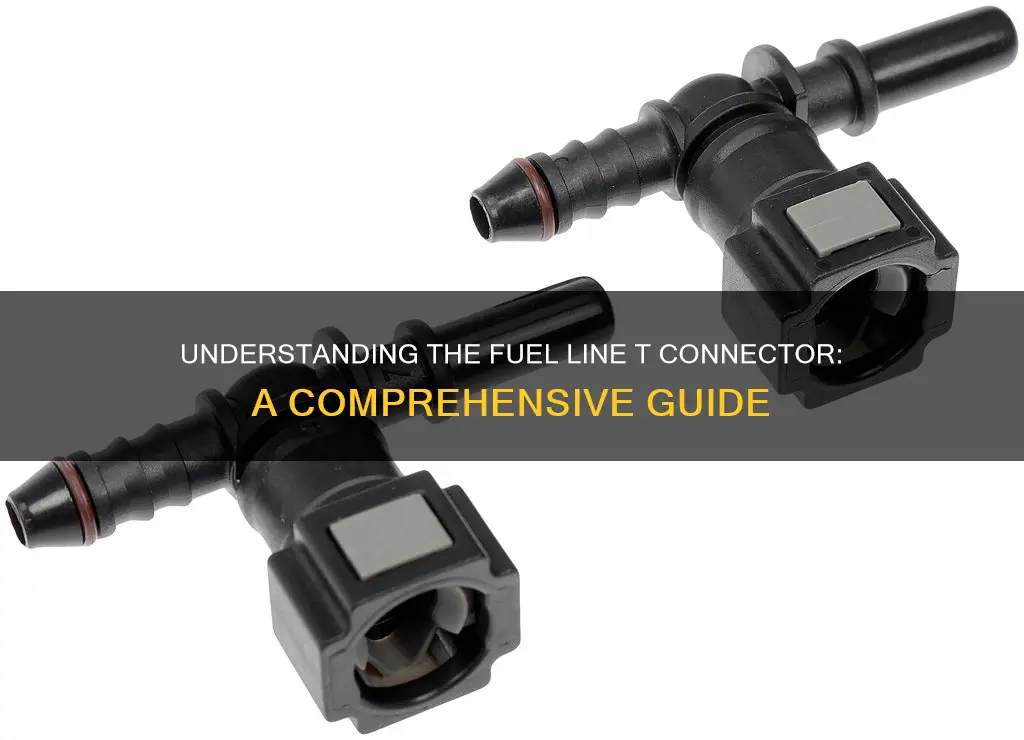

A fuel line T connector is a crucial component in fuel delivery systems, especially in automotive applications. It is designed to efficiently split fuel from a single source into two or more separate paths, allowing for the distribution of fuel to multiple engines or components. This connector typically consists of a T-shaped structure with an inlet port and two or more outlet ports, each connected to a respective fuel line. When the fuel enters the inlet port, it is divided and directed through the outlet ports, ensuring a controlled and precise flow of fuel to the desired destinations. Understanding the functionality of a fuel line T connector is essential for maintaining a reliable and efficient fuel supply in various vehicles and machinery.

What You'll Learn

- Fuel Line Routing: The T-connector connects to the fuel line, directing fuel to the engine

- Fuel Pressure Regulation: It helps maintain optimal fuel pressure for efficient combustion

- Fuel Flow Control: The connector regulates fuel flow, preventing over-fuelling and ensuring proper engine operation

- Engine Performance: Proper T-connector function enhances engine performance and fuel efficiency

- Maintenance and Inspection: Regular checks ensure the T-connector is intact and functioning correctly

Fuel Line Routing: The T-connector connects to the fuel line, directing fuel to the engine

The T-connector is a crucial component in the fuel line routing system of an engine. It is designed to efficiently direct fuel from the fuel tank to the engine, ensuring a steady and controlled supply of fuel for combustion. This connector plays a vital role in maintaining optimal engine performance and preventing fuel-related issues.

