A fuel line break is a common issue that can occur in vehicles, often due to wear and tear, corrosion, or physical damage. When a fuel line breaks, it can lead to a variety of problems, including engine misfires, reduced performance, and even complete engine failure. Understanding the causes and signs of a fuel line break is essential for prompt maintenance and repair to prevent further damage and ensure the vehicle's reliability.

What You'll Learn

- Physical Damage: Cracks, punctures, or kinks in the fuel line due to impact, corrosion, or improper installation

- Vibration Wear: Frequent vibrations from engine operation can weaken the fuel line over time

- Clogging: Debris, rust, or contaminants can block the fuel line, leading to pressure buildup and potential rupture

- Age and Degradation: Old fuel lines may become brittle and prone to cracking, especially in harsh environments

- Pressure Excess: Excessive fuel pressure can cause the line to burst, often due to faulty fuel pump or regulator

Physical Damage: Cracks, punctures, or kinks in the fuel line due to impact, corrosion, or improper installation

Physical damage to the fuel line is a common cause of fuel system failures and can lead to a variety of issues, including engine misfires, stalling, and even complete engine failure. This type of damage can occur due to several factors, including impact, corrosion, and improper installation.

Impact damage can result from accidents, collisions, or even the vehicle's normal operation. For example, if a vehicle hits a bump or a pothole, the fuel line could be subjected to sudden and intense pressure, causing it to crack or puncture. This is especially true for lines made of softer materials like rubber or plastic, which are more susceptible to impact-related damage. Over time, the repeated stress from driving over rough terrain can also contribute to the development of cracks or punctures.

