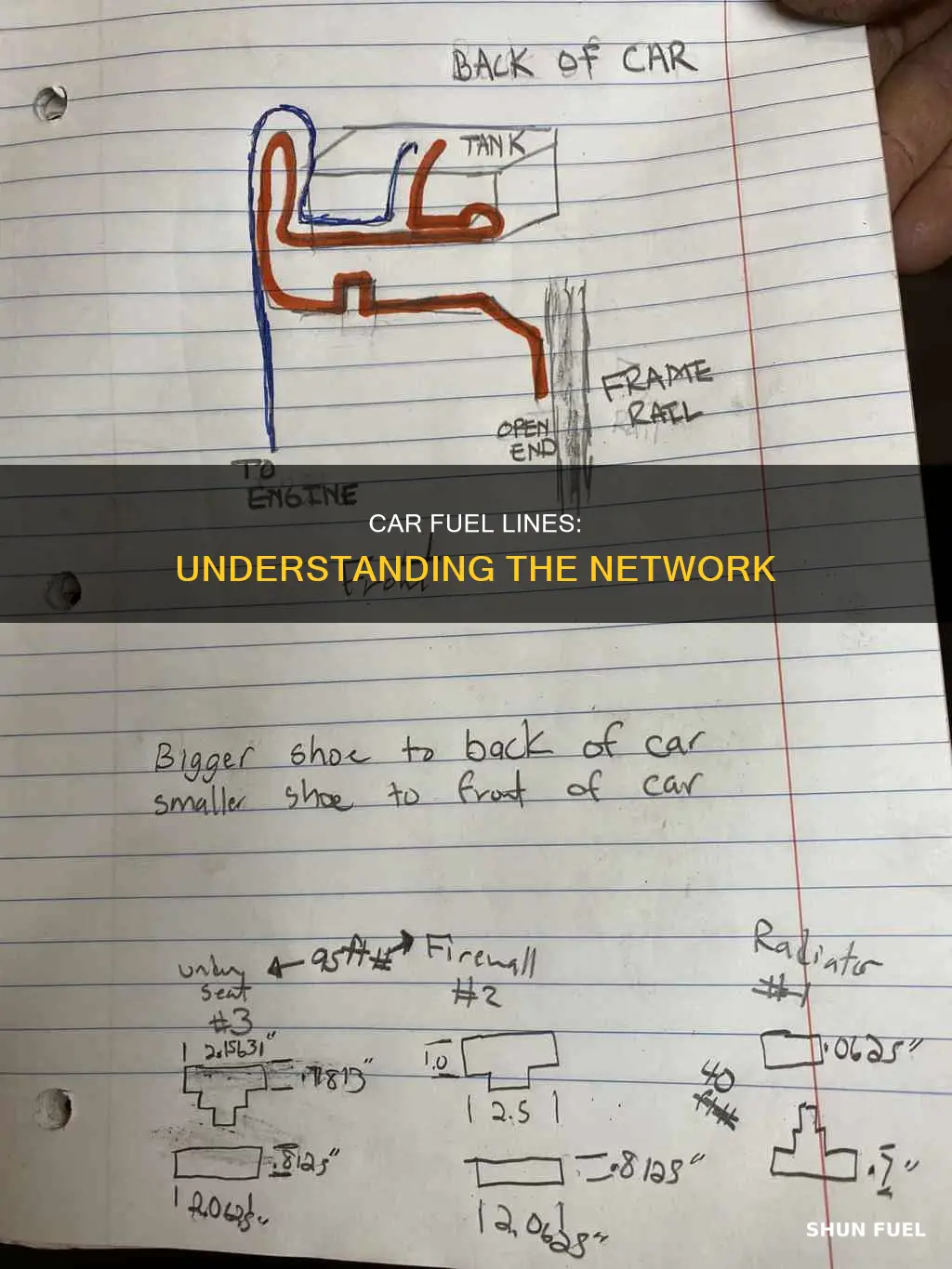

Understanding the fuel system of a car is essential for maintaining its performance and safety. The fuel lines in a car are a crucial component of the fuel delivery system, responsible for transporting fuel from the tank to the engine. The number of fuel lines in a car can vary depending on the make and model, as well as the engine configuration. Generally, a typical car has two primary fuel lines: one for the main fuel supply and another for the return line, which recirculates fuel back to the tank. However, some vehicles may have additional lines for specific functions, such as a fuel pressure regulator or a fuel pump, which can add complexity to the system. Knowing the exact number and layout of these lines is important for mechanics and car enthusiasts to ensure proper maintenance and troubleshooting.

