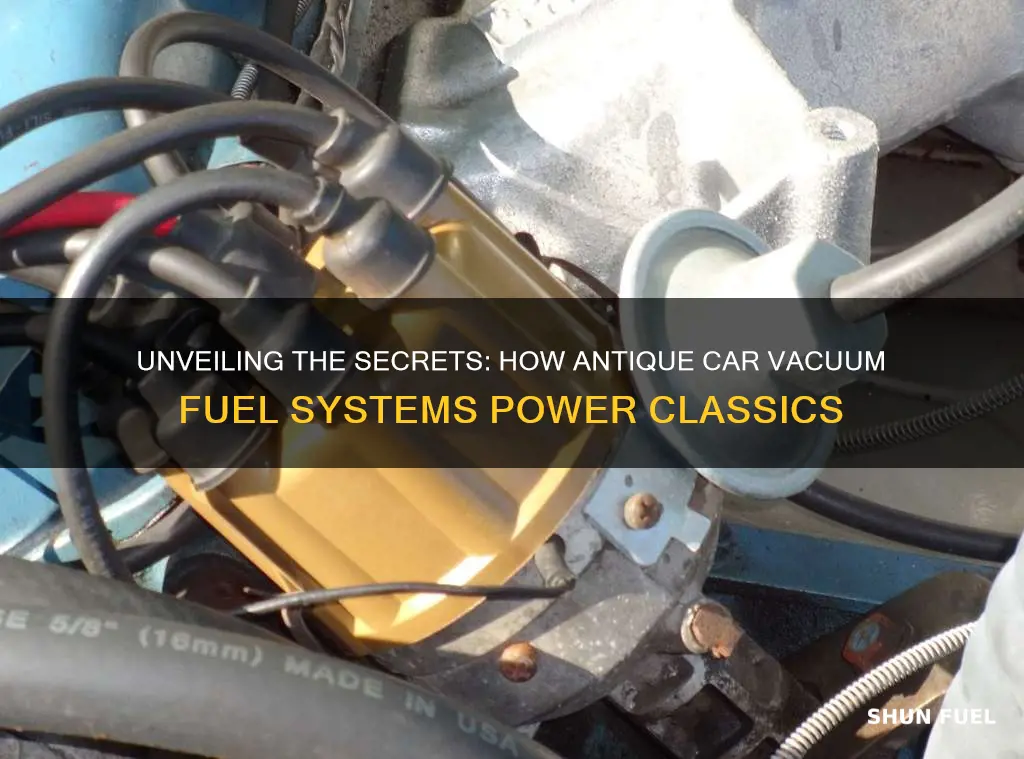

The antique car vacuum fuel system is a fascinating and intricate component of classic automobiles, offering a unique approach to fuel delivery. This system utilizes a vacuum pump to draw fuel from a reservoir, creating a low-pressure environment that allows the fuel to flow into the engine. The process involves a series of intricate parts, including a carburetor, which mixes air and fuel, and an intake manifold that directs the fuel-air mixture to the engine cylinders. Understanding the mechanics of this system is essential for enthusiasts and restorers of vintage vehicles, as it highlights the ingenuity of early automotive engineering and provides valuable insights into the evolution of fuel systems over time.

| Characteristics | Values |

|---|---|

| Fuel Type | Gasoline |

| Engine Type | Carburetor-equipped |

| Fuel Delivery | Carburetor-based system |

| Fuel Pump | Manual or foot-operated |

| Fuel Tank | Often located in the rear of the vehicle |

| Fuel Filter | Present but may be simpler than modern systems |

| Vacuum Source | Engine's intake manifold vacuum |

| Vacuum Control | Throttle body or carburetor's throttle plate |

| Vacuum Leaks | Can cause fuel starvation or engine misfires |

| Maintenance | Regular cleaning and inspection of the carburetor and fuel system components |

| Advantages | Simplicity, reliability for the era |

| Disadvantages | Less efficient fuel usage, potential for vapor lock |

What You'll Learn

- Engine Operation: The vacuum system draws fuel from the tank, creating a partial vacuum to draw fuel into the carburetor

