The government plays a crucial role in promoting fuel efficiency in the automotive industry, which can have significant environmental and economic benefits. One way to achieve this is by implementing stricter fuel efficiency standards for vehicles. These standards can be set through legislation, requiring car manufacturers to produce models that consume less fuel without compromising performance. Additionally, the government can incentivize the development and adoption of advanced technologies such as hybrid and electric powertrains, which offer higher efficiency compared to traditional internal combustion engines. By encouraging the use of these innovative systems, the government can drive the market towards more fuel-efficient cars, ultimately reducing greenhouse gas emissions and dependence on fossil fuels.

What You'll Learn

- Engine Design: Optimize internal combustion engines for reduced fuel consumption

- Hybrid Technology: Integrate electric motors to enhance efficiency and reduce emissions

- Aerodynamics: Improve car body design to minimize drag and enhance fuel economy

- Lightweight Materials: Use advanced materials to reduce vehicle weight without compromising safety

- Efficient Transmission: Develop transmissions that match engine power to vehicle speed for optimal performance

Engine Design: Optimize internal combustion engines for reduced fuel consumption

The optimization of internal combustion engines is a critical aspect of improving fuel efficiency in vehicles, and it involves several key design considerations. One of the primary goals is to minimize energy losses within the engine, ensuring that more of the fuel's energy is converted into useful work. This can be achieved through advanced engine architectures and innovative component designs.

Engine designers can focus on enhancing the combustion process, which is a major source of fuel inefficiency. One approach is to employ advanced combustion technologies such as direct fuel injection. This method allows for precise control of the fuel-air mixture, ensuring that it is optimally dense for efficient combustion. By improving the mixture's quality, the engine can burn fuel more completely, reducing unburned hydrocarbons and increasing overall efficiency. Additionally, the use of advanced ignition systems, such as spark plugs with improved heat range, can enhance the combustion process, leading to better fuel economy.

Another strategy to optimize engine design is to reduce friction within the engine's moving parts. Friction causes energy losses in the form of heat, which can be significant in internal combustion engines. Designers can achieve this by using advanced materials and coatings for engine components. For instance, implementing low-friction piston skirts and cylinder liners can minimize friction between moving parts, allowing for smoother operation and reduced fuel consumption. Furthermore, optimizing the engine's lubrication system to ensure adequate oil flow and film thickness can further reduce friction losses.

The layout and configuration of the engine also play a crucial role in fuel efficiency. Engineers can design engines with smaller displacement cylinders, as smaller engines generally have lower specific fuel consumption rates. This approach, known as downsizing, can lead to improved power-to-weight ratios while reducing fuel usage. Additionally, incorporating turbocharging or supercharging can provide the necessary boost in power without significantly increasing engine size or fuel consumption. These technologies allow for more efficient use of the available fuel, resulting in better overall efficiency.

In summary, optimizing internal combustion engines for reduced fuel consumption involves a multifaceted approach. By focusing on combustion process enhancements, reducing friction, and implementing innovative engine architectures, significant improvements in fuel efficiency can be achieved. These design considerations contribute to the government's goal of producing more fuel-efficient cars, ultimately benefiting the environment and consumers through reduced fuel costs.

Flex Fuel or Not? Signs to Identify Your Car's Flexibility

You may want to see also

Hybrid Technology: Integrate electric motors to enhance efficiency and reduce emissions

Hybrid technology is a key component in the government's strategy to produce more fuel-efficient cars and reduce emissions. This innovative approach integrates electric motors with traditional internal combustion engines, offering a more efficient and environmentally friendly driving experience. By combining the strengths of both power sources, hybrid vehicles can achieve superior performance while minimizing fuel consumption and harmful emissions.

The core principle of hybrid technology lies in its ability to switch seamlessly between the electric motor and the internal combustion engine. During acceleration or when additional power is required, the electric motor provides an instant boost, ensuring a smooth and responsive drive. This electric-assist feature is particularly beneficial in city driving, where frequent stops and starts are common. By utilizing the electric motor for these short bursts, hybrid vehicles can significantly reduce fuel consumption and emissions compared to conventional cars.

One of the key advantages of hybrid technology is its contribution to improved fuel efficiency. The electric motor, powered by a rechargeable battery, can drive the vehicle at low speeds or during deceleration, eliminating the need for constant engine operation. This results in reduced fuel usage and lower emissions, especially in stop-and-go traffic conditions. Additionally, the regenerative braking system in hybrids captures and stores energy that would otherwise be lost as heat during braking, further enhancing overall efficiency.

Integrating electric motors into vehicle design also allows for the development of smaller, more efficient internal combustion engines. These engines can operate at optimal performance levels, producing more power while consuming less fuel. The hybrid system's ability to manage power distribution between the electric motor and the engine ensures that the vehicle can maintain its performance capabilities while achieving better fuel economy. This dual-power approach is a significant step towards reducing the environmental impact of transportation.

