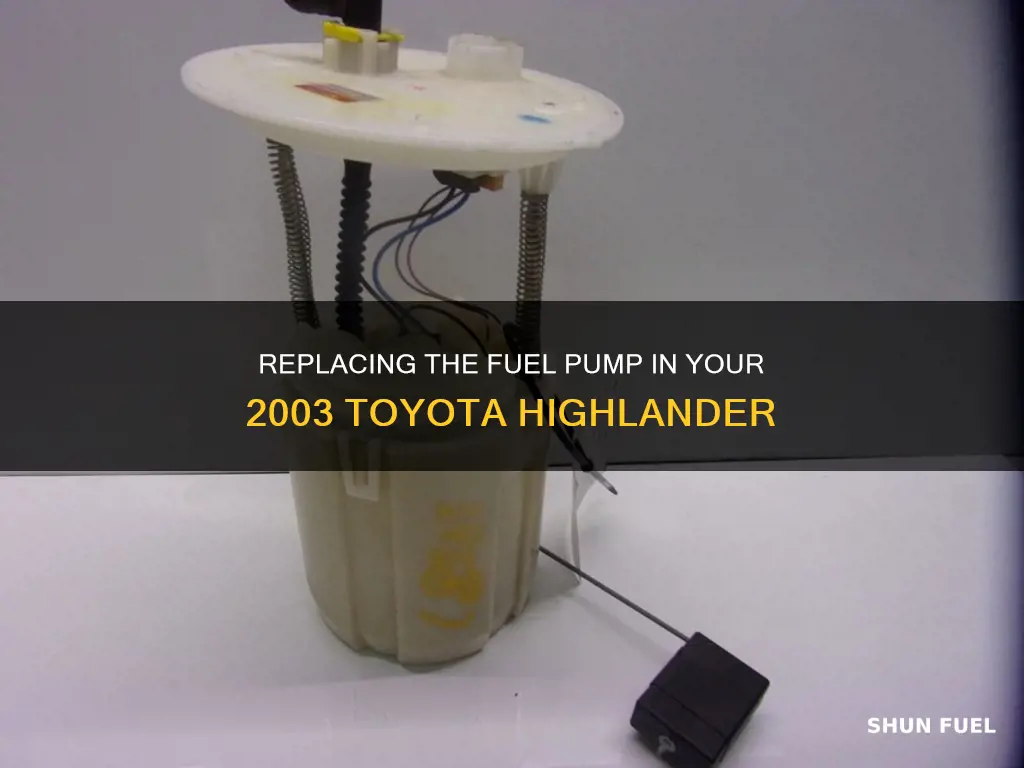

The fuel pump in a 2003 Toyota Highlander is located inside the fuel tank and delivers fuel to the engine. It is powered by a small electric motor and is designed to last the lifetime of the vehicle. However, in some cases, the fuel pump may fail and need to be replaced. Signs of a failing fuel pump include the engine stalling, a whirring sound coming from the fuel tank, and the check engine light coming on. If you suspect your fuel pump needs to be replaced, it is best to take your vehicle to a qualified mechanic or dealership service department as it is a moderately complicated job that requires expertise in auto repair. The cost of replacing a fuel pump in a 2003 Toyota Highlander can vary depending on location, but it typically includes parts and labor.

| Characteristics | Values |

|---|---|

| Vehicle | 2003 Toyota Highlander |

| Fuel pump location | Inside the fuel tank |

| Fuel pump function | Delivering pressurised gasoline to the fuel injectors |

| Fuel pump replacement cost | $1,319 to $1,416 on average |

| Labour cost | $191 to $241 on average |

| Parts cost | $1,128 to $1,175 on average |

| Shop/Dealer Price | $1414.19 to $2013.86 |

| Warning signs of a bad fuel pump | Engine struggles to maintain speed, noises, backfires, sputtering engine, hesitation at start or take-off, overheating, check engine light |

What You'll Learn

Disconnect the battery

Disconnecting the battery is the first step in replacing the fuel pump of a 2003 Toyota Highlander. This is a crucial safety precaution to reduce the chance of a fire when working on the fuel pump.