When installed, the T-connector is connected to the fuel line, typically made of rubber or plastic, which carries the fuel from the tank. The connector's design allows it to split the fuel flow into two paths: one leading directly to the engine and the other potentially supplying additional fuel to other components or systems that may require it. This branching structure is essential for engines with multiple fuel injectors or carburetors, ensuring each component receives the required amount of fuel.

The T-connector's functionality is based on its unique shape, featuring a main branch and a smaller branch. The main branch is the primary fuel supply route, connecting the fuel line to the engine's fuel injection system or carburetor. The smaller branch, often referred to as the return line, connects back to the fuel tank, allowing any excess fuel or pressure to be vented or recycled, depending on the engine's design. This return line is crucial for maintaining the correct fuel pressure and preventing fuel accumulation in the system.

Proper installation and routing of the T-connector are essential to ensure optimal performance. The connector should be securely attached to the fuel line, with no sharp bends or kinks that could restrict fuel flow. The fuel line should be routed away from heat sources and vibrations to minimize the risk of damage or fuel leakage. Additionally, the T-connector's position should be considered to avoid interference with other engine components during operation.

In summary, the T-connector is a critical component in fuel line routing, enabling efficient fuel distribution to the engine. Its design and proper installation ensure a reliable fuel supply, contributing to the overall performance and longevity of the engine. Understanding its function and following the recommended routing practices are essential for maintaining a well-functioning fuel system.

Braided Fuel Lines: The Ultimate Upgrade for Your Vintage Beetle's Performance and Reliability

You may want to see also

Fuel Pressure Regulation: It helps maintain optimal fuel pressure for efficient combustion

Fuel pressure regulation is a critical component in ensuring efficient combustion within an engine's fuel system. It involves maintaining the optimal fuel pressure to provide the right amount of fuel to the engine, which is essential for optimal performance and fuel economy. The primary goal of fuel pressure regulation is to ensure that the fuel delivered to the engine is at the correct pressure, allowing for precise control of the fuel-air mixture and efficient combustion.

In an internal combustion engine, the fuel system is designed to deliver fuel to the engine's cylinders at a specific pressure. This pressure is carefully regulated to ensure that the fuel atomizes properly and mixes with air for efficient burning. If the fuel pressure is too low, the fuel may not atomize effectively, leading to poor combustion and reduced engine performance. Conversely, if the pressure is too high, it can cause fuel spray to be too fine, potentially leading to misfires and engine knock.

The fuel pressure regulator plays a vital role in this process. It is typically located in the fuel line, close to the fuel pump, and is designed to maintain a consistent fuel pressure throughout the system. When the engine is running, the fuel pressure regulator monitors the pressure and adjusts it as needed to ensure it stays within the optimal range. This regulation is crucial, especially during changes in engine load or speed, as it helps to maintain a steady fuel supply, ensuring that the engine receives the correct amount of fuel for efficient operation.

The design of the fuel pressure regulator often includes a spring-loaded mechanism that adjusts the fuel pressure based on the engine's requirements. When the engine demands more fuel, the regulator opens slightly, allowing more fuel to pass through, thus increasing the pressure. Conversely, when the engine's fuel demand decreases, the regulator tightens, reducing the pressure to maintain the optimal level. This dynamic adjustment ensures that the fuel pressure remains stable and within the desired range, even under varying operating conditions.

Proper fuel pressure regulation is essential for engine performance, fuel efficiency, and emissions control. It ensures that the engine operates within its optimal parameters, providing the right amount of fuel for each cylinder. This results in improved power output, reduced fuel consumption, and lower emissions, making it a critical aspect of engine design and maintenance. Understanding and maintaining fuel pressure regulation can lead to better engine performance and longevity.

Mastering the Fuel Line Removal: A Step-by-Step Guide

You may want to see also

Fuel Flow Control: The connector regulates fuel flow, preventing over-fuelling and ensuring proper engine operation

The T-connector, a crucial component in fuel delivery systems, plays a vital role in managing fuel flow to the engine. Its primary function is to regulate the fuel supply, ensuring that the engine receives the precise amount of fuel required for optimal performance. This is particularly important as over-fuelling can lead to engine misfires, reduced power, and potential damage to the engine's internal components.

