Creating a 6AN fuel line is a crucial process for any vehicle enthusiast looking to enhance their engine's performance. This guide will provide a step-by-step approach to constructing a high-quality 6AN fuel line, ensuring optimal fuel delivery to the engine. From selecting the right materials to mastering the installation process, this tutorial will cover all the essential techniques and considerations to create a robust and efficient fuel line. Whether you're a seasoned mechanic or a DIY enthusiast, this comprehensive guide will empower you to build a reliable and powerful fuel line for your vehicle.

What You'll Learn

- Materials and Tools: Gather necessary supplies like fuel line, connectors, and crimping tools

- Preparation: Clean and prepare the fuel line and connectors for assembly

- Assembly: Connect the fuel line to the engine using appropriate connectors and fittings

- Testing: Inspect the fuel line for leaks and ensure proper flow

- Safety: Follow safety guidelines to prevent fuel leaks and ensure proper ventilation

Materials and Tools: Gather necessary supplies like fuel line, connectors, and crimping tools

To begin the process of creating a 6AN fuel line, it's crucial to gather the necessary materials and tools. This ensures you have everything required to complete the task efficiently and effectively. Here's a detailed breakdown of the supplies you'll need:

Materials:

- 6AN Fuel Line: This is the primary component of your project. Ensure you purchase the correct size and length of fuel line suitable for your specific application. Common sizes include 1/4" and 3/8", each with varying lengths depending on your vehicle's requirements.

- Connectors: You'll need fuel line connectors to join the fuel line to the engine, fuel pump, and other components. These connectors come in various types, such as quick-connect fittings, barbed fittings, or flare fittings. Choose the appropriate connectors based on your vehicle's make and model.

- Fuel Line Reinforcement: Depending on the length and route of your fuel line, you might want to add reinforcement to prevent damage. This can include steel braiding, rubber protection sleeves, or heat shrink tubing.

Tools:

- Crimping Tool: A crimping tool is essential for securely attaching the connectors to the fuel line. It applies pressure to the connectors, ensuring a tight and leak-proof connection. There are various types of crimping tools available, including manual and powered options.

- Pliers: Regular pliers can be useful for holding the fuel line and connectors in place during the crimping process.

- Pipe Cutter or Utility Knife: These tools will help you cut the fuel line to the desired length. Ensure you have a sharp and precise cutting tool to make clean, straight cuts.

- Sandpaper or Embellisher: Lightly sanding the fuel line and connectors can help create a smooth surface for a better connection. Embellishers can also be used to remove any sharp edges.

- Safety Gear: Don't forget to wear safety gloves and goggles to protect your hands and eyes during the process.

Having all these materials and tools ready will ensure a smooth and successful fuel line installation. It's essential to inspect each component carefully and double-check your work to guarantee a professional finish and reliable performance.