Furthermore, hybrid technology encourages the use of advanced materials and manufacturing processes. The development of lightweight batteries and efficient power electronics contributes to overall vehicle weight reduction and improved performance. Governments can incentivize the adoption of such technologies by providing subsidies or tax benefits to manufacturers, fostering innovation in the automotive industry. In summary, hybrid technology, with its seamless integration of electric motors, plays a vital role in the government's mission to promote fuel-efficient cars and a greener future.

Haddad Toyota Fuel Tank: Sold Cars, Now a Legacy

You may want to see also

Aerodynamics: Improve car body design to minimize drag and enhance fuel economy

Aerodynamics plays a crucial role in enhancing fuel efficiency and reducing drag for vehicles. The government can significantly impact the automotive industry by promoting and implementing aerodynamic improvements in car body design. Here's a detailed breakdown of how this can be achieved:

Streamlining Body Shapes: One of the primary focuses should be on redesigning car body shapes to minimize drag. Current vehicle designs often prioritize aesthetics and style, sometimes at the expense of aerodynamics. The government can encourage manufacturers to adopt more streamlined and sleek designs. This involves creating smooth, curved surfaces that reduce the formation of turbulent eddies and minimize the impact of air resistance. By ensuring that the car's body, including the roof, sides, and rear, follows a continuous, fluid shape, engineers can significantly reduce drag forces acting on the vehicle.

Airflow Management: Effective airflow management is essential to further enhance fuel efficiency. This includes designing front and rear underbody panels to direct air smoothly around the vehicle. The government can provide guidelines and incentives for manufacturers to invest in advanced wind tunnel testing and computational fluid dynamics (CFD) simulations. These tools enable engineers to study airflow patterns and identify areas of high drag. By optimizing the underbody and under-car regions, where air often creates turbulence, the car can cut down on drag-related fuel consumption.

Aerodynamic Components: Specific components can be tailored to improve aerodynamics. For instance, the design of the front grille, headlights, and front bumper can be optimized to reduce drag. These areas often create significant turbulence, especially at higher speeds. By employing techniques like active grille shutters or adaptive front splitters, the government can encourage manufacturers to develop dynamic systems that adjust to driving conditions, further minimizing drag. Additionally, the rear of the vehicle, including the trunk lid and spoiler, should be designed to manage airflow efficiently, reducing lift and drag.

Materials and Manufacturing: The choice of materials and manufacturing processes can also contribute to aerodynamic improvements. Lightweight materials, such as advanced composites and alloys, can reduce the overall weight of the vehicle, which in turn improves fuel efficiency. The government can promote the use of these materials and provide incentives for research and development in this area. Furthermore, manufacturing techniques that allow for precise control over body panel alignment and fit can ensure a more aerodynamic finish, minimizing gaps and creases that create drag.

By implementing these aerodynamic enhancements, the government can drive the automotive industry towards more fuel-efficient vehicles. This not only benefits the environment by reducing emissions but also contributes to economic savings for consumers through improved fuel economy. With the right incentives and regulations, manufacturers can embrace these changes, leading to a more sustainable and efficient transportation sector.

Green Energy: Powering Your Ride with Poop-Powered Fuel

You may want to see also

Lightweight Materials: Use advanced materials to reduce vehicle weight without compromising safety

The automotive industry is undergoing a significant transformation, driven by the urgent need to reduce fuel consumption and environmental impact. One of the most effective strategies to achieve this is by focusing on lightweight materials. These advanced materials offer a unique opportunity to reduce vehicle weight while maintaining, and in some cases, enhancing safety.

Lightweight materials, such as advanced composites, high-strength steel, and aluminum alloys, have gained prominence in modern automotive design. These materials offer a superior strength-to-weight ratio, allowing engineers to create structures that are both robust and lightweight. For instance, carbon fiber-reinforced polymers (CFRP) have been successfully utilized in high-performance sports cars, demonstrating exceptional strength and stiffness while reducing weight significantly. By incorporating these materials into the vehicle's body structure, chassis, and even engine components, manufacturers can achieve a substantial reduction in overall weight.

The benefits of using lightweight materials extend beyond fuel efficiency. Firstly, the reduced weight translates to improved acceleration and handling, providing a more responsive and engaging driving experience. Secondly, the use of advanced materials can enhance safety by increasing the vehicle's structural rigidity. High-strength steel, for example, offers excellent crash resistance without adding excessive weight. This material can be strategically placed in critical areas, such as the front and rear structures, to absorb and redistribute crash forces effectively.

Furthermore, the development of lightweight materials has led to innovative design solutions. For instance, the use of aluminum alloys in engine components can reduce the overall weight of the powertrain, resulting in improved fuel efficiency. Advanced composites can also be employed to create complex shapes and structures, allowing for more efficient packaging of components within the vehicle. This not only reduces weight but also optimizes the use of space, contributing to a more compact and aerodynamic design.

