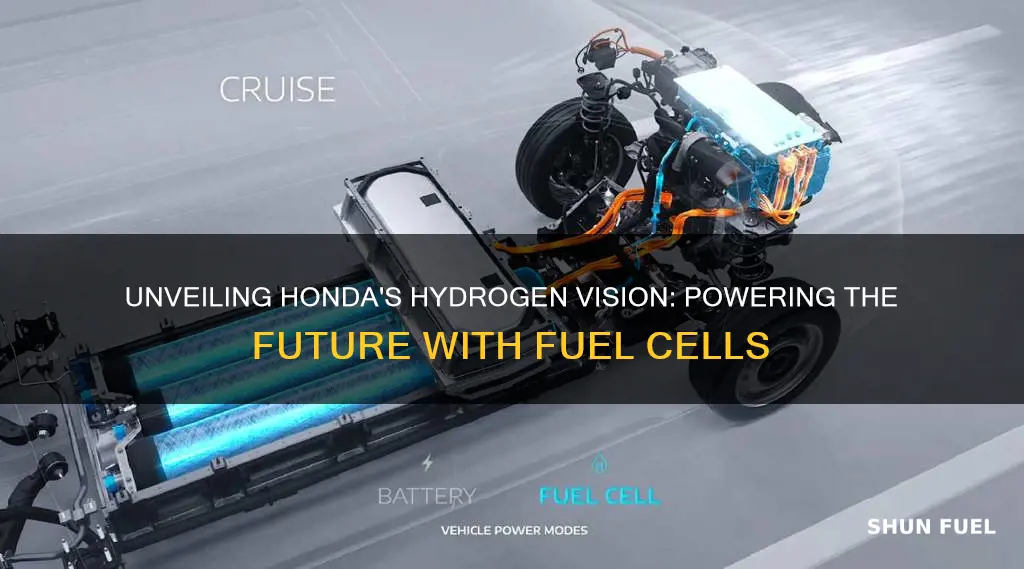

Honda's hydrogen fuel cell car is a groundbreaking innovation in the automotive industry, offering a sustainable and efficient alternative to traditional internal combustion engines. This car utilizes a unique technology that converts hydrogen gas into electricity through a chemical reaction, providing a clean and virtually emission-free driving experience. The process begins with the fuel cell stack, which consists of multiple cells that combine hydrogen and oxygen to generate electricity, heat, and water as the only byproducts. This technology is a key component of Honda's commitment to reducing environmental impact and promoting a greener future.

What You'll Learn

- Fuel Cell Basics: Hydrogen and oxygen react to produce electricity and water vapor

- Power Generation: Electrochemical reaction converts hydrogen into electricity, powering the vehicle

- Storage and Delivery: High-pressure tanks store hydrogen, and fuel cells regulate its flow

- Efficiency and Performance: Fuel cells offer high efficiency and zero emissions

- Infrastructure and Costs: Hydrogen refueling stations and production costs are key considerations

Fuel Cell Basics: Hydrogen and oxygen react to produce electricity and water vapor

The concept of a hydrogen fuel cell is a fascinating and innovative approach to powering vehicles, and Honda's development of a hydrogen fuel cell car is a significant step forward in sustainable transportation. At its core, the fuel cell operates on a simple yet powerful principle: the reaction of hydrogen and oxygen to generate electricity and water vapor. This process is the fundamental basis of fuel cell technology and offers a clean and efficient way to power vehicles.

In a fuel cell, the primary components include a fuel cell stack, where the magic happens. This stack consists of multiple fuel cell modules, each containing an anode and a cathode. The anode is where the hydrogen fuel enters, and the cathode is where oxygen from the air is introduced. When hydrogen and oxygen are combined, they undergo a chemical reaction, which is the key to generating electricity. This reaction is facilitated by a catalyst, typically made of platinum, which accelerates the process without being consumed in the reaction.