Before beginning any work on the fuel pump, locate the battery and identify the negative and positive terminals. The battery is usually located in the engine bay, but it can also be found in the trunk or under the rear seat in some vehicles. The positive terminal will have a "+" sign, and the negative terminal will have a "-" sign.

Once you have located the battery and identified the terminals, you can proceed to disconnect it. Start by loosening the negative terminal, which is usually indicated by a black cable. Use a wrench or socket to loosen the nut that secures the cable to the terminal. Be careful not to let the wrench or socket touch any other metal parts of the car, as this could cause a short circuit. Once the nut is loose, carefully remove the cable from the terminal.

After the negative terminal is disconnected, move on to the positive terminal. Again, use a wrench or socket to loosen the nut securing the cable to the terminal. Remove the cable from the terminal. With both cables disconnected, the battery is now safely disconnected.

It is important to note that disconnecting the battery will cause the car's computer to reset, and you may need to reprogram certain settings, such as the clock or radio stations. Additionally, make sure to exercise extreme caution when working around the battery, as it contains sulfuric acid, which can cause severe burns if it comes into contact with your skin or eyes. Always wear protective gear, including gloves and eye protection, when handling the battery.

Replacing Fuel Shutoff Inline: Step-by-Step Guide for Beginners

You may want to see also

Remove the access cover

To remove the access cover of your 2003 Toyota Highlander, start by disconnecting the battery to reduce the chance of a fire. This is an important safety precaution when working on any aspect of the fuel system.

Next, locate the access cover. This will be found above the fuel tank, in the passenger compartment. With the cover located, you can begin to remove it. In some cases, you will need to drain the fuel before removing the access panel. This is because the fuel pump is located inside the fuel tank.

Once the access cover is off, you will be able to access the fuel pump and pre-pump filter screen. You can then begin to remove the fuel pump and replace it with a new one.

Replacing Fuel Primer Bulb: A Step-by-Step Guide

You may want to see also

Replace the pump and pre-pump filter screen

To replace the fuel pump and pre-pump filter screen in a 2003 Toyota Highlander, you will first need to disconnect the battery to reduce the chance of a fire. The next steps depend on whether the pump is located inside or outside the fuel tank.

If the pump is inside the fuel tank, you will need to remove an access cover to reach the pump. In some cases, you will need to drain the fuel before removing the access panel. Once you have access to the pump, you can replace it along with the pre-pump filter screen.

If the pump is outside the tank, you will need to disconnect the fuel lines and EVAP system hoses, as well as the electrical connections to the pump. You can then remove the pump and install the new one, along with a new pre-pump filter screen.

In both cases, it is recommended to replace the fuel filters at the same time as the fuel pump. This includes the intake screen for in-tank fuel pumps. It is also a good practice to replace the fuel pump relay if your vehicle has one, as these are known to fail.

After replacing the pump and filter screen, you will need to add fuel to the tank and run the engine to test for leaks. Make sure to take all necessary precautions when working with the fuel system to prevent fires.

Replacing the Fuel Pump in Your Volvo 740: Step-by-Step Guide

You may want to see also

Re-establish fuel pump supply and return hoses

To re-establish the fuel pump supply and return hoses, you will need to follow these steps:

Firstly, locate the fuel pump supply and return hoses. These are usually found near the fuel pump, which is typically located inside the fuel tank. Once you have identified the hoses, you can begin the process of re-establishing the connections.

Next, you will need to disconnect the hoses from the fuel pump. This may involve simply pulling the hoses off, or there may be clamps or other fasteners that need to be removed first. Be sure to do this carefully, as the hoses may be fragile or brittle, especially if the car is older.

Now, take your new or replacement fuel pump and line up the hoses correctly. Ensure that the connections are secure and tight to prevent any leaks. If there are clamps or fasteners, be sure to reinstall them correctly.

