When it comes to replacing a fuel sender, many car owners wonder about the time it takes to complete this task. The duration of a fuel sender replacement can vary depending on several factors, including the make and model of the vehicle, the accessibility of the old sender, and the mechanic's experience. In this article, we will explore the typical time frame for this repair, providing insights into what factors influence the process and how long you can expect the job to take. Understanding these details can help car owners plan and make informed decisions about their vehicle's maintenance.

| Characteristics | Values |

|---|---|

| Time Duration | 1-2 hours |

| Complexity | Moderate |

| Tools Required | Wrenches, screwdrivers, fuel filter, new sender unit |

| Labor Cost | $50 - $100 |

| Parts Cost | $100 - $300 |

| Total Cost | $150 - $400 |

| DIY vs Professional | DIY-friendly, but professional help is recommended for complex cases |

| Common Issues | Malfunctioning fuel gauge, engine misfires, hard starting |

| Safety Precautions | Drain fuel tank, disconnect battery, wear safety gear |

What You'll Learn

- Fuel Sender Location: Identify the fuel sender's position in the vehicle

- Tools and Equipment: Gather necessary tools for the replacement

- Fuel System Isolation: Disconnect the fuel lines and battery

- Old Sender Removal: Carefully remove the old fuel sender

- New Sender Installation: Securely install the new fuel sender

Fuel Sender Location: Identify the fuel sender's position in the vehicle

The fuel sender, also known as the fuel level sensor, is a crucial component in your vehicle's fuel management system. It is responsible for accurately measuring the amount of fuel in the tank and sending this information to the engine control unit (ECU), which then displays the fuel level on the dashboard. Knowing the location of the fuel sender is essential for any DIY repairs or replacements, ensuring you can access it safely and efficiently.

In most vehicles, the fuel sender is typically located inside the fuel tank. It is designed to float on the surface of the fuel, with a small electrical connection that extends out of the tank. This connection is what allows the sender to communicate with the ECU. The sender's position is strategically placed to ensure it accurately reflects the fuel level, providing the driver with an accurate reading.

Identifying the exact location of the fuel sender can vary depending on the vehicle make and model. For some cars, it might be easily accessible, often found near the front of the tank. In other cases, it could be more challenging to reach, especially in vehicles with complex fuel systems or those with a lower tank placement. In such instances, you might need to lift the vehicle or remove certain panels to gain access.

To locate the fuel sender, start by inspecting the fuel tank. Look for any visible connections or ports that might indicate the sender's position. Sometimes, a small label or marking on the tank wall can provide a clue. If you're unsure, consult your vehicle's service manual, which should have detailed diagrams and instructions specific to your car. Alternatively, a professional mechanic can quickly identify the sender's location and guide you through the replacement process if needed.

Remember, working on your vehicle's fuel system requires caution and a systematic approach. Always ensure the engine is cool and disconnected from the battery before attempting any fuel-related repairs to avoid any hazards. Understanding the fuel sender's location is the first step towards successfully replacing it, ensuring your vehicle's fuel management system operates efficiently.

Replacing a Fuel Pump in a 1990 Mustang: Step-by-Step Guide

You may want to see also

Tools and Equipment: Gather necessary tools for the replacement

When preparing to replace a fuel sender, it's crucial to have the right tools and equipment to ensure a smooth and efficient process. Here's a detailed guide on what you'll need:

Safety Gear: Before you begin, prioritize your safety and that of anyone nearby. Wear safety goggles to protect your eyes from any potential debris or fuel splashes. Gloves are essential to prevent skin contact with fuel, which can be harmful. Consider wearing old clothing that you don't mind getting dirty or stained.

Jack and Jack Stands (if applicable): If your vehicle has a liftable engine bay, you'll need a jack to lift the vehicle. Ensure you have a suitable jack stand to support the vehicle's weight safely. This is crucial for accessing the fuel tank and sender without any risks.

