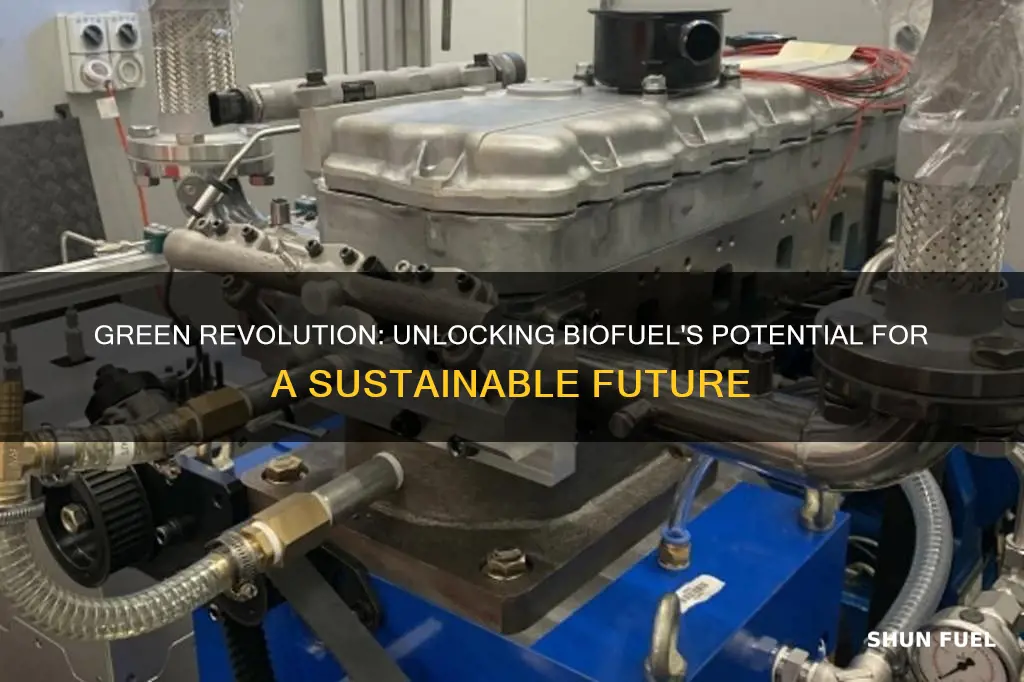

Biofuels are an increasingly popular alternative to traditional fossil fuels, offering a more sustainable and environmentally friendly way to power vehicles. The process of making a car run on biofuel involves converting organic matter, such as plant oils, animal fats, or even waste materials, into a usable fuel through various methods like transesterification or fermentation. This paragraph will explore the key steps and technologies involved in producing biofuels, highlighting their potential to reduce carbon emissions and promote a greener transportation system.

What You'll Learn

- Feedstock Selection: Choose suitable crops or waste materials for biofuel production

- Feedstock Preparation: Clean, grind, or preprocess feedstock for optimal biofuel conversion

- Biofuel Conversion Technologies: Employ processes like fermentation or transesterification to convert biomass into fuel

- Engine Modifications: Adapt engines to run efficiently on biofuels, ensuring performance and reliability

- Distribution and Storage: Develop infrastructure for biofuel transportation and safe storage

Feedstock Selection: Choose suitable crops or waste materials for biofuel production

Feedstock selection is a critical step in the process of producing biofuels, as it directly impacts the efficiency and sustainability of the entire production chain. The choice of feedstock determines the type of biofuel that can be produced and the environmental benefits it offers. When considering suitable crops or waste materials for biofuel production, several factors should be taken into account to ensure optimal results.

One of the primary considerations is the availability and abundance of the feedstock. It is essential to choose crops or waste materials that are readily available and can be sourced locally or regionally. This reduces transportation costs and minimizes the carbon footprint associated with feedstock acquisition. For example, if a specific region has a surplus of agricultural residues, such as corn stover or wheat straw, these can be utilized as feedstock for biofuel production, reducing the need to import materials from distant locations.

Another crucial factor is the energy content and oil yield of the chosen feedstock. Different crops and waste materials have varying oil concentrations and energy densities, which directly affect the amount of biofuel that can be extracted. For instance, oilseed crops like rapeseed and sunflower can produce high-quality biodiesel, while crops like sugarcane and switchgrass are suitable for ethanol production due to their high sugar content. Understanding the energy potential of each feedstock is vital to ensure efficient biofuel production.