Once the hoses are reattached, you will need to refill the fuel tank. This is important because running a fuel pump dry can cause damage. After refilling, start the engine and check for any signs of leaks around the fuel pump and hoses. If no leaks are detected, your fuel pump supply and return hoses have been successfully re-established.

Finally, it is important to note that working with the fuel system can be dangerous, and precautions should be taken to avoid the risk of fire. It is recommended that you allow a qualified repair shop or mechanic to handle this type of job, especially if you are not experienced in auto repair.

Replacing the Fuel Pump in Your Jeep Liberty: Step-by-Step Guide

You may want to see also

Test for leaks

Testing for leaks in your fuel pump system is a crucial step in ensuring the proper functioning of your engine. Here is a detailed guide on how to test for leaks in your 2003 Toyota Highlander's fuel pump:

Initial Troubleshooting

Before performing any tests, it is advisable to conduct a visual inspection of the fuel pump system for any obvious signs of leaks. Check the fuel lines, connections, and components for any damage or loose clamps. Ensure the rubber seal on the gas cap is tight and secure. This initial inspection can help identify any potential issues that may be causing leaks.

Check Engine Light

If the "Check Engine" light illuminates on your dashboard, it could indicate a problem with the fuel pump system. Use a code reader to identify any specific error codes related to leaks, such as error PO442, which indicates a small leak in the fuel vapor emissions system (EVAP system). Clearing the code and driving until the readiness monitors reset can help confirm if the issue persists.

Smoke Test

If visual inspection and code reading do not reveal the source of the leak, a smoke test can be performed. This involves pumping smoke into the EVAP system at 1-2 PSI to make leak detection easier. You can use a smoke machine designed for this purpose or create a makeshift setup using a fog machine or a sealed metal canister with a glow plug and regulated compressed air. Injecting smoke into the system will help identify the location of any leaks.

Pressure Gauge Test

Another method to test for leaks is by using a pressure gauge. Connect the pressure gauge to the fuel supply line leading to the high-pressure pump. Loosen the hose connection on the low-pressure nozzle and clamp the pressure gauge in between. Run the engine in idle mode and refer to the manufacturer's specifications for the correct fuel pressure range. If the pressure drops below the specified range, it could indicate a leak in the system.

Holding Pressure Test

For this test, connect the pressure gauge as described in the previous step. Start the engine and let it run until the operating pressure is reached. Then, switch off the engine and close the hose pipes to the high-pressure pump using clamping tongs or a shut-off valve. After about 10 minutes, the pressure should still be approximately 3.0 bar. A significant drop in pressure may suggest a leak in the system.

Checking Fuel Quantity

Loosen and close the fuel supply line on the high-pressure pump, then place it in a measuring cup. Disconnect the electrical connection to the pre-feed pump and set up a separate power supply to the vehicle battery. Turn on the pump until pressure is built up, then open the clamp and start measuring. After 30 seconds, the target volume should be approximately 600 ml. If the target volume is not reached, check for kinks or blockages in the fuel lines, a clogged fuel filter, or issues with the tank ventilation or fuel delivery unit.

Testing the High-Pressure System

The high-pressure system should be tested separately. The target value for the fuel system high pressure is typically 40-120 bar, depending on the operating status. However, it is important to note that there is no manual pressure test with a pressure gauge for this system. Refer to the vehicle's specific guidelines for testing the high-pressure system.

Always refer to safety guidelines and instructions provided by the manufacturer when working on your fuel pump system. Wear protective gear, including safety goggles and gloves, to avoid any injuries from leaking fuel.

A Guide to Replacing Your Car's Fuel Injection System

You may want to see also

Frequently asked questions

Signs of a bad fuel pump include a car that won't start, a car that stalls after starting, a slowly starving fuel flow causing the check engine light to come on, or a whirring sound coming from your fuel tank.

The fuel pump is located inside the fuel tank. A mechanic will need to get to the failed pump through the top of the fuel tank via an access panel in the passenger compartment or by removing the tank from the vehicle.

The cost for a Toyota Highlander fuel pump replacement varies depending on your location. The cost of parts and labor combined can be anywhere between $465 and $2,746.81.