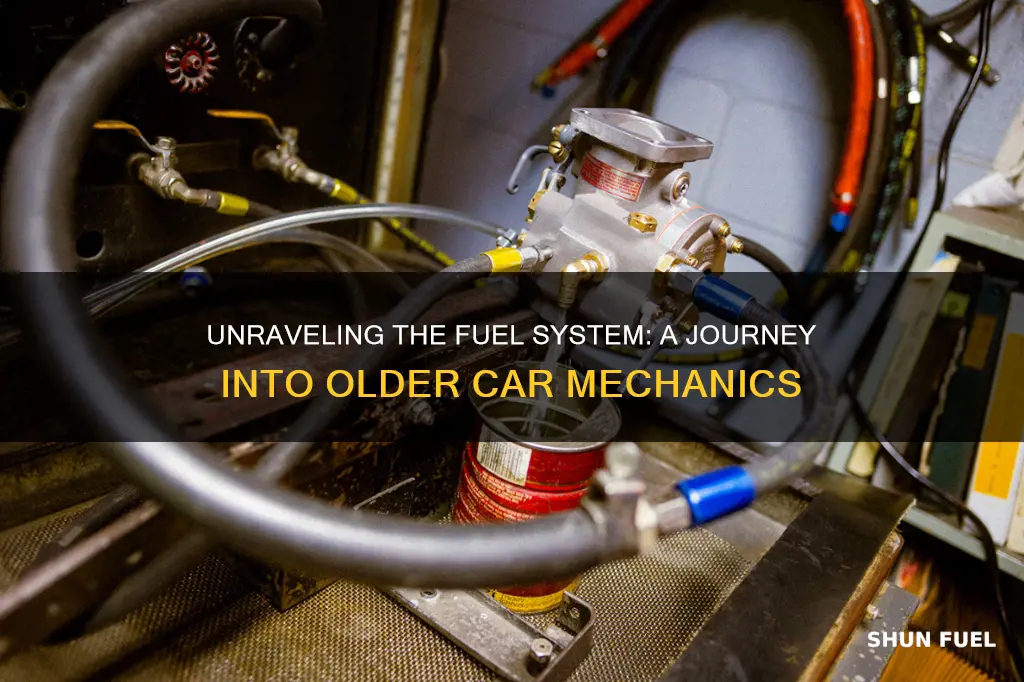

The fuel system in older cars is a crucial component that ensures the engine receives the necessary fuel for operation. It typically consists of a fuel tank, fuel pump, fuel filter, and injectors or carburetor. When the engine is started, the fuel pump activates, drawing fuel from the tank and sending it through the filter to remove impurities. The filtered fuel then travels to the injectors or carburetor, where it is precisely metered and mixed with air before being injected into the engine's cylinders for combustion. Understanding the mechanics of this system is essential for maintaining and troubleshooting older vehicles, ensuring they run efficiently and reliably.

| Characteristics | Values |

|---|---|

| Fuel Injection | Older cars often use a carburetor for fuel injection, which mixes air and fuel in a specific ratio before it enters the engine. |

| Fuel Pump | A mechanical fuel pump is typically used to deliver fuel from the tank to the carburetor. |

| Fuel Filter | Filters are present to ensure clean fuel reaches the engine, preventing contamination. |

| Fuel Pressure | The pressure of the fuel is regulated by a pressure regulator to maintain optimal engine performance. |

| Carburetor | This component is responsible for metering and mixing the fuel-air mixture, controlling the air-fuel ratio. |

| Fuel Lines | Rubber or plastic fuel lines carry fuel from the tank to the carburetor. |

| Fuel Tank | Older cars usually have a separate fuel tank, often located in the front or rear of the vehicle. |

| Fuel Level Sensor | A float-type sensor indicates the fuel level to the driver. |

| Fuel Efficiency | Older cars may have lower fuel efficiency compared to modern vehicles. |

| Engine Performance | The fuel system directly impacts engine performance, power, and responsiveness. |

| Maintenance | Regular maintenance, including fuel filter changes, is crucial to ensure optimal fuel system operation. |