| Characteristics | Values |

|---|---|

| Number of Fuel Lines | Varies, typically 3-5 lines for modern cars, but can range from 2 to 7 depending on the vehicle's make and model. |

| Purpose | Fuel lines deliver gasoline or diesel from the fuel tank to the engine, ensuring a steady supply of fuel for combustion. |

| Material | Usually made of rubber or plastic, with metal lines used in some high-performance or classic cars. |

| Placement | Fuel lines are strategically positioned to avoid heat sources and potential damage, often running along the frame or under the car's body. |

| Maintenance | Regular inspection and replacement are crucial to prevent fuel leaks and ensure optimal engine performance. |

| Common Issues | Cracks, leaks, and clogs can occur, often due to age, temperature fluctuations, or physical damage. |

What You'll Learn

- Fuel Pump Lines: These lines connect the fuel pump to the engine, delivering fuel under pressure

- Return Lines: They carry excess fuel back to the tank for recycling

- Fuel Injector Lines: These lines deliver fuel directly to the injectors for precise injection

- Vapor Recirculation Lines: These lines control fuel vapor emissions by recirculating fuel vapor

- Fuel Tank Lines: These lines connect the fuel tank to the engine, ensuring a steady fuel supply

Fuel Pump Lines: These lines connect the fuel pump to the engine, delivering fuel under pressure

The fuel pump lines in a car are a critical component of the fuel injection system, ensuring a steady and efficient supply of fuel to the engine. These lines are responsible for connecting the fuel pump, typically located in the fuel tank or near the engine, to the engine's fuel injectors or carburetor. The primary function of these lines is to deliver fuel under pressure, which is essential for proper engine operation.

In a typical car, there are usually two main types of fuel pump lines: the low-pressure line and the high-pressure line. The low-pressure line is responsible for delivering fuel from the fuel tank to the fuel pump. It is designed to handle the lower pressure required to draw fuel from the tank and maintain a consistent flow. This line is often made of a flexible material to accommodate the slight movement of the fuel tank during driving.

The high-pressure line, on the other hand, takes over once the fuel reaches the pump. It is designed to handle the increased pressure generated by the pump, which is necessary to deliver fuel to the engine at the required rate and pressure. This line is typically made of a more rigid material to withstand the higher pressure and ensure a reliable fuel supply.

Connecting these lines to the fuel pump and the engine requires precision and attention to detail. The fuel pump must be securely mounted to ensure it operates efficiently and reliably. The lines should be routed carefully to avoid any obstructions or damage, as they can be susceptible to wear and tear over time. Proper installation and maintenance of these lines are crucial to prevent fuel leaks and ensure optimal engine performance.

In summary, fuel pump lines play a vital role in the fuel delivery system of a car. They connect the fuel pump to the engine, ensuring a continuous supply of fuel under pressure. Understanding the different types of lines and their functions is essential for proper maintenance and troubleshooting, ensuring the engine receives the necessary fuel for efficient operation.

Jiffy Lube Fuel Line Fixes: Quick Solutions for Car Owners

You may want to see also

Return Lines: They carry excess fuel back to the tank for recycling

Return lines, also known as fuel return lines or return hoses, are an essential component of a vehicle's fuel system. These lines play a crucial role in ensuring efficient fuel management and preventing wastage. As the name suggests, return lines are responsible for transporting excess fuel from various parts of the fuel system back to the fuel tank. This process is vital for maintaining the proper fuel level and pressure, especially during different driving conditions and engine operations.

In a typical car's fuel system, there are multiple fuel lines, each serving a specific purpose. When the engine is running, the fuel pump delivers fuel from the tank to the engine's fuel injectors or carburetor. However, not all the fuel supplied is used immediately. The excess fuel, along with vaporized fuel, accumulates in the fuel bowl or the upper part of the fuel tank. This excess fuel needs to be returned to the tank to maintain the correct fuel level and prevent contamination.