The reaction can be simplified as follows: Hydrogen gas (H₂) and oxygen gas (O₂) react to produce water (H₂O) and electricity. The chemical equation for this process is 2H₂ + O₂ → 2H₂O + electricity. During this reaction, hydrogen atoms lose their electrons, becoming protons, which then travel through the electrolyte to the cathode. At the cathode, oxygen combines with these protons and electrons to form water, completing the circuit and producing electricity as a byproduct.

This process is highly efficient, converting chemical energy directly into electrical energy, with water as the only emission. The electricity generated can then power the vehicle's electric motor, providing a clean and sustainable source of power. Honda's fuel cell car utilizes this technology, storing hydrogen in high-pressure tanks and using it to generate electricity on-demand, ensuring a continuous and reliable power supply for the vehicle's operation.

The beauty of this system lies in its simplicity and environmental friendliness. By harnessing the power of chemical reactions, Honda's hydrogen fuel cell car offers a promising alternative to traditional internal combustion engines, reducing greenhouse gas emissions and contributing to a greener future. This technology is a significant advancement in the quest for sustainable transportation, and its development by Honda showcases their commitment to innovation and environmental responsibility.

Car Rental Fuel: What's Included and How to Save

You may want to see also

Power Generation: Electrochemical reaction converts hydrogen into electricity, powering the vehicle

The power generation process in Honda's hydrogen fuel cell vehicles is a fascinating and efficient method of converting chemical energy into electrical power. At the heart of this system is an electrochemical reaction, a process that occurs within the fuel cell stack. When hydrogen gas is supplied to the fuel cell, it undergoes a series of chemical reactions, primarily with oxygen from the air, to produce electricity. This electricity is then used to power the vehicle's electric motor, offering a clean and sustainable driving experience.

The electrochemical reaction in a fuel cell is a complex process that involves several steps. Firstly, the hydrogen gas is fed into the fuel cell, where it is split into its constituent protons and electrons through a process known as electrolysis. This separation occurs at the anode, one of the two electrodes in the fuel cell. The protons remain within the fuel cell, while the electrons are directed through an external circuit, creating an electric current. This current is the power source for the vehicle.

Simultaneously, at the cathode, oxygen from the air is combined with the protons that have remained in the fuel cell, along with the electrons that have traveled through the external circuit. This reaction forms water as a byproduct, which is released as steam. The key to the efficiency of this process is the direct conversion of chemical energy into electrical energy, bypassing the traditional combustion process.

The fuel cell stack is designed to maximize the surface area of the electrodes, allowing for a higher number of reactions to occur simultaneously. This stack is typically composed of multiple fuel cells, each containing a catalyst layer that facilitates the electrochemical reaction. The catalyst, often made of precious metals like platinum, accelerates the reaction rate, ensuring a rapid and efficient power generation process.

In summary, the power generation in Honda's hydrogen fuel cell car is a sophisticated electrochemical process. It harnesses the energy from hydrogen and oxygen, converting it directly into electricity through a series of reactions. This innovative approach to power generation offers a clean, efficient, and sustainable solution for powering vehicles, contributing to a greener future.

Flex Fuel Cars: Can They Run on 87 Octane Gasoline?

You may want to see also

Storage and Delivery: High-pressure tanks store hydrogen, and fuel cells regulate its flow

The storage and delivery of hydrogen in a fuel cell vehicle like Honda's FCX Clarity is a critical aspect of its operation, ensuring a steady supply of this energy source to power the vehicle's fuel cells. Hydrogen is stored in high-pressure tanks, typically made of lightweight, durable materials such as carbon fiber composites or aluminum alloys. These tanks are designed to withstand the extreme pressure required to store hydrogen safely and efficiently. The pressure inside these tanks can range from 350 to 700 bars (5,000 to 10,000 psi), which is significantly higher than the atmospheric pressure we experience at sea level. This high-pressure storage is necessary because hydrogen has a very low density, making it challenging to store in large quantities without applying significant force.