In summary, the adoption of lightweight materials is a crucial step towards achieving government-set fuel efficiency targets. By utilizing advanced materials, the automotive industry can create vehicles that are not only more fuel-efficient but also safer and more responsive. Continued research and development in this field will further drive innovation, ensuring that future generations of cars are both environmentally friendly and technologically advanced.

Smart Cars: Unlocking the Fuel Efficiency Mystery

You may want to see also

Efficient Transmission: Develop transmissions that match engine power to vehicle speed for optimal performance

The development of efficient transmissions is a critical aspect of improving fuel efficiency in vehicles, and it involves a deep understanding of the interplay between the engine, transmission, and vehicle dynamics. The primary goal is to ensure that the engine's power is effectively transferred to the wheels, optimizing performance while minimizing fuel consumption. This can be achieved through several key strategies.

One approach is to design transmissions that offer a wide range of gear ratios. By providing multiple gear options, the transmission can match the engine's power output to the vehicle's speed and load conditions. For example, a lower gear ratio can be used for acceleration, providing the necessary torque to get the vehicle moving quickly. As the vehicle gains speed, the transmission can shift to higher gear ratios, allowing the engine to operate at a more efficient speed range while maintaining the necessary power for the vehicle's speed. This dynamic gear selection ensures that the engine is always operating in its most efficient zone, reducing fuel wastage.

Advanced transmission technologies, such as dual-clutch or automated manual transmissions (AMT), can also play a significant role. These systems use two sets of clutches, allowing for faster and more efficient gear changes compared to traditional automatic transmissions. By rapidly switching between gears, these transmissions can provide seamless power delivery, ensuring that the engine's power is always matched to the vehicle's speed. This results in improved acceleration and overall efficiency, especially during city driving or frequent stop-and-go conditions.

Furthermore, the integration of electronic controls and sensors is essential. Modern transmissions are equipped with sophisticated sensors that monitor vehicle speed, engine load, and driver input. These sensors provide real-time data to the transmission control unit (TCU), which then adjusts gear shifts accordingly. For instance, if the driver rapidly accelerates, the TCU can prompt the transmission to downshift quickly, providing the necessary torque without wasting fuel. Similarly, during steady cruising, the TCU can optimize gear ratios to maintain a balanced power-to-speed relationship, further enhancing fuel efficiency.

In summary, developing transmissions that dynamically match engine power to vehicle speed is a powerful strategy for improving fuel efficiency. By offering a wide range of gear ratios, utilizing advanced transmission technologies, and employing electronic controls, the government and automotive manufacturers can ensure that vehicles deliver optimal performance while consuming less fuel. This approach not only benefits the environment but also contributes to cost savings for consumers, making it an essential aspect of the ongoing quest for more sustainable transportation.

The Surprising Truth: Driving Without a Fuel Cap

You may want to see also

Frequently asked questions

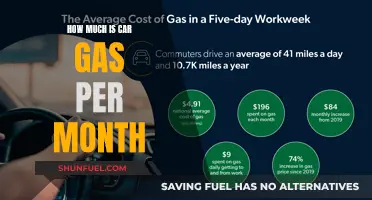

Governments can play a crucial role in incentivizing the automotive industry to develop and manufacture fuel-efficient cars. One common approach is to offer tax credits or rebates to both manufacturers and consumers. These financial incentives can reduce the cost of producing and purchasing fuel-efficient vehicles, making them more affordable and attractive to the market.

Implementing and enforcing strict fuel efficiency standards is a powerful policy tool. Governments can set mandatory targets for vehicle manufacturers, requiring them to meet certain fuel economy levels. These standards often lead to the development of more efficient engines, improved aerodynamics, and the use of advanced technologies, resulting in a wider range of fuel-efficient car models.

Absolutely. Subsidies and grants can be provided to automotive research institutions and companies working on innovative fuel-efficient technologies. This support can accelerate the development of new engine designs, hybrid systems, electric powertrains, and other technologies that contribute to improved fuel efficiency. Governments can also offer tax benefits to encourage private investments in R&D.

Governments often provide incentives specifically for electric vehicles to promote a shift towards cleaner transportation. These incentives can include tax breaks, reduced registration fees, and access to carpool lanes. By encouraging the adoption of EVs, which are inherently more fuel-efficient, governments can significantly reduce fuel consumption and lower greenhouse gas emissions.

Yes, consumer education is an essential aspect of promoting fuel efficiency. Governments and environmental organizations can launch awareness campaigns to teach drivers about efficient driving techniques, such as smooth acceleration and deceleration, maintaining steady speeds, and avoiding rapid starts and stops. Providing resources and training on fuel-efficient driving can lead to long-term behavioral changes and contribute to overall fuel savings.