- Fuel Delivery: A diaphragm or piston pump converts atmospheric pressure into a vacuum, drawing fuel into the system

- Carburetor Function: The carburetor mixes air and fuel, controlling the air-fuel ratio for efficient combustion

- Vacuum Control: A throttle valve regulates the vacuum, adjusting fuel flow based on engine speed and load

- Fuel Injection: Some antique cars use a vacuum-assisted fuel injection system for precise fuel delivery and improved performance

Engine Operation: The vacuum system draws fuel from the tank, creating a partial vacuum to draw fuel into the carburetor

The vacuum-assisted fuel system in antique cars is a fascinating and efficient mechanism that ensures a steady supply of fuel to the engine. When the engine is running, the vacuum system plays a crucial role in drawing fuel from the tank and delivering it to the carburetor. This process is a simple yet effective way to maintain the engine's performance and fuel efficiency.

As the engine operates, it creates a partial vacuum in the intake manifold due to the difference in air pressure between the inside and outside of the manifold. This vacuum is a result of the engine's compression and exhaust processes. The vacuum system harnesses this natural phenomenon to draw fuel from the tank. A small pump or a diaphragm-based mechanism is often used to create this vacuum, ensuring a consistent and controlled flow of fuel.

When the driver presses the accelerator pedal, the throttle opens, allowing air to enter the carburetor. The vacuum system then takes over, creating a partial vacuum that pulls fuel from the tank. This fuel is drawn into the carburetor, where it mixes with air and is atomized by the carburetor jet. The mixture is then directed into the engine's cylinders, where it is ignited by the spark plug, creating the power that drives the vehicle.

The key to this system's success is the precise control of the vacuum. The vacuum system must be calibrated to match the engine's requirements, ensuring that the correct amount of fuel is delivered at the right time. This calibration is crucial for maintaining optimal engine performance and fuel economy. Antique car enthusiasts often spend considerable time adjusting and fine-tuning the vacuum system to achieve the best results.

In summary, the vacuum system in antique cars is a clever and effective way to deliver fuel to the engine. By creating a partial vacuum, it draws fuel from the tank and ensures a steady supply to the carburetor, where it is mixed with air and ignited to power the vehicle. This simple yet ingenious mechanism showcases the ingenuity of early automotive engineering and continues to be a fascinating aspect of antique car restoration and operation.

Octane Fuel's Clean Car Magic: Unlocking Engine Power and Protection

You may want to see also

Fuel Delivery: A diaphragm or piston pump converts atmospheric pressure into a vacuum, drawing fuel into the system

The vacuum fuel system, a fascinating and intricate component of antique automobiles, relies on a clever mechanism to deliver fuel efficiently. At the heart of this system is a diaphragm or piston pump, a crucial element in the fuel delivery process. This pump plays a vital role in converting atmospheric pressure into a vacuum, which is essential for drawing fuel into the system.

When the engine is started, the pump begins its operation. It utilizes the force of atmospheric pressure to create a vacuum within the fuel tank. This vacuum is a powerful force that pulls fuel from the tank, ensuring a steady supply of gasoline or diesel to the engine. The pump's design is such that it can generate a strong suction, allowing it to draw fuel even from a significant distance or height.

The diaphragm or piston pump operates on a simple yet effective principle. As the engine runs, the pump's diaphragm or piston moves in a reciprocating motion. This movement creates a pressure difference, with the outside atmospheric pressure acting on one side and the vacuum on the other. The pump's design ensures that the vacuum side is always under lower pressure, facilitating the flow of fuel.

As the pump draws fuel into the system, it is essential to maintain a consistent vacuum. This is achieved through the use of a vacuum regulator, which monitors and adjusts the pressure to ensure optimal fuel delivery. The regulator helps prevent fuel starvation and ensures a steady supply, even during rapid acceleration or deceleration.