The high-pressure tanks are strategically placed in the vehicle's body, often in the front or rear, to ensure optimal weight distribution and maintain the car's balance. This placement is crucial for handling and driving dynamics. When the vehicle is in operation, the hydrogen is carefully regulated and delivered to the fuel cells through a network of pipelines and valves. The fuel cell system acts as a sophisticated regulator, controlling the flow of hydrogen and ensuring a precise and consistent supply. This regulation is vital to maintain the efficiency and performance of the fuel cells, as an inconsistent hydrogen supply can lead to reduced power output and potential damage to the fuel cell stack.

The fuel cell system's role in regulating hydrogen flow is twofold. Firstly, it monitors the pressure and temperature of the hydrogen to ensure it remains within safe operating limits. This is essential for the safety and longevity of the vehicle's hydrogen storage system. Secondly, the system controls the flow rate of hydrogen, adjusting it based on the vehicle's power demand and the state of charge of the fuel cell stack. This dynamic control allows the vehicle to provide a steady power output, ensuring a smooth and efficient driving experience.

In addition to the high-pressure tanks and fuel cell system, Honda's FCX Clarity also employs a sophisticated cooling and heating system to manage the temperature of the hydrogen and the fuel cell stack. This system is crucial for maintaining optimal performance and ensuring the safety of the vehicle's hydrogen storage and delivery process. By carefully managing the temperature, the vehicle can operate efficiently in various environmental conditions, from cold winter mornings to hot summer days.

The storage and delivery of hydrogen in Honda's hydrogen fuel cell car is a complex yet well-engineered process, ensuring a reliable and efficient power source for the vehicle's fuel cells. This technology showcases Honda's commitment to developing sustainable and innovative transportation solutions, offering a glimpse into a future where hydrogen fuel cell vehicles play a significant role in reducing our environmental impact.

Understanding Fuel Service Charges on Rental Cars: A Comprehensive Guide

You may want to see also

Efficiency and Performance: Fuel cells offer high efficiency and zero emissions

The Honda Fuel Cell Electric Vehicle (FCEV) is a groundbreaking innovation in the automotive industry, showcasing the potential of hydrogen fuel cell technology. This car operates on a unique principle, converting the chemical energy of hydrogen into electricity through a process called electrochemical reaction. At the heart of this efficiency lies the fuel cell stack, a series of thin, stacked cells that facilitate the reaction between hydrogen and oxygen, producing electricity, water, and heat.

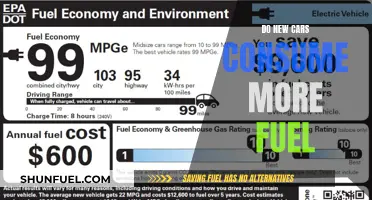

One of the most remarkable aspects of this technology is its efficiency. Fuel cells offer a significantly higher efficiency compared to traditional internal combustion engines. While conventional cars convert only about 20-30% of the energy in gasoline into useful work, fuel cell vehicles can achieve efficiencies of up to 60%, or even higher in certain conditions. This means that a larger portion of the energy stored in hydrogen is utilized to power the vehicle, resulting in reduced energy waste and improved overall performance.

The environmental benefits of this efficiency are substantial. As the name suggests, fuel cell cars produce zero tailpipe emissions, meaning they do not release harmful pollutants like carbon dioxide, nitrogen oxides, or particulate matter into the atmosphere. This is a significant improvement over conventional vehicles, which are major contributors to air pollution and climate change. By utilizing hydrogen as a clean energy source, these cars offer a sustainable and environmentally friendly alternative for transportation.

Furthermore, the performance of fuel cell vehicles is impressive. They provide instant torque, resulting in quick acceleration and a responsive driving experience. The electric motor delivers power directly to the wheels, ensuring smooth and efficient power delivery. This technology also offers a quiet and comfortable ride due to the absence of the typical engine noise associated with traditional cars.