Wrenches and Pliers: You'll require a set of wrenches, including various sizes of socket wrenches and adjustable wrenches. These are essential for loosening and tightening fuel lines, bolts, and other fasteners. Pliers are also handy for gripping small components and wires.

Fuel Drain Pan: A drain pan is necessary to catch any fuel that may spill during the replacement process. Place it beneath the fuel tank to collect the fuel safely. This step is vital to prevent fuel from contaminating the surrounding area.

New Fuel Sender and Gaskets: Ensure you have the correct replacement fuel sender for your vehicle model. Along with the sender, obtain the appropriate gaskets or seals to create a tight and leak-free connection.

Wiring Harness and Connectors: If your fuel sender requires wiring changes or updates, have the necessary wiring harness and connectors ready. This might include fuses, relays, and any additional components needed for the electrical connection.

Cleaning Supplies: Keep some rags or paper towels handy for cleaning up any spills or debris. Additionally, have a small brush for removing any dirt or contaminants from the fuel tank and surrounding areas.

Safety Equipment: Consider having a fire extinguisher nearby, especially when working with fuel. This is a standard safety precaution to address any potential fuel-related emergencies.

Having these tools and equipment ready will make the fuel sender replacement process more manageable and efficient, ensuring you can complete the task without unnecessary delays.

Replacing the Flex Fuel Sensor in Your 2004 Chevy Suburban

You may want to see also

Fuel System Isolation: Disconnect the fuel lines and battery

When replacing a fuel sender, it's crucial to isolate the fuel system properly to ensure a safe and efficient process. The first step in this process is to disconnect the fuel lines and battery. This step is essential as it prevents any accidental fuel release or electrical shorts that could lead to hazardous situations.

To begin, locate the fuel lines that connect to the fuel tank and the engine. These lines are typically made of rubber or plastic and are often color-coded for easy identification. Carefully detach the fuel lines from the sender unit and the engine's fuel rail or injection system. Take note of the positions of the lines to ensure a smooth reattachment later. It's important to have a clean workspace and wear protective gloves to avoid any potential fuel spills.

Next, disconnect the battery cables from the fuel sender unit. This step requires caution as it involves electrical components. Ensure you have a clear understanding of the battery's polarity to avoid any accidental disconnections. Loosen the battery terminals and carefully remove the cables, labeling them if necessary for future reference.

Once the fuel lines and battery connections are disconnected, it's a good practice to place drain plugs or rags in the fuel lines to catch any residual fuel. This step is crucial to prevent fuel from spilling onto the ground, which can be environmentally harmful and potentially dangerous. Additionally, cover the fuel sender unit with a plastic bag or cloth to protect it from dust and debris during the replacement process.

By following these steps, you effectively isolate the fuel system, ensuring a safe and controlled environment for the fuel sender replacement. This isolation process is a critical aspect of automotive repairs, allowing technicians to work on specific components without the risk of fuel-related hazards.

Dodge Neon Fuel Filter Swap: A Step-by-Step Guide

You may want to see also

Old Sender Removal: Carefully remove the old fuel sender

When replacing a fuel sender, the first step is to carefully remove the old one. This process requires precision and attention to detail to avoid any damage to the fuel tank or surrounding components. Here's a step-by-step guide to safely and effectively remove the old fuel sender:

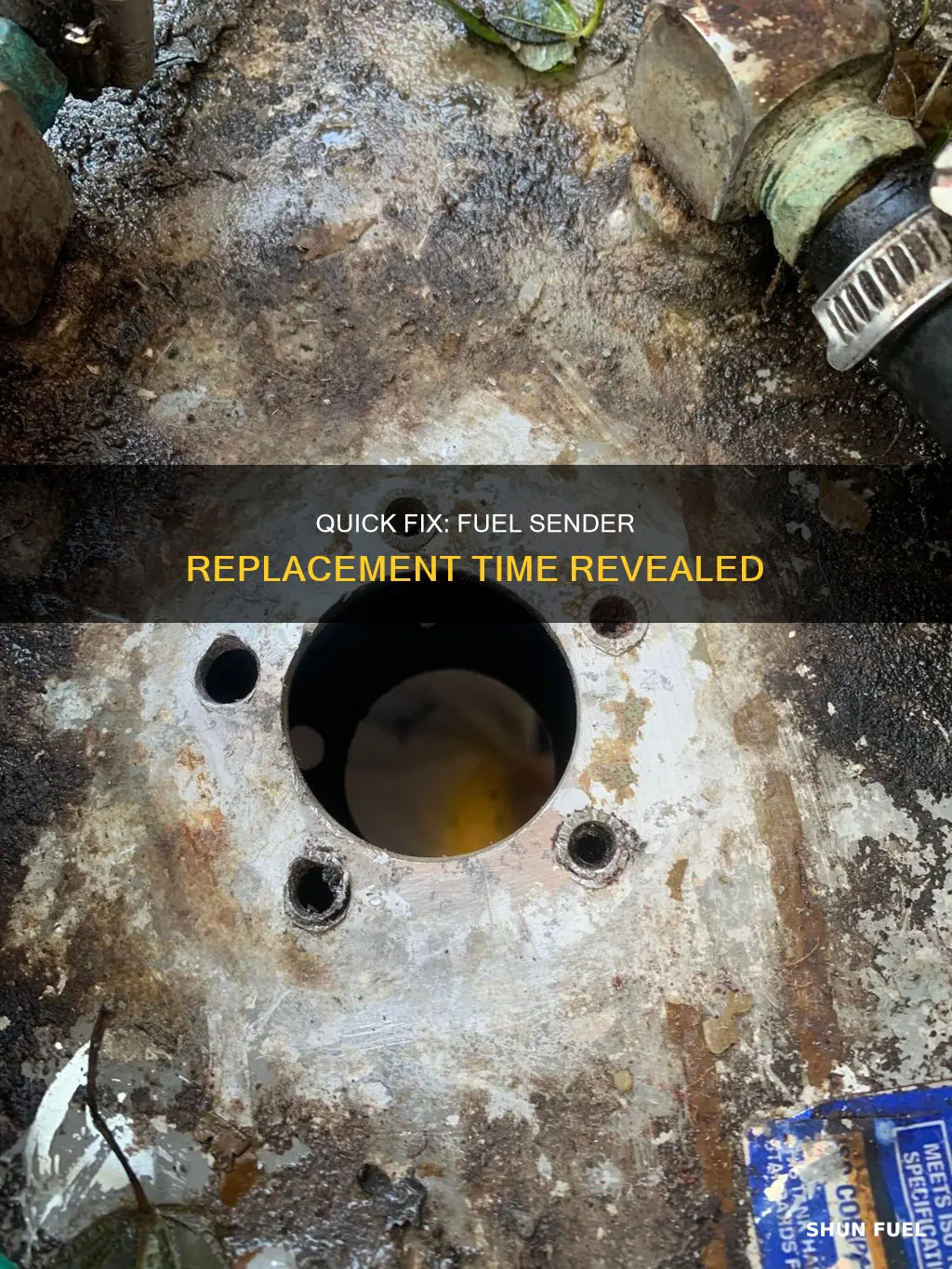

Locate the Fuel Sender: Start by identifying the fuel sender unit. It is typically located near the front of the fuel tank, often accessible through the tank's opening. Use a fuel tank diagram or consult your vehicle's manual to locate the exact position.

Prepare the Vehicle: Ensure the vehicle is parked on a level surface and the engine is off. Release the parking brake and engage the parking gear or use wheel chocks to prevent any movement. This step is crucial for safety and to provide easy access to the fuel sender.

Drain the Fuel: Before removing the sender, it is essential to drain the fuel from the tank. Locate the fuel drain valve, usually found at the bottom of the tank. Open the valve and allow the fuel to drain into an appropriate container or a fuel pump primer bulb. This step ensures that you don't spill fuel and helps prevent any contamination during the replacement process.