What You'll Learn

- Fuel Injection: Older cars use mechanical or electronic fuel injectors to deliver fuel to the engine

- Carburetors: A simpler system, carburetors mix air and fuel, then supply it to the engine

- Fuel Pump: This component pressurizes fuel and sends it to the engine via a fuel line

- Fuel Filters: Filters remove contaminants, ensuring clean fuel for optimal engine performance

- Fuel Gauges: These indicators show the fuel level, helping drivers manage their fuel usage

Fuel Injection: Older cars use mechanical or electronic fuel injectors to deliver fuel to the engine

The fuel system in older cars is a crucial component that ensures the engine receives the right amount of fuel for optimal performance. One of the key technologies used in these vehicles is fuel injection, which plays a vital role in delivering fuel to the engine.

In older cars, fuel injection systems can be either mechanical or electronic. The mechanical fuel injection system, often referred to as a carburetor, is a simpler design. It uses a series of valves and passages to mix air and fuel, creating a combustible mixture that is then drawn into the engine. This system relies on the driver's input, as they control the throttle, which regulates the amount of air entering the engine, and subsequently, the fuel-air mixture. Carburetors are known for their simplicity and have been a standard in older automobiles.

On the other hand, electronic fuel injection (EFI) is a more advanced system. It employs an electronic control unit (ECU) to precisely manage the fuel delivery process. The ECU receives input from various sensors, such as the engine's temperature, speed, and load, to calculate the optimal fuel-air ratio. This ratio is then achieved by injecting fuel directly into the engine's intake manifold or individual cylinders. EFI offers improved performance, better fuel efficiency, and reduced emissions compared to carburetors.

Both mechanical and electronic fuel injection systems have their advantages. Carburetors are generally more durable and require less maintenance, making them a reliable choice for older car enthusiasts. They provide a smooth power delivery and are often preferred for their simplicity. On the other hand, EFI systems offer enhanced control and precision, resulting in better engine performance and responsiveness. Modern EFI systems can also adapt to different driving conditions, optimizing fuel usage and reducing harmful emissions.

Understanding the fuel injection system in older cars is essential for maintenance and troubleshooting. When dealing with these vehicles, it's important to consider the specific type of fuel injection system they employ. Regular maintenance, such as replacing spark plugs and fuel filters, can help ensure optimal engine performance and longevity. Additionally, monitoring fuel pressure and addressing any issues promptly can prevent costly repairs and maintain the overall health of the engine.

Hydrogen's Promise: Powering the Future of Sustainable Transportation

You may want to see also

Carburetors: A simpler system, carburetors mix air and fuel, then supply it to the engine

Carburetors were the primary fuel system in older cars before the advent of electronic fuel injection. They are a simpler and more mechanical approach to delivering fuel to the engine. This system operates on the principle of creating a precise air-fuel mixture and then supplying it to the engine's cylinders.

At its core, a carburetor is a device that combines air and fuel, ensuring the correct ratio is achieved. This process is crucial because the engine requires a specific amount of fuel for efficient combustion. The carburetor achieves this by using a series of passages and valves. As the engine's vacuum pulls air through the carburetor, it draws fuel from a reservoir, typically a small tank mounted on the engine. This fuel is then atomized and mixed with the incoming air, creating a combustible mixture.

The design of a carburetor involves a series of steps. Air enters through an intake pipe and passes through a throttle valve, which controls the amount of air entering the system. This air then moves through a series of passages that gradually reduce its pressure, creating a vacuum. The vacuum pulls fuel from the carburetor's float bowl, where it is stored in a small amount of liquid to ensure a steady supply. The fuel is then atomized by a series of jets and passages, breaking it down into tiny droplets. These droplets are then mixed with the air, creating a fine mist.

The key to a carburetor's function is the precise control of this air-fuel mixture. A series of valves and passages regulate the flow, ensuring the correct ratio is achieved. This mixture is then directed into the engine's cylinders, where it is ignited by the spark plug, causing combustion and powering the vehicle. Carburetors were highly efficient and reliable for their time, providing a simple yet effective solution to fuel delivery.