In summary, the diaphragm or piston pump is a critical component in the antique car's vacuum fuel system. Its ability to convert atmospheric pressure into a vacuum enables the efficient delivery of fuel to the engine. This innovative system, with its reliance on pressure differentials, showcases the ingenuity of automotive engineering from past eras.

Government's Role in Boosting Car Fuel Efficiency: Strategies and Solutions

You may want to see also

Carburetor Function: The carburetor mixes air and fuel, controlling the air-fuel ratio for efficient combustion

The carburetor is a crucial component in the fuel system of antique cars, especially those with vacuum-based fuel injection. Its primary function is to precisely mix air and fuel, ensuring an optimal air-fuel ratio for efficient combustion within the engine's cylinders. This process is fundamental to achieving the power and performance that antique car enthusiasts strive for.

Inside the carburetor, a complex process takes place. It starts with the fuel, typically gasoline, being drawn from the fuel tank through a series of small passages and orifices. The vacuum created by the engine's operation pulls the fuel, ensuring a steady supply. As the fuel enters the carburetor, it encounters a carefully designed series of passages and chambers. These passages are engineered to atomize the fuel, breaking it down into tiny droplets. This atomization is crucial because it allows the fuel to mix thoroughly with the incoming air.

The air-fuel mixture is then directed towards the carburetor's throat, where it encounters a throttle plate. This plate is a critical component as it controls the amount of air entering the engine. By adjusting the throttle, the driver can regulate the air-fuel ratio, which directly impacts the engine's performance. The carburetor's design ensures that the fuel is injected at the precise point where it mixes with the air, creating a homogeneous mixture. This mixture is then directed into the engine's intake manifold, where it is ready for combustion.

One of the key advantages of a carburetor is its ability to adjust the air-fuel ratio on the fly. This is achieved through a series of linkages and valves that respond to the engine's load and speed. For instance, when the engine is idling, the carburetor enriches the mixture to ensure smooth operation. As the engine speeds up, it leans out the mixture to promote more efficient combustion. This dynamic adjustment is essential for maintaining optimal performance across various driving conditions.

In summary, the carburetor's role in antique car fuel systems is to meticulously mix air and fuel, creating a precise air-fuel ratio. This process is vital for efficient combustion, power generation, and overall engine performance. Understanding the carburetor's function provides a deeper appreciation for the intricate mechanisms that power these classic vehicles.

Car Heater's Impact: Fuel Efficiency and Winter Driving

You may want to see also

Vacuum Control: A throttle valve regulates the vacuum, adjusting fuel flow based on engine speed and load

The vacuum-controlled fuel system in antique cars is a fascinating and intricate mechanism that ensures optimal fuel delivery to the engine. At the heart of this system is a throttle valve, a critical component that plays a pivotal role in regulating the vacuum and adjusting the fuel flow according to the engine's speed and load. This valve is designed to respond dynamically to the engine's demands, ensuring efficient performance and smooth operation.

When the engine is at rest or operating at low speed, the throttle valve is positioned to allow minimal vacuum into the system. This restricted vacuum creates a low-pressure environment, which is essential for the carburetor to draw in a precise amount of air-fuel mixture. As the engine speed increases, the throttle valve opens wider, allowing more vacuum to enter the system. This increase in vacuum is a direct response to the rising engine speed, ensuring that the fuel flow is adjusted accordingly. The throttle valve's movement is precisely calibrated to match the engine's requirements, providing the right amount of fuel for efficient combustion.

The beauty of this vacuum control system lies in its ability to adapt to varying engine loads. When the engine encounters a heavy load, such as during acceleration or climbing a steep hill, the throttle valve responds by opening further. This action increases the vacuum, which in turn allows for a higher fuel flow rate. By adjusting the fuel supply based on the engine's load, the system ensures that the engine receives the necessary power to overcome the additional resistance. This dynamic adjustment is crucial for maintaining optimal performance and preventing issues like stalling or inadequate power delivery.

In the context of antique cars, where technology and engineering were often more basic, the vacuum-controlled fuel system showcases the ingenuity of early automotive design. This system required careful calibration and understanding of engine dynamics to function effectively. Modern vehicles have since evolved to use electronic fuel injection, but the principles behind the vacuum-controlled system remain relevant, demonstrating the evolution of automotive technology over time.