Return lines are designed to handle this task efficiently. They are typically made of flexible materials like rubber or plastic, allowing them to bend and move with the vehicle's components during operation. These lines are connected to the fuel bowl or the upper fuel tank and extend towards the fuel pump. When the engine is running, the fuel pump creates a slight vacuum, pulling the excess fuel and vapor through the return lines back into the tank. This process ensures that the fuel system remains clean and that the fuel level is regulated, promoting optimal engine performance.

The design of return lines takes into account various factors to ensure their effectiveness. They are often equipped with check valves or one-way valves that allow fuel to flow in one direction, preventing it from flowing back into the engine when the vehicle is stationary. This feature ensures that the engine does not start running with excess fuel in the system, which could lead to inefficient combustion and potential performance issues.

In summary, return lines are a critical part of a car's fuel system, facilitating the recycling of excess fuel to the tank. They work in conjunction with other fuel lines and components to maintain proper fuel management, ensuring the engine operates efficiently and effectively. Understanding the role of return lines can help car owners appreciate the intricate design and functionality of their vehicle's fuel system.

Optimizing Fuel Delivery: Choosing the Right Size for Your Viva HC

You may want to see also

Fuel Injector Lines: These lines deliver fuel directly to the injectors for precise injection

Fuel injector lines are an essential component of a car's fuel system, playing a crucial role in ensuring optimal engine performance. These lines are responsible for delivering fuel directly to the fuel injectors, which are located at the intake manifold or directly on the cylinder head. The primary function of these lines is to provide a precise and controlled amount of fuel to the injectors, allowing for efficient combustion and power generation.

In modern vehicles, the number of fuel lines can vary depending on the make and model of the car. However, a typical fuel system may include multiple lines to ensure efficient fuel distribution. For instance, there might be a primary fuel line that carries the main supply of fuel from the fuel pump to the engine, and several smaller lines that branch off to supply fuel to individual cylinders or banks of cylinders. This setup ensures that each cylinder receives the required amount of fuel for optimal performance.

The fuel injector lines are designed to handle high-pressure fuel, which is necessary to atomize the fuel into a fine mist for efficient combustion. These lines are typically made of durable materials such as steel or aluminum alloys to withstand the pressure and temperature variations within the engine. The lines are also insulated to prevent heat transfer from the engine block, ensuring that the fuel remains at the optimal temperature for efficient operation.

Proper installation and maintenance of fuel injector lines are critical to the overall performance and longevity of the engine. Leaks or blockages in these lines can lead to poor fuel distribution, resulting in reduced power, inefficient combustion, and potential engine damage. Regular inspections and replacements of fuel lines are recommended to ensure that the fuel system operates optimally.

In summary, fuel injector lines are a vital part of a car's fuel system, responsible for delivering fuel directly to the injectors for precise injection. The number of fuel lines can vary, but they are essential for efficient fuel distribution and engine performance. Proper maintenance and care of these lines are crucial to ensure the engine operates at its best.

Volvo VNL Fuel Line Sizing: Expert Guide

You may want to see also

Vapor Recirculation Lines: These lines control fuel vapor emissions by recirculating fuel vapor

Vapor Recirculation Lines: A Crucial Component in Fuel Management

In the intricate network of a car's fuel system, vapor recirculation lines play a vital role in maintaining optimal performance and minimizing environmental impact. These lines are specifically designed to address the issue of fuel vapor emissions, which can significantly contribute to air pollution. By implementing a clever mechanism, these lines ensure that fuel vapor is carefully controlled and managed.

The primary function of vapor recirculation lines is to capture and redirect fuel vapor that would otherwise escape into the atmosphere. When fuel is injected into the engine, it undergoes a combustion process, and the resulting vapor can be harmful if released unchecked. These lines act as a conduit, capturing the vapor and routing it back into the engine's intake system. This process is particularly important in modern vehicles, where fuel injection systems are prevalent, and precise control of fuel-air mixture is essential for efficient combustion.

The design of vapor recirculation lines is meticulous, ensuring that the fuel vapor is recirculated in a controlled manner. These lines are typically made of high-quality materials that can withstand the corrosive nature of fuel and the high temperatures involved. They are strategically positioned to facilitate the efficient capture and redirection of vapor, often integrating with the engine's intake manifold or other components to ensure seamless integration.