However, with advancements in technology, electronic fuel injection systems have become more prevalent. These systems offer improved performance, better fuel efficiency, and reduced emissions. Despite this, carburetors remain a significant part of automotive history, especially in classic and vintage cars, where their simplicity and reliability are appreciated by enthusiasts. Understanding how carburetors work provides insight into the evolution of fuel systems and the ongoing pursuit of more efficient and environmentally friendly engines.

Government's Role in Boosting Car Fuel Efficiency: Strategies and Solutions

You may want to see also

Fuel Pump: This component pressurizes fuel and sends it to the engine via a fuel line

The fuel pump is a critical component in the fuel system of older cars, responsible for pressurizing the fuel and ensuring a steady supply to the engine. Its primary function is to maintain the necessary pressure to overcome the resistance in the fuel lines, allowing the fuel to flow efficiently to the engine's carburetor or fuel injectors. This process is essential for optimal engine performance and fuel economy.

When the engine is started, the fuel pump is activated, typically by an electric motor or a diaphragm-operated mechanism. The pump is designed to run continuously as long as the engine is operating, ensuring a constant supply of pressurized fuel. The pump's operation is often controlled by a pressure regulator, which monitors the fuel pressure and adjusts the pump's output accordingly. This regulation is crucial to prevent excessive pressure, which could lead to fuel line damage or engine misfires.

Inside the fuel pump, there is a diaphragm or a diaphragm-like mechanism that moves in response to the fuel's pressure. This movement creates a pumping action, forcing the fuel through a small orifice or a precision-engineered passageway. The design of the pump ensures that the fuel is pressurized to the required level, often around 40-60 psi (pounds per square inch), which is sufficient to overcome the system's resistance and provide the engine with the necessary fuel volume.

The pressurized fuel then exits the pump and travels through a fuel line, which is typically made of a flexible material like rubber or a more durable synthetic material. The fuel line is designed to withstand the pressure and temperature changes associated with the engine's operation. It connects the pump to the engine's fuel rail or carburetor, where the fuel is distributed to the individual cylinders.

In older cars, the fuel pump's location can vary, but it is often positioned close to the engine to minimize the length of the fuel line, reducing pressure loss. Some cars may have the pump mounted externally, while others have it integrated into the fuel tank, which is a common design in older vehicles. The fuel pump's efficiency and longevity are vital to the car's performance and reliability, and regular maintenance, including fuel filter changes, can help ensure its optimal operation.

Hydrogen Fuel Cell Cars: The Future of Sustainable Driving?

You may want to see also

Fuel Filters: Filters remove contaminants, ensuring clean fuel for optimal engine performance

The fuel system in older cars is a complex network designed to deliver the right amount of fuel to the engine for efficient combustion. One crucial component of this system is the fuel filter, which plays a vital role in maintaining engine performance and longevity. Fuel filters are essential for ensuring that the fuel supplied to the engine is clean and free from contaminants, which can cause significant issues if left unchecked.

In older vehicles, the fuel system often relies on gravity and pressure to move fuel from the tank to the engine. As fuel travels through this system, it can pick up various contaminants, including dirt, rust, and water. These impurities can lead to engine problems, such as reduced performance, hard starting, and even engine damage over time. This is where the fuel filter comes into play.

Fuel filters are designed to trap and remove these contaminants, ensuring that only clean fuel reaches the engine. They are typically located along the fuel line, often near the fuel tank or the engine itself. The filter's primary function is to act as a barrier, catching particles and impurities before they can enter the engine's critical components. This process is crucial, as it helps prevent blockages in the fuel injectors or carburetor, which could lead to poor fuel atomization and incomplete combustion.

Over time, fuel filters can become clogged with the very contaminants they are designed to trap. This can happen due to regular use, old age, or the presence of dirty fuel in the tank. When this occurs, the filter's efficiency decreases, and it may no longer effectively remove impurities. As a result, unfiltered fuel with contaminants can enter the engine, causing performance issues and potential damage. Regular maintenance, including replacing the fuel filter at recommended intervals, is essential to keep the fuel system in good working order.