Tygon Fuel Line: Unlocking the Secrets of High-Performance Fuel Delivery

You may want to see also

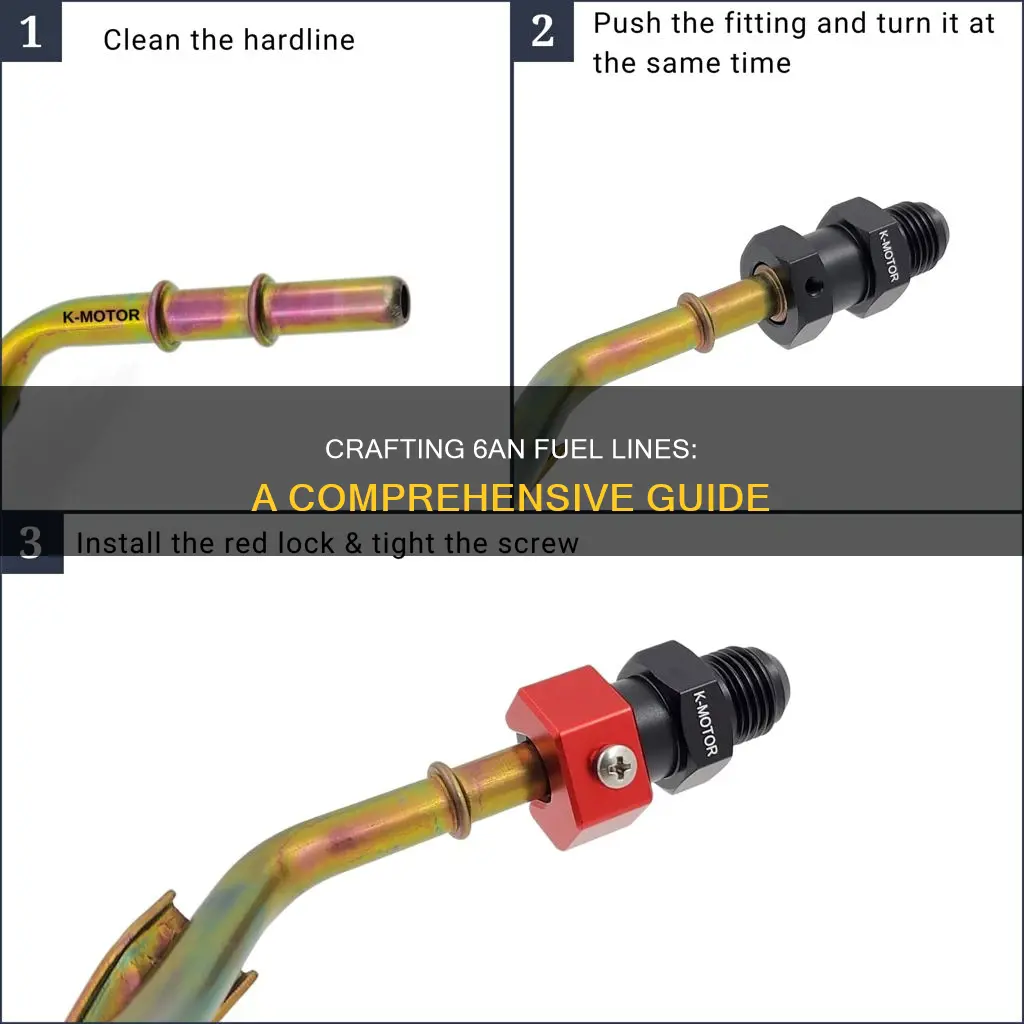

Preparation: Clean and prepare the fuel line and connectors for assembly

Before you begin the assembly process, it's crucial to ensure that the fuel line and connectors are clean and prepared correctly. This step is often overlooked but is essential for a successful and safe installation. Here's a detailed guide on how to prepare the fuel line and connectors:

Step 1: Cleaning the Fuel Line

Start by removing the old fuel line (if applicable) and inspecting it for any signs of damage, cracks, or contamination. Use a fuel line cleaner or a mild detergent solution to thoroughly clean the interior of the fuel line. This step is vital as any residue or contaminants left from the previous fuel line can affect the performance and longevity of the new 6AN fuel line. Rinse the fuel line thoroughly with clean water to remove any cleaning agent residue. Ensure that the fuel line is completely dry before proceeding.

Step 2: Connector Preparation

Inspect the fuel line connectors for any damage or wear. Clean the connectors using a suitable solvent or cleaner to remove any dirt, corrosion, or old fuel residue. Pay attention to the threads and ensure they are free from debris. If the connectors have any damage, consider replacing them to ensure a secure and leak-free connection. It's recommended to use new O-rings or seals with the connectors to maintain a tight seal.

Step 3: Inspect and Test

After cleaning and preparing the fuel line and connectors, thoroughly inspect them for any signs of damage or defects. Check for bends, kinks, or any visible imperfections. Once you're satisfied with the preparation, test the fuel line by applying slight pressure to ensure there are no leaks. This step is crucial to identify any potential issues before final assembly.

Safety Precaution: When handling fuel lines, always wear protective gloves and ensure proper ventilation to avoid inhaling any fumes. It's also advisable to work in a well-lit area to prevent any accidents.

By following these preparation steps, you'll ensure that the 6AN fuel line is assembled correctly and functions optimally, providing a reliable fuel supply to your engine. Remember, proper preparation is key to a successful DIY project.

