly important for those who modify their vehicles or use them in extreme conditions.

What You'll Learn

- Pressure Rating: Stock steel fuel lines typically have a pressure rating of 150-200 psi

- Line Diameter: Thicker lines can handle higher psi, but diameter limits flow rate

- Temperature Effects: Temperature can reduce psi capacity; lines may burst at high temps

- Vibration Resistance: Stock lines may not withstand high vibration, leading to psi loss

- Line Length: Longer lines have lower psi capacity due to increased surface area

Pressure Rating: Stock steel fuel lines typically have a pressure rating of 150-200 psi

Stock steel fuel lines are an essential component in any vehicle's fuel system, responsible for transporting fuel from the tank to the engine. When it comes to the pressure these lines can handle, it's crucial to understand the typical ratings to ensure optimal performance and safety.

The pressure rating of stock steel fuel lines is a critical factor in their design and functionality. These lines are engineered to withstand a specific range of pressure levels, which can vary depending on the make and model of the vehicle. Typically, stock steel fuel lines are rated to handle a pressure range of 150-200 psi (pounds per square inch). This rating is a standard specification for many automotive applications and ensures that the fuel lines can safely and efficiently deliver fuel to the engine without compromising performance or safety.

At 150 psi, the fuel lines are designed to provide a robust and reliable connection, ensuring that fuel is delivered under controlled pressure. This pressure range is considered safe for most everyday driving conditions and allows for efficient fuel flow without putting excessive strain on the lines. When the pressure reaches 200 psi, it indicates a higher capacity, which is often required in high-performance vehicles or those with larger fuel tanks.

It's important to note that the pressure rating of 150-200 psi is a general guideline, and specific vehicle requirements may vary. Some vehicles might have higher or lower pressure ratings depending on their engine specifications and fuel system design. Always refer to the vehicle's manual or consult with a professional mechanic to determine the exact pressure requirements for your particular make and model.

Understanding the pressure rating of stock steel fuel lines is essential for maintaining a safe and efficient fuel system. By knowing the typical range of 150-200 psi, vehicle owners and mechanics can ensure that the fuel lines are operating optimally, providing reliable fuel delivery to the engine. This knowledge also helps in identifying potential issues, such as leaks or pressure-related problems, allowing for prompt maintenance and ensuring the longevity of the fuel system.

Mastering the C & Fuel Line Quick Disconnect: A Comprehensive Guide

You may want to see also

Line Diameter: Thicker lines can handle higher psi, but diameter limits flow rate

When it comes to fuel lines, the diameter of the line plays a crucial role in determining its ability to handle pressure. Thicker fuel lines, with larger diameters, are designed to withstand higher psi (pounds per square inch) levels. This is because a larger diameter provides more surface area, which can better accommodate the force exerted by the pressure. As a result, thicker lines can handle the increased stress and are less prone to bursting or leaking under high-pressure conditions.

However, it's important to note that while thicker lines can handle higher psi, the increased diameter also has its limitations. A larger diameter fuel line may restrict the flow rate of the fuel. This is because the fuel has to travel a longer path through the line, which can lead to reduced velocity and potentially slower fuel delivery to the engine. Finding the right balance between psi handling capacity and flow rate is essential to ensure optimal engine performance.

Engineers and designers often consider the specific requirements of the vehicle and engine when selecting fuel line diameters. For high-performance applications or engines with higher psi needs, thicker lines might be chosen to handle the increased pressure. On the other hand, for everyday vehicles with standard psi requirements, thinner lines may be sufficient while still providing adequate flow rates.

In practice, the choice of fuel line diameter depends on various factors, including the engine's power output, the vehicle's intended use, and the overall fuel system design. It's crucial to consult manufacturer specifications and guidelines to determine the appropriate line diameter for a particular application. This ensures that the fuel lines can handle the expected psi levels while also optimizing fuel delivery for optimal engine performance.

Understanding the relationship between line diameter and psi handling capacity is vital for anyone working on fuel system modifications or upgrades. By selecting the right diameter, enthusiasts and professionals can ensure the safety and efficiency of their fuel lines, ultimately contributing to a well-functioning engine.

Cool Fuel Lines: The Ultimate Guide to Choosing the Right Lines

You may want to see also

Temperature Effects: Temperature can reduce psi capacity; lines may burst at high temps

The performance and safety of fuel lines in vehicles are significantly influenced by temperature, which can have a direct impact on the pressure they can withstand. Stock steel fuel lines, commonly used in many vehicles, have a specific psi (pounds per square inch) capacity that is designed to handle the typical operating conditions. However, this capacity is not infinite, and temperature plays a crucial role in determining the actual psi limit.

As temperatures rise, the psi capacity of the fuel lines decreases. This is primarily due to the expansion of the fuel and the steel material itself. When a fuel line is exposed to high temperatures, the fuel molecules gain more kinetic energy, causing them to occupy a larger volume. Simultaneously, the steel material expands, leading to a reduction in the internal diameter of the fuel line. This expansion results in a decrease in the cross-sectional area available for fuel flow, which directly affects the pressure that can be maintained.

In extreme cases, if the temperature becomes too high, the fuel lines may burst or fail. This is a critical issue as it can lead to fuel leaks, potential fires, and even engine damage. For instance, if a vehicle is used in high-temperature environments, such as racing or off-road activities, the fuel lines must be designed or upgraded to handle the anticipated temperature variations. Overheating can cause the steel to weaken, leading to a loss of structural integrity and potential failure at the psi capacity limit.