In summary, fuel filters are a critical component of the fuel system in older cars. They ensure that the engine receives clean fuel, free from contaminants, which is essential for optimal performance and longevity. By regularly checking and replacing fuel filters, car owners can help maintain their vehicle's efficiency and avoid potential issues caused by dirty fuel. This simple maintenance task can contribute significantly to the overall health and reliability of an older car's engine.

Understanding the Causes of Bad Fuel in Cars

You may want to see also

Fuel Gauges: These indicators show the fuel level, helping drivers manage their fuel usage

The fuel gauge is an essential component in older cars, providing drivers with a visual indication of the vehicle's fuel level. This gauge is designed to offer a clear and immediate representation of the remaining fuel, allowing drivers to make informed decisions about their driving and fuel consumption. By monitoring the fuel gauge, drivers can efficiently manage their fuel usage, ensuring they have enough fuel to reach their destination and avoid unexpected fuel shortages.

In older vehicles, the fuel gauge typically operates through a mechanical or electronic system. The mechanical version often utilizes a float or a pressure sensor to measure the fuel level in the tank. As the fuel level changes, the float or sensor moves, which is then translated into a visual display on the gauge. This mechanical system is relatively simple and has been used for many years, providing a reliable indication of fuel status.

On the other hand, electronic fuel gauges offer more advanced functionality. These gauges use sensors to monitor the fuel level and then provide a digital or analog display. The electronic system can often provide additional information, such as fuel consumption rates and estimated range, which can be valuable for drivers. Modern cars may also incorporate self-learning algorithms to adjust the gauge's sensitivity based on driving patterns, ensuring more accurate fuel level readings.

The design of the fuel gauge is crucial for its effectiveness. It should be easily visible to the driver, often located in the instrument cluster, where the driver's attention is naturally focused. The gauge's needle or digital display should provide a clear and distinct representation of the fuel level, allowing for quick interpretation. Some fuel gauges also incorporate warning indicators, such as a low fuel light, to alert drivers when the fuel level is critically low.

Understanding how the fuel gauge works is essential for drivers to manage their fuel efficiently. By regularly checking the gauge, drivers can plan their trips, ensuring they have sufficient fuel. This practice also helps in avoiding the inconvenience and potential risks associated with running out of fuel. Additionally, monitoring the fuel gauge can provide insights into driving habits, allowing drivers to make adjustments to improve fuel economy and overall vehicle performance.

Flex Fuel Car: Octane Choice and Performance

You may want to see also

Frequently asked questions

In older cars, the fuel injection system typically uses a carburetor to mix air and fuel and deliver it to the engine. The carburetor has a series of jets and passages that meter the fuel, creating a precise air-fuel mixture based on the engine's requirements. This system allows for better fuel efficiency and performance compared to older carburetors.

The fuel pump is responsible for delivering fuel from the tank to the carburetor or fuel injection system. It is usually located near the fuel tank and operates at a specific pressure to ensure a steady fuel supply. Older cars often have mechanical fuel pumps that are driven by the engine, while some may have electric pumps for more precise control.

The fuel tank in older cars is designed to store gasoline and is typically made of metal or composite materials. It has a fuel gauge to indicate the remaining fuel level and a fuel cap to seal the tank. Older tanks often have a single outlet for fuel delivery, which connects to the fuel pump and then to the engine.

The fuel filter is crucial for maintaining the health of the engine. It is placed in the fuel line to trap contaminants, such as dirt, water, and debris, that may be present in the fuel. Over time, the filter needs to be replaced to ensure clean fuel delivery, preventing potential engine damage caused by contaminated fuel.

The fuel gauge in older cars is an analog instrument that provides an estimate of the remaining fuel in the tank. It is typically connected to a float inside the fuel tank, which rises and falls as the fuel level changes. The gauge sends a signal to the dashboard, allowing the driver to monitor the fuel status and plan for refueling.