In summary, the Honda Fuel Cell Car's efficiency and performance are key advantages of this technology. The high efficiency of fuel cells translates to reduced energy consumption and lower environmental impact. Additionally, the zero-emission nature of the vehicle contributes to a cleaner and healthier environment. With its advanced technology, this car demonstrates the potential for a more sustainable and efficient future in the automotive sector.

The Dangers of Fueling a Running Car: What You Need to Know

You may want to see also

Infrastructure and Costs: Hydrogen refueling stations and production costs are key considerations

The widespread adoption of hydrogen fuel cell vehicles, such as Honda's offering, relies heavily on the development of a robust infrastructure for hydrogen refueling stations and the management of production costs. Hydrogen refueling stations are the gas stations of the future for fuel cell vehicles, providing the necessary hydrogen gas to power the vehicle's fuel cell. These stations are typically high-pressure gas dispensers, similar to those used for compressed natural gas (CNG) vehicles, but with specialized equipment to handle the unique properties of hydrogen. The infrastructure required for these stations includes high-pressure gas storage tanks, dispensing nozzles, and safety systems to manage the potential hazards associated with hydrogen, such as its low ignition energy and high compressibility.

Building out this infrastructure is a significant challenge and a critical factor in the success of hydrogen fuel cell vehicles. The distribution and storage of hydrogen gas require specialized knowledge and equipment, and the construction of refueling stations can be costly. The initial investment in infrastructure is substantial, and the return on investment is uncertain, especially in regions with low vehicle adoption. As a result, governments and private investors often play a crucial role in funding the development of hydrogen refueling networks, recognizing the long-term benefits for the environment and energy security.

The cost of hydrogen production is another critical aspect. Hydrogen can be produced through various methods, including steam methane reforming, electrolysis of water, and biomass gasification. Each method has its own set of advantages and disadvantages in terms of cost, environmental impact, and energy efficiency. For instance, steam methane reforming is a mature and widely used process, but it is energy-intensive and results in significant carbon dioxide emissions. Electrolysis, on the other hand, offers a cleaner and more sustainable approach, but it is currently more expensive due to the high cost of electricity and the efficiency of the electrolysis process.

Advancements in technology and economies of scale are expected to drive down the cost of hydrogen production over time. As the demand for hydrogen fuel cell vehicles increases, the production processes can become more efficient, reducing the overall cost. Additionally, the development of renewable energy sources for electrolysis can further decrease the environmental impact and cost of hydrogen production. The key to making hydrogen fuel cell vehicles competitive lies in the continuous improvement of production methods and the establishment of a comprehensive infrastructure network.

In summary, the success of Honda's hydrogen fuel cell car and similar technologies depends on the development of a robust hydrogen refueling infrastructure and the reduction of production costs. While the initial investment in infrastructure may be high, the long-term benefits for the environment and energy security make it a worthwhile endeavor. As technology advances and production methods become more efficient, the cost of hydrogen fuel cell vehicles is expected to decrease, making them a more viable and sustainable transportation option.

Fuel Pump Failure: When Your Car's Engine Dies

You may want to see also

Frequently asked questions

Honda's fuel cell vehicle utilizes a process called electrochemical reaction to generate electricity. It combines hydrogen gas from a tank with oxygen from the air, producing electricity, water, and heat through a chemical reaction in the fuel cell stack.

Hydrogen fuel cell cars offer several benefits. They produce zero tailpipe emissions, only releasing water vapor and warm air, making them environmentally friendly. Additionally, hydrogen vehicles can refuel quickly, similar to conventional gasoline cars, providing a convenient driving experience.

The fuel cell stack is the heart of the hydrogen fuel cell car's power system. It consists of multiple fuel cells, each containing an anode, cathode, and electrolyte. Hydrogen from the fuel tank is directed to the anode, where it undergoes a reaction with oxygen, producing electrons, water, and heat. These electrons flow through an external circuit, providing the power to run the electric motor, while the water and heat are managed by the vehicle's cooling system.