At its core, the T-connector is designed with a branching structure, featuring a main fuel line that splits into two or more branches. One branch directs fuel to the engine, while the other may be used for additional functions like fuel pressure regulation or return to the fuel tank. The key to its functionality lies in the precise control it offers over the fuel flow rate. This control is achieved through a combination of factors, including the size of the fuel passages, the design of the connector, and the presence of any valves or restrictors.

The connector's design is critical to its performance. It must be constructed to ensure minimal fuel resistance and turbulence, as these factors can impact the fuel's atomization and mixing with air, affecting combustion. The connector's internal passages should be smooth and free of obstructions to allow for efficient fuel flow. Additionally, the connector may incorporate valves or restrictors to further regulate fuel delivery. These valves can be solenoid-operated or pressure-responsive, opening and closing to control the flow rate based on engine demand or fuel pressure.

In operation, the T-connector ensures that the engine receives a steady and controlled supply of fuel. When the engine is idling or operating at low speeds, the connector may restrict fuel flow to maintain a stable idle and prevent excessive emissions. During high-speed or high-load conditions, it can increase fuel flow to meet the engine's increased demand. This dynamic regulation is essential for maintaining optimal engine performance and fuel efficiency.

Furthermore, the T-connector's role in fuel flow control contributes to the overall reliability of the fuel system. By preventing over-fuelling, it reduces the risk of fuel-related issues such as engine knocking, carbon buildup, and potential damage to the fuel injectors or engine cylinders. Proper fuel flow management also ensures that the engine operates within its optimal performance range, maximizing power output and fuel economy.

2008 Cobalt Fuel Line: Size and Compatibility Guide

You may want to see also

Engine Performance: Proper T-connector function enhances engine performance and fuel efficiency

The T-connector, also known as a T-fitting or tee fitting, is a crucial component in the fuel delivery system of an engine. Its primary function is to allow the fuel line to split into two or more paths, providing fuel to different parts of the engine simultaneously. This design is essential for optimizing engine performance and ensuring efficient fuel distribution. When the T-connector is functioning correctly, it plays a vital role in enhancing overall engine performance and fuel efficiency.

In the context of engine performance, the T-connector's proper operation is critical. It ensures that fuel is delivered precisely where it is needed, allowing for better combustion and power generation. The T-connector's design enables the fuel to be divided into multiple streams, each directed to specific engine components. This precise fuel distribution is key to achieving optimal engine operation, as it ensures that each cylinder receives the correct amount of fuel at the right time. As a result, the engine can operate at its peak efficiency, producing more power and torque while consuming fuel more effectively.

The efficiency of the T-connector is further emphasized in terms of fuel economy. By allowing for accurate fuel distribution, the T-connector helps prevent fuel wastage. When fuel is delivered directly to the cylinders, there is less chance of it being lost or spilled, especially in high-performance engines where fuel flow rates can be high. This efficient fuel management contributes to improved fuel efficiency, allowing the engine to go further on a single tank of fuel.

Moreover, the T-connector's design can also impact engine response and acceleration. A well-functioning T-connector ensures that fuel is readily available to all parts of the engine, including the cylinders and fuel injectors. This prompt fuel supply enables the engine to respond quickly to driver input, resulting in faster acceleration and improved overall performance. The T-connector's role in maintaining a steady and consistent fuel supply is crucial for achieving the desired engine response, especially during high-demand driving conditions.

In summary, the proper function of a T-connector is essential for maximizing engine performance and fuel efficiency. Its ability to split and direct fuel streams accurately ensures optimal combustion, power output, and fuel economy. By preventing fuel wastage and enabling quick engine response, the T-connector plays a critical role in enhancing the overall driving experience and the longevity of the engine. Understanding the importance of this component highlights the intricate relationship between fuel delivery systems and engine performance.