Understanding the operation of the vacuum-controlled fuel system is essential for anyone working on or restoring antique cars. By recognizing the role of the throttle valve and its response to engine speed and load, enthusiasts can ensure the proper functioning of these classic vehicles. This knowledge allows for accurate adjustments and maintenance, preserving the performance and character of these timeless machines.

Maximizing Fuel Efficiency: GM Car Fuel Pump Tips

You may want to see also

Fuel Injection: Some antique cars use a vacuum-assisted fuel injection system for precise fuel delivery and improved performance

The vacuum-assisted fuel injection system is an innovative feature found in some antique cars, offering a unique approach to fuel delivery and performance enhancement. This system utilizes the power of vacuum to precisely manage the fuel flow, ensuring optimal combustion and improved engine efficiency. By harnessing the vacuum created by the engine's operation, this technology provides a reliable and efficient fuel injection process.

In these antique vehicles, the vacuum-assisted fuel injection system operates by drawing fuel from a reservoir and passing it through a series of filters and valves. The vacuum created by the engine's intake process creates a low-pressure environment, which draws the fuel into the system. This process ensures a consistent and controlled fuel supply, allowing for precise metering and timing. The system's design often includes a fuel pump that maintains a steady pressure, ensuring the fuel is delivered at the right amount and rate to the engine's intake manifold.

One of the key advantages of this vacuum-assisted system is its ability to provide accurate fuel injection, which is crucial for antique car enthusiasts who aim to restore and enhance the performance of their classic vehicles. By utilizing the engine's vacuum, the system can precisely control the fuel-air mixture, resulting in improved power output and better overall engine performance. This level of control is essential for maintaining the delicate balance required in antique engines, where even small adjustments can significantly impact the vehicle's operation.

The design and implementation of this fuel injection system require careful consideration of the engine's specifications and the vehicle's overall mechanics. Antique car enthusiasts and restorers must ensure that the system is compatible with the engine's design and that all components are properly sized and positioned. This attention to detail is vital to guarantee the system's effectiveness and the overall success of the restoration project.

In summary, the vacuum-assisted fuel injection system in antique cars is a fascinating example of how technology can be adapted to enhance performance and precision in classic vehicles. By leveraging the engine's vacuum, this system provides a reliable and efficient fuel delivery method, contributing to improved engine operation and overall driving experience for antique car enthusiasts.

Safe Driving: Can You Add Fuel While Your Car Is Running?

You may want to see also

Frequently asked questions

The vacuum fuel system, often referred to as a "carburetor," is a mechanical device that mixes air and fuel in precise proportions and delivers it to the engine's cylinders. In an antique car, this system typically consists of a carburetor, a throttle body, and a series of tubes and passages. When the driver presses the accelerator pedal, it opens the throttle, allowing a controlled amount of air to enter the engine. The carburetor then injects a measured amount of fuel, often a gasoline-air mixture, into the engine's intake manifold. This process creates a controlled explosion in the engine, providing power to the vehicle.

The main components include the carburetor, which is the heart of the system, and the throttle body, which regulates the air flow. The carburetor has a series of jets, a float chamber, and a venturi tube. The jets spray fuel into the air stream, and the float chamber stores a small amount of fuel. The venturi tube creates a low-pressure area, drawing fuel into the air stream and creating a precise fuel-air mixture. The throttle body, located between the carburetor and the engine, controls the air flow and ensures the correct mixture is delivered.

The fuel mixture is controlled through a delicate balance of mechanical and physical principles. The carburetor's float chamber regulates the fuel level, ensuring it remains at a specific height. This height is critical as it determines the amount of fuel available for the engine. The jets and venturi tube create a precise fuel-air mixture by adjusting the fuel flow rate and air pressure. The throttle body further refines this mixture by controlling the air-fuel ratio based on engine speed and load. This intricate process ensures optimal engine performance and fuel efficiency in these classic vehicles.