To ensure the longevity and safety of the fuel system, it is essential to consider the temperature effects. Manufacturers often provide guidelines and recommendations for operating temperatures to maintain the integrity of the fuel lines. In some cases, using fuel line insulators or heat shields can help manage temperature-related issues. Additionally, regular maintenance and inspections can identify any signs of damage or degradation caused by temperature fluctuations.

Understanding the relationship between temperature and psi capacity is vital for vehicle owners and mechanics. By recognizing how temperature impacts the performance of fuel lines, appropriate measures can be taken to mitigate risks and ensure the overall reliability of the fuel system. This knowledge is particularly important for vehicles operating in diverse environmental conditions, where temperature variations can significantly affect the psi capacity of stock steel fuel lines.

Diagnosing Chainsaw Fuel Line Leaks: A Step-by-Step Guide

You may want to see also

Vibration Resistance: Stock lines may not withstand high vibration, leading to psi loss

Stock steel fuel lines, often an integral part of a vehicle's fuel system, are designed to handle a certain amount of pressure, typically around 150-200 psi. However, their performance and longevity can be significantly impacted by a factor that is often overlooked: vibration. High levels of vibration, especially those experienced during aggressive driving or when the vehicle is subjected to rough terrain, can cause these lines to weaken over time.

The primary issue arises from the repetitive stress that vibration places on the fuel lines. This stress can lead to a variety of problems, including the development of cracks, which may not be immediately visible but can grow over time. As these cracks progress, they can compromise the structural integrity of the fuel line, leading to a loss of pressure and, in severe cases, a fuel leak. This is particularly concerning as it can result in reduced engine performance and, in extreme scenarios, engine failure.

Vibration-induced damage is a common issue, especially in vehicles that are used for off-road adventures or in applications where the engine operates at high RPMs for extended periods. The constant back-and-forth motion of the fuel lines under these conditions can cause the inner walls to rub against the outer protective layer, leading to wear and eventual failure. This is especially true for stock fuel lines, which are not designed to withstand the extreme conditions that some vehicles may encounter.

To mitigate these issues, it is recommended to upgrade to high-quality, vibration-resistant fuel lines. These upgraded lines are often made from more robust materials and are designed to handle the increased pressure and vibration levels. They can be a worthwhile investment, ensuring that your fuel system remains reliable and efficient, even in the most demanding environments. Additionally, regular inspections and maintenance can help identify and address any potential issues before they become major problems.

Fuel Line as Water Line: Exploring the Possibilities

You may want to see also

Line Length: Longer lines have lower psi capacity due to increased surface area

The pressure capacity of a fuel line is directly related to its length, and this relationship is primarily due to the increased surface area that longer lines present. When a fuel line is extended, it creates more surface area in contact with the fuel, which can lead to several issues when it comes to pressure. Firstly, the longer the line, the more fuel it can hold, and this increased volume of fuel can lead to a higher potential for pressure buildup. This is because the fuel has more space to expand, and any pressure fluctuations or changes in the fuel's state (e.g., temperature variations) can have a more significant impact on the overall pressure within the line.

In a stock steel fuel line, the material itself also plays a role in pressure capacity. Steel is a robust and durable material, but it can still be susceptible to certain limitations. The increased surface area of a longer line means that there is more material exposed to the fuel, which can lead to potential issues. For instance, the steel may start to corrode or deteriorate over time, especially if the fuel contains corrosive elements or if the line is not properly maintained. This corrosion can weaken the structural integrity of the line, reducing its ability to withstand high-pressure fuel.

Additionally, the design and construction of the fuel line also come into play. Longer lines may require more complex bends and fittings to accommodate the extended length, which can introduce additional stress points. These stress points can be susceptible to pressure-related damage, especially if the line is not properly secured or supported. The increased surface area can also lead to more opportunities for fuel to leak or spill, as any small cracks or imperfections in the line can become more significant issues.

To ensure optimal performance and safety, it is crucial to consider the length of the fuel line when determining its pressure capacity. Longer lines may require thicker walls or specialized materials to handle the increased pressure and surface area. Regular inspections and maintenance are also essential to identify and address any potential issues, ensuring that the fuel line can safely handle the required psi levels. Understanding these factors will help in making informed decisions when working with fuel lines, especially in high-performance or modified vehicles.

Locating the Fuel Line: A 2005 Mazda 6 Guide

You may want to see also

Frequently asked questions

The psi rating for a stock steel fuel line can vary depending on the make and model of the vehicle, but generally, it ranges from 150 to 250 psi. This is the pressure the line is designed to withstand without permanent deformation or failure.

While it is possible to upgrade to a higher psi fuel line, it is crucial to consider the vehicle's engine and fuel system specifications. Using a fuel line with a significantly higher psi rating than the stock one might not be beneficial and could even be dangerous. It is recommended to consult the vehicle's manual or a professional mechanic to determine the appropriate psi range for your specific car.

The psi rating is often labeled on the fuel line itself or can be found in the vehicle's service manual. If you cannot locate this information, it is best to consult a professional mechanic or contact the vehicle manufacturer's customer support for assistance.

Yes, there are a few indicators that your stock fuel line might be under excessive pressure. These include fuel leaks, engine misfires, reduced fuel efficiency, and in extreme cases, visible damage to the fuel line. If you notice any of these symptoms, it is advisable to have your fuel system inspected and potentially upgraded to a higher psi-rated line if necessary.