Nylon's Fuel Line: A Reliable Choice for Your Engine?

You may want to see also

Maintenance and Inspection: Regular checks ensure the T-connector is intact and functioning correctly

Regular maintenance and inspections are crucial to ensuring the longevity and proper functioning of the T-connector in a fuel line system. This component plays a vital role in directing fuel from the fuel tank to the engine, and any issues can lead to performance problems or even engine failure. Here's a guide on how to maintain and inspect the T-connector:

Visual Inspection: Start by visually examining the T-connector and the surrounding fuel lines. Look for any signs of damage, such as cracks, leaks, or corrosion. Check for any visible bends or kinks in the lines that might restrict fuel flow. Over time, fuel lines can develop small punctures or leaks due to vibrations and temperature changes, so a thorough visual inspection is essential. Pay attention to the T-connector's mounting points and ensure they are secure and free from any signs of deterioration.

Pressure Testing: Conducting pressure tests is an effective way to assess the integrity of the T-connector and fuel lines. Use a fuel pressure gauge to measure the pressure at the T-connector and compare it to the manufacturer's specifications. If the pressure is significantly lower or higher than the recommended range, it may indicate a blockage, leak, or issue with the fuel pump. Pressure testing can help identify potential problems before they cause major engine issues.

Fuel Flow Inspection: Inspecting the fuel flow is another critical aspect of maintenance. Start the engine and monitor the fuel flow using a fuel flow meter or by observing the engine's performance. A well-functioning T-connector should allow for smooth and consistent fuel delivery to the engine. If you notice any fluctuations or a lack of power, it could be a sign of a clogged or malfunctioning T-connector. Regularly checking the fuel flow ensures that the system is operating optimally.

Replace Worn Components: During your inspections, pay attention to the condition of the fuel lines and the T-connector itself. Over time, fuel lines can become brittle and crack, especially in areas with high heat or vibration. If you find any damaged lines or a compromised T-connector, replace them promptly. It is also advisable to replace the fuel filter regularly to prevent contaminants from entering the system and affecting the T-connector's performance.

Professional Maintenance: While regular visual inspections and pressure tests can be performed by vehicle owners, it is recommended to have a professional mechanic perform more comprehensive maintenance checks. They can use specialized tools and equipment to thoroughly inspect the fuel system, including the T-connector. Professionals can identify issues that might not be visible to the naked eye and ensure that all components are functioning correctly.

By implementing these maintenance and inspection practices, you can ensure that the T-connector remains in optimal condition, providing reliable fuel delivery to your engine. Regular checks and timely replacements will help prevent unexpected breakdowns and maintain the overall health of your vehicle's fuel system.

Fuel Line Flexibility: Can A1-15 Handle Coolant?

You may want to see also

Frequently asked questions

A fuel line T connector, also known as a T-shaped fuel fitting, is a component used in automotive fuel systems. It is designed to connect two fuel lines, allowing for the distribution of fuel from a single source to multiple destinations, such as the engine and auxiliary systems.

The T connector works by providing a branching point in the fuel line. It typically consists of a main fuel line with a right-angle or T-shaped fitting. The main line carries the fuel supply, and the T connector splits it into two or more smaller lines, each leading to a different component. This design ensures efficient and controlled fuel distribution.

This component offers several benefits. Firstly, it allows for a compact and organized fuel system layout, especially in engines with limited space. Secondly, it enables fuel to be directed to specific areas, ensuring that each component receives the required amount. Additionally, T connectors can improve fuel flow by reducing pressure drop and providing a more direct path for fuel delivery.

While some basic automotive repairs can be DIY projects, installing a fuel line T connector might require specialized knowledge and tools. Fuel systems involve high-pressure components, and improper installation can lead to fuel leaks or system malfunctions. It is recommended to consult a professional mechanic or refer to detailed repair manuals specific to your vehicle's make and model for guidance on installation or seeking professional assistance.