One of the key advantages of vapor recirculation lines is their ability to reduce harmful emissions. By recirculating fuel vapor, these lines prevent the release of volatile organic compounds (VOCs) and other pollutants into the atmosphere. This not only contributes to a cleaner environment but also helps vehicles comply with stringent emission regulations. Additionally, this system can improve fuel efficiency by ensuring that the fuel-air mixture is precisely controlled, leading to more complete combustion and reduced fuel wastage.

In summary, vapor recirculation lines are a critical component in the complex fuel management system of modern vehicles. Their primary purpose is to control and reduce fuel vapor emissions, ensuring that the combustion process is efficient and environmentally friendly. With their precise design and strategic placement, these lines play a vital role in maintaining the overall performance and environmental compliance of automobiles. Understanding the function of these lines highlights the intricate engineering that goes into creating sustainable and efficient transportation systems.

Blue Uerathyane Fuel Line: Safe for Ethanol Gasoline?

You may want to see also

Fuel Tank Lines: These lines connect the fuel tank to the engine, ensuring a steady fuel supply

Fuel tank lines are an essential component of a vehicle's fuel system, playing a crucial role in ensuring a continuous and efficient fuel supply to the engine. These lines are designed to connect the fuel tank, typically located at the rear or bottom of the vehicle, to the engine, which is responsible for converting the fuel into power. The primary function of these lines is to provide a reliable and steady flow of fuel, allowing the engine to operate optimally.

The number of fuel lines in a car can vary depending on the vehicle's make, model, and year. Generally, most cars have two primary fuel lines: one for the primary fuel supply and another for the return line, which recirculates fuel back to the tank. However, some vehicles, especially those with more complex fuel systems, may have additional lines for specific functions. For instance, a fuel pump line is used to deliver fuel from the tank to the pump, and a fuel pressure regulator line maintains the correct fuel pressure.

These fuel tank lines are typically made of durable materials such as rubber, plastic, or metal, chosen for their ability to withstand the corrosive nature of fuel and the high temperatures inside the engine compartment. The lines are designed with various fittings and connectors to ensure a secure and leak-free connection between the tank and the engine. Proper installation and maintenance of these lines are critical to prevent fuel leaks, which can lead to dangerous situations and potential engine damage.

In addition to the primary fuel lines, some vehicles may also have auxiliary lines for specific purposes. For example, a fuel filter line is used to route fuel through the filter, ensuring clean fuel reaches the engine. Another line might be dedicated to the fuel injection system, delivering fuel directly to the injectors for precise engine control. Understanding the layout and purpose of these lines is essential for mechanics and car enthusiasts when performing maintenance or troubleshooting fuel-related issues.

Regular inspection and maintenance of fuel tank lines are recommended to ensure the vehicle's safety and performance. Over time, these lines can deteriorate due to fuel contamination, extreme temperatures, or physical damage. A thorough inspection can help identify any cracks, leaks, or blockages, allowing for prompt repairs or replacements. Proper care of the fuel system, including the lines, contributes to a reliable and efficient vehicle, ensuring the driver's peace of mind.

Engine Flush: Does It Really Clean Fuel Lines?

You may want to see also

Frequently asked questions

The number of fuel lines in a car can vary depending on the make and model, as well as the engine configuration. Generally, a standard car has at least three fuel lines: one for the primary fuel supply to the engine, one for the return of excess fuel from the carburetor or fuel injection system, and sometimes an additional line for the fuel pump.

Yes, it is possible to replace a single damaged fuel line. However, it's important to ensure that the replacement line is compatible with the vehicle's fuel system and that all connections are properly secured. It's recommended to consult the car's manual or seek professional assistance to identify the correct fuel line and ensure a safe and successful repair.

Yes, several symptoms can indicate a problem with the fuel lines. These include engine misfires, difficulty starting the car, reduced power or performance, strange noises from the engine, and the presence of fuel leaks. If any of these issues arise, it's advisable to inspect the fuel lines for damage or blockages.

Regular maintenance and inspections are crucial to ensure the health of your car's fuel system. It is recommended to inspect the fuel lines during routine service intervals or whenever there are concerns about potential damage. Look for any signs of cracks, corrosion, or clogs, and address any issues promptly to prevent further complications.

Modifying the fuel system, including adding extra fuel lines, should be done with caution and proper knowledge. While some enthusiasts might modify their vehicles for performance gains, it's essential to understand the potential risks and legal implications. Consulting with automotive experts or professionals is advisable to ensure any modifications are safe and compliant with local regulations.