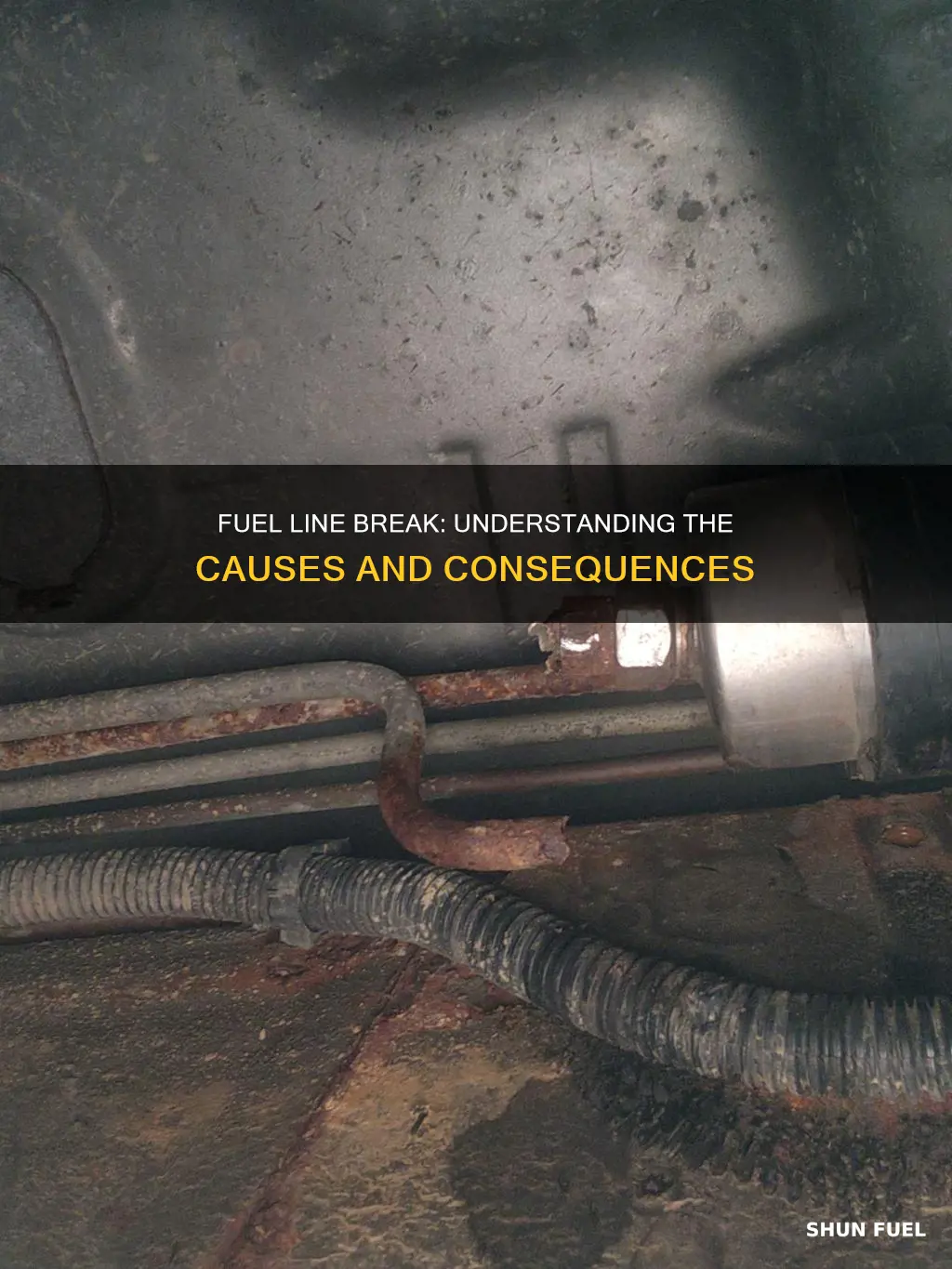

Corrosion is another significant factor in fuel line deterioration. Fuel lines are often exposed to fuel, which can contain moisture, and the harsh conditions of the engine bay, including high temperatures and varying humidity levels. Over time, this can lead to the formation of rust and corrosion within the line, weakening its structural integrity. Corrosion can also cause internal blockages, reducing fuel flow and potentially leading to engine performance issues.

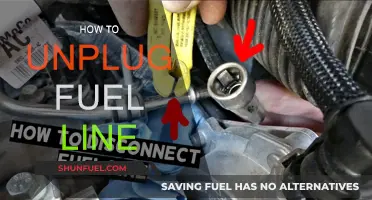

Improper installation is a critical aspect that often goes unnoticed until it causes problems. When fuel lines are not installed correctly, they may not be securely fastened or positioned to withstand the forces acting upon them. This can result in kinks, twists, or even complete disconnection of the line. Kinks can restrict fuel flow, causing engine performance issues, while a complete disconnection can lead to a sudden loss of power and potential engine damage.

To prevent physical damage to the fuel line, regular maintenance and inspections are essential. Checking for any signs of impact damage, corrosion, or improper installation should be part of routine vehicle care. If any issues are identified, prompt repairs or replacements should be made to ensure the fuel system's reliability and the overall performance of the vehicle.

Understanding Fuel Line Seals: A Comprehensive Guide

You may want to see also

Vibration Wear: Frequent vibrations from engine operation can weaken the fuel line over time

Vibration wear is a significant factor in the deterioration of fuel lines, especially in vehicles with high-performance engines or those subjected to frequent, intense vibrations. The fuel lines in an engine are responsible for transporting fuel from the tank to the carburetor or fuel injectors, and they are designed to withstand the pressure and flow of fuel while maintaining a secure connection. However, the constant and intense vibrations generated during engine operation can have a detrimental effect on these lines over time.

The fuel lines are typically made of flexible materials such as rubber or plastic, which are chosen for their ability to absorb vibrations and maintain flexibility. While these materials are durable, they are not indestructible. Frequent and intense vibrations can cause the walls of the fuel line to thin and weaken, leading to potential cracks or tears. This is particularly true for the areas where the fuel line connects to the engine block or other components, as these points experience the highest stress and movement. Over time, the repeated stress from vibrations can cause the fuel line to become brittle and more susceptible to damage.

One of the consequences of vibration wear is the development of small cracks or holes in the fuel line. These cracks may not be visible to the naked eye and can go unnoticed until the fuel line fails completely. As the fuel line deteriorates, the pressure and flow of fuel may be affected, leading to reduced engine performance or even stalling. In some cases, the fuel may leak out of the line, causing a dangerous situation, especially if the leak occurs near a hot engine component.