Additionally, the environmental impact of feedstock cultivation or collection should be considered. Some crops may require extensive irrigation or chemical inputs, which can have negative effects on the local ecosystem. It is important to choose feedstocks that are environmentally friendly and do not contribute to deforestation or water scarcity. For example, using waste materials such as used cooking oil, animal fats, or even algae can provide a more sustainable and eco-friendly approach to biofuel production, as these materials would otherwise be considered waste and have minimal environmental impact.

Furthermore, the processing and conversion methods for different feedstocks should be evaluated. Certain crops or waste materials may require specific pretreatment or processing techniques to unlock their biofuel potential. For instance, lignocellulosic biomass, which includes agricultural residues and wood chips, needs advanced conversion technologies like enzymatic hydrolysis to break down the complex cellulose and hemicellulose structures. Understanding the compatibility of feedstock with available conversion technologies is essential for a successful biofuel production process.

In summary, feedstock selection is a key decision point in the biofuel production process, requiring careful consideration of availability, energy content, environmental impact, and processing requirements. By choosing suitable crops or waste materials, it is possible to optimize the production of biofuels while minimizing the environmental footprint of the entire process. This approach contributes to a more sustainable and efficient bioenergy sector, making it an attractive alternative to conventional fossil fuels.

Unveiling Honda's Hydrogen Vision: Powering the Future with Fuel Cells

You may want to see also

Feedstock Preparation: Clean, grind, or preprocess feedstock for optimal biofuel conversion

Feedstock preparation is a critical step in the process of converting biomass into biofuel, ensuring that the raw materials are ready for efficient and effective conversion processes. This initial stage involves several key processes to optimize the quality and suitability of the feedstock for biofuel production.

Cleaning: The first step in feedstock preparation is cleaning, which aims to remove any impurities, contaminants, and unwanted materials from the feedstock. This is crucial as impurities can hinder the conversion process and reduce the overall efficiency of biofuel production. Cleaning methods may include sieving, where the feedstock is passed through screens of different mesh sizes to separate larger impurities from the smaller particles. Magnetic separation is another technique used to remove ferrous materials, ensuring that only the desired biomass remains. For organic feedstocks, washing with water or specific solvents can help remove dirt, debris, and any non-biomass components. Proper cleaning ensures that the feedstock is free from contaminants, which is essential for the subsequent conversion steps.

Grinding and Size Reduction: After cleaning, the feedstock often needs to be ground or reduced in size to increase the surface area and enhance the conversion process. Grinding can be achieved through various methods such as hammer mills, roller mills, or ball mills. These machines break down the feedstock into smaller particles, increasing the exposed surface area of the biomass. This step is particularly important for cellulosic biomass, which requires extensive preprocessing to access the complex carbohydrates and lignin. Grinding also helps to ensure that the feedstock is in a consistent size range, which is beneficial for the subsequent enzymatic or thermal conversion processes.

Preprocessing and Pretreatment: Depending on the type of biomass and the desired biofuel, additional preprocessing steps may be required. For example, in the case of lignocellulosic biomass, pretreatment is essential to remove lignin and make the cellulose and hemicellulose more accessible for conversion. Common pretreatment methods include chemical pretreatment (using acids or bases), physical pretreatment (such as steam explosion), and biological pretreatment (using enzymes). These processes help to break down the complex structure of the biomass, making it more susceptible to further conversion steps. Pretreatment also plays a vital role in removing inhibitors that can negatively impact the conversion process.

The goal of feedstock preparation is to transform the raw biomass into a form that is more readily convertible into biofuel. This involves a series of processes that ensure the feedstock is clean, properly sized, and, in some cases, pretreated to enhance its suitability for the specific biofuel production method. Efficient feedstock preparation is a key factor in the overall success and sustainability of biofuel production, contributing to the development of renewable and environmentally friendly energy sources.

Manual Transmission: Fuel Efficiency Advantage or Myth?

You may want to see also

Biofuel Conversion Technologies: Employ processes like fermentation or transesterification to convert biomass into fuel

Biofuel conversion technologies play a crucial role in transforming various organic materials, known as biomass, into usable fuels, primarily for transportation. This process is essential for developing sustainable alternatives to conventional fossil fuels. Two prominent methods employed in this conversion are fermentation and transesterification, each offering unique advantages and applications.