Fuel Return Line Disconnect: A Step-by-Step Guide for 1993 Ford F250 460 Owners

You may want to see also

Assembly: Connect the fuel line to the engine using appropriate connectors and fittings

When connecting the fuel line to the engine, it's crucial to use the right connectors and fittings to ensure a secure and leak-free assembly. Here's a step-by-step guide to help you through this process:

Step 1: Prepare the Components

Before you begin, ensure you have all the necessary components, including the fuel line itself, the appropriate connectors (such as 6AN connectors), and the required fittings. Check the specifications of your engine to determine the correct sizes and types of connectors needed. It's essential to use the right parts to guarantee a proper fit and prevent any potential issues.

Step 2: Locate the Fuel Line Connections

Identify the specific areas on your engine where the fuel line needs to be connected. These points are typically located near the fuel pump and the engine's fuel injection system. Carefully examine the engine's layout to locate the fuel line ports and ensure you have access to the necessary mounting points.

Step 3: Attach the Fuel Line to the Engine

Start by securing the fuel line to the engine using the appropriate fittings. Slide the fuel line through the connectors and ensure it is properly aligned with the engine's mounting points. Use the recommended tools, such as fuel line clips or ties, to hold the line in place temporarily. Tighten the connectors securely, but be careful not to overtighten, as this can damage the fuel line.

Step 4: Use the Right Connectors

Select the correct 6AN connectors for your fuel line. These connectors should be compatible with the fuel line's diameter and material. Ensure that the connectors are designed for the specific fuel pressure and flow rate of your engine. Properly insert the connectors onto the fuel line, ensuring a snug fit. Tighten the connectors securely, following the manufacturer's guidelines to avoid over-tightening.

Step 5: Test for Leaks

After completing the connections, it's vital to test for any leaks. Start the engine and check for any signs of fuel leakage around the connectors and fittings. If you notice any leaks, carefully inspect the connections and tighten or adjust them as necessary. Ensure that all components are properly sealed to prevent fuel loss and potential engine damage.

Remember, taking your time and following the manufacturer's instructions for each component will ensure a successful and safe fuel line assembly.

Mastering the Art of Removing Rendezvous Fuel Lines: A Comprehensive Guide

You may want to see also

Testing: Inspect the fuel line for leaks and ensure proper flow

When it comes to testing the fuel line for your 6AN system, there are several crucial steps to ensure its functionality and safety. Firstly, you'll need to locate the fuel line and identify any potential areas where leaks could occur. This includes checking the connections between the fuel pump, fuel tank, and the engine's fuel injectors or carburetor. Look for any signs of corrosion, damage, or wear around these connections, as these can be potential sources of leaks.

The next step is to use a simple yet effective method to test for leaks. You can use a soapy water solution as a leak detection tool. Start by cleaning the fuel line and connections with a degreaser to remove any contaminants. Then, carefully apply a thin layer of soapy water to the fuel line, ensuring it covers all the areas where fuel might come into contact. Observe the fuel line closely for any bubbles or soapy suds forming. If you notice any, it indicates a potential leak, and you should investigate further.

To ensure proper flow, you should also check the fuel pressure. Low fuel pressure can lead to poor engine performance and potential engine damage. You can use a fuel pressure gauge to measure the pressure at the fuel rail or injectors. The ideal pressure range can vary depending on your engine and vehicle specifications, so consult your vehicle's manual for the correct range. If the pressure is below the recommended level, you may need to adjust the fuel pump or consider other factors that could be affecting the flow.

Additionally, it's essential to inspect the fuel line for any blockages or restrictions. Over time, debris, contaminants, or even fuel line damage can cause blockages, leading to reduced fuel flow. Use a fuel line cleaner or a compressed air gun to blow through the line and clear any obstructions. Ensure that the fuel line is not kinked or pinched, as this can also restrict flow.

Lastly, consider using a fuel flow meter to measure the actual fuel flow rate. This tool will provide you with a quantitative measurement of the fuel being delivered to the engine. By comparing the measured flow rate with the expected value, you can identify any discrepancies and further troubleshoot the fuel system. Regular testing and inspection of the fuel line will help ensure optimal performance and longevity of your 6AN fuel system.