To mitigate vibration wear, engineers often design fuel lines with additional support or reinforcement in areas prone to high vibration. This can include the use of metal braids or protective sleeves made of durable materials. Regular maintenance and inspections are also crucial, as they can help identify weakened fuel lines before they fail. During routine checks, mechanics may use pressure testing to ensure the integrity of the fuel lines and replace any lines showing signs of vibration wear.

In summary, vibration wear is a critical consideration in the maintenance of fuel lines, especially in high-performance vehicles. The frequent and intense vibrations from engine operation can weaken the fuel line over time, leading to potential cracks, leaks, and reduced engine performance. Understanding and addressing this issue through proper design, maintenance, and inspections are essential to ensure the safe and efficient operation of the vehicle's fuel system.

Understanding 'What's in Line' for Fuel Filter Maintenance

You may want to see also

Clogging: Debris, rust, or contaminants can block the fuel line, leading to pressure buildup and potential rupture

The fuel line, a critical component in any vehicle's engine, is susceptible to various issues that can lead to its failure. One of the most common causes of fuel line damage is clogging, which can occur due to several factors. Debris, such as small stones, dirt, or even plant matter, can enter the fuel line during the fueling process or through small openings in the tank. Over time, these particles accumulate and can cause blockages, especially in the narrower sections of the line. This obstruction restricts the flow of fuel, leading to increased pressure within the system.

As the pressure builds, it can exert significant force on the fuel line, causing it to weaken and eventually rupture. The rupture may occur at a weak point, such as a bend or a fitting, or even at a seemingly solid section if the pressure becomes too intense. When this happens, fuel can leak out, potentially causing damage to the engine and creating a hazardous situation. In some cases, the force of the rupture can propel debris or fuel droplets, creating a safety hazard for nearby individuals or objects.

Rust is another common culprit when it comes to clogging and fuel line damage. Over time, especially in older vehicles, the fuel line can corrode due to exposure to fuel and the environment. This corrosion can lead to a buildup of rust particles, which, like debris, can block the line. Contaminants, such as water or fuel additives, can also contribute to this issue. Water, for instance, can condense in the fuel tank and, when introduced into the fuel line, can cause corrosion and subsequent clogging.

Regular maintenance and inspections are essential to prevent these issues. Fuel filters should be checked and replaced periodically to ensure they capture debris and contaminants. Keeping the fuel tank clean and dry can also help prevent corrosion. Additionally, using high-quality fuel and additives can reduce the risk of contamination. By addressing these potential causes of clogging, vehicle owners can significantly decrease the chances of fuel line damage and ensure the longevity of their engines.

Fuel Line Flexibility: Can A1-15 Handle Coolant?

You may want to see also

Age and Degradation: Old fuel lines may become brittle and prone to cracking, especially in harsh environments

The age and degradation of fuel lines are significant factors in their potential to break, especially in harsh operating conditions. Over time, fuel lines can undergo structural changes that make them more susceptible to damage. One of the primary concerns is the material's brittleness, which can occur due to various factors.

As fuel lines age, the materials used in their construction, such as rubber or plastic, may start to degrade. This degradation can be accelerated by exposure to harsh environments, including extreme temperatures, UV radiation, and chemical contaminants present in the fuel. Rubber, for instance, can become brittle and lose its flexibility, making it more prone to cracking. When this happens, the fuel line may not be able to withstand the pressure and movement associated with the engine's operation, leading to potential failures.

In harsh environments, such as those found in high-performance vehicles or in regions with extreme weather conditions, the fuel lines are subjected to additional stress. Temperature fluctuations can cause the fuel lines to expand and contract, leading to repeated stress on the material. Over time, this can result in micro-cracks forming within the fuel line, which may initially go unnoticed but can eventually lead to larger cracks and potential fuel leaks.