Remove the Old Sender: With the fuel drained, you can now proceed with removing the old sender. Start by disconnecting any electrical connections attached to the sender. Carefully unscrew or unclip the sender from its mounting position. Take note of any specific tools or techniques required for removal, as some senders may have unique retention mechanisms. Gently pull the sender straight up and out of the tank to avoid damaging the fuel lines.

Clean and Inspect: Once the old sender is removed, clean the fuel tank opening and any debris or residue around the sender's mounting area. Inspect the old sender for any signs of damage, wear, or contamination. This step is crucial for identifying potential issues and ensuring the new sender will function correctly. Proper cleaning and inspection will also help prevent any future problems.

Replacing Fuel Pump in 2001 Chevy Suburban: Step-by-Step Guide

You may want to see also

New Sender Installation: Securely install the new fuel sender

When replacing a fuel sender, the installation process requires careful attention to detail to ensure a secure and functional setup. Here's a step-by-step guide to help you through the installation of the new fuel sender:

- Prepare the Necessary Tools and Materials: Before you begin, gather all the required tools and components. This includes the new fuel sender unit, appropriate wrenches or tools for tightening connections, and possibly a fuel filter if it needs replacement as well. Ensure you have a clean workspace with good lighting to facilitate the installation.

- Locate the Old Fuel Sender: Start by identifying the location of the old fuel sender. It is typically mounted inside the fuel tank, often near the bottom. Carefully inspect the old sender to understand its orientation and any unique features, such as a float or a magnetic sensor. This knowledge will be crucial for proper installation.

- Remove the Old Fuel Sender: Drain the fuel tank if necessary to prevent spills during the process. Use the appropriate tools to carefully detach the old sender from its mounting. Take note of any wiring connections and secure them temporarily to avoid losing them. Be gentle to avoid damaging the fuel tank's interior.

- Install the New Fuel Sender: Position the new fuel sender in the same location as the old one. Ensure it is aligned correctly and securely mounted. Use the provided fasteners or screws to attach the sender firmly. Double-check that all connections are tight and secure. If your vehicle has a float-style sender, ensure the float ball is properly seated and functioning.

- Wiring and Testing: Connect the wiring harness to the new fuel sender, matching the color-coded wires to their respective terminals. Double-check the connections to ensure they are secure. After wiring, start the vehicle and check for any error codes related to the fuel system. If everything is functioning correctly, you should see the fuel gauge reading accurately.

Remember, each vehicle model may have slight variations in the installation process, so always refer to your vehicle's manual for specific instructions. Taking your time during the installation ensures a reliable and safe fuel system.

Replacing Strimmer Fuel Lines: A Step-by-Step Guide

You may want to see also

Frequently asked questions

The time required for a fuel sender replacement can vary depending on several factors, including the make and model of your vehicle, your mechanical expertise, and the availability of tools and replacement parts. On average, it can take anywhere from 1 to 3 hours for a professional mechanic to complete this task. If you're a DIY enthusiast, it might take you a bit longer, especially if you're not familiar with the process or lack the necessary tools.

Replacing a fuel sender is a task that can be tackled by experienced DIY enthusiasts, but it's not always recommended for beginners. It requires a certain level of mechanical knowledge and skill to ensure proper installation. If you're confident in your abilities and have access to the right tools, you can certainly attempt it yourself. However, if you're unsure or prefer a guaranteed result, hiring a professional mechanic is a safer option. They have the expertise and experience to handle the job efficiently and minimize the risk of any potential issues.

Before starting the replacement process, it's crucial to take a few precautions. First, ensure that you have the correct replacement parts, including the fuel sender assembly, which might vary depending on your vehicle's make and model. Additionally, drain the fuel tank and disconnect the fuel lines to prevent any spills or accidents. It's also a good idea to wear protective gear, such as gloves and safety goggles, to safeguard yourself from potential fuel splashes. Finally, make sure to follow the manufacturer's instructions or a trusted online guide to ensure a successful replacement.