Fermentation: This ancient process, dating back to early civilizations, involves the breakdown of carbohydrates in biomass through microbial action. Typically, sugars derived from sources like corn, wheat, or sugar cane are the primary feedstock. The process begins with the enzymatic breakdown of these sugars into simpler molecules, such as glucose or fructose. Microorganisms, often yeast, then metabolize these sugars, producing ethanol as a byproduct. This ethanol can be further refined and blended with gasoline to create a biofuel suitable for use in conventional vehicles. Fermentation is a relatively simple and cost-effective method, making it a popular choice for producing bioethanol, a common biofuel.

Transesterification: This chemical process is more complex and involves the conversion of triglycerides, found in vegetable oils or animal fats, into biodiesel. The process utilizes an alcohol, typically methanol or ethanol, and a catalyst, often sodium hydroxide or potassium hydroxide. During transesterification, the triglycerides react with the alcohol, forming fatty acid methyl esters (FAME) and glycerol. This reaction is highly efficient, producing a high-quality biofuel with similar properties to conventional diesel. Biodiesel, a product of this process, is known for its cleanliness, high energy content, and reduced emissions, making it an attractive alternative to diesel fuel.

Both fermentation and transesterification offer viable pathways to convert biomass into biofuels. Fermentation is well-suited for producing ethanol from agricultural residues or dedicated energy crops, while transesterification excels in converting waste vegetable oils and animal fats into biodiesel. These technologies contribute to the development of a sustainable biofuel industry, reducing our reliance on finite fossil fuel resources and mitigating environmental impacts. As research and development in this field continue, we can expect further improvements in conversion efficiency, feedstock versatility, and the overall sustainability of biofuel production.

Carburetor and Fuel Injection: A Dual-Fuel Engine's Tale

You may want to see also

Engine Modifications: Adapt engines to run efficiently on biofuels, ensuring performance and reliability

To make a car run on biofuel, engine modifications are essential to ensure optimal performance and reliability. Here's a detailed guide on the necessary adaptations:

Engine Design and Components:

The first step is to assess and potentially redesign the engine's internal components. Biofuels often have different chemical properties compared to conventional gasoline or diesel. This can lead to changes in combustion behavior, requiring modifications to the engine's intake, compression, and combustion chambers. The engine block, cylinder head, valves, and piston design might need adjustments to accommodate the new fuel. For instance, using a different piston material or altering the valve train to optimize fuel-air mixing and combustion efficiency.

Fuel Injection and Delivery System:

Modifying the fuel injection system is crucial. Biofuels often have higher lubricity, which can affect the engine's fuel delivery mechanism. The fuel injectors may need to be calibrated or replaced to ensure precise fuel dispersion. This includes adjusting the injection timing, spray angle, and pressure to match the unique characteristics of biofuels. Additionally, the fuel pump and lines should be inspected for any potential issues, as biofuels might have different flow rates and pressures compared to traditional fuels.

Ignition System:

The ignition system plays a vital role in the combustion process. Biofuels may require a more advanced ignition system to ensure proper spark timing and intensity. This could involve upgrading to a higher-performance ignition coil, spark plugs, and potentially a more sophisticated engine control unit (ECU) to manage the ignition timing precisely. The ECU will need to be programmed to optimize performance with the new fuel, adjusting for differences in combustion characteristics.

Engine Control Unit (ECU) Programming:

Programming the ECU is a critical aspect of engine modification. The ECU controls various engine parameters, and its programming needs to be tailored to the specific biofuel being used. This includes adjusting fuel injection maps, timing curves, and other parameters to match the engine's new operating conditions. The ECU can also be programmed to monitor and optimize performance, ensuring the engine runs efficiently and reliably with the biofuel.

Testing and Calibration:

After the modifications, extensive testing and calibration are necessary. This involves running the engine on a test bench and various road tests to ensure it meets performance, emissions, and reliability standards. The engine's response, power output, fuel consumption, and emissions should be carefully monitored and adjusted as needed. Calibration tools and software can be utilized to fine-tune the engine's performance, ensuring it runs smoothly and efficiently with the biofuel.

By implementing these engine modifications, you can successfully adapt a vehicle to run on biofuel, providing an environmentally friendly and potentially cost-effective alternative to traditional fuels while maintaining or even enhancing performance.