The brittleness of old fuel lines is a critical issue, especially in high-performance applications where engines operate at their limits. When a fuel line becomes brittle, it may crack or split under the pressure and vibration of the engine. This can result in fuel leakage, which not only poses a fire hazard but also reduces engine performance and efficiency. In some cases, a cracked fuel line can also cause fuel to spray onto hot engine components, leading to potential engine damage.

Regular inspection and maintenance are essential to prevent fuel line failures due to age and degradation. Vehicle owners and mechanics should look for signs of cracking, brittleness, or fuel leaks during routine checks. Replacing old fuel lines with new ones made from more durable materials can also help mitigate the risks associated with age-related degradation. Additionally, using fuel additives that protect the fuel system can further enhance the longevity of the fuel lines.

Unveiling the Mystery: What Exactly is HIPAA Fuel Line?

You may want to see also

Pressure Excess: Excessive fuel pressure can cause the line to burst, often due to faulty fuel pump or regulator

Excessive fuel pressure is a critical issue that can lead to the failure of a fuel line, posing a significant risk to the performance and safety of a vehicle. When the pressure in the fuel system becomes too high, it can exert immense force on the fuel lines, leading to potential damage and even rupture. This problem is often associated with faulty components, particularly the fuel pump and regulator, which play a crucial role in maintaining the appropriate pressure within the fuel system.

The fuel pump is responsible for drawing fuel from the tank and delivering it to the engine at a controlled rate. If this pump fails or operates inefficiently, it can result in an overpressure situation. Over time, the constant high pressure can weaken the fuel lines, causing them to crack or burst. Similarly, the fuel regulator, which controls the pressure by adjusting the fuel-air mixture, can malfunction and allow pressure to rise beyond safe limits. When the regulator fails to regulate the pressure effectively, it can lead to an accumulation of excessive force within the fuel lines.

One common cause of excessive fuel pressure is a clogged or damaged fuel filter. When the filter becomes obstructed, it restricts the flow of fuel, causing a pressure buildup. This issue is often overlooked as it may not exhibit immediate symptoms, but over time, the increased pressure can lead to fuel line damage. Additionally, issues with the fuel pump itself, such as internal leaks or mechanical failures, can contribute to pressure spikes, further exacerbating the risk of fuel line breakage.

To prevent fuel line breakage due to pressure excess, regular maintenance and inspections are essential. Vehicle owners should pay attention to any unusual noises or vibrations during operation, as these could indicate a failing fuel pump or regulator. It is also crucial to check for any signs of fuel line damage, such as cracks or corrosion, especially in areas where the lines are exposed to extreme temperatures or vibrations. Timely repairs or replacements of faulty components can significantly reduce the risk of fuel line failure.

In summary, excessive fuel pressure is a critical factor in fuel line breakage, often resulting from faulty fuel pumps or regulators. Understanding the causes and implementing regular maintenance can help prevent costly repairs and ensure the safe operation of a vehicle's fuel system. Vehicle owners should be vigilant in monitoring their fuel system's performance to avoid potential hazards associated with fuel line failures.

Understanding Fuel Filter Lines: A Comprehensive Guide

You may want to see also

Frequently asked questions

Fuel line breaks can occur due to several factors, including age and wear, corrosion, damage from accidents or collisions, improper installation or maintenance, and the use of low-quality or contaminated fuel. Over time, fuel lines can degrade, especially if they are made of materials that are susceptible to corrosion or if they are exposed to harsh conditions.

Regular maintenance and inspections are crucial to preventing fuel line issues. It is recommended to have your vehicle's fuel system checked periodically, especially if you notice any signs of leaks or damage. Using high-quality fuel and ensuring proper fuel filter changes can also help prevent contamination and degradation. Additionally, driving habits play a role; avoiding rapid acceleration and sudden stops can reduce stress on the fuel system.

If you notice any signs of a potential fuel line break, such as fuel leaks, strange noises from the engine, or reduced performance, it is essential to address the issue promptly. Do not attempt to fix it yourself unless you have the necessary expertise and tools. Instead, contact a professional mechanic who can safely inspect and repair the fuel system. Ignoring a potential break can lead to more severe engine damage and costly repairs.