Powerful Engine Demands: Choosing the Right Fuel Line for 535 HP

You may want to see also

Safety: Follow safety guidelines to prevent fuel leaks and ensure proper ventilation

When working with fuel lines, it's crucial to prioritize safety to prevent accidents and ensure the well-being of those around you. Here are some essential guidelines to follow:

Personal Protective Equipment (PPE): Always wear appropriate PPE, such as gloves and safety goggles, to protect your hands and eyes from potential hazards. Fuel can be harmful if it comes into contact with your skin or eyes, so taking this simple precaution is vital. Ensure that the PPE you choose is suitable for the task and provides adequate protection.

Ventilation: Proper ventilation is critical to avoid inhaling harmful fumes. When working in enclosed spaces or areas with poor air circulation, open windows and doors to allow fresh air to flow in. Consider using a portable fan to enhance air movement and disperse any potential fumes. Working outdoors is generally safer, but if you must work in a confined space, ensure it is well-ventilated to minimize the risk of inhalation of toxic gases.

Fuel Line Inspection: Before connecting or modifying a fuel line, inspect it for any signs of damage, cracks, or leaks. Look for any visible corrosion or deterioration, especially at connections and bends. If you notice any issues, do not attempt to repair them yourself. Instead, consult a professional mechanic or technician who can safely replace or repair the fuel line to prevent potential leaks.

Fuel Handling: When handling fuel, always exercise caution. Avoid sparks or open flames, as they can ignite the fuel and lead to dangerous explosions. Keep fuel containers closed and secure when not in use. Never smoke or allow open flames in areas where fuel is present. Additionally, be mindful of static electricity, as it can also spark and cause fires. Ground yourself by touching a metal surface before handling fuel to dissipate any static charge.

Emergency Preparedness: It is essential to be prepared for emergencies. Keep a fire extinguisher nearby and ensure it is suitable for fuel-related fires. Know the location of the nearest fire extinguisher and how to use it effectively. In the event of a fuel leak, have a plan to contain and clean up the spill promptly. Keep a supply of absorbent materials, such as cat litter or sand, to soak up spilled fuel and prevent it from spreading. Always have a first-aid kit readily available to address any minor injuries that may occur during the process.

By adhering to these safety guidelines, you can significantly reduce the risks associated with working on fuel lines, ensuring a safer environment for yourself and those around you. Remember, safety should always be the top priority when dealing with potentially hazardous materials.

Mastering Ford Fuel Line Connector Removal: A Step-by-Step Guide

You may want to see also

Frequently asked questions

A 6AN fuel line is a type of fuel line commonly used in automotive applications, particularly for high-performance engines. It is designed to handle high-pressure fuel and is known for its durability and flexibility, ensuring efficient fuel delivery to the engine.

Selecting the appropriate size involves considering the engine's fuel requirements and the pressure it operates under. Typically, you'll find 6AN fuel lines in various diameters, with common sizes ranging from 3/8" to 1/2" ID (inside diameter). It's crucial to match the line's size to the engine's specifications to ensure optimal performance and prevent fuel pressure issues.

While it is possible to install a 6AN fuel line yourself, especially if you have some mechanical experience, it is generally recommended to seek professional assistance. Fuel line installation requires precision and knowledge of engine systems to ensure a secure and leak-free connection. Professionals can also help identify any potential issues and provide guidance on the best practices for your specific vehicle.

6AN fuel lines are typically made from high-quality materials such as stainless steel or aluminum. Stainless steel is popular due to its corrosion resistance and durability, making it ideal for high-pressure fuel applications. Aluminum lines are also used, offering lightweight alternatives that can improve fuel efficiency without compromising performance.

Regular maintenance is essential to ensure the longevity of your 6AN fuel lines. It is recommended to check for any signs of damage, cracks, or leaks periodically. Keep the lines clean and free from debris, and avoid using sharp objects that could puncture the lines. Additionally, ensure that all connections are tight and secure to prevent fuel leaks and maintain optimal engine performance.