Can You Power Your Car with Oil? The Ultimate Guide

You may want to see also

Distribution and Storage: Develop infrastructure for biofuel transportation and safe storage

The successful integration of biofuels into the transportation sector requires a robust distribution and storage infrastructure. This infrastructure is crucial to ensure the efficient and safe transportation of biofuels from production sites to refueling stations, ultimately enabling their use in vehicles. Here's a detailed breakdown of the key considerations and steps involved in developing this essential component of the biofuel ecosystem:

Pipeline Networks:

- Design and Construction: Biofuel producers and distributors should invest in the development of dedicated pipeline networks specifically designed for biofuels. These pipelines need to be constructed with materials compatible with biofuel properties, ensuring compatibility and preventing contamination.

- Route Planning: Careful route planning is essential to connect biofuel production hubs, processing facilities, and refueling stations. Pipelines should be strategically located to minimize transportation costs and ensure efficient distribution.

- Safety Measures: Implementing stringent safety protocols is paramount. This includes regular inspections, leak detection systems, and emergency response plans to mitigate potential risks associated with biofuel transportation.

Transportation Methods:

- Tanker Trucks and Trailers: For shorter distances or areas without pipeline infrastructure, tanker trucks and specialized trailers are essential. These vehicles should be designed to handle biofuels safely and efficiently, with proper insulation and containment systems to prevent spills.

- Rail Transportation: Rail freight offers a cost-effective and environmentally friendly option for transporting biofuels over long distances. Specialized rail cars with secure locking mechanisms are necessary to ensure safe transit.

- Biodegradable Packaging: When transporting biofuels in smaller quantities, consider using biodegradable packaging materials to minimize environmental impact in case of accidental spills.

Storage Facilities:

- Terminals and Tanks: Secure and dedicated storage terminals are required at strategic locations along the distribution network. These terminals should house large capacity tanks designed specifically for biofuels, taking into account factors like temperature sensitivity and fire safety.

- Safety Regulations: Stringent safety regulations must govern the design, construction, and operation of biofuel storage facilities. This includes measures for fire prevention, spill containment, and emergency response.

- Monitoring and Control: Implement advanced monitoring systems to track biofuel levels, temperature, and pressure. Real-time data allows for efficient inventory management and proactive safety measures.

Regulations and Standards:

- Government Oversight: Governments play a crucial role in establishing and enforcing regulations for biofuel distribution and storage. These regulations should address safety, environmental protection, and quality standards.

- Industry Collaboration: Collaboration between biofuel producers, distributors, transportation companies, and regulators is essential for developing and implementing best practices and standards.

- Research and Development: Continuous research and development efforts are needed to improve biofuel storage technologies, materials, and safety protocols.

By implementing these infrastructure development strategies, we can ensure a reliable and safe distribution network for biofuels, paving the way for widespread adoption and the successful transition to a more sustainable transportation system.

Unleash Savings: Understanding Company Car Fuel Cards

You may want to see also

Frequently asked questions

Biofuel is a renewable energy source derived from organic materials such as plants, agricultural residues, and waste oils. It can be converted into a liquid fuel similar to gasoline or diesel through processes like transesterification. When used in a car engine, biofuel is injected and mixed with regular fuel, or it can be used alone, depending on the engine's design and the specific biofuel blend.

Yes, there are several types of biofuels, including ethanol, biodiesel, and bioethanol. Ethanol is commonly blended with gasoline, typically up to 10% (E10). Biodiesel, made from vegetable oils or animal fats, can be used in diesel engines without modification. Bioethanol, another ethanol-based fuel, is often used as an additive to gasoline and is more common in some European countries.

To determine if your car is compatible with biofuel, check the vehicle's owner's manual or consult the manufacturer. Some cars are designed to run exclusively on biofuel, while others may require specific modifications to the fuel system. It's essential to use the recommended biofuel blend to avoid engine damage.

Biofuel offers several advantages, including reduced greenhouse gas emissions compared to fossil fuels, as it is derived from organic matter that absorbs carbon dioxide during growth. It can also help reduce dependence on non-renewable resources and promote energy security. Additionally, biofuel production can support local agriculture and create new economic opportunities.

While biofuel has numerous benefits, there are some challenges. Biofuel production can compete with food crops for land and resources, potentially impacting food prices and availability. Engine performance and maintenance may require adjustments, and not all biofuel blends are readily available at every fuel station. Additionally, the infrastructure for biofuel distribution and storage might not be as extensive as that for conventional fuels.